PHOTOACOUSTIC SPECTROSCOPY

Light and sound—photoacoustic

spectroscopy

C. Haisch and R. Niessner

Institute of Hydrochemistry,Technical University of Munich, Marchioninistrasse 17, D-81377 Munich, Germany.

E-mail: Christoph.Haisch@ch.tum.de

Introduction

Like many other spectroscopic tech-

niques, which are today carried out

with laser light sources, photoacoustic

spectroscopy is much older than the

development of the first laser in 1960.

In 1881 A.G. Bell proposed a spectro-

phone (Figure 1) “for the purpose of

examination of the absorption spectra

of bodies in those portions of the spec-

trum that are invisible”.1 This instru-

Figure 1. The spectrophone, the

first proposed application of

photothermal spectrometry for

absorption analysis, taken from

a publication from the year 1881.

ment was based on his experiments for

the transmission of sound without a

cable connection. The field then lay

largely dormant until the mid-1970s,

when Allan Rosencwaig and Allen

Gersho laid the theoretical basis for the

photoacoustic effect in solids, the so-

called R-G Theory.2

The basic principle of all photother-

mal (PT) techniques is the absorption

of light in a sample with a subsequent

change of its thermal state. This may be

either a change of the temperature or

other thermodynamical parameter of

the sample related to the temperature.

Measurement of either the tempera-

ture, pressure or density change that

occurs due to optical absorption is ulti-

mately the basis for all PT spectroscop-

ic methods. PT analysis can be consid-

ered as an indirect absorption measure-

ment as the measured quantity is not an

optical signal. (It should be noted here

that the classical absorption measure-

ment is not a direct measurement

either. Though the measurement value

10 © Spectroscopy Europe 2002

in this case is an optical one, namely

the transmitted light, the absorbed light

quantity is derived from the difference

of the incident and the transmitted

energy.) The sample heating which

produces the PT signal is correlated

directly to the absorbed electromagnet-

ic energy. In contrast to conventional

transmission spectroscopy, neither scat-

tered nor reflected light contributes to

the signal. This makes PT spectroscopy

particularly attractive for absorption

measurements in gaseous, liquid and

solid media containing scattering parti-

cles, and on solid boundaries.

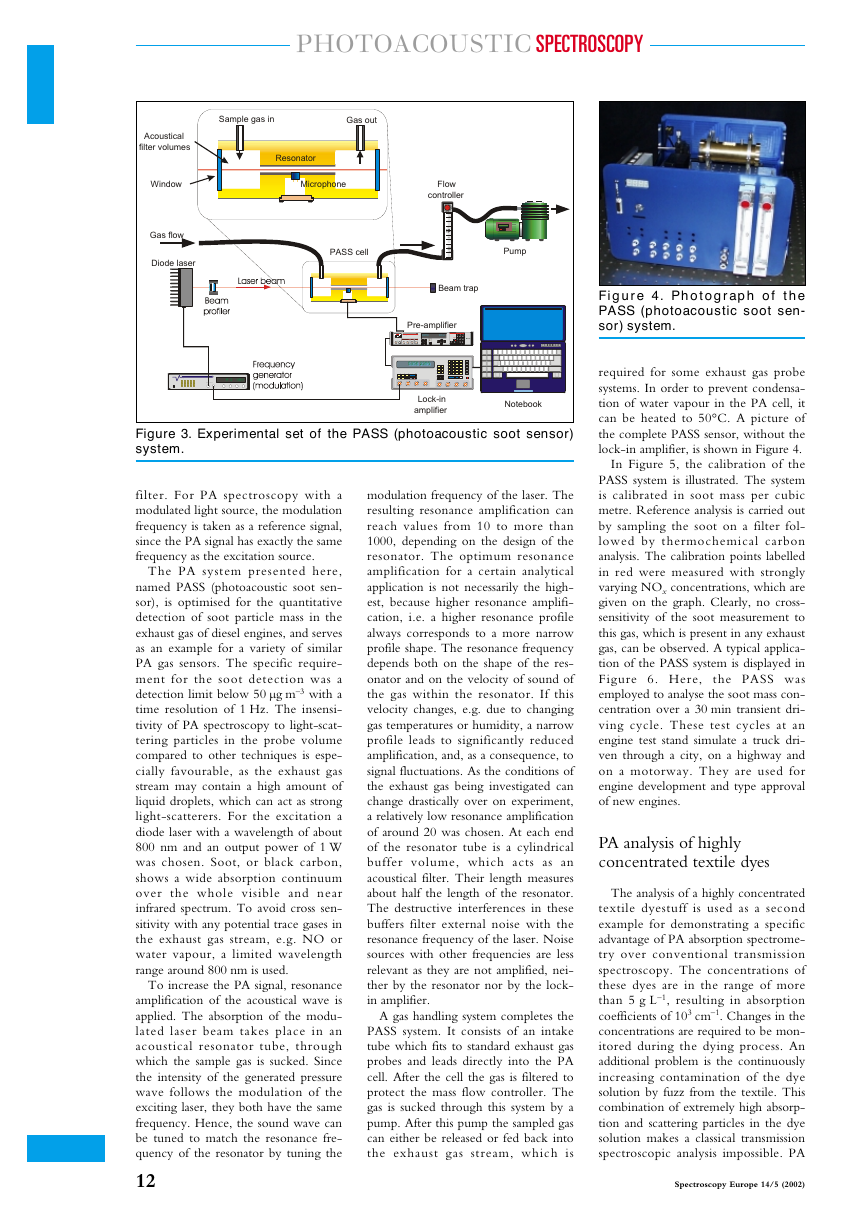

The most straightforward detection

scheme for a photoacoustic signal is the

observation of the temperature change

at the irradiated sample surface. If this

observation is carried out by tempera-

ture transducers on the sample surface

the technique is called thermometric

detection. The more common tech-

nique is the detection of the emitted

thermal radiation from the sample sur-

face, which represents the temperature

distribution within the sample. If the

temperature rise in the absorbing sam-

ple volume occurs faster than this vol-

ume can expand a local pressure

increase (wave) is the consequence.

This pressure wave can be considered

as a sound signal. PT absorption mea-

surements based on the detection of

this sound wave are named photo-

acoustic (PA) techniques. The basic

steps of PA analysis are summarised in

Figure 2. The means for the detection

of a PA signal are multifarious: in a

gaseous matrix a microphone may be

employed, whereas pressure fluctua-

tions in a solid or liquid sample can be

probed by pressure sensitive elements

like piezo transducers. Alternatively,

the pressure fluctuations can be

observed by optical methods.

Although a PT effect can be induced

by any light source, lasers are the pre-

ferred excitation source nowadays for

two reasons: (i) the PT signal, to a first

approximation, is proportional to the

temperature rise in the sample and thus

proportional to the absorbed energy,

i.e. the pulse energy, (ii) for many

Figure 2. Principle of a photo-

acoustic experiment.

applications the selectivity of a PT

analysis, as with any other absorption

analysis, depends on the band-width of

the excitation wavelength.

Selected

applications

Quantification of soot

particles in diesel engine

exhaust gas

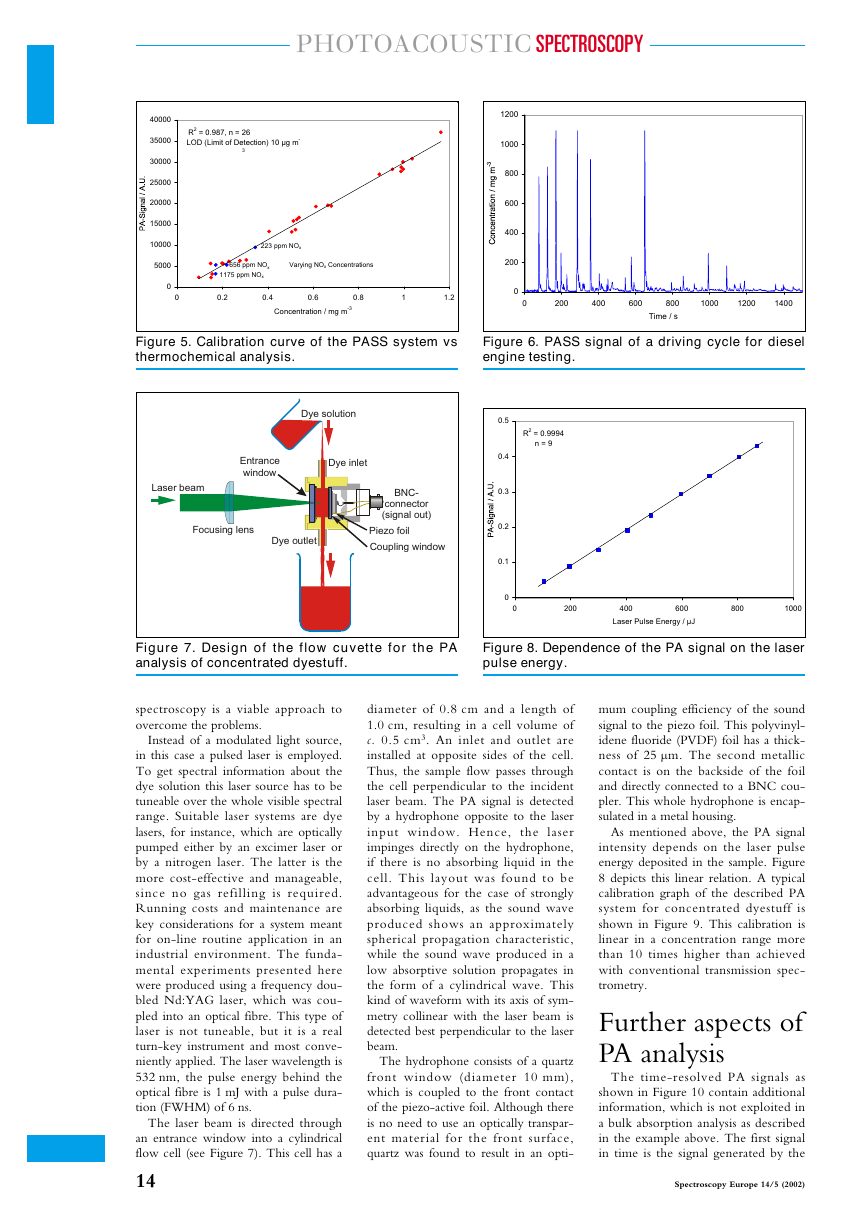

For analytical purposes, gas analysis is

the oldest application of PA spec-

troscopy (PAS). The components of

A.G. Bell’s set-up can all also be found

in today’s PAS gas analysers. A modu-

lated laser source, tuned to an absorp-

tion band of the analyte gas, replaces

the sun as the light source (see Figure

3). Instead of the ear, a sensitive micro-

phone detects the sound signal. The

microphone signals are electronically

amplified and detected by a lock-in

amplifier. A lock-in amplifier is a fre-

quency and phase-sensitive data

recorder that picks up only signals with

the same frequency as a reference sig-

nal. This type of data recorder can be

used as an extremely narrow band-pass

Spectroscopy Europe 14/5 (2002)

�

PHOTOACOUSTIC SPECTROSCOPY

Acoustical

filter volumes

Sample gas in

Gas out

Resonator

Window

Microphone

Flow

controller

Fig. 3

Gas flow

Diode laser

<<< >>>

Designed by Haisch

Digital Delay Generator

PASS cell

Pump

Beam trap

Pre-amplifier

Made by

Main Aux.

W IDTH

W IDTH

100 ns

100 ns

^

<

>

1 2 3

4 5 6

7 8 9

.

0 #

Func.

C

E

Powe

5350 2390

5350 2390

1

1

1

1

1

1

1

1

1

1

ENTER

1

1

1

1

1

1

1

1

1

1

1

ST

Designed by

Lock-in

amplifier

Notebook

Figure 3. Experimental set of the PASS (photoacoustic soot sensor)

system.

filter. For PA spectroscopy with a

modulated light source, the modulation

frequency is taken as a reference signal,

since the PA signal has exactly the same

frequency as the excitation source.

The PA system presented here,

named PASS (photoacoustic soot sen-

sor), is optimised for the quantitative

detection of soot particle mass in the

exhaust gas of diesel engines, and serves

as an example for a variety of similar

PA gas sensors. The specific require-

ment for the soot detection was a

detection limit below 50 µg m–3 with a

time resolution of 1 Hz. The insensi-

tivity of PA spectroscopy to light-scat-

tering particles in the probe volume

compared to other techniques is espe-

cially favourable, as the exhaust gas

stream may contain a high amount of

liquid droplets, which can act as strong

light-scatterers. For the excitation a

diode laser with a wavelength of about

800 nm and an output power of 1 W

was chosen. Soot, or black carbon,

shows a wide absorption continuum

over the whole visible and near

infrared spectrum. To avoid cross sen-

sitivity with any potential trace gases in

the exhaust gas stream, e.g. NO or

water vapour, a limited wavelength

range around 800 nm is used.

To increase the PA signal, resonance

amplification of the acoustical wave is

applied. The absorption of the modu-

lated laser beam takes place in an

acoustical resonator tube, through

which the sample gas is sucked. Since

the intensity of the generated pressure

wave follows the modulation of the

exciting laser, they both have the same

frequency. Hence, the sound wave can

be tuned to match the resonance fre-

quency of the resonator by tuning the

12

modulation frequency of the laser. The

resulting resonance amplification can

reach values from 10 to more than

1000, depending on the design of the

resonator. The optimum resonance

amplification for a certain analytical

application is not necessarily the high-

est, because higher resonance amplifi-

cation, i.e. a higher resonance profile

always corresponds to a more narrow

profile shape. The resonance frequency

depends both on the shape of the res-

onator and on the velocity of sound of

the gas within the resonator. If this

velocity changes, e.g. due to changing

gas temperatures or humidity, a narrow

profile leads to significantly reduced

amplification, and, as a consequence, to

signal fluctuations. As the conditions of

the exhaust gas being investigated can

change drastically over on experiment,

a relatively low resonance amplification

of around 20 was chosen. At each end

of the resonator tube is a cylindrical

buffer volume, which acts as an

acoustical filter. Their length measures

about half the length of the resonator.

The destructive interferences in these

buffers filter external noise with the

resonance frequency of the laser. Noise

sources with other frequencies are less

relevant as they are not amplified, nei-

ther by the resonator nor by the lock-

in amplifier.

A gas handling system completes the

PASS system. It consists of an intake

tube which fits to standard exhaust gas

probes and leads directly into the PA

cell. After the cell the gas is filtered to

protect the mass flow controller. The

gas is sucked through this system by a

pump. After this pump the sampled gas

can either be released or fed back into

the exhaust gas stream, which is

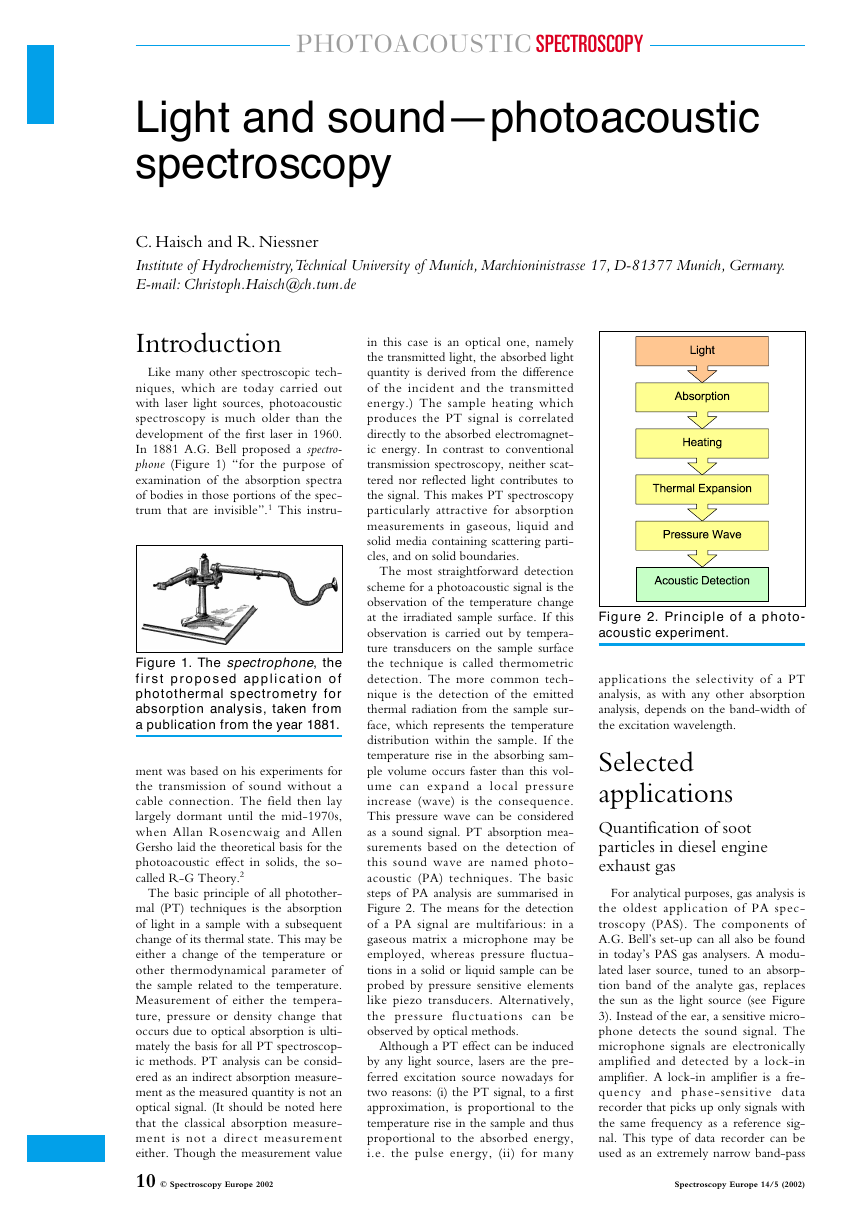

Figure 4. Photograph of the

PASS (photoacoustic soot sen-

sor) system.

required for some exhaust gas probe

systems. In order to prevent condensa-

tion of water vapour in the PA cell, it

can be heated to 50°C. A picture of

the complete PASS sensor, without the

lock-in amplifier, is shown in Figure 4.

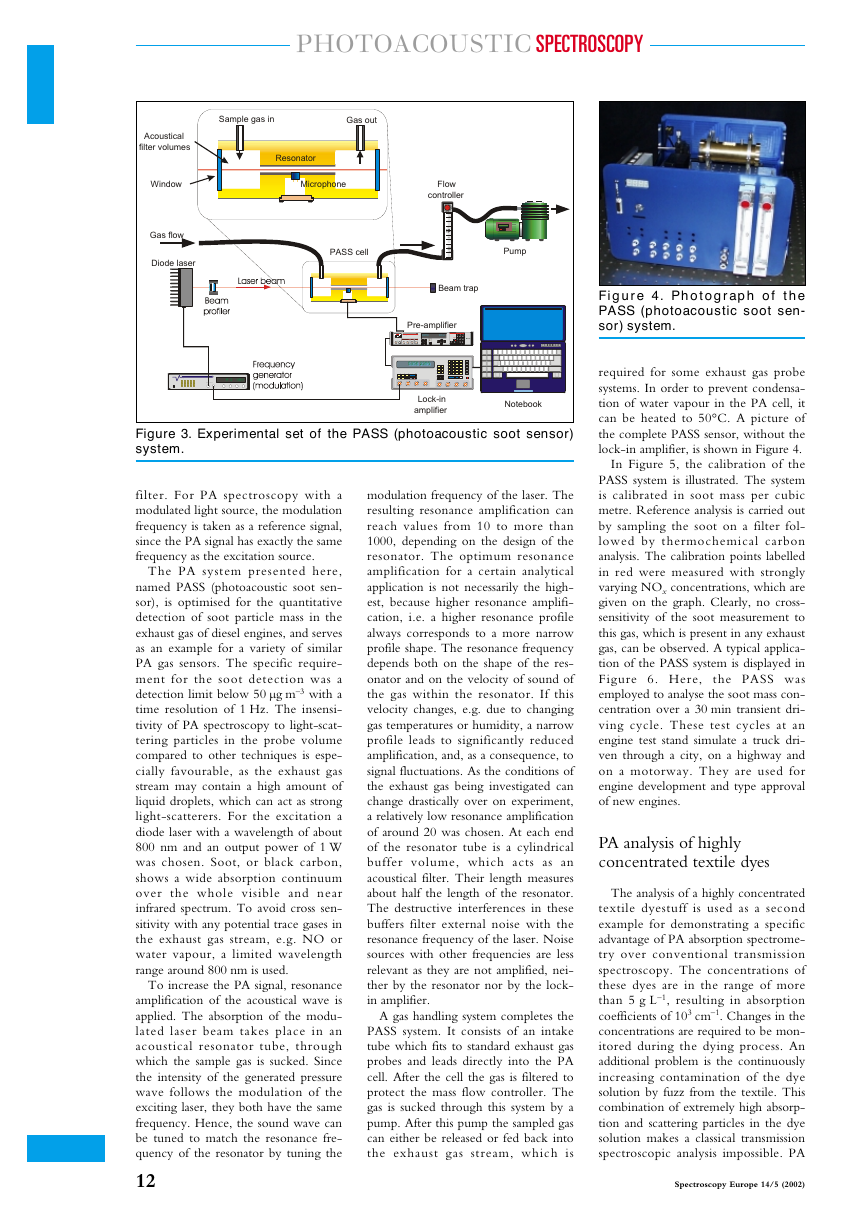

In Figure 5, the calibration of the

PASS system is illustrated. The system

is calibrated in soot mass per cubic

metre. Reference analysis is carried out

by sampling the soot on a filter fol-

lowed by thermochemical carbon

analysis. The calibration points labelled

in red were measured with strongly

varying NOx concentrations, which are

given on the graph. Clearly, no cross-

sensitivity of the soot measurement to

this gas, which is present in any exhaust

gas, can be observed. A typical applica-

tion of the PASS system is displayed in

Figure 6. Here, the PASS was

employed to analyse the soot mass con-

centration over a 30 min transient dri-

ving cycle. These test cycles at an

engine test stand simulate a truck dri-

ven through a city, on a highway and

on a motorway. They are used for

engine development and type approval

of new engines.

PA analysis of highly

concentrated textile dyes

The analysis of a highly concentrated

textile dyestuff is used as a second

example for demonstrating a specific

advantage of PA absorption spectrome-

try over conventional transmission

spectroscopy. The concentrations of

these dyes are in the range of more

than 5 g L–1, resulting in absorption

coefficients of 103 cm–1. Changes in the

concentrations are required to be mon-

itored during the dying process. An

additional problem is the continuously

increasing contamination of the dye

solution by fuzz from the textile. This

combination of extremely high absorp-

tion and scattering particles in the dye

solution makes a classical transmission

spectroscopic analysis impossible. PA

Spectroscopy Europe 14/5 (2002)

�

PHOTOACOUSTIC SPECTROSCOPY

40000

35000

30000

25000

20000

15000

10000

5000

0

0

R2 = 0.987, n = 26

LOD (Limit of Detection) 10 µg m-

3

223 ppm NOx

656 ppm NOx

Varying NOx Concentrations

1175 ppm NOx

0.2

0.4

0.6

0.8

1

1.2

Concentration / mg m-3

1200

1000

800

600

400

200

0

0

200

400

600

800

1000

1200

1400

Time / s

Figure 5. Calibration curve of the PASS system vs

thermochemical analysis.

Figure 6. PASS signal of a driving cycle for diesel

engine testing.

Dye solution

Entrance

window

Dye inlet

Laser beam

Focusing lens

Dye outlet

0.5

0.4

0.3

0.2

0.1

0

0

BNC-

connector

(signal out)

Piezo foil

Coupling window

R2 = 0.9994

n = 9

200

400

600

800

1000

Laser Pulse Energy / µJ

Figure 7. Design of the flow cuvette for the PA

analysis of concentrated dyestuff.

Figure 8. Dependence of the PA signal on the laser

pulse energy.

spectroscopy is a viable approach to

overcome the problems.

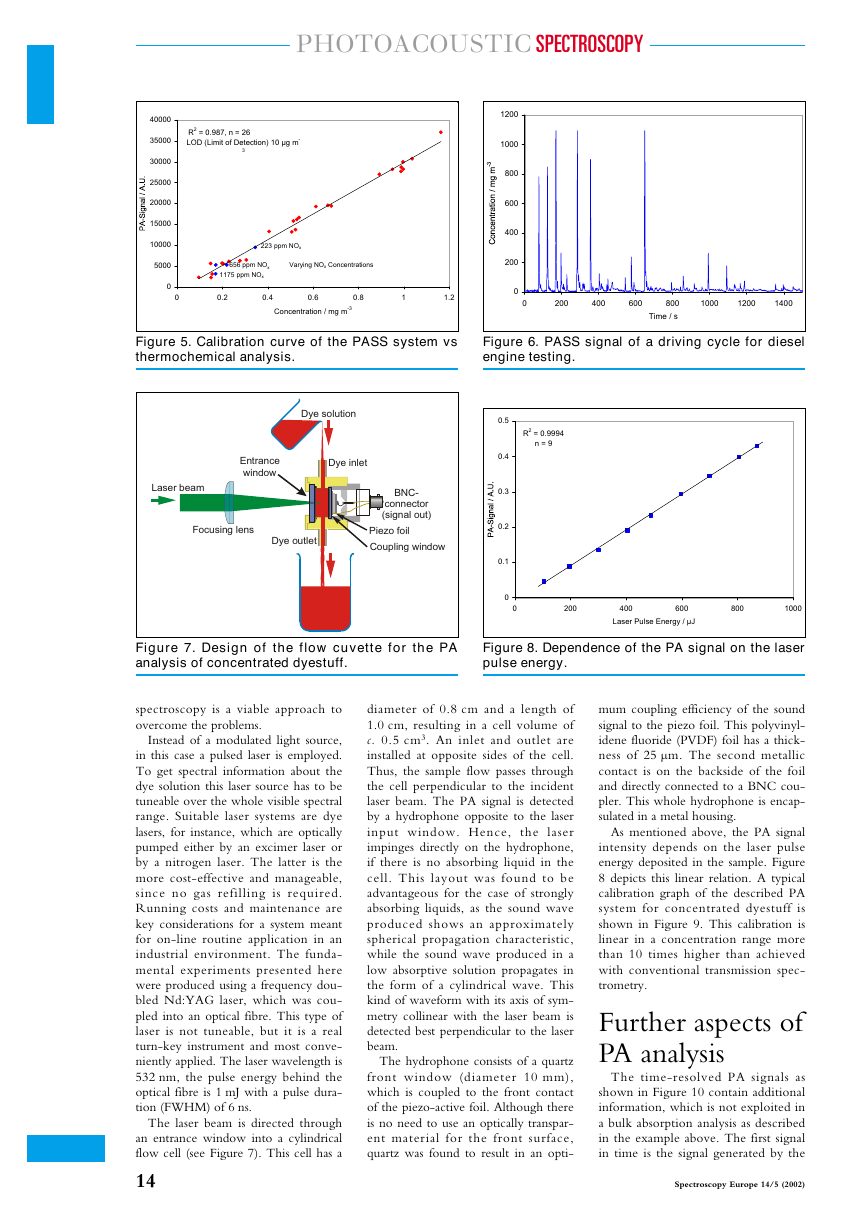

Instead of a modulated light source,

in this case a pulsed laser is employed.

To get spectral information about the

dye solution this laser source has to be

tuneable over the whole visible spectral

range. Suitable laser systems are dye

lasers, for instance, which are optically

pumped either by an excimer laser or

by a nitrogen laser. The latter is the

more cost-effective and manageable,

since no gas refilling is required.

Running costs and maintenance are

key considerations for a system meant

for on-line routine application in an

industrial environment. The funda-

mental experiments presented here

were produced using a frequency dou-

bled Nd:YAG laser, which was cou-

pled into an optical fibre. This type of

laser is not tuneable, but it is a real

turn-key instrument and most conve-

niently applied. The laser wavelength is

532 nm, the pulse energy behind the

optical fibre is 1 mJ with a pulse dura-

tion (FWHM) of 6 ns.

The laser beam is directed through

an entrance window into a cylindrical

flow cell (see Figure 7). This cell has a

14

diameter of 0.8 cm and a length of

1.0 cm, resulting in a cell volume of

c. 0.5 cm3. An inlet and outlet are

installed at opposite sides of the cell.

Thus, the sample flow passes through

the cell perpendicular to the incident

laser beam. The PA signal is detected

by a hydrophone opposite to the laser

input window. Hence, the laser

impinges directly on the hydrophone,

if there is no absorbing liquid in the

cell. This layout was found to be

advantageous for the case of strongly

absorbing liquids, as the sound wave

produced shows an approximately

spherical propagation characteristic,

while the sound wave produced in a

low absorptive solution propagates in

the form of a cylindrical wave. This

kind of waveform with its axis of sym-

metry collinear with the laser beam is

detected best perpendicular to the laser

beam.

The hydrophone consists of a quartz

front window (diameter 10 mm),

which is coupled to the front contact

of the piezo-active foil. Although there

is no need to use an optically transpar-

ent material for the front surface,

quartz was found to result in an opti-

mum coupling efficiency of the sound

signal to the piezo foil. This polyvinyl-

idene fluoride (PVDF) foil has a thick-

ness of 25 µm. The second metallic

contact is on the backside of the foil

and directly connected to a BNC cou-

pler. This whole hydrophone is encap-

sulated in a metal housing.

As mentioned above, the PA signal

intensity depends on the laser pulse

energy deposited in the sample. Figure

8 depicts this linear relation. A typical

calibration graph of the described PA

system for concentrated dyestuff is

shown in Figure 9. This calibration is

linear in a concentration range more

than 10 times higher than achieved

with conventional transmission spec-

trometry.

Further aspects of

PA analysis

The time-resolved PA signals as

shown in Figure 10 contain additional

information, which is not exploited in

a bulk absorption analysis as described

in the example above. The first signal

in time is the signal generated by the

Spectroscopy Europe 14/5 (2002)

�

PHOTOACOUSTIC SPECTROSCOPY

R2 = 0.995

n = 9

25

20

15

10

5

0

0.6

0.4

0.2

0

0

-0.2

-0.4

-0.6

-0.8

10 g/L

25 g/L

2

4

6

8

10

12

Transmitted light

absorbed by the

piezodetector

Light absorbed in the cuvette,

soundwave propagated through

the cuvette

0

5

10

15

20

25

Concentration / g L-1

Time / µs

Figure 9. Calibration of the PA sensor system for

textile dyestuff.

Figure 10. PA signal of two different concentrations

of textile dyestuff in water.

light that is transmitted through the

sample and impinges directly on the

hydrophone. The second signal stems

from the light absorbed in the sample

liquid. Due to the high absorption in

the sample the electromagnetic ener-

gy is deposited mostly directly on the

front side of the cuvette. The pressure

wave generated there propagates

through the cuvette and is detected

after a delay. This delay is the time

(~7 µs) the sound needs to propagate

the length of the cuvette (1 cm), (the

speed of sound in water ~1500 m s–1).

For a non-homogeneous sample a

depth-resolved absorption measure-

ment can be carried out in this way.

Each delay corresponds to a certain

depth in the sample. This simple

example is included to give an idea of

an interesting field of application or

PA analysis. Of course, the design of

such a sensor system would be differ-

ent, for example, the hydrophone

could be placed on the same side as

the laser. However, the description of

depth resolved analysis by PA spec-

troscopy is beyond the scope of this

short article.

References

1.

(a) A.G. Bell, Phil. Mag. 11, 510

(1881).

2. A. Rosencwaig and A. Gersho,

“Theory of the Photoacoustic

Effect in Solids”, J. Appl. Phys. 47,

64–69 (1976).

Spectroscopy Europe 14/5 (2002)

15

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc