有限元分析

有限元分析

段少东 整理

�

1

Module 1: Introduction to Finite Element Analysis

Lecture 1: Introduction

1.1.1 Introduction

The Finite Element Method (FEM) is a numerical technique to find approximate solutions of partial

differential equations. It was originated from the need of solving complex elasticity and structural

analysis problems in Civil, Mechanical and Aerospace engineering. In a structural simulation, FEM

helps in producing stiffness and strength visualizations. It also helps to minimize materialweight and

its cost of the structures. FEM allows for detailed visualization and indicates the distribution of

stresses and strains inside the body of a structure. Many of FE software are powerful yet complex

tool meant for professional engineers with the training and education necessary to properly interpret

the results.

Several modern FEM packages include specific components such as fluid, thermal,

electromagnetic and structural working environments. FEM allows entire designs to be constructed,

refined and optimized before the design is manufactured. This powerful design tool has significantly

improved both the standard of engineering designs and the methodology of the design process in

many industrial applications. The use of FEM has significantly decreased the time to take products

from concept to the production line. One must take the advantage of the advent of faster generation

of personal computers for the analysis and design of engineering product with precision level of

accuracy.

1.1.2 Background of Finite Element Analysis

The finite element analysis can be traced back to the work by Alexander Hrennikoff (1941)and

Richard Courant(1942). Hrenikoff introduced the framework method, in which a plane elastic

medium was represented as collections of bars and beams.These pioneers share one essential

characteristic: mesh discretization of a continuous domain into a set of discrete sub-domains, usually

called elements.

•

•

•

•

•

In 1950s, solution of large number of simultaneous equations became possible because of the

digitalcomputer.

In 1960, Ray W. Clough first published a paper using term “Finite Element Method”.

In 1965, First conference on “finite elements” was held.

In 1967, the first book on the “Finite Element Method” was published by Zienkiewicz and

Chung.

In the late 1960s and early 1970s, the FEM was applied to a wide variety of engineering

problems.

�

IIT Kharagpur NPTEL Web Course

- 1 -�

2

•

•

In the 1970s, most commercial FEM software packages (ABAQUS, NASTRAN, ANSYS,

etc.) originated.Interactive FE programs on supercomputer lead to rapid growth of CAD

systems.

In the 1980s, algorithm on electromagnetic applications, fluid flow and thermal analysis were

developed with the use of FE program.

• Engineers can evaluate ways to control the vibrations and extend the use of flexible,

deployablestructures in space using FE and other methods in the 1990s. Trends to solve fully

coupled solution of fluid flows with structural interactions, bio-mechanics related problems

with a higher level of accuracy were observed in this decade.

With the development of finite element method, together with tremendous increases in computing

power and convenience, today it is possible to understand structural behavior with levels of

accuracy. This was in fact the beyond of imagination before the computer age.

1.1.3 Numerical Methods

The formulation for structural analysis is generally based on the three fundamental relations:

equilibrium, constitutive and compatibility. There are two major approaches to the analysis:

Analytical and Numerical. Analytical approach which leads to closed-form solutions is effective in

case of simple geometry, boundary conditions, loadings and material properties. However, in reality,

such simple cases may not arise. As a result, various numerical methods are evolved for solving such

problems which are complex in nature. For numerical approach, the solutions will be approximate

when any of these relations are only approximately satisfied. The numerical method depends heavily

on the processing power of computers and is more applicable to structures of arbitrary size and

complexity. It is common practice to use approximate solutions of differential equations as the basis

for structural analysis. This is usually done using numerical approximation techniques. Few

numerical methods which are commonly used to solve solid and fluid mechanics problems are given

below.

• Finite Difference Method

• Finite Volume Method

• Finite Element Method

• Boundary Element Method

• Meshless Method

The application of finite difference method for engineering problems involves replacing the

governing differential equations and the boundary condition by suitable algebraic equations. For

�

IIT Kharagpur NPTEL Web Course

- 2 -�

3

example in the analysis of beam bending problem the differential equation is reduced to be solution

of algebraic equations written at every nodal point within the beam member. For example, the beam

equation can be expressed as:

wd

4

dx

=4

q

EI

(1.1.1)

To explain the concept of finite difference method let us consider a displacement function variable

namely

w f x

( )

=

Fig. 1.1.1 Displacement Function

+Δ −

x)

f(x)

f(x+ Δx)- f(x)

Δx

=

1

h

(

w - w

i+1

i

)

0

0

=

=

So,

Lt

→

Δx

Lt

→

Δx

Δ =

Now, w f (x

Δw

Δx

dw

dx

Thus,

⎡

d w d 1

2

⎢

⎢

dx h

dx

⎣

1=

d w

3

h

dx

3

1=

w - 3w +3w - w

i+3

i

h

w - w =

i+1

1

h

2

⎤

)

⎥

⎥

⎦

=

i+2

(

3

(

3

2

)

i+1

(

i

(

)

w - w - w +w =

i+2

i+1

i+1

i

w - w - 2w + 2w + w - w

i+3

i

i+2

i+2

i+1

i+1

1

h

2

(

w - 2w +w

i+2

i

i+1

)

)

(1.1.2)

(1.1.3)

(1.1.4)

�

IIT Kharagpur NPTEL Web Course

- 3 -�

4

(

4

w - w - 3w +3w +3w - 3w - w + w

i+4

i

i+2

i+2

i+3

i+3

i+1

i+1

i+3

1=

h

w - 4w +6w - 4w + w

i+4

i

d w

4

dx

4

1=

h

1=

h

Thus, eq. (1.1.1) can be expressed with the help of eq. (1.1.5) and can be written in finite difference

form as:

w - 4w +6w - 4w +w

i+2

i-2

(1.1.5)

i+2

i+1

i+1

(

(

4

4

i

i-1

)

)

)

(

w

i

−

2

−

4

w

i

1

−

+

6

w

i

−

4

w

i

1

+

+

w

i

+

2

)

=

q

EI

4

h

(1.1.6)

Fig. 1.1.2 Finite difference equation at node i

Thus, the displacement at node i of the beam member corresponds to uniformly distributed load can

be obtained from eq. (1.1.6) with the help of boundary conditions. It may be interesting to note that,

the concept of node is used in the finite difference method. Basically, this method has an array of

grid points and is a point wise approximation, whereas, finite element method has an array of small

interconnecting sub-regions and is a piece wise approximation.

Each method has noteworthy advantages as well as limitations. However it is possible to

solve various problems by finite element method, even with highly complex geometry and loading

conditions, with the restriction that there is always some numerical errors. Therefore, effective and

reliable use of this method requires a solid understanding of its limitations.

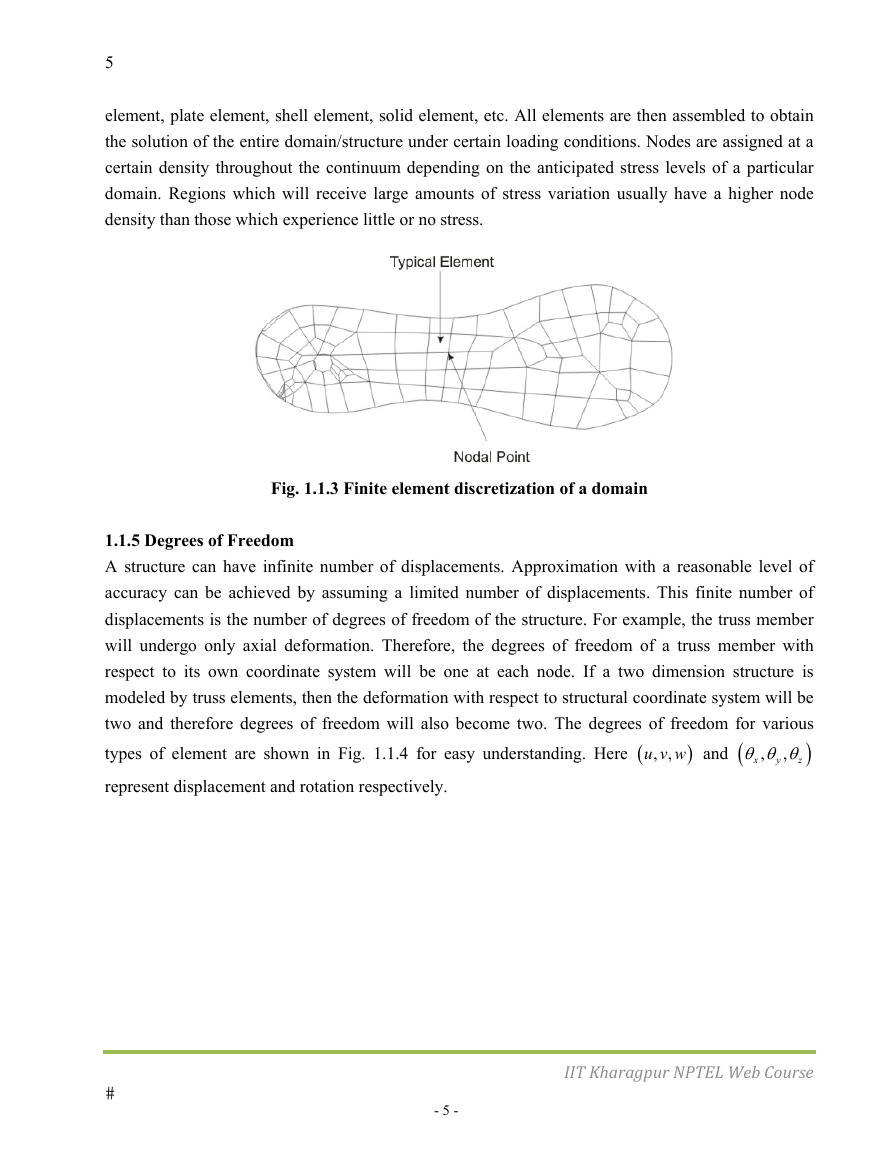

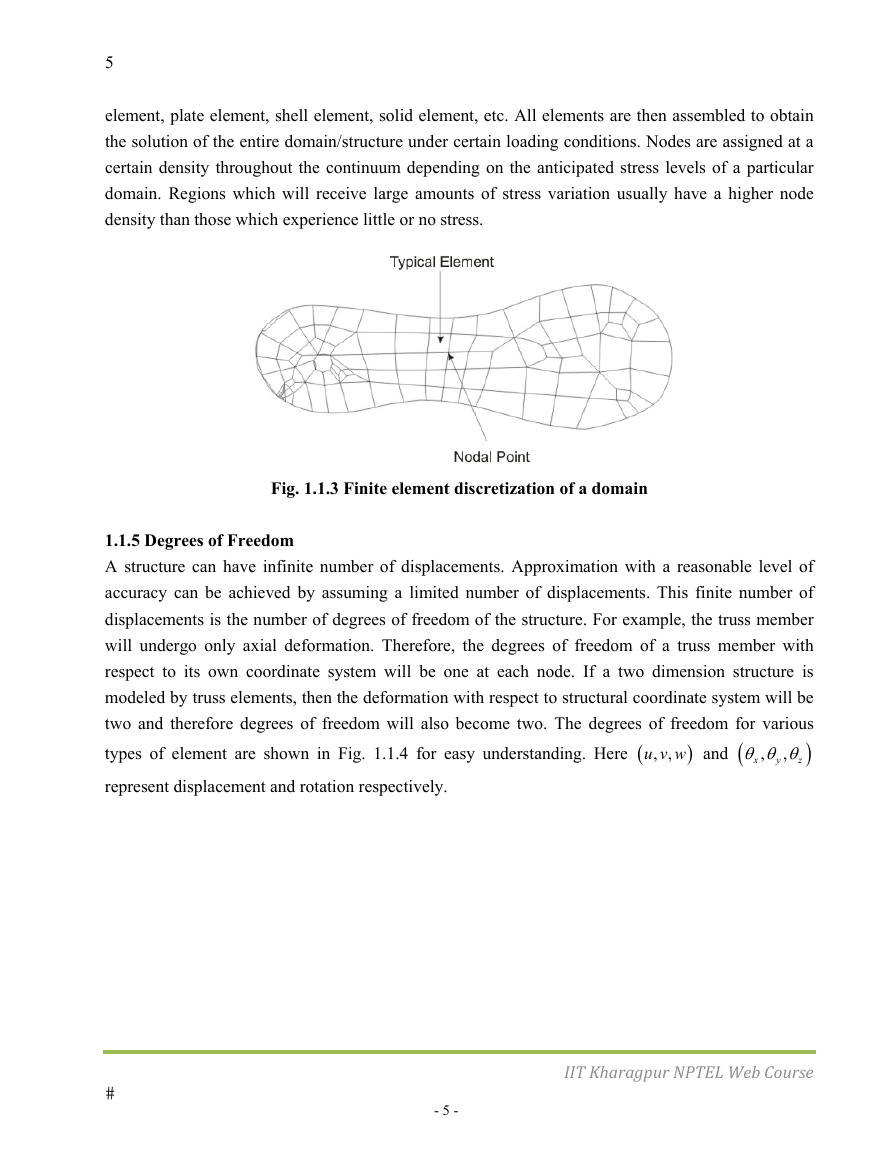

1.1.4 Concepts of Elements and Nodes

Any continuum/domain can be divided into a number of pieces with very small dimensions. These

small pieces of finite dimension are called ‘Finite Elements’ (Fig. 1.1.3). A field quantity in each

element is allowed to have a simple spatial variation which can be described by polynomial terms.

Thus the original domain is considered as an assemblage of number of such small elements. These

elements are connected through number of joints which are called ‘Nodes’. While discretizing the

structural system, it is assumed that the elements are attached to the adjacent elements only at the

nodal points. Each element contains the material and geometrical properties. The material properties

inside an element are assumed to be constant. The elements may be 1D elements, 2D elements or 3D

elements. The physical object can be modeled by choosing appropriate element such as frame

IIT Kharagpur NPTEL Web Course

�

- 4 -�

5

element, plate element, shell element, solid element, etc. All elements are then assembled to obtain

the solution of the entire domain/structure under certain loading conditions. Nodes are assigned at a

certain density throughout the continuum depending on the anticipated stress levels of a particular

domain. Regions which will receive large amounts of stress variation usually have a higher node

density than those which experience little or no stress.

Fig. 1.1.3 Finite element discretization of a domain

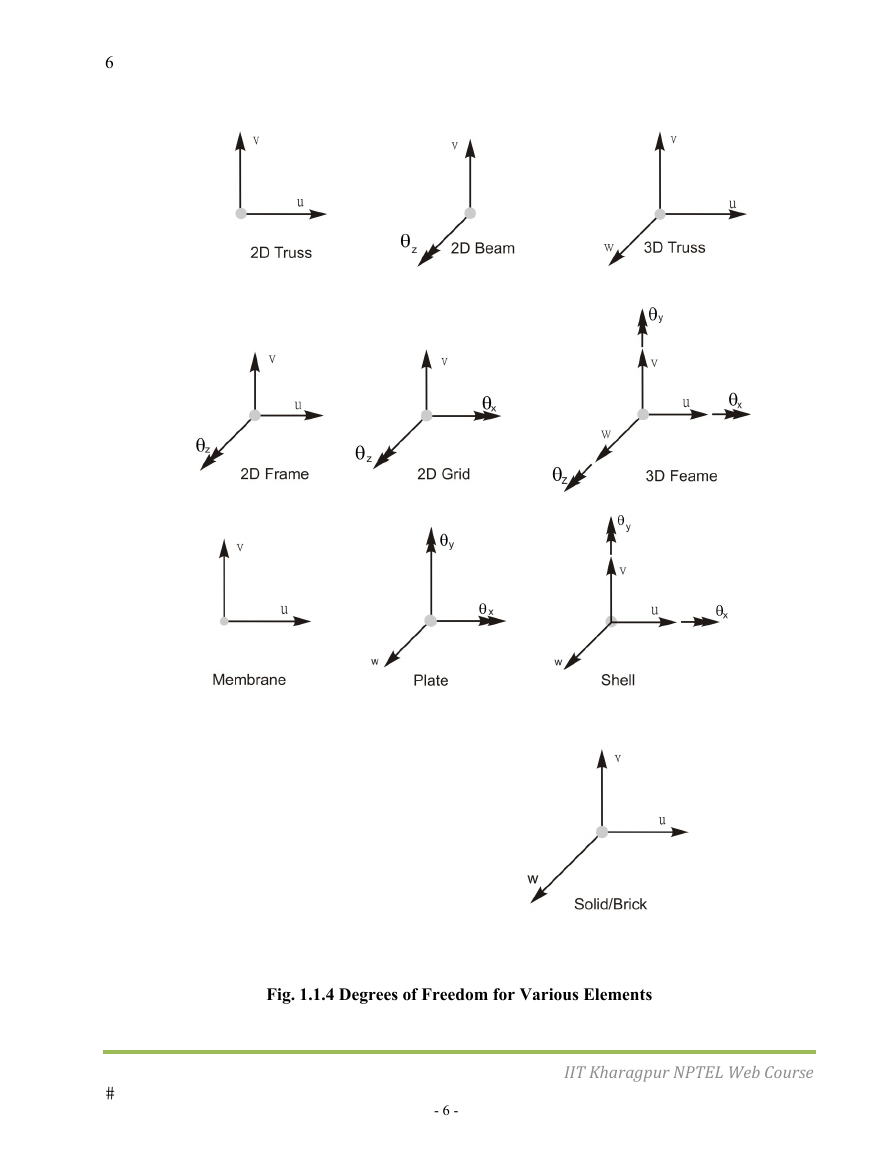

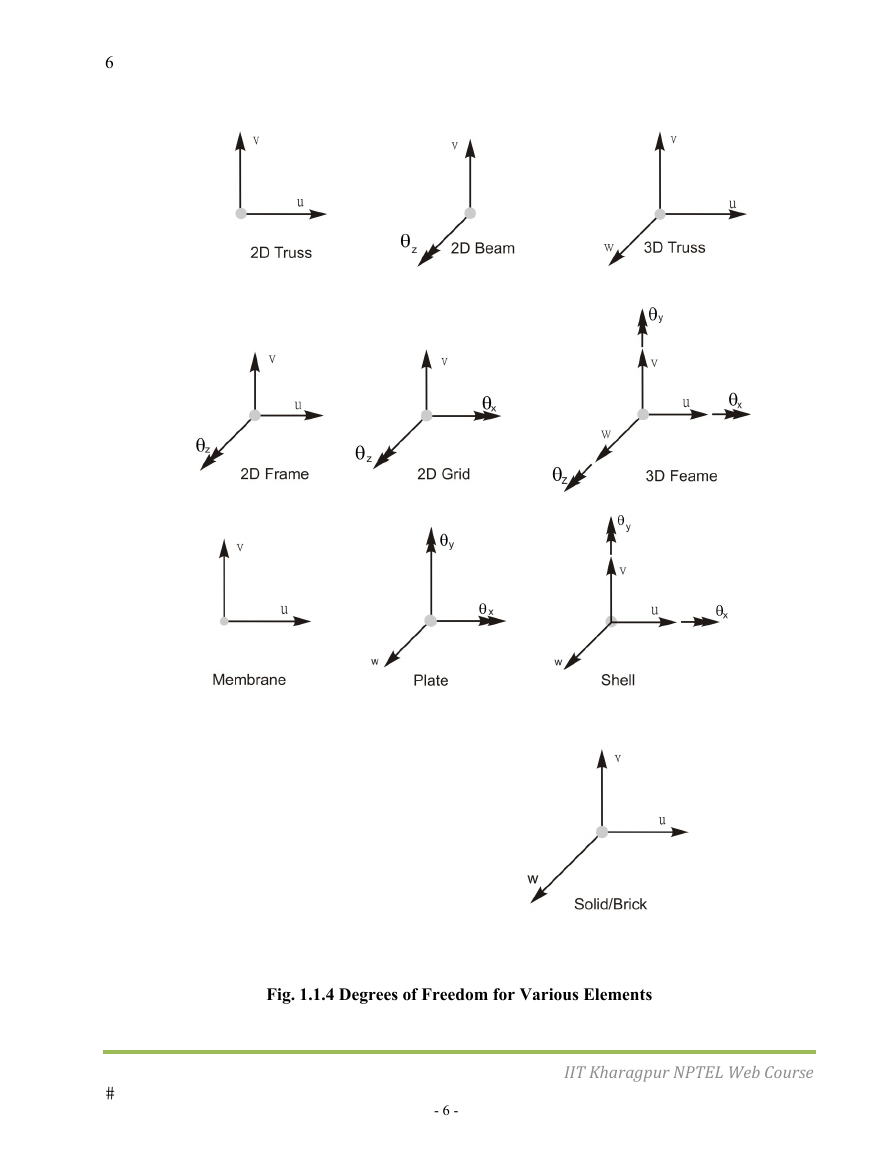

1.1.5 Degrees of Freedom

A structure can have infinite number of displacements. Approximation with a reasonable level of

accuracy can be achieved by assuming a limited number of displacements. This finite number of

displacements is the number of degrees of freedom of the structure. For example, the truss member

will undergo only axial deformation. Therefore, the degrees of freedom of a truss member with

respect to its own coordinate system will be one at each node. If a two dimension structure is

modeled by truss elements, then the deformation with respect to structural coordinate system will be

two and therefore degrees of freedom will also become two. The degrees of freedom for various

)

types of element are shown in Fig. 1.1.4 for easy understanding. Here (

θ θ θ

represent displacement and rotation respectively.

,u v w and (

,

)

,

x

,

y

z

�

IIT Kharagpur NPTEL Web Course

- 5 -�

6

�

Fig. 1.1.4 Degrees of Freedom for Various Elements

IIT Kharagpur NPTEL Web Course

- 6 -�

7

Module 1: Introduction to Finite Element Analysis

Lecture 2: Basic Concepts of Finite Element Analysis

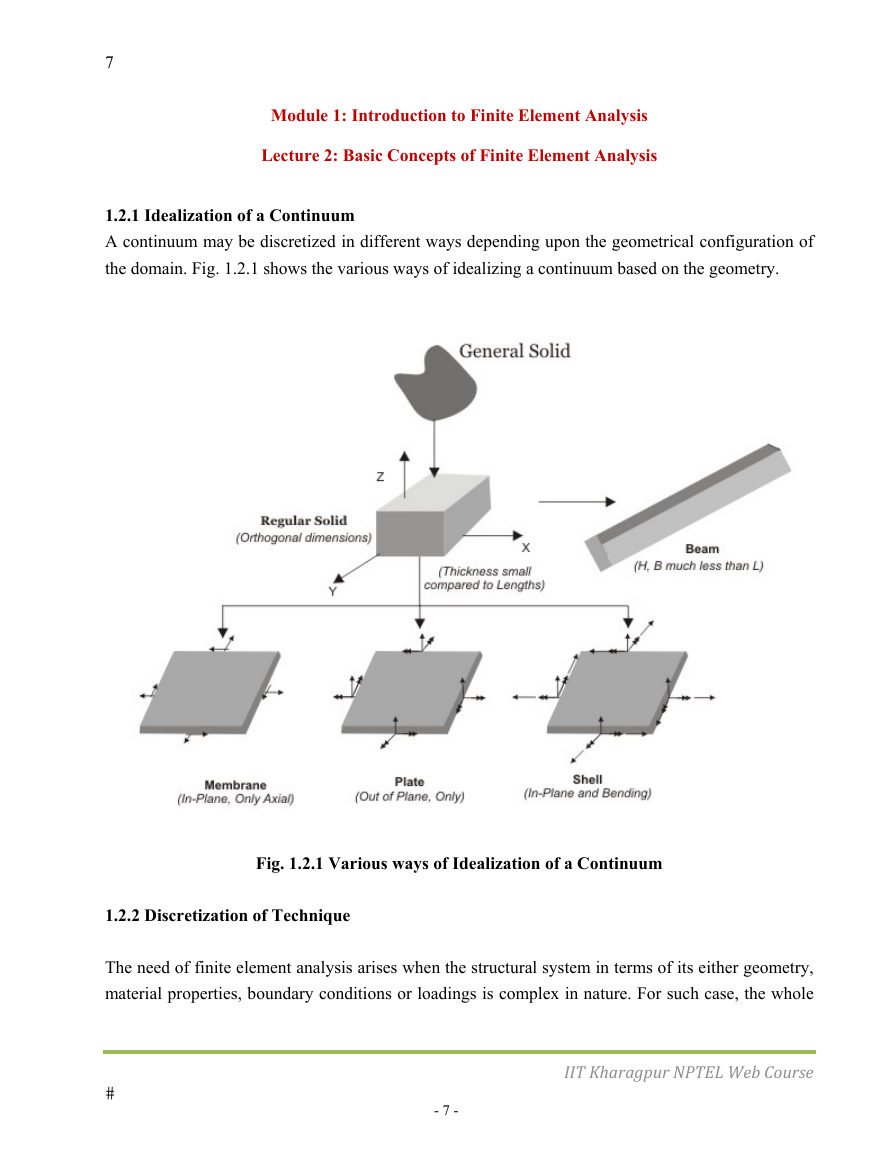

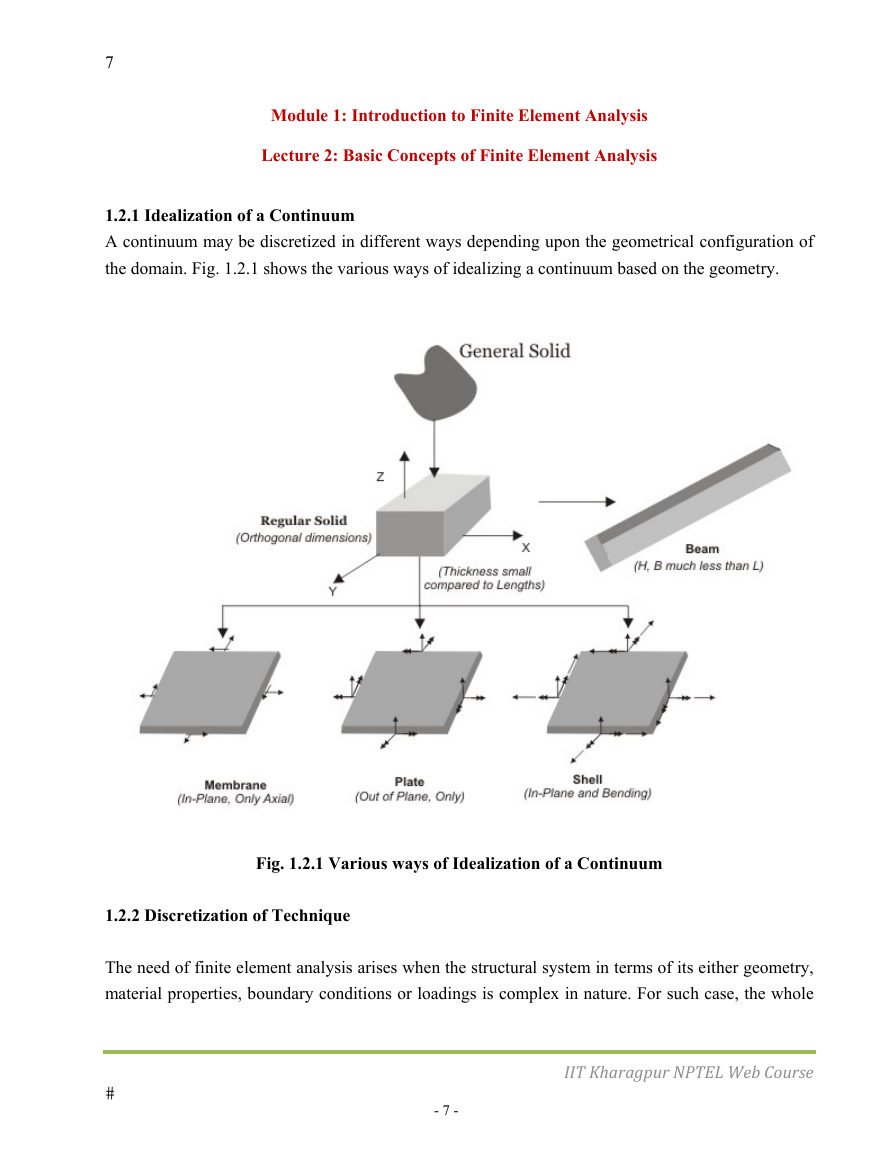

1.2.1 Idealization of a Continuum

A continuum may be discretized in different ways depending upon the geometrical configuration of

the domain. Fig. 1.2.1 shows the various ways of idealizing a continuum based on the geometry.

Fig. 1.2.1 Various ways of Idealization of a Continuum

1.2.2 Discretization of Technique

The need of finite element analysis arises when the structural system in terms of its either geometry,

material properties, boundary conditions or loadings is complex in nature. For such case, the whole

�

IIT Kharagpur NPTEL Web Course

- 7 -�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc