AIR BEARING APPLICATION

AND DESIGN GUIDE

REVISION E -- JANUARY 2006

New Way Air Bearings 50 McDonald Blvd. Aston, PA 19014 USA 610.494.6700 www.newwayairbearings.com

�

New Way Air Bearings

Air Bearing Application and Design Guide

TABLE OF CONTENTS

PART I: UNDERSTANDING AIR BEARINGS .............................................................................3

1. Introduction ...........................................................................................................................................3

2. What is an air bearing?.......................................................................................................................3

3. Why use air bearings? ........................................................................................................................3

Friction ........................................................................................................................................3

Wear............................................................................................................................................3

Stiffness ......................................................................................................................................3

Load Capacity .............................................................................................................................3

4. Types of air bearing technology ........................................................................................................3

Aerodynamic bearings ................................................................................................................3

Aerostatic bearings .....................................................................................................................3

Orifice and Porous Media Technology........................................................................................3

5. Air Bearing Products ...........................................................................................................................3

Flat Bearings (Pucks)..................................................................................................................3

Air Bushings................................................................................................................................3

Vacuum Preloaded Bearings (VPLs)..........................................................................................3

Air Bearing Slides. ......................................................................................................................3

Radial Bearings...........................................................................................................................3

6. Air Bearing Applications......................................................................................................................3

Machines for the Image Setting Industry ....................................................................................3

Coordinate Measuring Machines ................................................................................................3

Testing Equipment......................................................................................................................3

High Speed Equipment...............................................................................................................3

Ultra accurate machine tools ......................................................................................................3

Linear Stages..............................................................................................................................3

OEM............................................................................................................................................3

Custom Projects and Test Rigs ..................................................................................................3

PART II: CHOOSING AIR BEARINGS ........................................................................................3

7. Selecting the right air bearing product for your application...........................................................3

© 2006, New Way Air Bearings

Air Bearing Application and Design Guide – Revision E

Page 2 of 68

�

Air Bearing Application and Design Guide

New Way Air Bearings

PART III: DESIGNING WITH AIR BEARINGS.............................................................................3

8. Air Bearing Guides ..............................................................................................................................3

Guide Surface Considerations....................................................................................................3

Surface finish ..............................................................................................................................3

Local flatness ..............................................................................................................................3

Holes in the guide .......................................................................................................................3

Seams in the guide way..............................................................................................................3

9. Stiffness and Preload..........................................................................................................................3

10. Loads Acting on Air Bearing Systems ..............................................................................................3

Gravity Loading...........................................................................................................................3

Payload distribution and mobility ................................................................................................3

Preloading with other air bearings ..............................................................................................3

Dynamic Loading ........................................................................................................................3

PART IV: SETTING UP AND USING AIR BEARINGS................................................................3

11. Flat Bearings ........................................................................................................................................3

Mounting and Adjusting ..............................................................................................................3

Adjusting Main bearings..............................................................................................................3

Adjusting Preload bearings.........................................................................................................3

Typical Configurations ................................................................................................................3

12. VPLs ......................................................................................................................................................3

Vacuum Preloaded Air Bearing Technology...............................................................................3

Kinematics and Elastic Averaging ..............................................................................................3

13. Air Bushings..........................................................................................................................................3

Air bushing installation................................................................................................................3

Assembling an Air Bushing Slide................................................................................................3

Typical Configurations ................................................................................................................3

14. Rotary Tables .......................................................................................................................................3

PART V: ADDITIONAL INFORMATION ......................................................................................3

15. Air Supply..............................................................................................................................................3

16. Measuring flow .....................................................................................................................................3

17. Flow .......................................................................................................................................................3

18. Plumbing ...............................................................................................................................................3

19. Airflow through the bearing gap.........................................................................................................3

20. Air Supply Requirements....................................................................................................................3

Technical Support: 610.494.6700

www.newwayairbearings.com

Page 3 of 68

�

New Way Air Bearings

Air Bearing Application and Design Guide

PART I: UNDERSTANDING AIR BEARINGS

1.

1.

Introduction

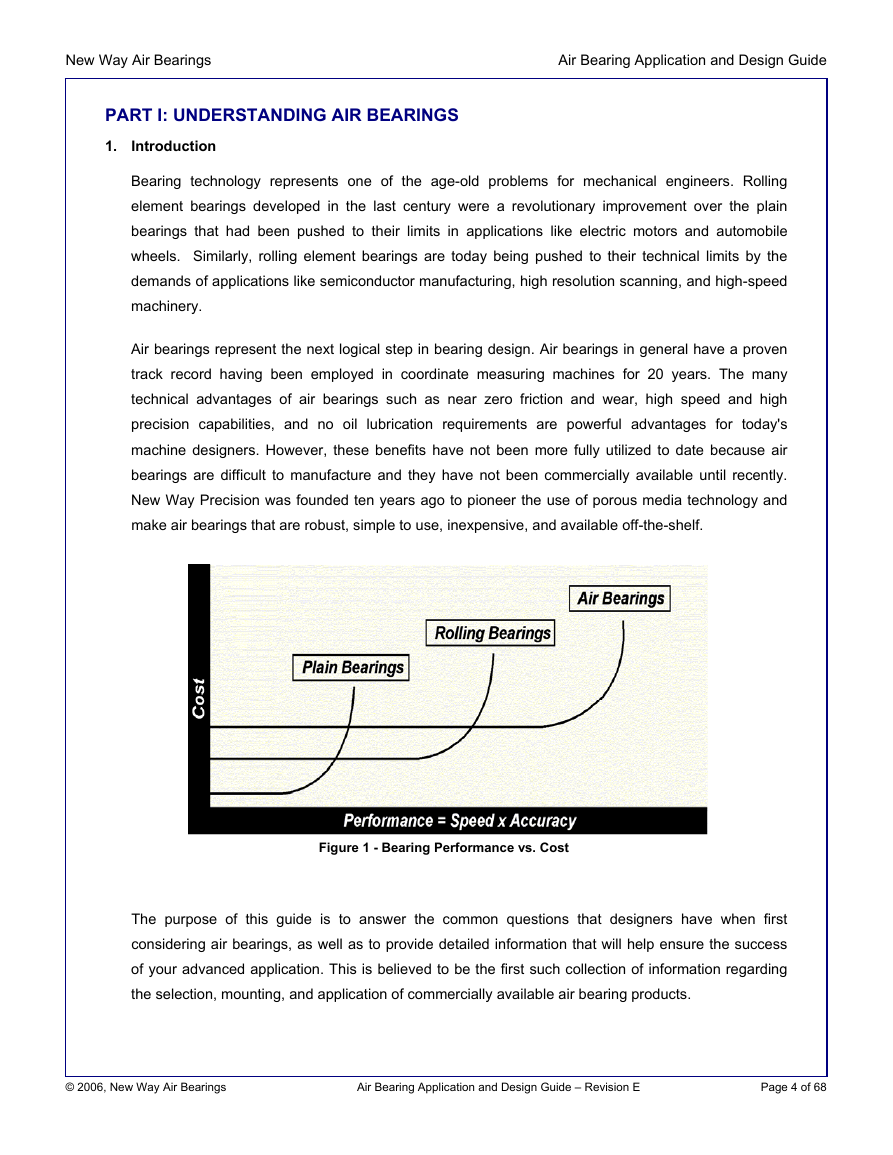

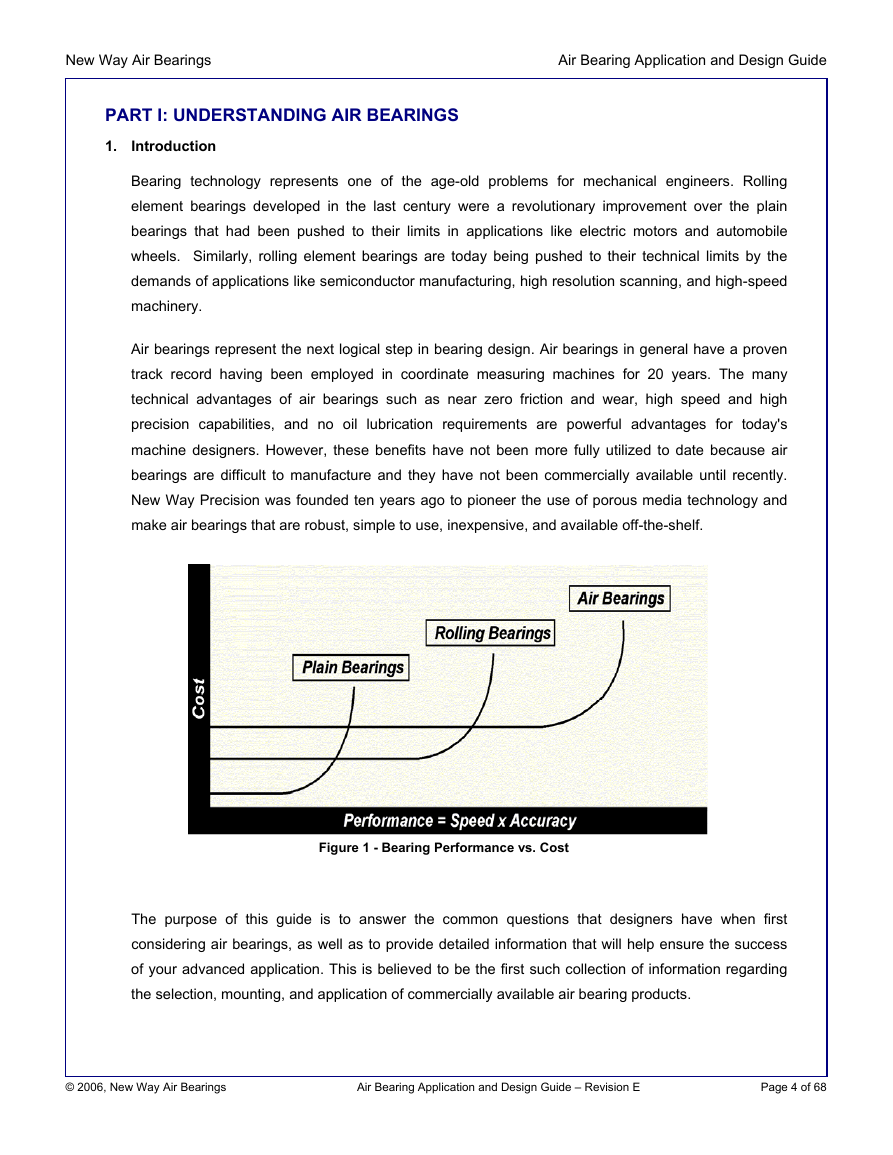

Bearing technology represents one of the age-old problems for mechanical engineers. Rolling

element bearings developed in the last century were a revolutionary improvement over the plain

bearings that had been pushed to their limits in applications like electric motors and automobile

wheels. Similarly, rolling element bearings are today being pushed to their technical limits by the

demands of applications like semiconductor manufacturing, high resolution scanning, and high-speed

machinery.

Air bearings represent the next logical step in bearing design. Air bearings in general have a proven

track record having been employed in coordinate measuring machines for 20 years. The many

technical advantages of air bearings such as near zero friction and wear, high speed and high

precision capabilities, and no oil lubrication requirements are powerful advantages for today's

machine designers. However, these benefits have not been more fully utilized to date because air

bearings are difficult to manufacture and they have not been commercially available until recently.

New Way Precision was founded ten years ago to pioneer the use of porous media technology and

make air bearings that are robust, simple to use, inexpensive, and available off-the-shelf.

Figure 1 - Bearing Performance vs. Cost

The purpose of this guide is to answer the common questions that designers have when first

considering air bearings, as well as to provide detailed information that will help ensure the success

of your advanced application. This is believed to be the first such collection of information regarding

the selection, mounting, and application of commercially available air bearing products.

© 2006, New Way Air Bearings

Air Bearing Application and Design Guide – Revision E

Page 4 of 68

�

Air Bearing Application and Design Guide

New Way Air Bearings

2. What is an air bearing?

Unlike contact roller bearings, air bearings utilize a thin film of pressurized air to provide a ‘zero

friction’ load bearing interface between surfaces that would otherwise be in contact with each other

(Figure 2). Being non-contact, air bearings avoid the traditional bearing-related problems of friction,

wear, and lubricant handling, and offer distinct advantages in precision positioning and high speed

applications.

The fluid film of the bearing is achieved by supplying a flow of air through the bearing face and into

the bearing gap. This is typically accomplished through an orifice or a porous media that restricts or

meters the flow of air into the gap, referred to in Figure 2 as R1. The restriction is designed such that,

although the air is constantly escaping from the bearing gap, the flow of pressurized air through the

restriction is sufficient to match the flow through the gap. It is the restriction through the gap, R2 that

maintains the pressure under the bearing and supports the working load. If air pressure were

introduced to the gap without restriction (R1), the flying height would be higher, the air consumption

higher, and the stiffness would be lower than could be achieved with proper restriction. This

restriction is referred to as air bearing compensation. It is used to optimize the bearing with respect to

lift, load, and stiffness for particular applications and will be discussed later in more detail.

Threaded ball stud

for easy adjustment

Slide Housing

Air Bearing

(Puck)

Air Supply

(60 PSI)

Gap Restriction (R2)

Air film

Orifice Restriction (R1)

Guide Surface

Figure 2 - Flat Air Bearing

Technical Support: 610.494.6700

www.newwayairbearings.com

Page 5 of 68

�

New Way Air Bearings

Air Bearing Application and Design Guide

3. Why use air bearings?

Because of their advantages over rolling element bearings, air bearings are a natural choice for

applications such as Coordinate Measuring Machines, precision machine tools, semiconductor wafer

processing machines, and other clean room, high speed, and precision positioning environments. The

main advantages of air bearings are listed below. Some of the specific concerns of the design

engineer (friction, wear, stiffness, and load capacity) are then discussed in more detail.

ZERO FRICTION....

Because of zero static friction, infinite resolution and very high repeatability are possible.

ZERO WEAR....

Non-contact means virtually zero wear resulting in consistent machine performance and low particle

generation.

STRAIGHTER MOTION....

Rolling element bearings are directly influenced by surface finish and irregularities on the guide. Being

non-contact air bearings average these errors.

SILENT AND SMOOTH OPERATION....

Recirculating rollers or balls create noise and vibration as hard elements become loaded and unloaded

and change direction in return tubes. This is especially noticeable in the resolution of scanners.

HIGHER DAMPING....

Being fluid film bearings, air bearings have a squeeze film damping effect resulting in higher dynamic

stiffness and better controllability.

ELIMINATES OIL....

Air bearings do not use oil lubrication, eliminating the problems associated with oil. In dusty

environments (dry machining) ways are dry and bearings are self-cleaning because positive air pressure

pushes dust away. In contrast, oil lubrication becomes a lapping slurry.

HIGH SPEEDS....

High speeds - high acceleration. No balls or rollers to slip at high acceleration.

© 2006, New Way Air Bearings

Air Bearing Application and Design Guide – Revision E

Page 6 of 68

�

Air Bearing Application and Design Guide

New Way Air Bearings

Friction

Variances in friction have always been at the heart of precision positioning problems, particularly

when attempting to initiate or stop motion precisely. This is because especially in plain bearings, but

also in rolling bearings, the static coefficient of friction is higher than the dynamic coefficient of friction.

In other words it takes more force to initiate motion than it does to maintain motion. So when a motor

turns a screw to push a slide, the screw winds up and stores some of the energy because of the high

static friction. When the slide starts to move, the friction falls and the screw unwinds, pushing the

slide past its desired position. This phenomenon is known as ‘stick-slip’ and is most pronounced in

plain way systems. However, it can also cause positioning or bandwidth issues even in machines with

rolling element bearings and closed loop feed back.

tool slides can be

Today heavy machine

positioned within .0001” using rolling element

bearings because the difference between the

static and dynamic coefficients of friction is

reduced by an order of magnitude compared to

plain bearings.

But even rolling element

bearings are reaching their limits. For instance,

in some areas of

the electronics capital

equipment industry, positioning to even .00001”

is considered too course. Rolling element

bearing manufacturers have started to reduce

their preloading (compromising stiffness) in

what has become known as a ‘California Fit’ in

an effort to meet these requirements, but there

are limits to how effective this can be.

In air bearings there is no difference between

static and dynamic coefficients of friction so the

stick-slip issue is completely eliminated. Friction in air bearings is a function of air shear from motion,

so at zero velocity there would be zero friction making infinite motion resolution theoretically possible.

Figure 3 - Coefficients of Friction

Friction has a direct effect on efficiency. In fact one of the first air bearing patents applied for was by

Westinghouse for use in vertical steam driven generating turbines. Westinghouse knew that because

the viscosity of air is several hundred times lower than that of oil, he could reduce the energy loss due

to oil shear. Unfortunately for Westinghouse, at that time (1890) it was exceedingly difficult to

manufacture the large bearing surfaces to the high precision required for air bearings to work. Today

large turbines still use oil based hydrodynamic bearings, but many of the new micro turbines on the

Technical Support: 610.494.6700

www.newwayairbearings.com

Page 7 of 68

�

New Way Air Bearings

Air Bearing Application and Design Guide

market are employing aerodynamic bearing systems to improve efficiency. Friction also has an effect

on precision. Remember the old saying, what are the three main sources of error in a precision

machine? Heat, heat, and heat! Friction creates heat, which is a precision engineer’s worst enemy.

For instance when a spindle heats up it grows axially. As the heat conducts into the headstock it will

expand and the center of rotation will grow away from the base. In most cases air bearings will create

significantly less heat in a given application than a rolling element or plain bearing. This is not to say

that air bearings cannot create heat, as they can but relative speeds need to exceed 100 feet per

second before significant heat can be measured.

Wear

Mechanical wear is another thorn in the side of the design engineer. Advanced machines are

requiring faster speeds and higher reliability. In fact, there are machines currently on the market that

make a billion moves per year. It is impractical to perform accelerated testing on such a machine so

at best the engineer must employ speed, acceleration, and loading calculations in order to estimate

the life of the bearing. This problem is avoided with air bearings due to their non-contact nature.

Speed, acceleration, and loading are not wear factors and they have no influence on the life of the air

bearing.

The mode of wear in an air bearing is erosion, so the cleanliness of the air has the greatest effect. Air

bearings are immune to conventional notions of wear and will perform exactly the same in the 10th

year of operation as they did in the first, even after a billion cycles per year. This is a big advantage

when it comes to machine reliability. Equipment builders that can say to their customers that wear

has been eliminated, as a variable that could affect their statistical process control will have a distinct

competitive advantage. The lack of debris from wear and no need for oil lubrication due to the non-

contact nature of air bearings also means that they are ideally suited for use in clean room, medical,

pharmaceutical, and food processing environments. Air bearings also excel in dry dusty environments

such as salt or sugar factories, which can be highly corrosive. In these environments any oil

lubrication quickly becomes a lapping slurry. Air bearings have a self-purging effect with constant air

exiting the bearing blowing away light dry dust.

© 2006, New Way Air Bearings

Air Bearing Application and Design Guide – Revision E

Page 8 of 68

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc