Testing Expo North America 2008

Introduction to Standardized Diagnostic

Communication: UDS on CAN (ISO 15765)

with MVCI (ISO 22900) and ODX (ISO 22901)

Dipl.-Ing. Peter Subke

Key Account Manager

Automotive Electronics

Softing AG, Germany

sub@softing.com

�

Onboard Communication

2

ECU # 1

ECU # 2

Input Info

Output Info

Input Info

Output Info

in-vehicle network (e.g. CAN bus)

onboard communication

ECUs convert input information from sensors to output information

for actuators.

ECUs send information to other ECUs and receice information from

other ECUs (onboard communication).

For onboard communication, ECUs are interconnected via an in-vehicle

network (e.g. CAN)

�

Diagnostic Communication

3

ECU # 1

ECU # 2

Input Info

Output Info

Input Info

Output Info

For diagnostic communication, a TESTER is

connected to the in-vehicle network.

TESTER

The TESTER (client) sends a request to

a specific ECU (e.g. #1) and the ECU

(server) answers the request with a response.

�

Diagnostic Services

4

Diagnostic communication requires a diagnostic protocol.

A diagnostic protocol contains a set of communication parameters and

diagnostic services (request / response).

Typical examples for diagnostic protocols include KWP2000 and UDS.

ISO 14229-1(2006) : Road vehicles –Unified diagnostic services

(UDS) specifies a diagnostic protocol on layer 7 of the OSI model.

Examples for diagnostic services of ISO 14229 include:

11hex = ECU reset

86hex = response on event

19hex = read DTC information

23hex = read memory by address

31hex = routine control

36hex = transfer data

�

UDS on CAN

5

Today, diagnostic communication uses the existing in-vehicle network

to transport requests and responses.

The transport protocol for UDS on CAN is specified in

ISO 15765-3 (2004): Road vehicles –

Diagnostics on controller area network (CAN) –

Part 3: Implementation of unified diagnostic services (UDS on CAN)

ISO 14229-1:2006 (UDS) and ISO 15765-3:2004 (Diagnostics on CAN)

are complementary standards that together specify the diagnostic

protocol “UDS on CAN”.

�

Communication system

6

Tester

Applications (e.g. MONACO, INCA, LabView, AD

Databases (EDF, ODX, FBX,CANdb, A2L)

D-Server (EDIABAS, ETESTER, COS, MVCI)

PC-to-ECU interface software

e.g. EIDBSS, Vecom, D-PDU API

PC-to-ECU interface hardware

e.g. ETK, EDIC, DCDI, VCI

Onboard communication

CAN, LIN, FlexRay, MOST

Diagnostic communication

Diagnostic protocols

KWP 2000, UDS on CAN

UDS on FlexRay

ECU software (e.g. AUTOSAR)

�

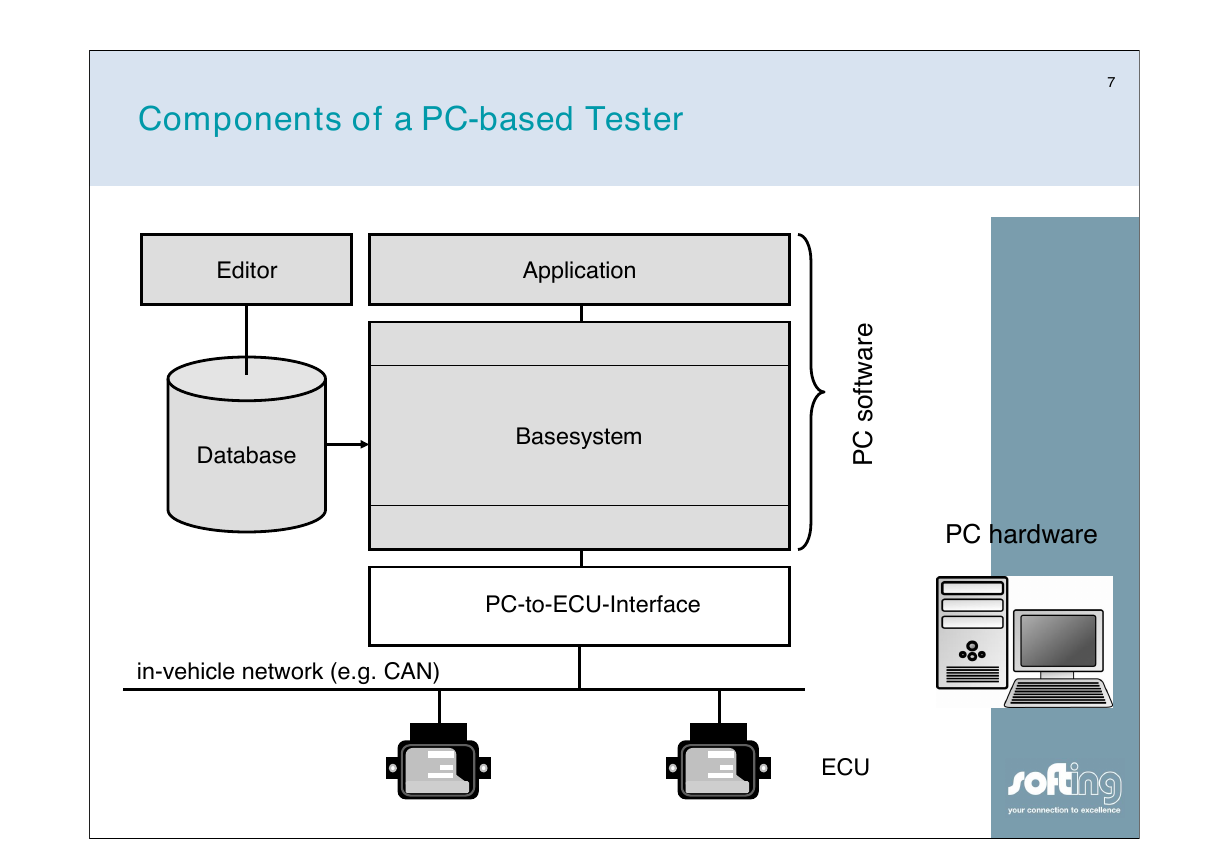

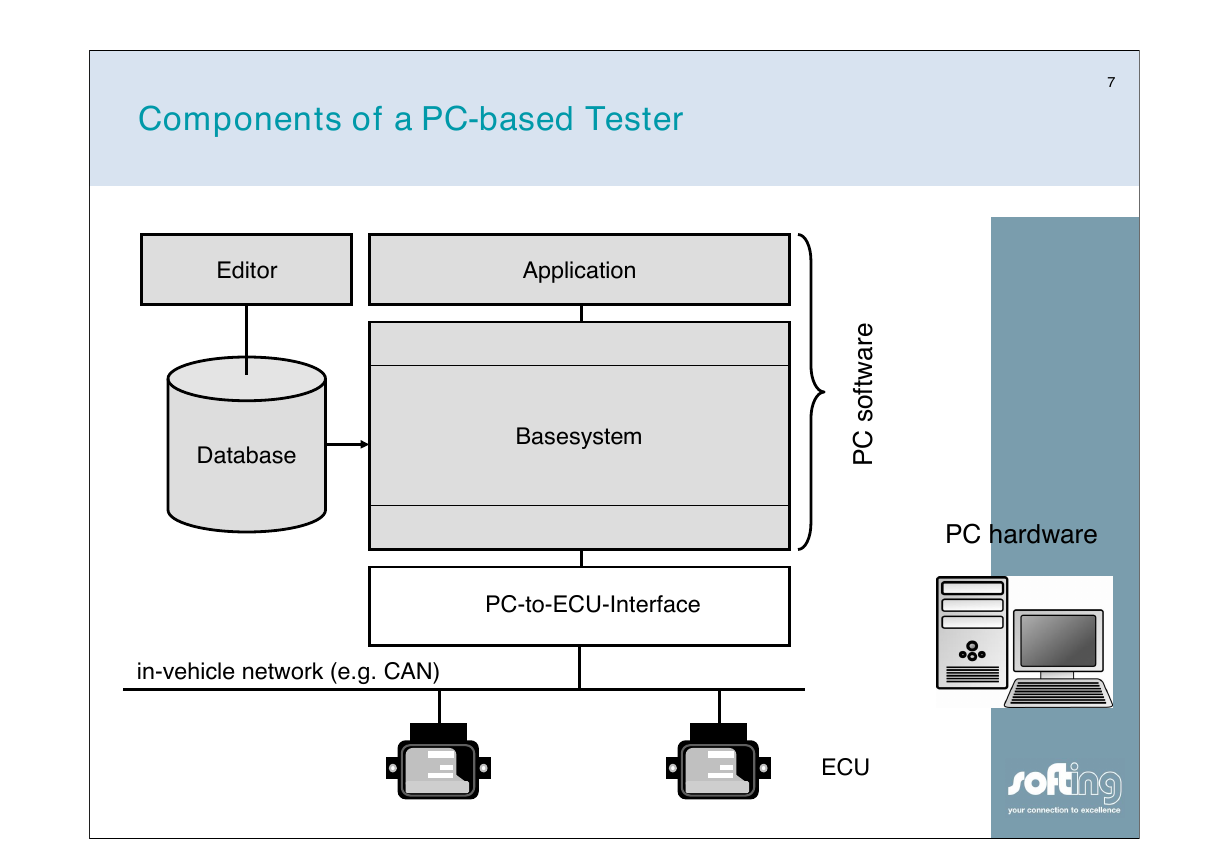

Components of a PC-based Tester

7

Editor

Application

Database

Basesystem

PC-to-ECU-Interface

in-vehicle network (e.g. CAN)

PC hardware

e

r

a

w

t

f

o

s

C

P

ECU

�

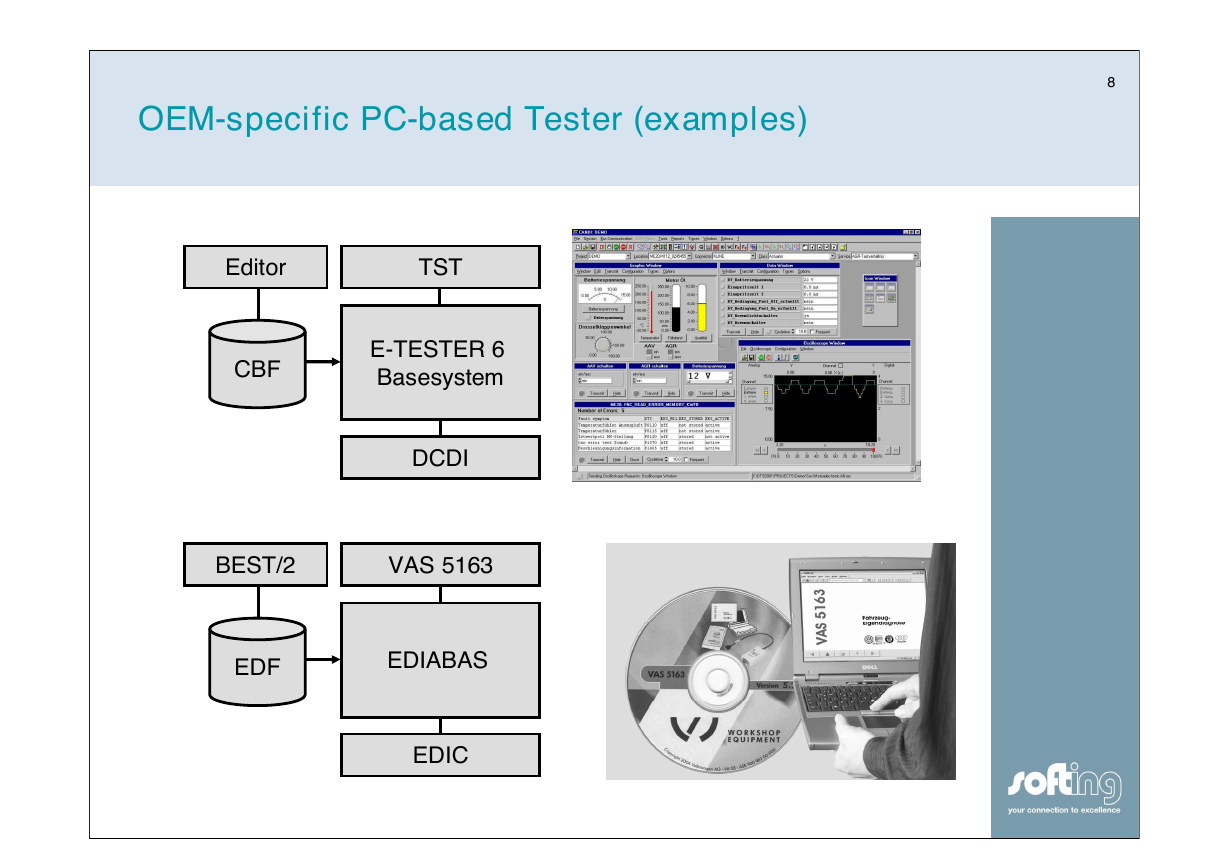

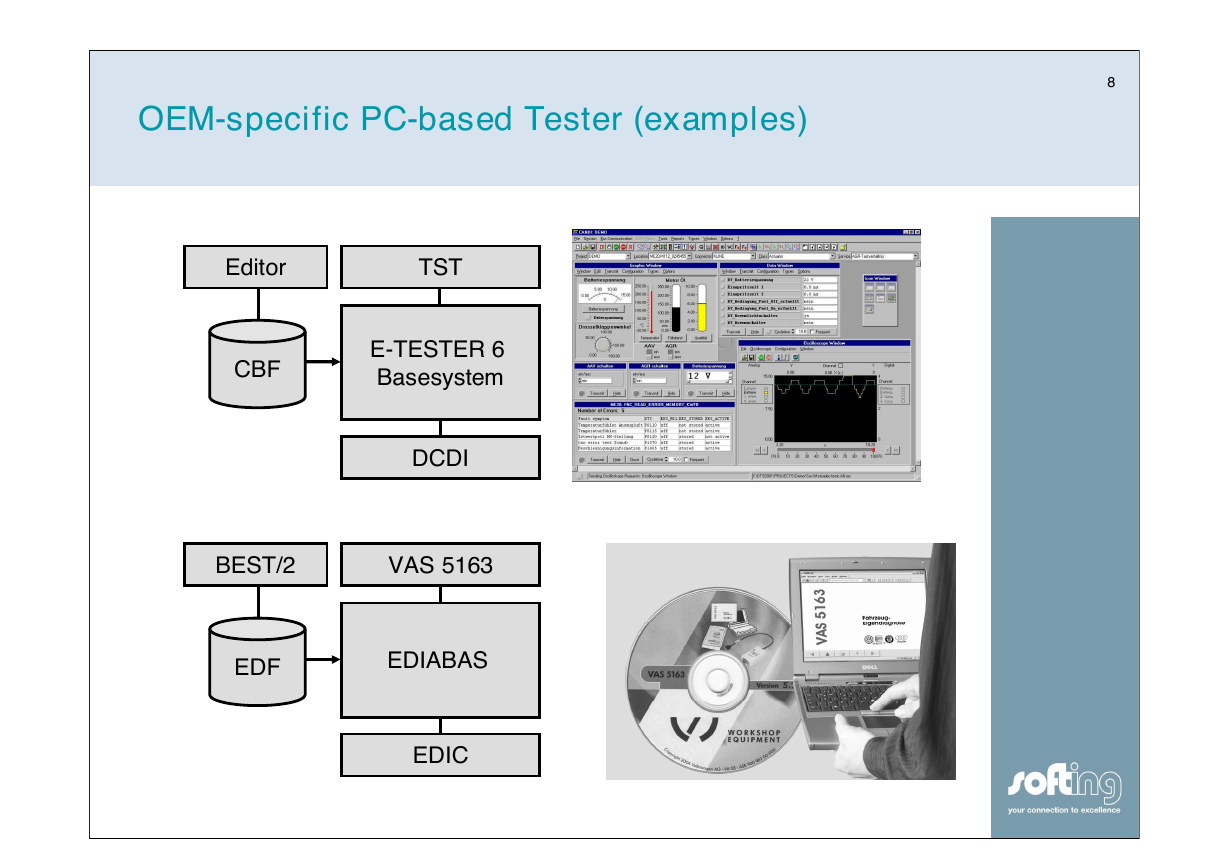

OEM-specific PC-based Tester (examples)

8

Editor

TST

CBF

E-TESTER 6

Basesystem

DCDI

BEST/2

VAS 5163

EDF

EDIABAS

EDIC

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc