Getting Started with AKD EtherCAT Drives and the LabVIEW NI SoftMotion Module

Contents

What You Need to Get Started

Hardware

Software

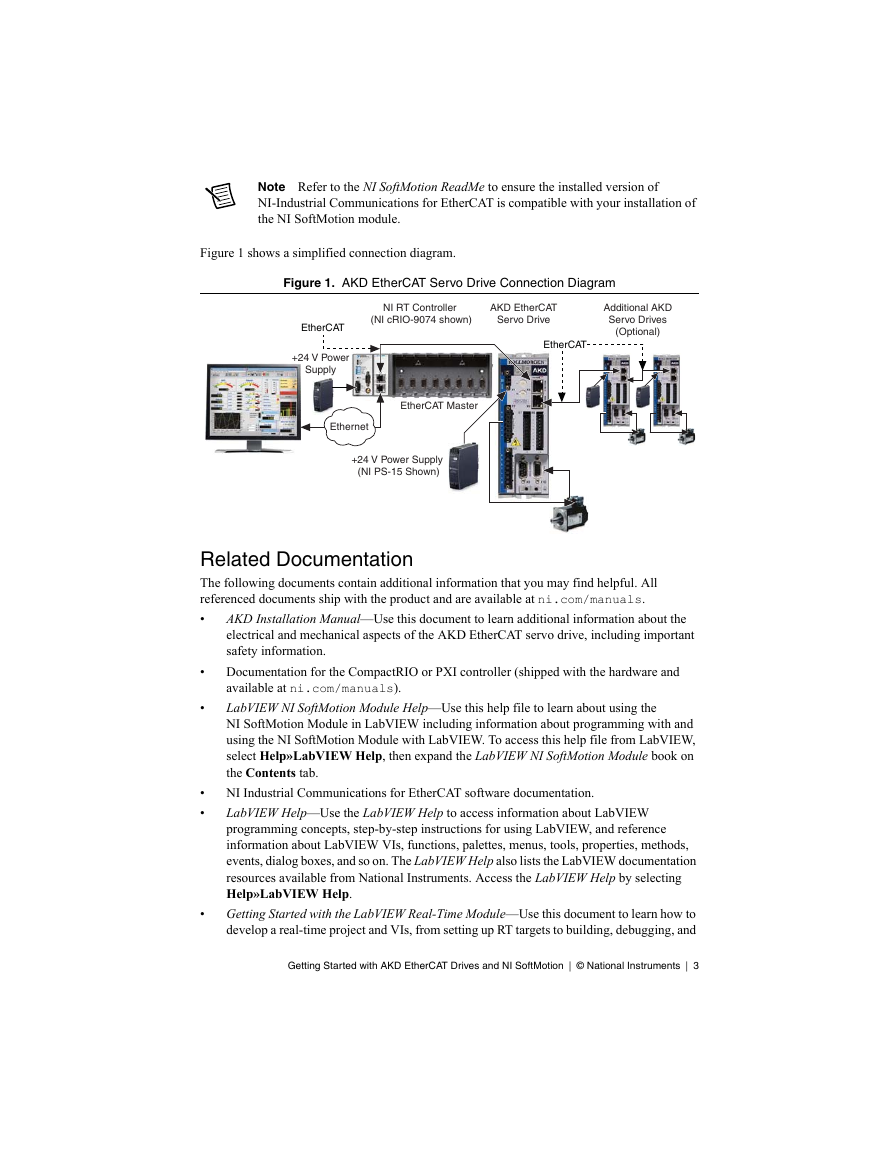

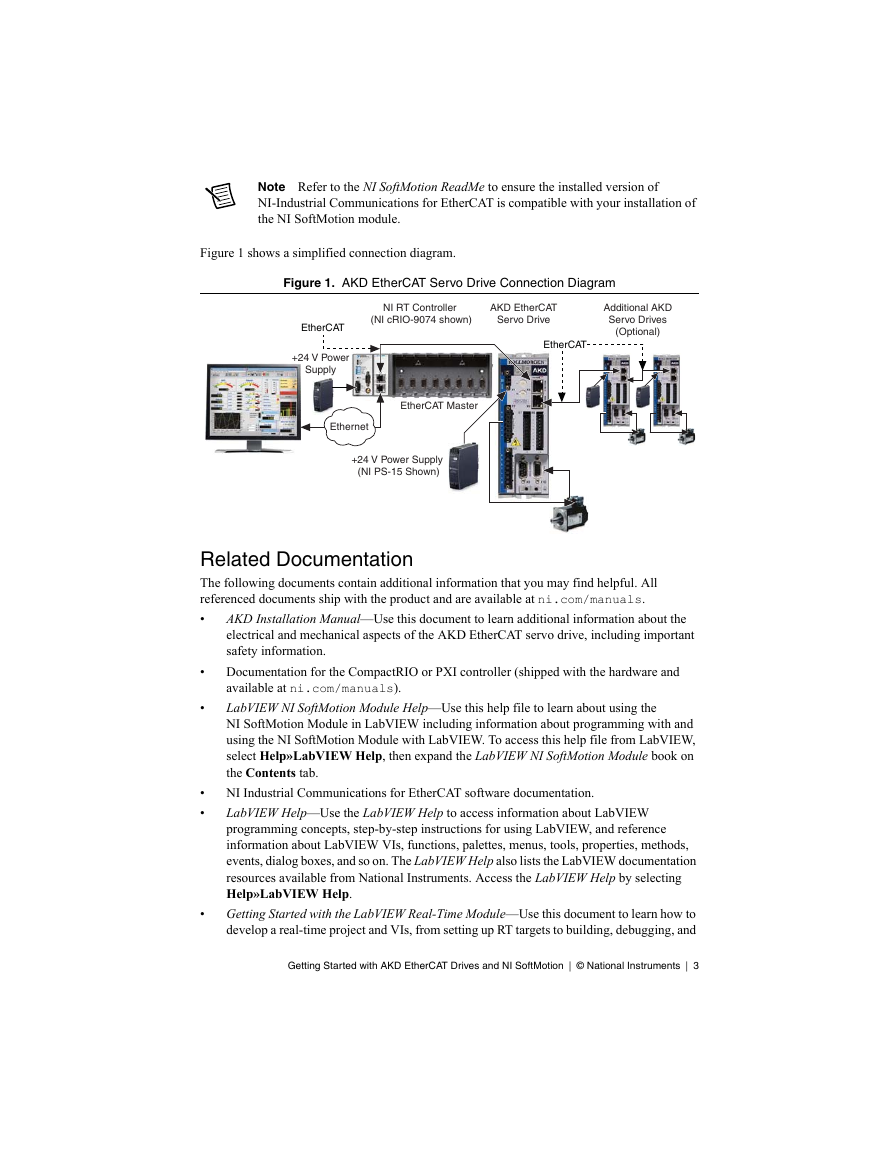

Figure 1. AKD EtherCAT Servo Drive Connection Diagram

Related Documentation

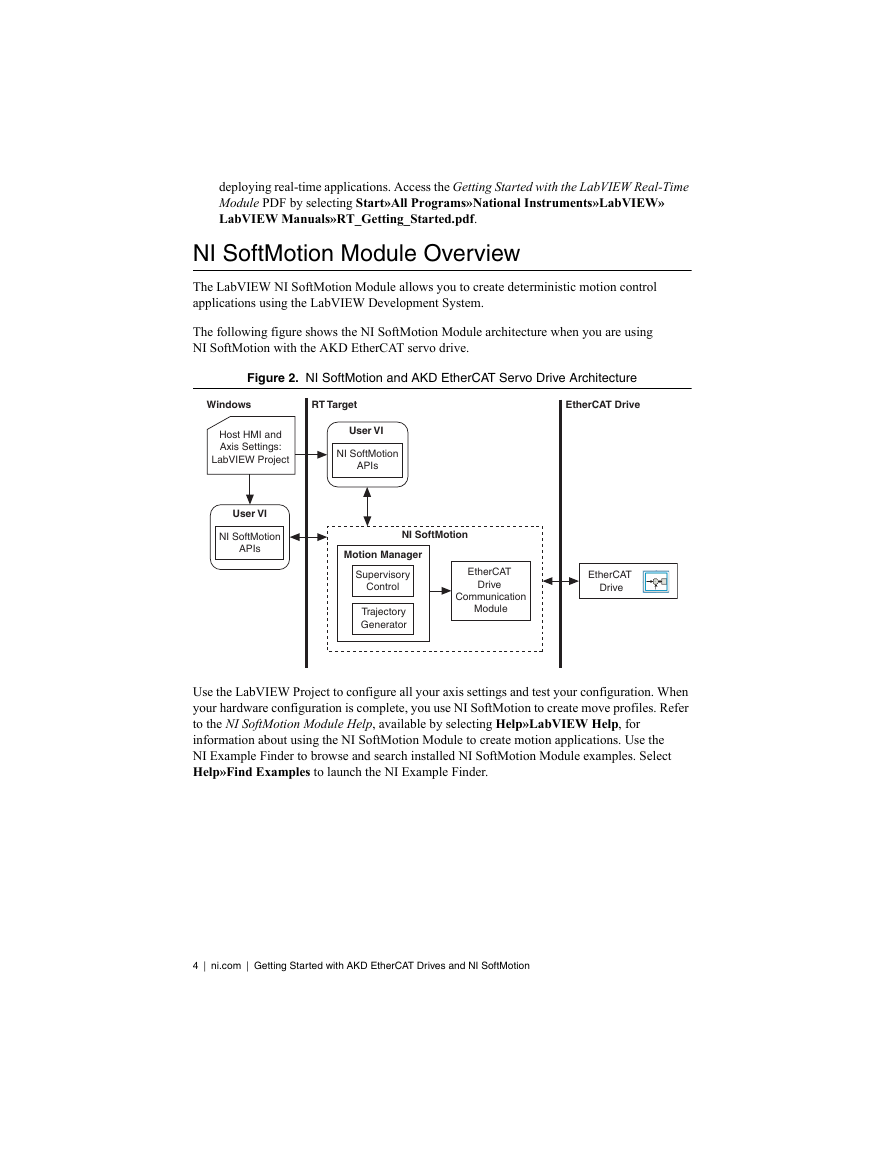

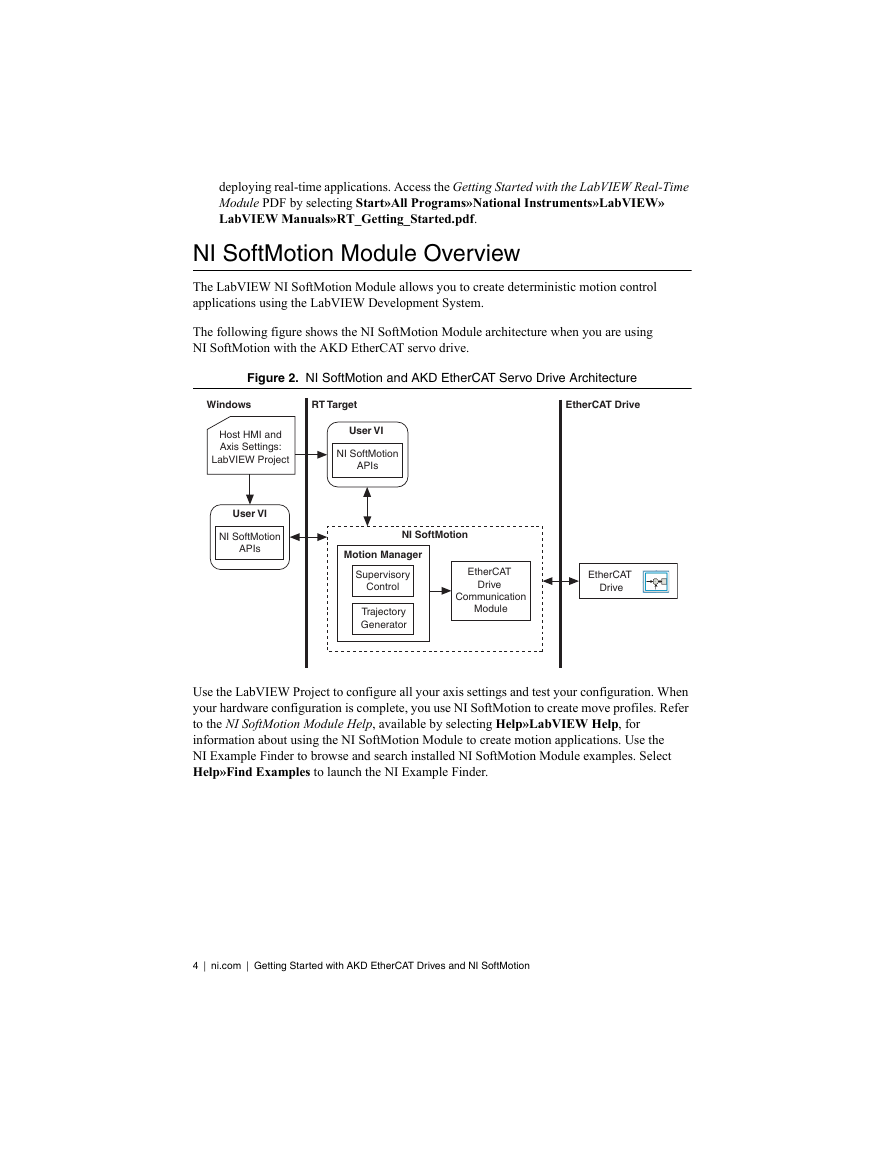

NI SoftMotion Module Overview

Figure 2. NI SoftMotion and AKD EtherCAT Servo Drive Architecture

Hardware and Software Configuration

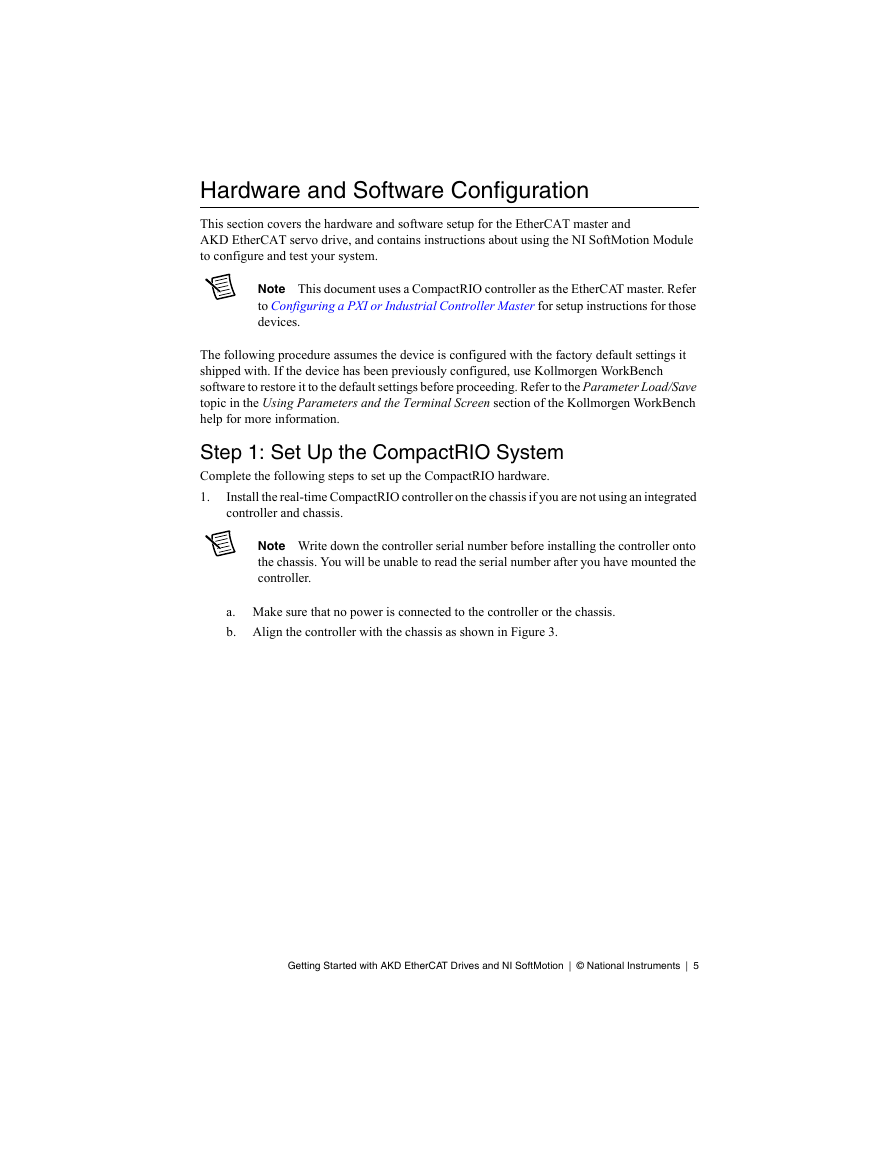

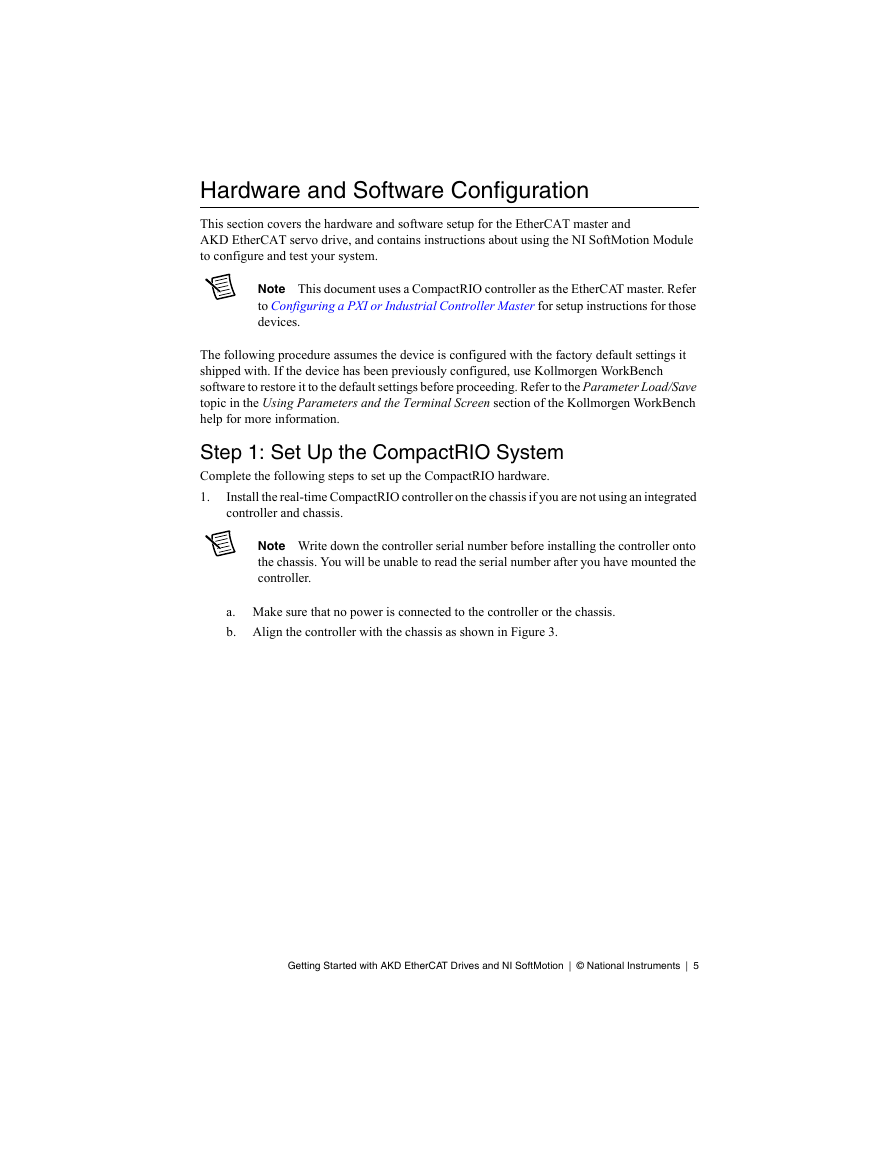

Step 1: Set Up the CompactRIO System

Figure 3. Installing the Controller on the Chassis (Eight-Slot Chassis Shown)

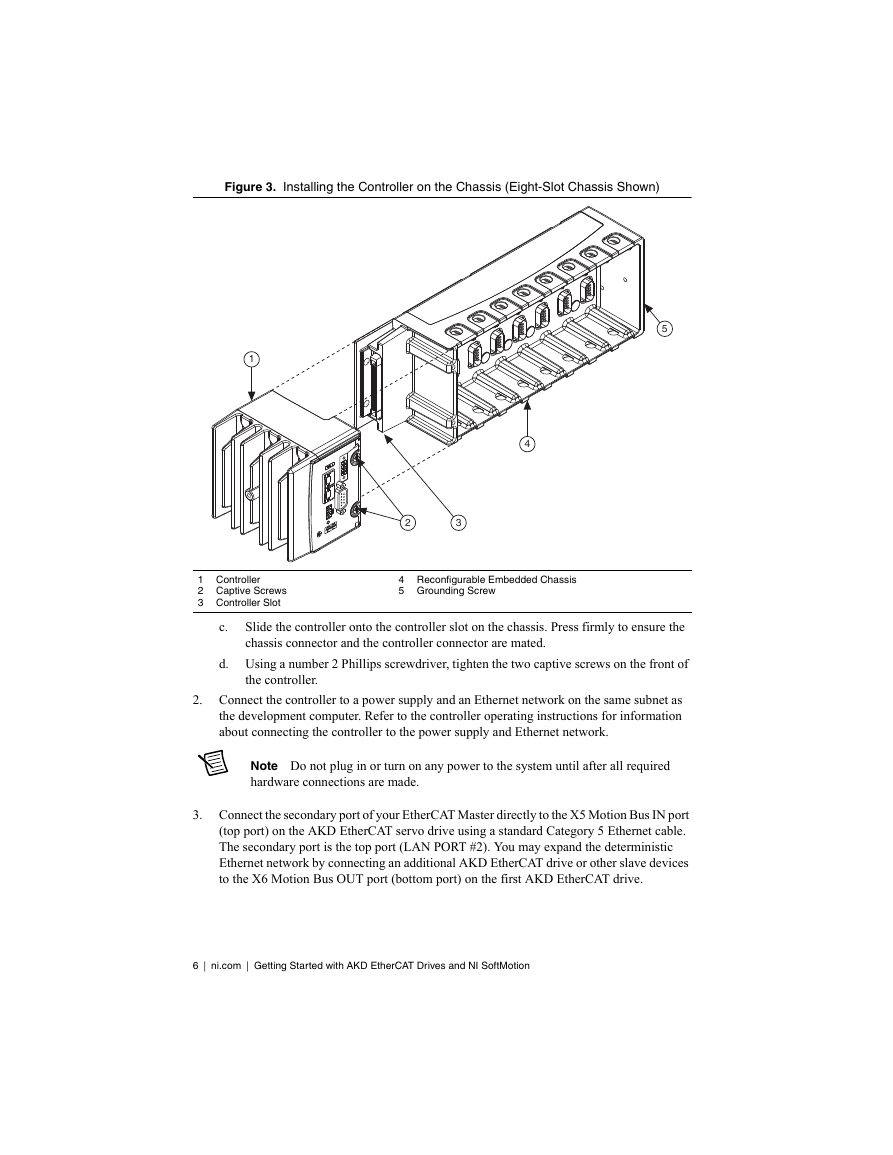

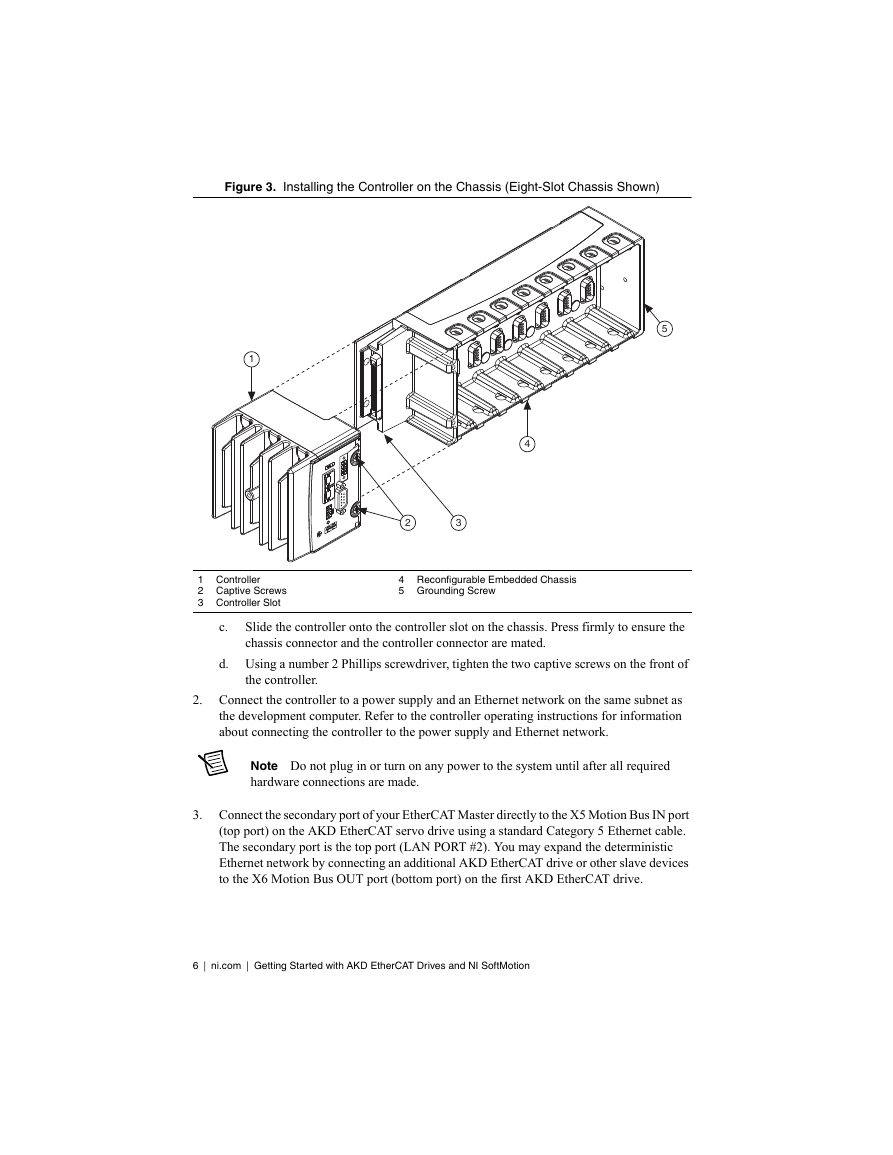

Figure 4. Connecting the AKD EtherCAT Drive to the Network

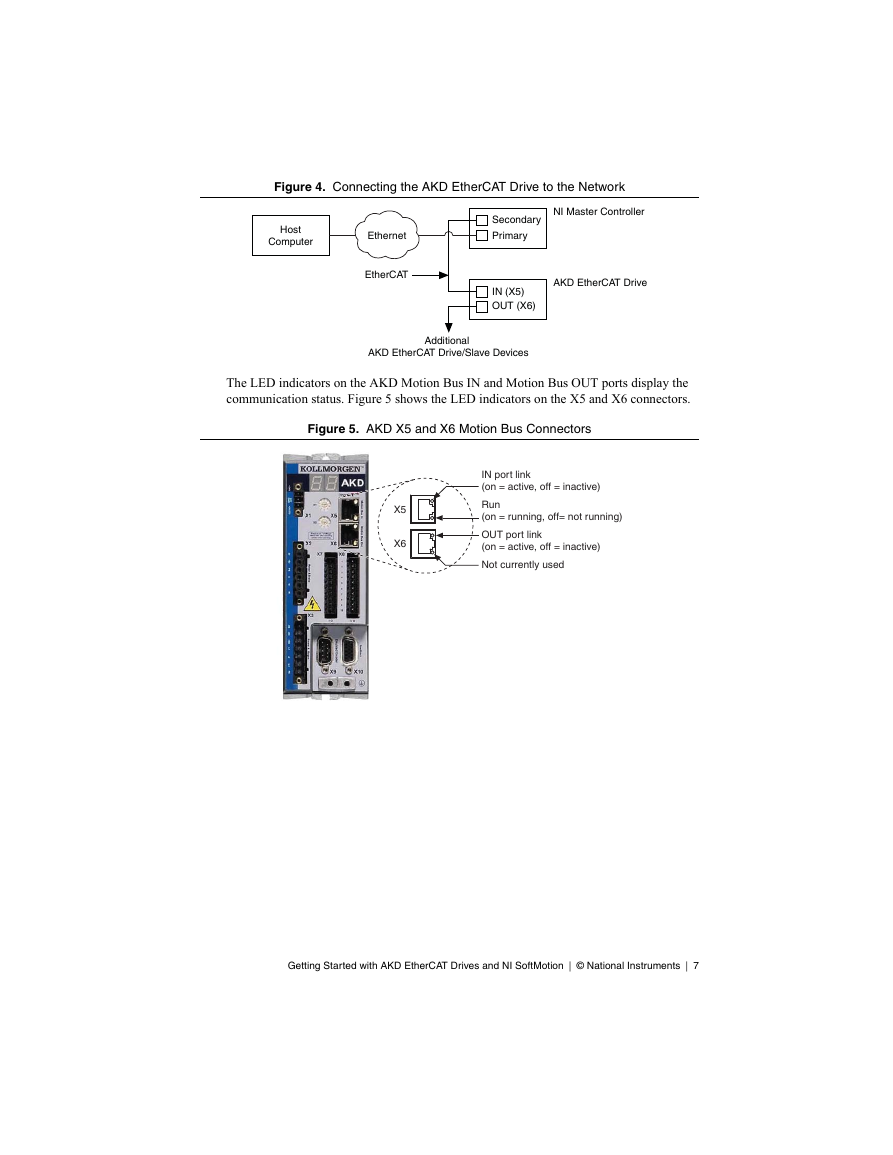

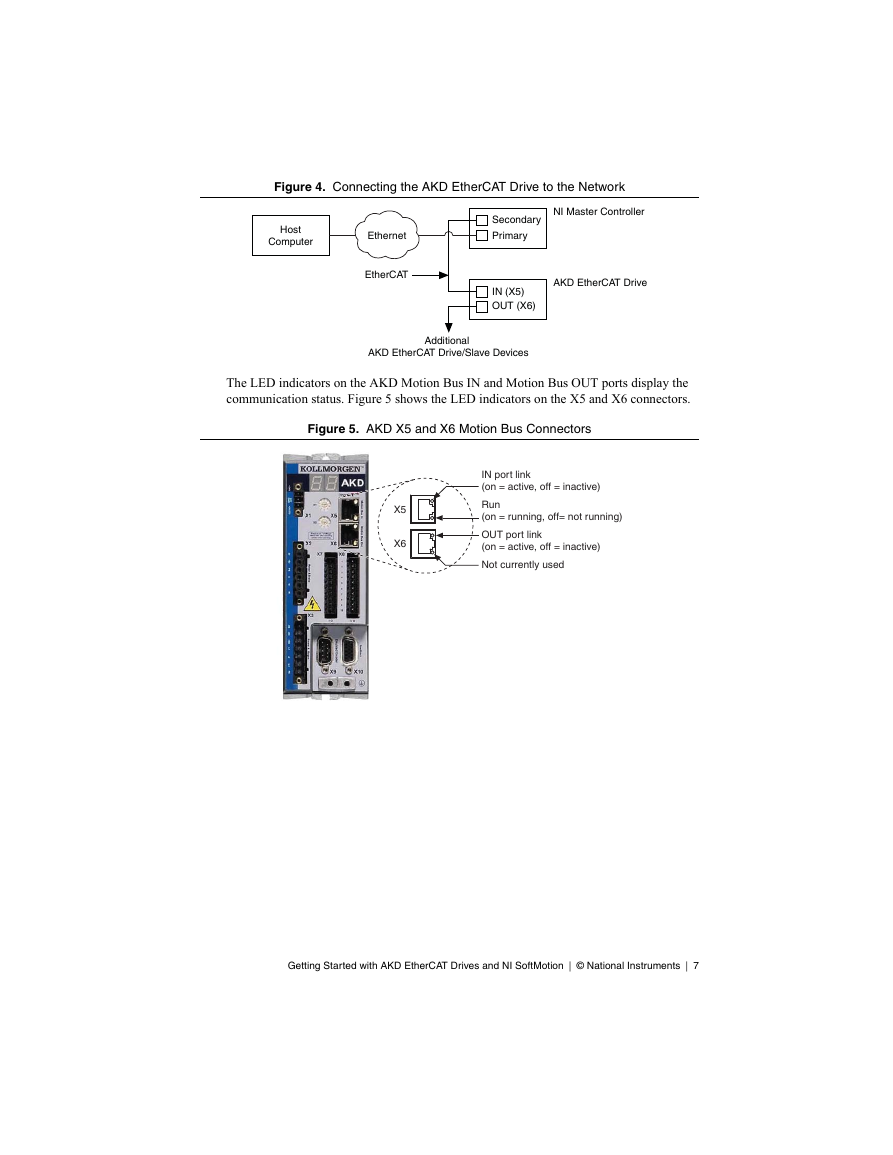

Figure 5. AKD X5 and X6 Motion Bus Connectors

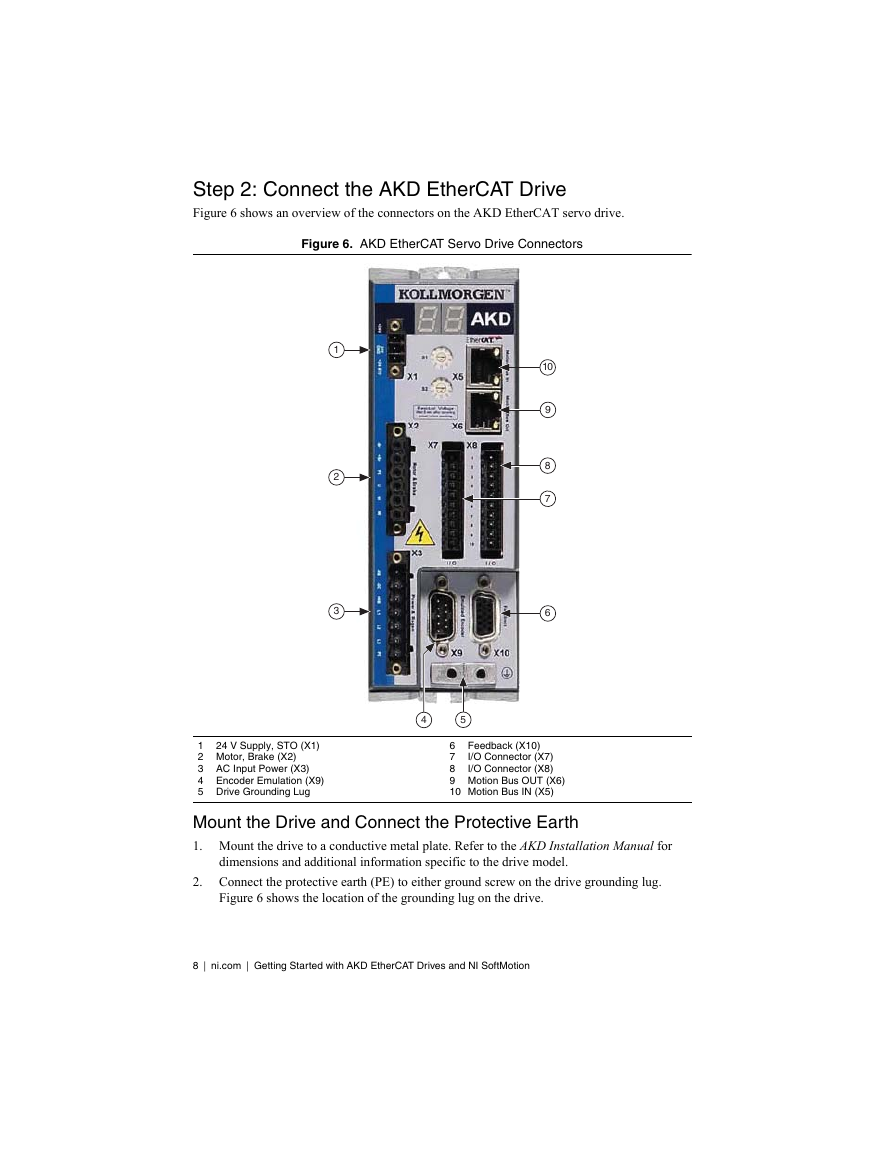

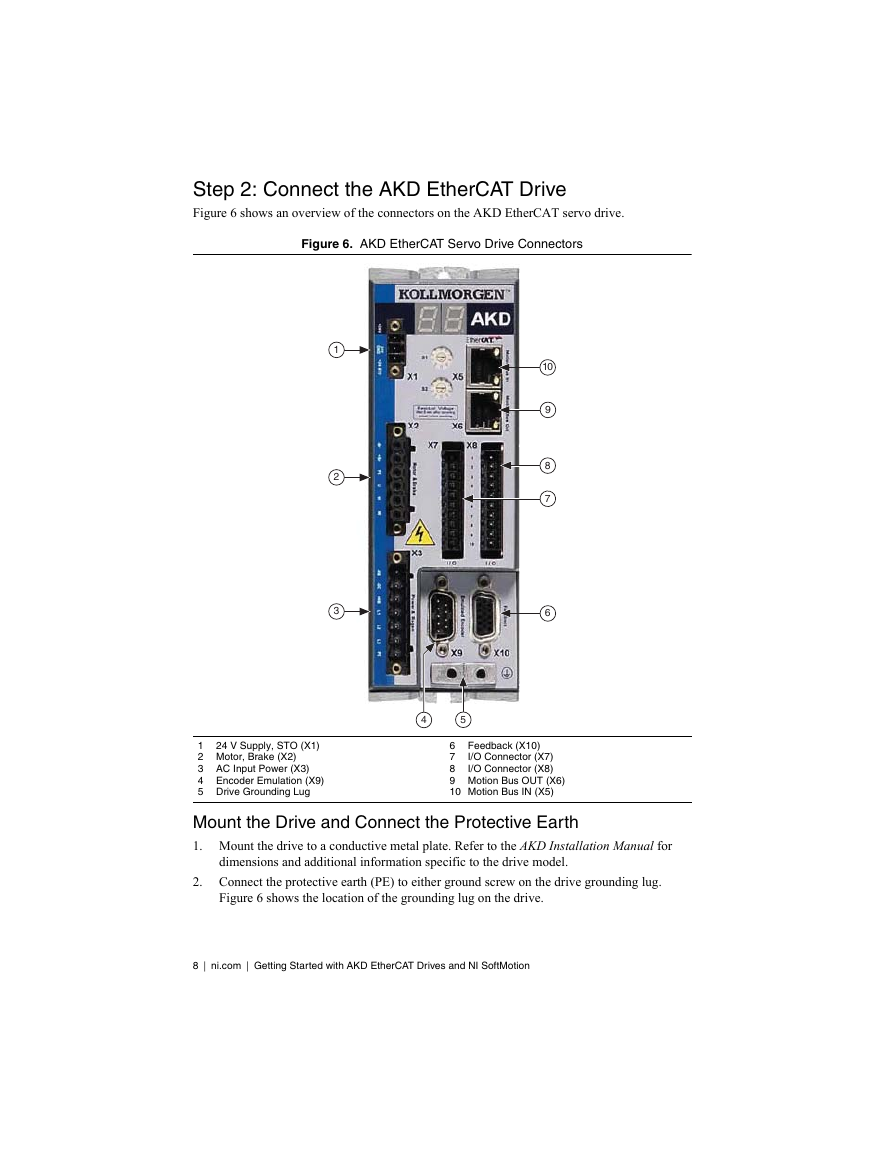

Step 2: Connect the AKD EtherCAT Drive

Figure 6. AKD EtherCAT Servo Drive Connectors

Mount the Drive and Connect the Protective Earth

Connect the Logic Power Supply to the X1 Connector

Figure 7. AKD X1 Connector

Connect the Hardware Enable on the X8 Connector

Connect the Motor and Encoder to the AKD Drive

Figure 8. Motor and Encoder Connections

Connect Additional I/O On the X7 and X8 Connectors

Figure 9. AKD X7 and X8 Connectors

Table 1. AKD to NI SoftMotion Signal Mapping

Connect the AC Input Power

Figure 10. AKD EtherCAT Servo Drive X3 Connector

Figure 11. AC Input Power Three-Phase Connection

Figure 12. AC Input Power Single-Phase Connection

Confirm Drive Connections

Step 3: Install Software on and Configure the NI RT Controller

Figure 13. Network Settings Tab

Step 4: Creating a Project and Adding an NI SoftMotion Axis

Figure 14. Adding the EtherCAT Master

Figure 15. Axis Manager Dialog Box

Figure 16. Project Explorer Window with AKD EtherCAT Servo Drive Axis

Step 5: Install Kollmorgen WorkBench and Configure the Drive

Figure 17. Kollmorgen WorkBench Start Page

Figure 18. Kollmorgen WorkBench Overview Page

Step 6: Tune the System using Kollmorgen WorkBench

Step 7: Configure the AKD EtherCAT Servo Drive Axis

Figure 19. Axis Configuration Dialog Box for AKD EtherCAT Servo Drives

Step 8: Enable and Test the Drive using LabVIEW

Configuring a PXI or Industrial Controller Master

Figure 20. Connecting the AKD EtherCAT Drive to the Network

Figure 21. AKD X5 and X6 Motion Bus Connectors

Tips and Troubleshooting

The Drive Does Not Enable

The Axis Does Not Appear To Move

The Drive Is Not Automatically Added to the LabVIEW Project

The Drive Returns a Synchronization Fault or Warning

Wiring Diagram

Figure 22. AKD Wiring Diagram

Worldwide Support and Services

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc