368

Communications

IEEE TRANSACTIONS ON ROBOTICS AND AUTOMATION. VOL 6. kO 3 . JUNE 1YYO

Direct Calculation of Minimum Set of Inertial

Parameters of Serial Robots

Abstract-The determination of the minimum set of inertial param-

eters of robots contributes to the reduction of the computational cost

of the dynamic models and simplifies the identification of the inertial

parameters. These parameters can be obtained from the classical inertial

parameters by eliminating those that have no effect on the dynamic

model and by regrouping some others.

This paper presents a direct method of determining the minimum

set of inertial parameters of serial robots. The given method permits

determination of most of the regrouped parameters by means of closed-

form relations.

I. I\-rRODL CTIOY

In order to increase the dynamic performance of robots, many

control schemes based on the dynamic model have been presented

[1]-[4]. Two problems have to he solved for real time implementation

of these control laws:

1) The numerical values of the inertial parameters must be known.

The solution of this problem has been investigated by the use of iden-

tification procedures based on a dynamic model linear in the inertial

parameters [5]-[9]. The classification and the determination of the

identifiable parameters (the minimum inertial parameters) increases

the robustness of the identification process [8].

2) The computational cost of the dynamic model must be reduced.

The solution of this problem has been carried out by the use of the

customized Newton-Euler method [lo], [ 1 11. To increase the number

of parameters that are equal to zero and, consequently, to reduce the

number of operations of the dynamic model, the use of the minimum

set of inertial parameters in a customized Newton-Euler method has

been proposed [ 121, [ 131.

The determination of the minimum set of inertial parameters has

been investigated in [ 121-[15]:

Khosla [14] has used a symbolic Newton-Euler algorithm. Some

results concerning some parameters in the case of robots whose suc-

cessive axes are either parallel or perpendicular are given. The detec-

tion of most of the combined parameters requires a long examination

of the symbolic Newton-Euler model on a case-by-case basis.

Khalil et al. [13], [15] have determined the minimum set of inertial

parameters by the examination of the symbolic expressions of the

inertia matrix and the gravity forces of a Lagrangian dynamic model.

Although these expressions are generated automatically by computer

[16], the detection of the combined inertial parameters may take

several hours.

The aim of this paper is to present a general and direct method to

determine the minimum set of inertial parameters of serial robots.

Most of these parameters (or in most cases, all of them) will be

determined by the use of the closed-form solution.

Coincidently with our work [17], similar results concerning the

special case of rotational robots whose successive axes are perpen-

dicular or parallel have been given by Mayeda et al. [ 181.

Manuscript received April 20, 1988; revised June 9, 1989.

The authors are with the Laboratoire d'Automatique de Nantes URA

C.N.R.S., E.N.S.M., Nantes, France

IEEE Log Number 8933674.

11. DESCRIPTION

OF THt~ ROBOT

The system to be considered is an open-loop mechanism of n +

1 links, where link 0 is the base, whereas link n is the terminal

link. The description of the system will be carried out by the use

of the modified Denavit-Hartenberg notation [ 191, [20]. Thanks to

this description, the closed-form solution of regrouping the inertial

fixed with respect to link j . The z , axis is along the axis of joint j ,

parameters has been obtained. The coordinate frame j is assigned

and the x, axis is along the common perpendicular of E , and z , ,

The frame j is defined with respect to frame j - 1 as a function of

the parameters (a,, d,, O,, r,). The type of joint j will be defined

by a:, where a, = 0 for j rotational, a, = 1 for j translational, and

f.7, = ( 1 -a,).

111. THL MINIMUM

INERTML PARAMETERS

The minimum inertial parameters are defined as the minimum set

of constant inertial parameters that do not conrain the zero element

and are sufficient to calculate the dynamic model of the robot. They

can be obtained from the classical inertial parameters by eliminating

those that have no effect on the dynamic model and by regrouping

some other parameters.

A . The Classical Inertial Parameters

The inertial parameters of link j are given by the vector X J , which

is denoted as

X J = IXX,XY~X~,.YY,.YZ,.ZZ,.~X,.~Y,~.~Z,.~,I~(I)

where ( X X j , . . ,ZZ,) are the elements of the inertia matrix ' J , ,

which defines the inertia of link j around the origin of frame j ,

( m X j , m y , , mZ,) are the elements of JmS,, which defines the first

moments of linkj, and m j is the mass of link j .

Using this set of parameters and denoting E as the kinetic energy

and U as the potential energy of the robot, we deduce that

where m is equal to 10n, XI is an inertial parameter, and W', is

constant.

B. Parameters Having No Eflect on the Dynamic Model

Using the Lagrange equation, one can derive that if

DE, - 0

(4)

the corresponding inertial parameter X I has no effect on the dy-

namic model. Thus, X , is not an element of the minimum inertial

parameters.

and d U , = 0

'The inertial parameters satisfying these conditions belong to the

links near the base side. They can be determined easily by hand

or automatically by computer [16]. Supposing that r l is the first

rotational joint and r2 the first succeeding rotational joint not parallel

to r I , one can derive most of the parameters having no effect by the

following rules:

1) If joint j

is translational and j < rI, then X X , , X Y , ,

X Z , , Y Y , , Y Z , , ZZ,, mX,, m y , , mZ, have no effect on the dy-

1042-296X/90/06OO-0368$01 .OO 0 1990 IEEE

�

IEEE TRANSACTIONS ON ROBOTICS AND AUTOMATION, VOL. 6 , NO. 3, JUNE 1990

369

namic model due to the fact that the angular velocity of link j is

equal to zero.

2 ) If the axis of joint r l is parallel to the direction of gravity and

the axes of joints j < r l are parallel to the axes of joint r l , or if

r l = 1 , then m X r I , m y r I have no effect on the dynamic model.

Moreover, in the case of r l = 1, m I has no effect on the dynamic

model.

3) For a linkj such that r l 5 j < r2 and the axis of link; is paral-

lel to that of r l , the parameters X X , , X Y , , X Z j , Y Y , , Y Z , , mZ,

have no effect on

the dynamic model. The elimination of

m X , , mY J , m j must be studied on a case-by-case basis. The pa-

rameters to be eliminated if the axis of joint j is perpendicular to

that of r l can be deduced easily.

4) For the links j 2 r2, all the parameters of the inertia tensor

have an effect on the dynamic model. Therefore, if the parameters

mXk, mYk, mZk appear in the model, then all the parameters of

links j > k will appear in the dynamic model.

C . Conditions for Regrouping the Inertial Parameters

An inertial parameter X I can be regrouped to some other param-

eters X;l , . . . ,Xir if

DE; = ~ ; I D E , I + . .. + a,,DE,, = x f f , k D E , k

r

(Sa)

and

dU; = f

f ; ~ dU;i + . . . + f f j r dUjr - m;k dU;k

k = l

-2

k = l

(5b)

with (Y;k = constant; therefore, we get the same value of E and

dU/dq (and consequently, the dynamic model) if we use the pa-

rameters x;, x;~,

. . . ,Xir or if we put X i equal to zero and the

parameters X;k equal to XR;k where

XRjk = Xjk + (YjkXj.

(6)

Relation (5) is similar to that given in [13]. Its use by calculating

DE; and dU; is time consuming and error prone, especially for

robots having n 2 3. In the following section, we present a method

that overcomes this difficulty.

IV. CLOSED-FORM SOLUTION OF REGROUPING

and j = l , . . . , n . Denoting DE'

aE/dX! and DUJ the vector of the components dU/dXj

Let X j be the ith inertial parameter of link j , with i = 1 , . . . , l o ,

the vector of the components

THE INERTIAL PARAMETERS

(7)

The main idea is to calculate DEJ and DUJ as a function of DE'-'

and D U J - l , respectively.

A . Recursive Relations of DE' and DUJ

The recursive relations of DEJ and DUJ can be written as

DEJ = XiDEJ-' + q J j ( q , q )

and

or in the expanded form, we have

DUJ = P D u J - l

(9)

(10)

As dU/dXi-' = 0 for k = 1,. . . ,6, and taking into account that

(see the Appendix) p:,k = A;,, ( k = 7 , . . . , lo), (12) can be written

as

The expressions of hi and f' are given in the Appendix.

B . General Regrouping Relations of Inertial Parameters

Let us examine the regrouping of the inertial parameters of link j

on those of link j - 1 by the use of the recursive relations of Xi and

f J given in the Appendix. We consider the following two cases:

1) If joint j is rotational, we see that

a) the coefficients A{,

are constant for k = 1, . . , l o , whereas

f {o(q, q ) = 0. Thus, DE',, can be obtained as linear combinations of

DE;-', i.e., DE{, verifies the condition (5a). Taking into account

(13), (5b) is also verified. Thus, the tenth parameter m, can be

regrouped to the ,inertial parameters of link j - 1. Using (6) and the

expressions of A{o, given in the Appendix, we get

X X R , - I = X X J - , +r?m,

X Y R J P I = X Y j - , + d j r j S a j m j

X Z R j - , = X Z , - , - d,r,Ca,m,

YYRj-, = Y Y , - I + (d: + r:Ca:)m,

Y Z R J - , = Y Z J P l + r ~ C a , S a j m ,

ZZR,-I = Z Z j - I + (d: + r:Sa:)m,

mXR,-I = mX,-l + d j m j

mYRj-I = m Y j - , - r,Sajmj

mZRjPl = mZ,-, +r,Ca,m,

mRj-, = m j P l + m,.

b) The coefficients A;,

(14)

are constant for k = 1,. . . ,lo, whereas

fi(q, q ) = 0. Similar to the foregoing case, the parameter mZ, can

be regrouped to the inertial parameters of link j - 1 .

c) The sum of DE: and DE:, corresponding to the parameters

X X j and YY j , respectively, can be expressed through constant co-

efficients as a function of DE$-', k = l , . . . , 10. Thus, X X , or

Y Y j can be regrouped to the parameters of link j - 1 and Y Y , or

X X j , We will always choose to regroup Y Y , .

As a conclusion,

the parameters

( Y Y , , m Z j , m j ) can be eliminated, whereas the combined parame-

ters of links j and j - 1 are given as

is rotational,

if joint j

X X R j = X X j - YYj

X X R j - , = X X , - I + Y Y j + 2rjmZ, + r:mj

X Y R j - , = X Y j - , + d j S a j m Z j + d j r j S a J m j

X Z R j - I = X Z j - , - d,CajmZj - d,r,Ca,m,

YYRj-I = Y Y j - , + Ca:YYj + 2rjCa:mZ, + (d: + r:Caj)m,

Y Z R j P I = Y Z , - , + C a j S a j Y Y j + 2rjCa,SajmZ,

+r:Ca,Sa,m,

ZZRj-I = Z Z j - , +Sa:YYj + 2rjSa;mZj + (d: + r:Sa?)m,

m X R j - , = m X j P l + d j m ,

m Y R j P l = m y , - , - Sa,mZ, - rjSa,m,

mZRj-, = mZ,-, + C a j m Z j +r,Ca,mj

mRj-, = m j - l +m,.

(15)

�

370

IEEE TRANSACTIONS ON ROBOTICS AND AUTOMATION. VOL. 6, NO. 3, JUNE 1990

2 ) If joint j is translational, we see that A:,,

are constant, whereas

f:(q,q) = O for i = 1 , . . . , 6 and k = 1 , . . . , 1 0 . Thus, the param-

eters X X , , X Y , , X Z , , Y Y , , Y Z j , Z Z j can be regrouped to the

inertial parameters of link j - 1 by the use of the following rela-

tions:

XXR,-1 = XXj-1 +C8:XXJ -2CS8jXYj +SB:YY,

XYRj-1 = XYj-1 + CS8jCajXXJ + (C8: - SO:)CajXY,

- c t l j S ~ ~ j X Z j - CS8jCajYYj + SBJS~,YZj

XZR,-l = XZj-1 +CS8jSaJXX, + (C8: -SB?)Sa,XY,

+CBjCajXZj - CSBjSajYY, - S8jC~ijYZj

YYR,-I = Y Y j - , +S8:CajXX, +2CSOjCaSXY,

- 2SBjCSajX2, + CB~ZCCY~YY,

- 2C8jCS~rjYZj + S a s Z Z j

YZR,-l = YZj-1 +S8:CSa,XX, + 2CS8,CSaJXY,

I

I

I

i

i

+SB,(Ca: -Sa:)XZ, +C8:CSa,YYJ

+ C8j(Ca: - Sa:)YZ, - CSa,ZZ,

ZZRj-, = ZZj-I +SBfSa:XX, + 2CS8,Sa;XYj

+2S8jCSa,XZJ + C B ~ S a ~ Y Y , + 2COjCSajYZj + CajZZ

(16)

where CS( .) is equal to cos ( . ) sin ( ).

Remarks: 1) We note that (16) corresponds to the following

= J - I J , - ,

J-lJRj-l

+'-'A I .JJ J JA I - 1

matrix equation:

(17)

where J-IA , is the (3 x 3) matrix defining the orientation of frame

j with respect to frame j - I .

This relation can be obtained directly by noting that the angular

velocity of link j is equal to that of link j - 1 if joint j is translational.

2) From the general regrouped results and taking into account

the eliminated parameters of link 1, we deduce that the number of

minimum inertial parameters is equal or less than

7n, +4n, - 3 - 51

(18)

where n, is the number of rotational joints = Eaj and n, is the

number of translational joints = Coj .

C. Particular Regrouping of the Inertial Parameters

As we have seen in Section 111-B, some of the inertial parameters

of the first links may have no effect on the dynamic model; there-

fore, particular regrouping, other than that denoted in Section IV-B,

may take place. The detection of these particular cases have to be

studied on a case-by-case basis using (5). We find that the particular

regrouping will concern only the parameters m X , mY, and mZ of

the translational links lying between the joints rl and r2 defined in

Section 111-B. For the general case, it is not easy to calculate this

regrouping by a closed-form solution. If we consider that the joints

between r l and r2 are either parallel or perpendicular such that the

angular velocity of the links referred to the link frame will have only

one component different than zero, then the particular cases will take

place if the axis of the joint is parallel to r l ; in this case, the param-

eter mZj has no effect on the model, whereas the parameters m X j

and mY will be regrouped to the parameters of link j - I . Two

cases are considered.

and

1) If Sa, = 0, then mZ,-I has no effect on the dynamic model,

ZZRj-, = Z Z j - , + 2d,CBjmXj - 2d,SBjmYJ

m X R j P I = m X J P I + C8,mX, - SBjmYj

mYRj-, = m Y j - , +SBjCajmXi +C8,CajmYj.

(19)

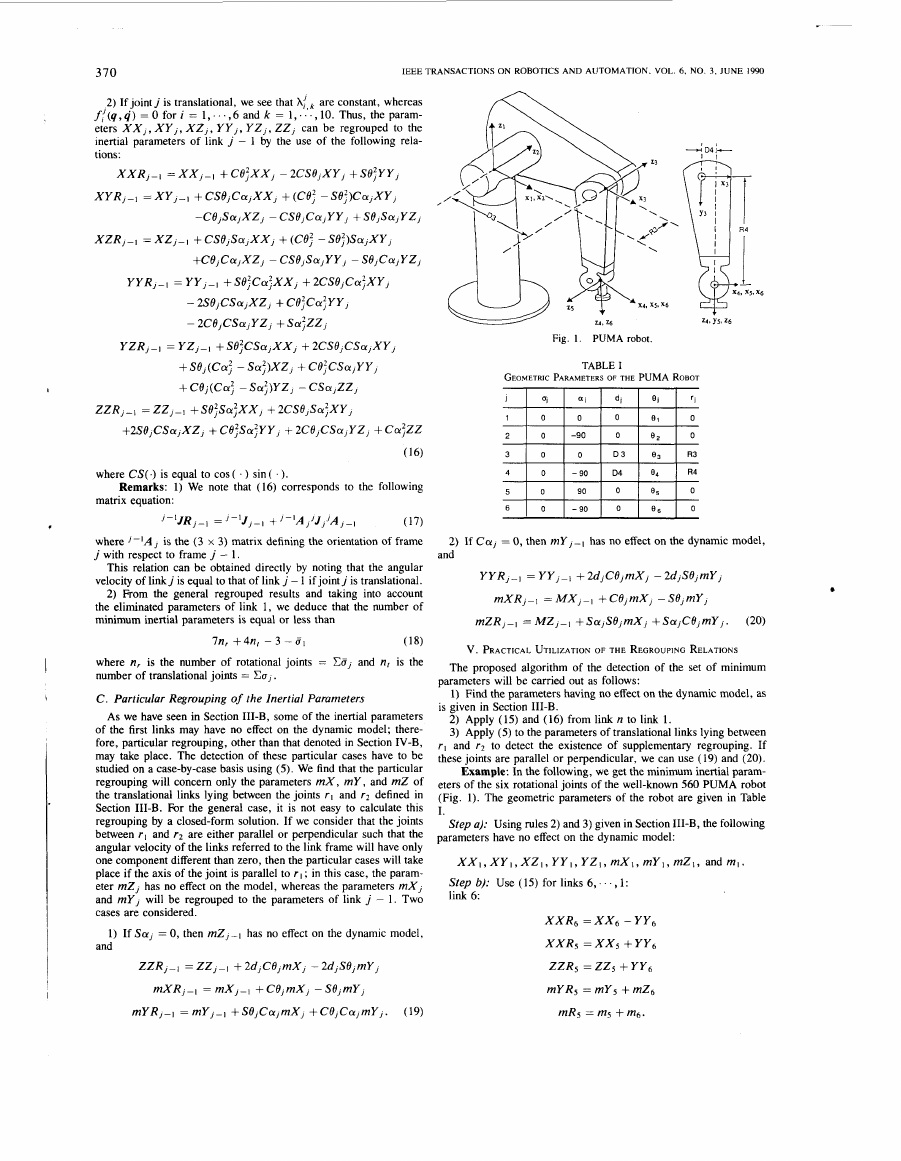

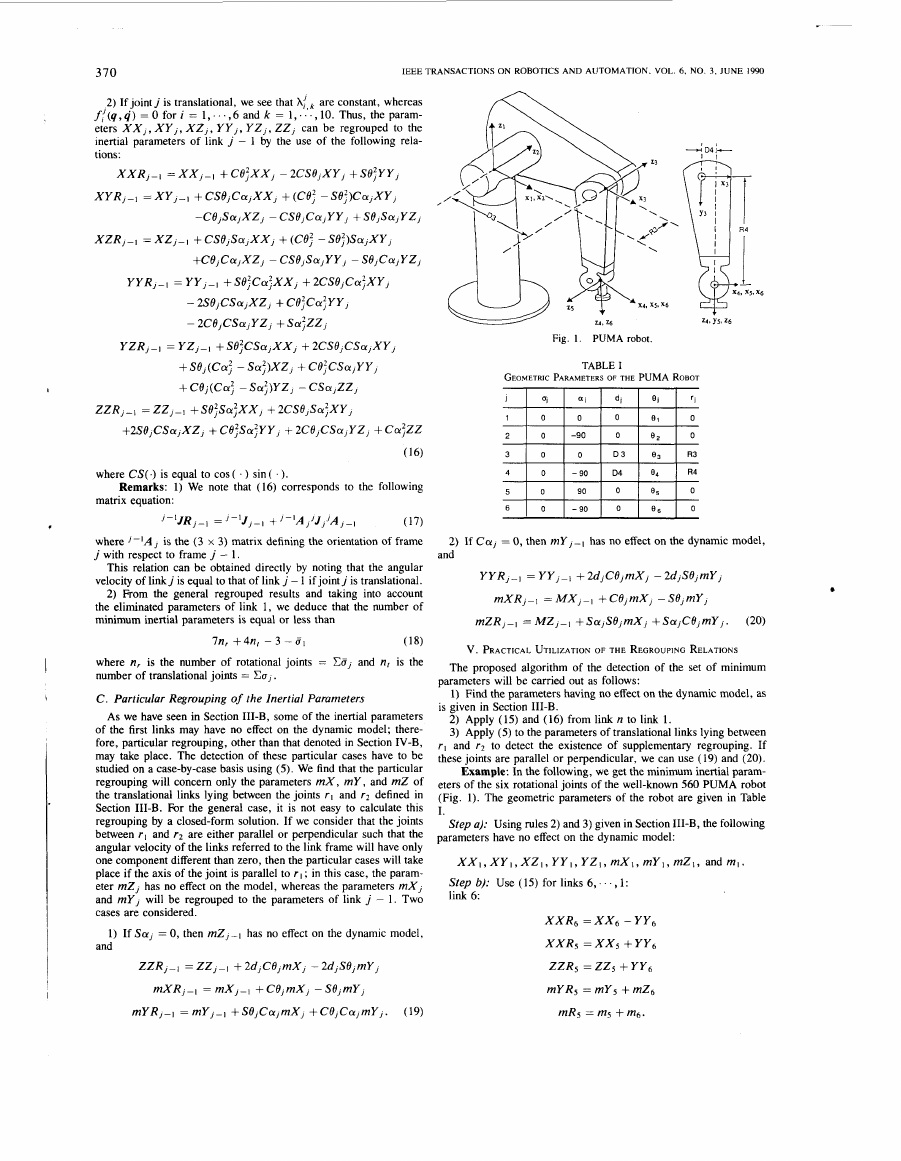

Fig. 1. PUMA robot.

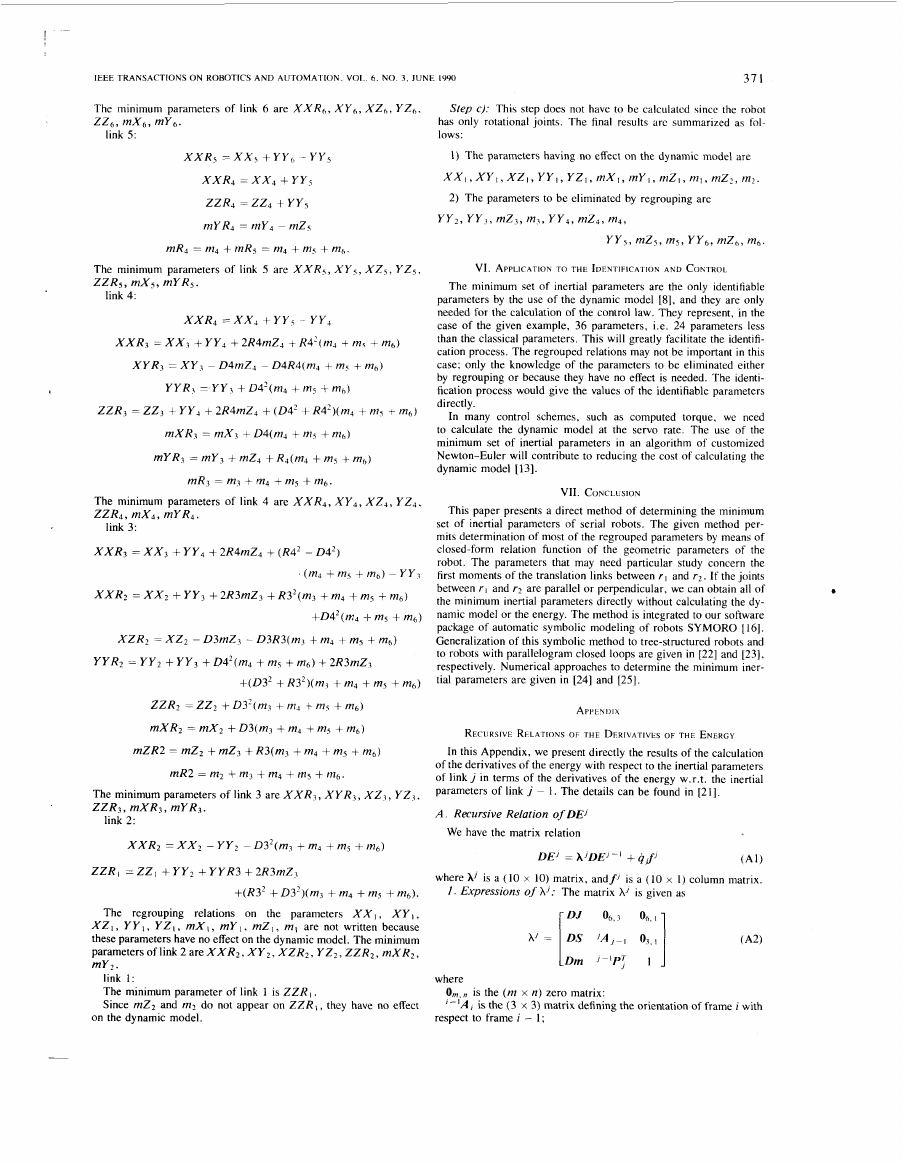

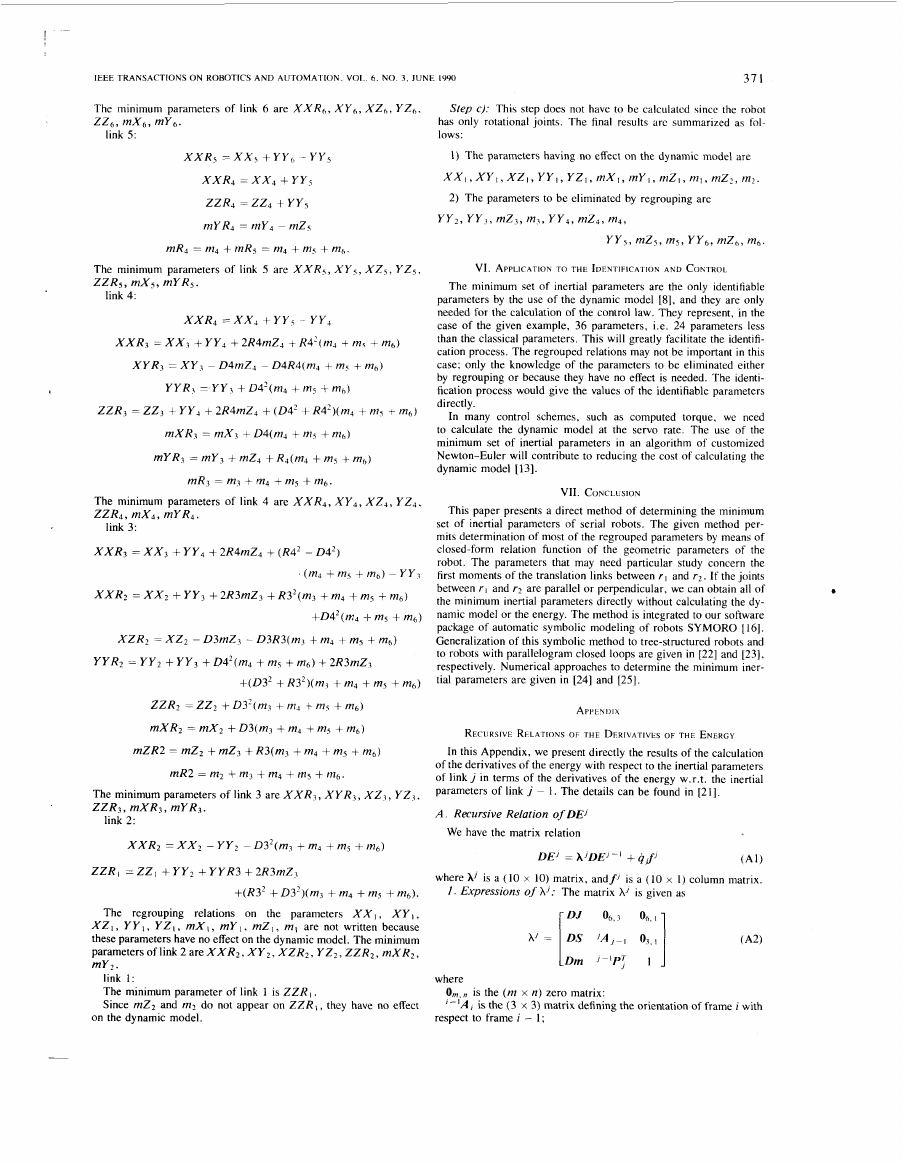

TABLE I

GEOMETRIC PARAMETERS

OF THE PUMA ROBOT

3

4

0

0

0

-90

D 3

D4

e3

84

6 I

o

I

o

I e 6

I

I

I

1 - 9 0

I

R3

R4

o

2) If Ca, = 0, then m y ,

has no effect on the dynamic model,

and

YYR,-l = YY,-I + 2dJC8,mX, - 2dJS8,mY,

mXR, = M X , -, + C8, mXJ - S8, m y ,

mZR,-, = MZ,-I +Sa,SB,mX, +Sa,CB,mY,.

(20)

V. PRACTICAL UTILIZATION

OF THE REGROUPING RELATIONS

c

The proposed algorithm of the detection of the set of minimum

parameters will be carried out as follows:

1) Find the parameters having no effect on the dynamic model, as

is given in Section 111-B.

2 ) Apply (15) and (16) from link n to link 1.

3) Apply (5) to the parameters of translational links lying between

r l and r2 to detect the existence of supplementary regrouping. If

these joints are parallel or perpendicular, we can use (19) and (20).

Example: In the following, we get the minimum inertial param-

eters of the six rotational joints of the well-known 560 PUMA robot

(Fig. 1). The geometric parameters of the robot are given in Table

I.

Step a): Using rules 2) and 3) given in Section 111-B, the following

parameters have no effect on the dynamic model:

X X I , X Y , , X Z I , Y Y , , Y Z 1 , m X 1 , m y 1 , m Z , , and m l .

Step b): Use (15) for links 6, . . . , 1:

link 6:

�

IEEE TRANSACTIONS ON ROBOTICS AND AUTOMATION. VOL. 6. NO. 3. JUNE 1990

37 I

The minimum parameters of link 6 are X X R 6 , X Y 6 , X Z 6 , Y Z 6 .

ZZb, m x b , myb.

link 5:

XXR5 = X X s +YYt, - Y Y s

XXR4 L X X 4 + YYs

ZZRj ZZ4 + YYS

mYRJ = mY4 - mZs

mR4 = m4 t mRS = m4 + ms + m 6 .

The minimum parameters of link 5 are X X R S , X Y 5 , X Z s , Y Z s ,

ZZR5, m X 5 , mYRs.

link 4:

XXR4 = X X J +YY5 - YYI

X X R , = X X 3 + Y Y 4 + 2R4mZJ + R4'(mJ -t mc + m6)

XYR3 = X Y 3 - D4mZJ - D4R4(m4 + mc t m,)

Y Y R ? =-YY-\ + D4'(m4 + m5 + m6)

ZZR3 = ZZ3 + Y Y J + 2R4mZ4 + (04' + R4')(m4 + m5 t m6)

m X R s = mX3 + D4(m4 + m5 + m6)

mYRi = my3 + m Z j + R4(m4 + ms + mb)

mR3 = m3 + m4 + m5 + mb.

The minimum parameters of link 4 are X X R j , X Y 4 , X Z 4 , Y Z 4 .

ZZR4, m X 4 , mYR4.

link 3:

X X R S = X X 3 + Y Y 4 t 2R4mZ4 + (R42 - 0 4 ' )

.(m4 + m 5 + m 6 ) - Y Y 7

XXR2 = X X 2 + Y Y 3 + 2R3mZ3 + R32(m3 + m4 + m5 + mh)

-E M 5 + mg)

+ D 4 2 ( ~ 4

XZR2 = XZ2 - DSmZ, - D3R3(m3 + m4 + ms + mb)

YYR2 = yy2 + y y 3 + D42(m4 + m5 + 1716) + 2R3mZ3

+(D32 + R3')(m3 + m4 + ms + mg)

ZZR2 = ZZ2 + D3'(m3 t m, t mc + mb)

m X R 2 = m X 2 + D3(m3 + m4 -t ms + m 6 )

mZR2 = m Z z + mZ3 + R3(m3 + m4 + ms + m b )

mR2 = m2 + m3 + m4 + m5 + mb.

The minimum parameters of link 3 are X X R 3 , X Y R 3 , X Z 3 , Y Z 3 ,

ZZR3, m X R 3 , mYR3.

link 2:

X X R 2 = X X 2 - Y Y 2 - D32(m3 + m4 + m5 + m e )

Z Z R , = Z Z I + Y Y 2 t Y Y R 3 + 2R3mZ3

The regrouping relations on

+(R3* + D3')(m3 + m4 + m5 + m6).

the parameters X X , , X Y , ,

x z i , y y ~ , Y Z I , m X , , m y , , m Z , , m l are not written because

these Parameters have no effect on the dynamic model. The minimum

parametersoflink2areXXR2, X Y 2 , X Z R 2 , Y Z 2 , Z Z R 2 , m X R 2 ,

m y 2 .

link 1:

The minimum parameter of link 1 is Z Z R , .

Since mZ2 and mz do not appear on Z Z R , , they have no effect

on the dynamic model.

Step cJ: This step does not have to be calculated since the robot

has only rotational joints. The final results arc summarized as fol-

lows:

1) The parameters having no effect on the dynamic model are

X X , , X Y , , X Z I , Y Y , , Y Z , , m X l , m y , , m Z I , m , , m Z z , m z .

2) The parameters to be eliminated by regrouping are

YY2, YY3, mZ3, m3, YYq, m Z 4 , m4,

Y Y s , mZs, ms, y y b , m Z 6 , mb.

VI. APPLICATION

TO T H E I D E N T I F I C A T I ~ N A N D CONTROL

The minimum set of inertial parameters are the only identifiable

parameters by the use of the dynamic model [SI, and they are only

needed for the calculation of the control law. They represent, in the

case of the given example, 36 parameters, i.e. 24 parameters less

than the classical parameters. This will greatly facilitate the identifi-

cation process. The regrouped relations may not be important in this

case; only the knowledge of the parameters to be eliminated either

by regrouping or because they have no effect is needed. The identi-

fication process would give the values of the identifiable parameters

directly.

In many control schemes, such as computed torque, we need

to calculate the dynamic model at the servo rate. The use of the

minimum set of inertial parameters in an algorithm of customized

Newton-Euler will contribute to reducing the cost of calculating the

dynamic model [13].

VII. CONCLUsroN

This paper presents a direct method of determining the minimum

set of inertial parameters of serial robots. The given method per-

mits determination of most of the regrouped parameters by means of

closed-form relation function of the geometric parameters of the

robot. The parameters that may need particular study concern the

first moments of the translation links between r I and r2. If the joints

between r l and r2 are parallel or perpendicular, we can obtain all of

the minimum inertial parameters directly without calculating the dy-

namic model or the energy. The method is integrated to our software

package of automatic symbolic modeling of robots SYMORO [ 161.

Generalization of this symbolic method to tree-structured robots and

to robots with parallelogram closed loops are given in [22] and [23],

respectively. Numerical approaches to determine the minimum iner-

tial parameters are given in [24] and [25).

A wENi)rX

c

RECLIRSIVE

RSLA'TIONS OF THE DERIVATIVES

OF THE ENERGY

In this Appendix, we present directly the results of the calculation

of the derivatives of the energy with respect to the inertial parameters

of link j in terms of the derivatives of the energy w.r.t. the inertial

parameters of link j

A . Recursive Relation of DE'

We have the matrix relation

- 1. The details can be found in [21].

DEJ = XJDEJ-l + . s f

where Xi is a ( I O x IO) matrix, andf'

I . Expressions of XI: The matrix XI is given as

(AI)

is a (10 x 1) column matrix.

where

Om,n is the ( m x n) zero matrix:

' - ' A , is the ( 3 x 3) matrix defining the orientation of frame i with

respect to frame i - 1;

�

372

IEEE TRANSACTIONS ON ROBOTICS AND AUTOMATION, VOL. 6. NO. 3. JUNE 1990

‘ - ’ P , is the (3 x 1) vector defining the position of the origin of

frame i with respect to frame i - 1;

and J-’PJ are functions of the geometric

DJ, DS, D m ,

parameters d j , r , , OJ , aJ . They are given as follows (the indexj has

been omitted to simplify the writing):

We initialize the recursive relation by

DUO = [ O 1 , 6

*T

OIT

(‘412)

where g is the acceleration of gravity.

csecff

CSOSff

ssocca

SSOCSCY

SSOSSa

(CCO - SSO)SCU ~CSOCCCY

ceca

-CSOSa

4OCa

0

2CSOCSa

2CSOSSa

-2SOCSff SO(CCff - S S a ) 2SOCSa

CCOSSa

CCOCCa

CCOCSa

ssa) 2cecsa

-2cocsff ce(ccff

cca 1

-csa

ssa

~

(-43)

*

~~~~

~~~

~~

REFERENCES

W. Khalil, A. Liegeois, and A. Fournier, “Commande dynamique de

robots,” RAIRO Automatique Syst. Anal. Contr., vol. 13, no. 2,

pp. 189-201, 1979.

J . Y. S . Luh, M. W. Walker, and R. Paul, “Resolved-acceleration

control of mechanical manipulators,” IEEE Trans. Automat. Contr.,

vol. AC-25, pp. 468-474, 1980.

0. Khatib, “A unified approach for motion and force control: The

operational space formulation,’‘ IEEE J . Robotics Automat., vol. 3,

pp. 43-53, 1987.

C. S . G. Lee and M. J . Chung, “An adaptive control strategy for

mechanical manipulators,” IEEE Trans. Aufomat. Contr., vol. AC-

29, no. 9, pp. 837-840, 1984.

E. Ferreira, “Contribution a l’identification des parametres et a la com-

mande dynamique adaptative des robots manipulateurs,” These Doct.

Ing., Toulouse, France, 1984.

C. H. An, C. G. Atkeson and J. M. Hollerbach, “Estimation of inertial

parameters of rigid body links of manipulators,” in Proc. 24th Conf.

Decision Contr., 1985, pp. 990-995.

A. Mukerjee and D. H. Ballard, “Self-calibration in robot manipu-

lators,” in Proc. IEEE Int. Conf. Robotics Automat., 1985, pp.

1050- 1057.

P. K. Khosla and I. Kanade, “Parameter identification of robot dynam-

its," in Proc. 24th Conf. Decision Contr., 1985, pp. 1754-1760.

M. Gautier and W. Khalil, “On the identification of the inertial pa-

rameters of robots,” in Proc. 27th Conf. Decision Contr., 1988, pp.

2264-2269.

T. Kanade, P. Khosla, and N. Tanaka, “Real-time control of CMU

direct-drive arm I1 using customized inverse dynamics.” in Proc. 23

CDC, 1984, pp. 1345-1352.

W. Khalil and J. F. Kleinfinger, “Une modelisation performante pour

la commande dynamique de robots,” RAIRO, APII, vol. 6, pp.

561-574, 1985.

W. Khalil, J. F. Kleinfinger, and M. Gautier, “Reducing the computa-

tional burden of the dynamic model of robots,” in Proc. IEEE Conf.

Robotics Automat. (San Francisco), 1986, pp. 525-531.

W. Khalil and J . F. Kleinfinger, “Minimum operations and minimum

parameters of the dynamic models of tree structure robots,” IEEE

Trans. Robotics Automat., vol. RA-3, pp. 517-526. Dec. 1987.

P. Khosla, ‘‘Real-time control and identification of direct-drive manip-

ulators,” Ph.D. thesis, Carnegie Mellon University, Pittsburgh, 1986.

W. Khalil, M. Gautier, and J. F. Kleinfinger, “Automatic generation

of identification models of robots,” Int. J . Robotics Automat., vol.

1, pp. 2-6, 1986.

W. Khalil, J. F. Kleinfinger, and C. Chevallereau, “SYMORO:

system pour ia modelisation des robots,” Notice d’utilisation, Note

interne LAN, Nantes, 1987.

M. Gautier and W. Khalil, “A direct determination of minimum iner-

tial parameters of robots,” in Proc. IEEE Conf. Robotics Automat.

(Philadelphia), 1988, pp. 1682- 1687.

H. Mayeda, K. Yoshida, and K. Ousuka, “Base parameters of manipu-

lator dynamics,” in Proc. IEEE Conf. Robotics Automat. (Philadel-

phia), 1988, pp. 1367-1373.

W. Khalil and J. F. Kleinfinger, “A new geometric notation for open

and closed loop robots,” in Proc. IEEE Conf. Robotics Automat.

(San Francisco), 1986, pp. 1174-1 180.

E. Dombre and W. Khalil, “Modelisation et commande des robots,”

Edition Hermes, Paris, 1988.

DJ =

-2CSO

0

SSO

0

0

-

(CCO

SSO)Ca

~

- a s f f

-cseca

SOSa

0

Dm

= [ r 2 drSa

I

- d r C a

d ? + r ’ C C a

r 2 C S a

/ - l p T - - [ d

- r s a

r c a ]

2) Expression of f J : Two cases are considered:

a) For j rotational

case

sase

J A ~ - ~ =

CMO

-sa

S ~ C O

cff

[

C O

-se

0

1

b) for j translational

f J = [ O 0 0 0 0 0

-wz,j

W I , J 0

( V 3 , J - ; q j ) I T

(‘49)

where 0, is the velocity of the joint variable J , whereas wk, J , and

V k , j denotes the kth component of J w j and ’ V , , respectively, and

where J V , is the velocity of the origin of the link j fixed frame,

referred to frame j , and Jo, is the angular velocity of link j , referred

to frame j .

3) Znitialization of the recursive relations of DE’: Since link 0

is fixed, then we initialize the calculation by

. . . 0 I T .

(A101

D E o = [ O 0

B . Recursive Relations of DUJ

We have the relation

DU’ = 03.6 JA,-l

( A l l )

[

0 6 , 6

0 6 , I

0 6 , 3

J-bY ‘y‘]

DuJ-‘’

�

IEEE TRANSACTIONS ON ROBOTICS AND AUTOMATION, VOL 6 . NO. 3. JUNE 1990

373

1211

[22]

[23]

1241

[25]

M. Gautier, “Contribution a la modelisation et a I‘identification des

robots,” these d’etat, Nantes, 1990.

W. Khalil, F. Bennis, and M. Gautier. “Calculation of the minimum

inertial parameters of tree structure robots,” in Proc. 3rd ICAR Conf.

(Columbus), 1989.

F. Bennis and W. Khalil, “Minimum inertial parameters of robots

with parallelogram closed loops,” in Proc. IEEE Conf. Robotics Au-

tomat. (Cincinnati), 1990.

H. Sheu and M. W. Walker, “Basis sets for manipulator inertial pa-

rameters,” in Proc. IEEE Conf. Roborics Automat. (Scottsdale),

1989, pp. 1517-1522.

M. Gautier, “Numerical calculation of the base inertial parameters,”

in Proc. IEEE Conf. Roborics Automat. (Cincinnati), 1990.

Robustness Analysis of Nonlinear Decoupling for

Elastic-Joint Robots

WOLFGANG M. GRIMM. UEMBER. IEEE

Absmct- In this communication, a robustness analysis of feedback

linearization or nonlinear decoupling is proposed for a class of elastic-

joint robot manipulator control loops. it is shown that by splitting the

modeling-error nonlinearities of incomplete feedback linearization or

nonlinear decoupling by a suitable transformation, a robustness analy-

sis becomes feasible under weak assumptions without the necessity of

estimating bounds on derivatives of robot nonlinearities.

I. INTRODUCTION

The robustness analysis for rigid robot manipulators, which is out-

lined in [1]-[5], is based on feedback linearization [6] or nonlinear

decoupling [7], where the rigid robot model is always feedback lin-

earizable. This may not be the case for elastic-joint robot models

in general [8]; however, under assumptions outlined in [9] or [IO],

the conditions for feedback linearization, or equivalently, for the ex-

istence of a completely observable nonlinear decoupling, can always

be fulfilled. Then, the globally linearized elastic-joint robot model

can be represented by a chain of four integrators. In [ 1 I], the robust-

ness of such nonlinear-decoupled robot control loops is discussed.

It turns out that the robust design method in [I]-[5] for rigid robot

models cannot be carried over to the elastic-joint case without ma-

jor difficulties when the system description of the globally linearized

system is used. Either bounds on derivatives of robot nonlinearities

have to be estimated, as is also suggested in [9], or a loss of per-

formance has to be tolerated when, for example, a compensation of

gravitational forces is abandoned [IO].

In this contribution, the results in [IO] are modified and developed

further. The idea is not to transform a given nth-order nonlinear

system into a chain of n integrators for the robustness analysis but

to compensate nonlinearities “in between” the integrators exactly

where they physically appear. This means that the summation point

of modeling error terms that contain derivatives is shifted beyond

integrators such that derivatives in these terms vanish.

Feedback linearization or nonlinear decoupling applied to rigid

robot models, which is equivalent to the well-known computed-

torque method, yield control laws that contain no derivatives of

robot nonlinearities. Thus, it is obviously not necessary to apply

such a nonlinear transformation to the case of rigid robots; however,

it may be advantageous for any system that has a control law derived

from feedback linearization or nonlinear decoupling that contains

derivatives of nonlinearities. As a result, the integrator chain will be

partitioned into groups, where nonlinear decoupling is accomplished

in stages. This transformation does not change the nature of the con-

trol law, but it is attractive for a robustness analysis, and it facilitates

the controller design.

It is shown in this communication that a robustness analysis of

feedback linearization, or equivalently, of nonlinear decoupling, be-

comes feasible under weak assumptions. The features of the trans-

formed globally linearized system are twofold: First, derivatives of

the control-loop nonlinearities due to model uncertainties vanish. Sec-

ond, measurements of the external-joint accelerations and jerks that

would be needed for control [9] are reconstructed by the proposed

transformation and are not used for control. However, robust ob-

servers as proposed in [12]-[I31 can still be used to overcome mea-

surement difficulties [9].

This communication is organized as follows: In Section 11, the con-

trol law of feedback linearization or nonlinear decoupling is stated for

a class of elastic-joint robot models. The globally linearized system

is then transformed in Section 111 for the robustness analysis, which

is sketched in Section IV. The robustness condition to be used is an

extension of those previously obtained for the “rigid case” in [4].

Finally, some remarks in Section V conclude this communication.

11. NONLINEAR DECOUPLINC

FOR A CLASS OF ELASTIC-JOINT ROBOT

MODELS

A class of robot manipulators that can be described by a set of

linear and decoupled and a set of nonlinear and coupled differential

equations is considered according to [9]-[ 1 11:

vector of applied torques at the motor shaft

diagonal matrix with gear ratios ng; < 1 (i =

1 , . ’ . ,n)

diagonal matrix with constant motor inertia

external joint position vector

= q M - N;’qa vector of angular displacements at

the motor shaft, where qM is the vector of motor shaft

positions

diagonal matrices of spring stiffness and damping co-

efficients, respectively, measured at the motor shaft

nonlinear and coupled robot inertia matrix without any

entries of motor mass

vector of centripetal, Coriolis, and frictional forces

vector of gravitational forces.

C and D

The model description of (1) and (2) can be shown to include the

rigid robot model as C 4 x or D 4 x. It represents a class of

elastic-joint robots under the assumptions stated in [9]-[IO]. A major

assumption is that the kinetic energy of the ith motor mass due to the

motion of all jth robot links, where j < i, can be neglected ( i , j =

1, . . , n). As is shown by Spong [9], this assumption is easy to justify

for a large class of robots that have high gear transmission rates.

Furthermore, the gear elasticities of industrial robots are commonly

weakly damped [14], and D = 0 is considered in the sequel.

Applying feedback linearization [6] or nonlinear decoupling [7] to

the system of (1) and (2) for D = 0 leads to the control law

H = A 2 G C - t ~ g A 2 R

h = -H* - P(i. + g) + (PN,’ + 1)CAq

(3)

(4)

( 5 )

Manuscript received December 19, 1988; revised September 18, 1989. where

This work was supported by the Volkswagen-Stiftung (U61 394).

The author is with Fachgebiet Mess-und Regelungstechnik, University of

Duisburg, West Germany.

IEEE Log Number 8933040.

1042-296X/90/0600-0373$01 .OO O 1990 IEEE

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc