吉林化工学院课程设计说明书

基于 RS-232 的数据采集系统设计

Based on RS-232 Data Acquistion System Design

学生学号:

学生姓名:

专业班级

指导教师:

起止日期:

吉林化工学院

Jilin Institute of Chemical Technology

�

�

吉林化工学院课程设计说明书

课程设计任务书

一、设计题目:基于 RS-232 的数据采集系统设计

二、设计目的

1、掌握 X5045 看门狗电路、MAX232 转换芯片、ADC0832 转换器等电路的的工作原理;

2、掌握 RS-232 串行接口基本工作原理及单片机与 PC 机之间通过 RS-232 的通信的编程方法;

3、熟练掌握电路设计及软件编程方法;

4、熟练掌握硬件电路的焊接和利用软件仿真调试的方法。

三、设计任务及要求

设计并实现模拟量以及开关量的采集。使硬件电路调试后具有以下基本功能:

1、实现由 CD4051 和 ADC8032 组成的模拟量电路对 8 个模拟量的实时采集;

2、实现由 DIP8 为拨码开关和 LED 发光二级管组成的开关量电路对 8 个开关量的实时采集;

四、设计时间及进度安排

设计时间共三周(2012.4.16~2012.5.6),具体安排如下表:

周安排

设 计 内 容

第一周

了解各电路中、以及各器件的作用和工作原理,进行硬件电路

设计。

第二周 焊接电路板、进行调试、完成硬件作品。

第三周 编写硬件作品的说明书。

五、指导教师评语及学生成绩

指导教师评语:

设计时间

2012.4.16~

2012.4.20

2012.4.23~

2012.4.27

2012.4.30~

2012.5.6

成绩

指导教师(签字):

年 月

日

- I -

�

基于 RS-232 的数据采集系统设计

目 录

课程设计任务书····································································································· I

第 1 章 概述········································································································· 1

第 2 章 单元电路原理······························································································2

2.1 X4051 看门狗电路························································································ 2

2.1.1 X4051 引脚说明··················································································· 2

2.1.2 X4051 工作原理··················································································· 3

2.1.3 X4051 指令寄存器················································································ 3

2.1.4 X4051 状态寄存器················································································ 4

2.2 MAX232 转换芯片························································································ 4

2.2.1 MAX232 引脚说明················································································ 4

2.2.2 MAX232 工作原理················································································ 5

2.2.3 MAX232 特性······················································································5

2.3 单片机 8051································································································6

2.3.1 单片机 8051 引脚说明············································································ 6

2.3.1 单片机 8051 特点··················································································7

2.4 RS-232 串口································································································ 7

2.4.1RS-232 串口引脚说明············································································· 8

2.4.2RS-232 串口电气特性············································································· 8

2.4.3 RS-232 连接器的机械特性·······································································9

2.5 ADC0832 A/D 转换器···················································································· 9

2.5.1 ADC0832 的引脚说明············································································ 9

2.5.2 ADC0832 的特点·················································································· 9

2.5.3 单片机对 ADC0832 的控制原理······························································10

2.6 CD4051 开关器件························································································11

2.6.1 CD4051 的引脚说明············································································· 11

2.6.2 CD4051 的参数···················································································12

2.7 开关量电路·······························································································12

2.8 时钟电路··································································································13

第 3 章 焊机硬件作品及调试····················································································14

3.1 焊接硬件作品···························································································· 14

3.2 硬件作品的调试························································································· 14

- II -

�

吉林化工学院课程设计说明书

第 4 章 软件说明·································································································15

4.1 实验器材··································································································15

4.2 仿真软件说明···························································································· 15

4.2.1 仿真头·····························································································16

4.2.2 仿真器·····························································································16

4.3 程序流程图·······························································································17

4.4 利用仿真进行上位机程序调试········································································17

第 5 章 结论········································································································ 19

参考文献············································································································ 20

附录·················································································································· 21

- III -

�

�

吉林化工学院课程设计说明书

第 1 章 概述

数据采集是对一个或多个信号获取对象信息的过程,数据采集器是一种具有实验室或现场进行

实时数据采集、自动存储记录、信号预处理、即时显示、即时状态分析、自动传输等功能的自动化

设备。

数据采集是工、农业控制系统中至关重要的一环,在医药、化工、食品等领域生产过程中,往

往需要随时检测各生产环节的温度、湿度、流量及压力等参数。同时,还要对某一检测点任意参数

能够进行随机查询,将其在某一时间段内检测到的数据经过转换提取出来,以便进行比较,做出策

略。

数据采集系统从严格意义来说,应该使用计算机控制的多路数据自动检测或巡回检测,并且能

够对数据实行存储、处理、分析计算以及从检测的数据中提取可用的信息,供显示、记录、打印或

描绘的系统。

由于 RS-232 在微机通信接口中广泛应用,技术已相当成熟。在近端与远端通信过程中,采用

串行 RS-232 标准,实现 PC 机与单片机间的数据传输。

数据采集与通信控制采用了模块化的设计,数据采集与通信控制采用了单片机 8051 来实现,

硬件部分是以单片机为核心,还包括 A/D 模数转换模块,显示模块,和串行接口部分。该系统从

机负责数据采集并应答主机的命令。8 路被测电压通过模数转换器 ADC0832 进行模数转换,实现

对采集到的数据进行模拟量到数字量的转换,并将转换后的数据通过串行口传输到上位机,并用

LED 数码显示管来显示所采集的结果。

- 1 -

�

基于 RS-232 的数据采集系统设计

第 2 章 单元电路原理

本硬件电路包括的单元电路有 X5045 看门狗电路、MAX232 电平转换芯片、时钟电路、指示

电路、开关量采集电路、模拟量采集电路以及 ADC0832A/D 转换电路。

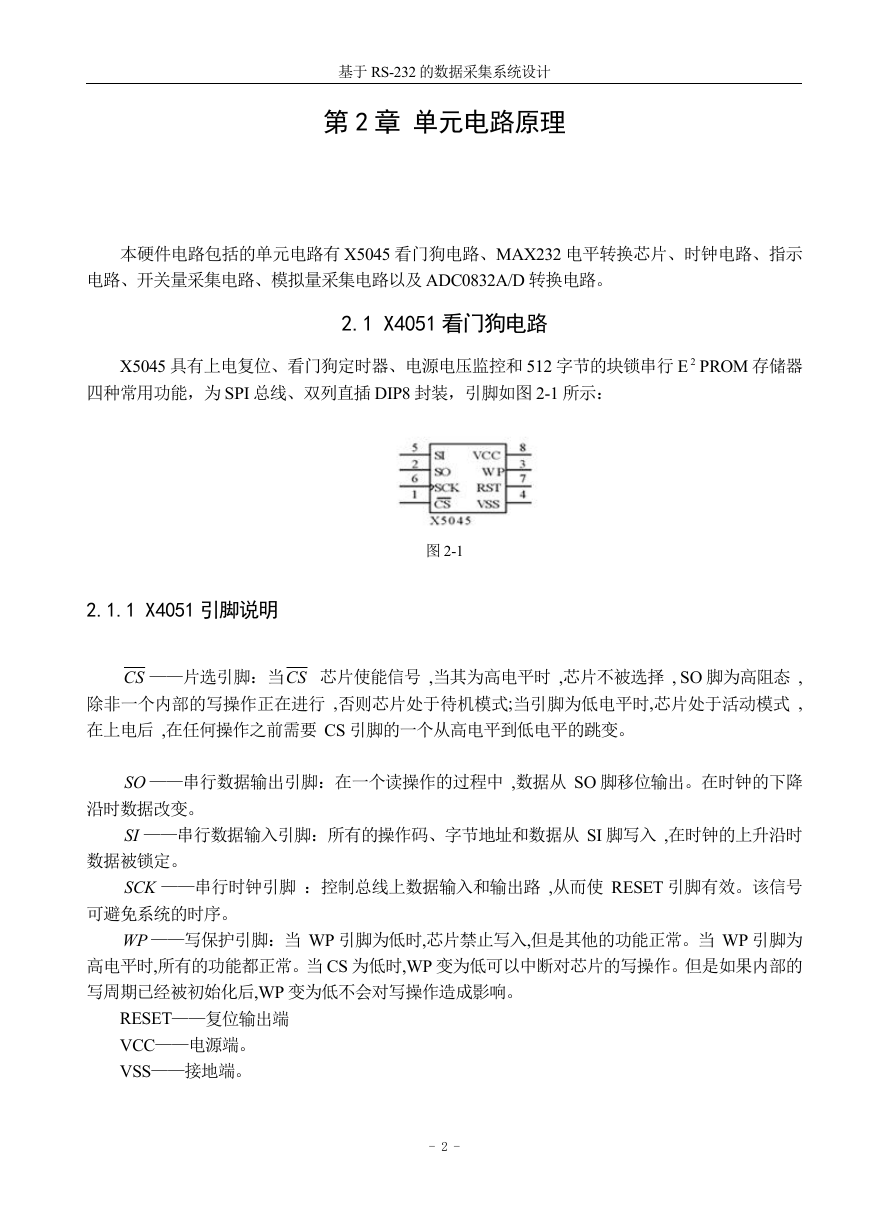

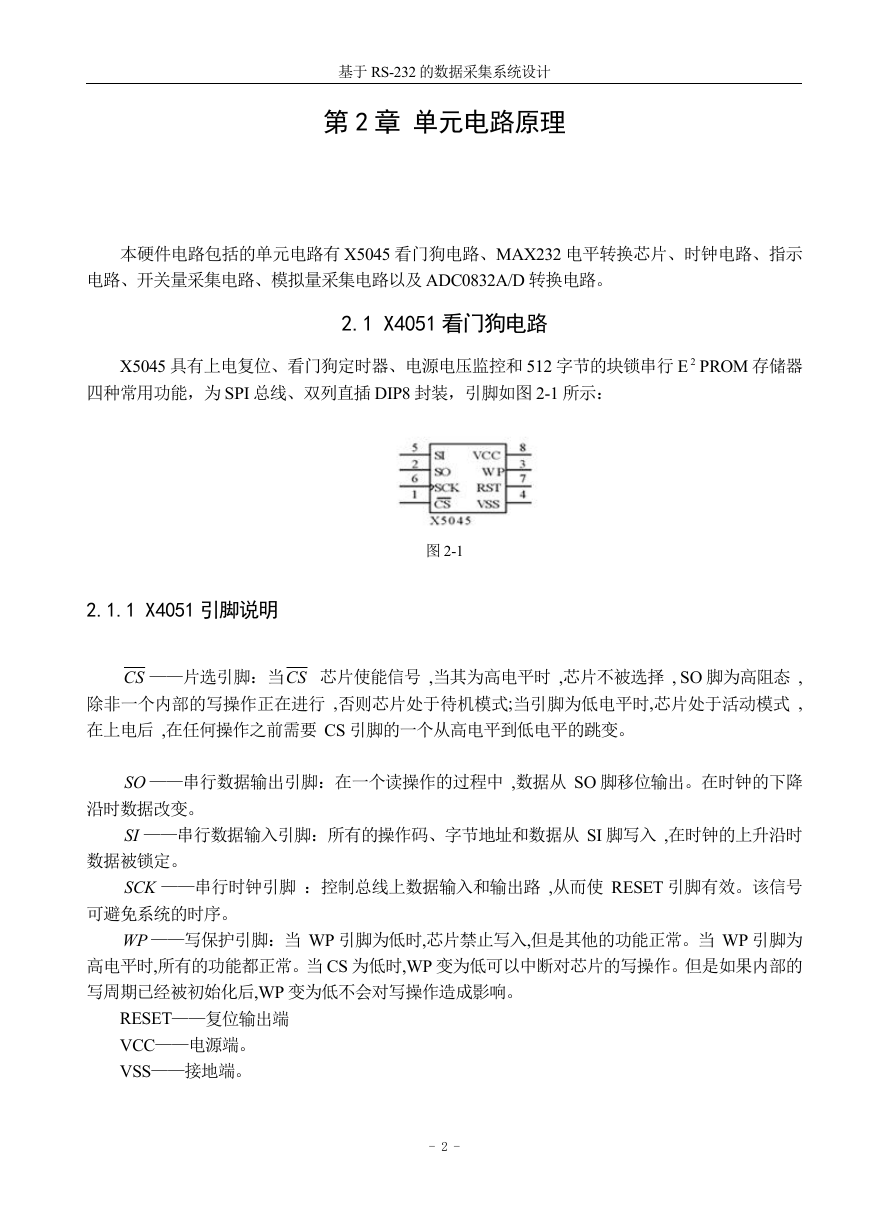

2.1 X4051 看门狗电路

X5045 具有上电复位、看门狗定时器、电源电压监控和 512 字节的块锁串行 E 2 PROM 存储器

四种常用功能,为 SPI 总线、双列直插 DIP8 封装,引脚如图 2-1 所示:

图 2-1

2.1.1 X4051 引脚说明

CS ——片选引脚:当CS 芯片使能信号 ,当其为高电平时 ,芯片不被选择 , SO 脚为高阻态 ,

除非一个内部的写操作正在进行 ,否则芯片处于待机模式;当引脚为低电平时,芯片处于活动模式 ,

在上电后 ,在任何操作之前需要 CS 引脚的一个从高电平到低电平的跳变。

SO ——串行数据输出引脚:在一个读操作的过程中 ,数据从 SO 脚移位输出。在时钟的下降

沿时数据改变。

SI ——串行数据输入引脚:所有的操作码、字节地址和数据从 SI 脚写入 ,在时钟的上升沿时

数据被锁定。

SCK ——串行时钟引脚 :控制总线上数据输入和输出路 ,从而使 RESET 引脚有效。该信号

可避免系统的时序。

WP ——写保护引脚:当 WP 引脚为低时,芯片禁止写入,但是其他的功能正常。当 WP 引脚为

高电平时,所有的功能都正常。当 CS 为低时,WP 变为低可以中断对芯片的写操作。但是如果内部的

写周期已经被初始化后,WP 变为低不会对写操作造成影响。

RESET——复位输出端

VCC——电源端。

VSS——接地端。

- 2 -

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc