IEEE Std 1101.1-1998

(Revision of

IEEE Std 1101.1-1991)

IEEE Standard for Mechanical Core

Specications for Microcomputers

Using IEC 60603-2 Connectors

Sponsor

Microprocessor and Microcomputer Standards Subcommittee

of the

IEEE Computer Society

Approved 28 September 1998

IEEE-SA Standards Board

Abstract:

The basic dimensions of a range of modular subracks conforming to IEC 60297-3 (1984-

01) and IEC 60297-4 (1995-03) for mounting in equipment according to IEC 60297-1 (1986-09) and

ANSI/EIA 310-D-1992, together with the basic dimensions of a compatible range of plug-in units,

printed boards, and backplanes, are covered. The dimensions and tolerances necessary to ensure

mechanical function compatibility are provided. This standard offers total system integration guide-

lines with attendant advantages, such as reduction in design and development time, manufacturing

cost savings, and distinct marketing advantages.

Keywords:

compatibility, mechanical interchangeability, plug-in units, subracks

The Institute of Electrical and Electronics Engineers, Inc.

345 East 47th Street, New York, NY 10017-2394, USA

Copyright ' 1998 by the Institute of Electrical and Electronics Engineers, Inc.

All rights reserved. Published 18 December 1998. Printed in the United States of America.

Print:

PDF:

ISBN 0-7381-1449-9 SH94691

ISBN 0-7381-1450-2 SS94691

No part of this publication may be reproduced in any form, in an electronic retrieval system or otherwise, without the prior

written permission of the publisher.

�

IEEE Standards

documents are developed within the IEEE Societies and the Standards Coordinat-

ing Committees of the IEEE Standards Association (IEEE-SA) Standards Board. Members of the

committees serve voluntarily and without compensation. They are not necessarily members of the

Institute. The standards developed within IEEE represent a consensus of the broad expertise on the

subject within the Institute as well as those activities outside of IEEE that have expressed an inter-

est in participating in the development of the standard.

Use of an IEEE Standard is wholly voluntary. The existence of an IEEE Standard does not imply

that there are no other ways to produce, test, measure, purchase, market, or provide other goods and

services related to the scope of the IEEE Standard. Furthermore, the viewpoint expressed at the

time a standard is approved and issued is subject to change brought about through developments in

the state of the art and comments received from users of the standard. Every IEEE Standard is sub-

jected to review at least every ve years for revision or reafrmation. When a document is more

than ve years old and has not been reafrmed, it is reasonable to conclude that its contents,

although still of some value, do not wholly reect the present state of the art. Users are cautioned to

check to determine that they have the latest edition of any IEEE Standard.

Comments for revision of IEEE Standards are welcome from any interested party, regardless of

membership afliation with IEEE. Suggestions for changes in documents should be in the form of a

proposed change of text, together with appropriate supporting comments.

Interpretations: Occasionally questions may arise regarding the meaning of portions of standards as

they relate to specic applications. When the need for interpretations is brought to the attention of

IEEE, the Institute will initiate action to prepare appropriate responses. Since IEEE Standards rep-

resent a consensus of all concerned interests, it is important to ensure that any interpretation has

also received the concurrence of a balance of interests. For this reason, IEEE and the members of its

societies and Standards Coordinating Committees are not able to provide an instant response to

interpretation requests except in those cases where the matter has previously received formal

consideration.

Comments on standards and requests for interpretations should be addressed to:

Secretary, IEEE-SA Standards Board

445 Hoes Lane

P.O. Box 1331

Piscataway, NJ 08855-1331

USA

Note: Attention is called to the possibility that implementation of this standard may

require use of subject matter covered by patent rights. By publication of this standard,

no position is taken with respect to the existence or validity of any patent rights in

connection therewith. The IEEE shall not be responsible for identifying patents for

which a license may be required by an IEEE standard or for conducting inquiries into

the legal validity or scope of those patents that are brought to its attention.

Authorization to photocopy portions of any individual standard for internal or personal use is

granted by the Institute of Electrical and Electronics Engineers, Inc., provided that the appropriate

fee is paid to Copyright Clearance Center. To arrange for payment of licensing fee, please contact

Copyright Clearance Center, Customer Service, 222 Rosewood Drive, Danvers, MA 01923 USA;

(978) 750-8400. Permission to photocopy portions of any individual standard for educational class-

room use can also be obtained through the Copyright Clearance Center.

�

Introduction

(This introduction is not a part of IEEE Std 1101.1-1998, IEEE Standard for Mechanical Core Specications for Micro-

computers Using IEC 60603-2 Connectors.)

With the introduction of international (IEC) microcomputer architectures based on the Euroboard form fac-

tor, the IEEE Computer Society Technical Committee on Microprocessors and Microcomputers found it

appropriate to form a separate IEEE standard to expand upon the IEC 60297 series of standards, Dimensions

of mechanical structures of the 482.6 mm (19 in) series. (See Clause 3 of this standard.)

This standard provides design engineers with the dimensions and tolerances necessary to ensure mechanical

function compatibility. This standard also provides environmental specications as an addendum to IEC

60297-3 (1984-01).

This mechanical standard offers total system integration guidelines. It offers advantages such as reduction in

design and development time, manufacturing cost savings, and distinct marketing advantages.

This standard covers standardized dimensions of a range of modular subracks and a compatible range of

plug-in units, printed boards, backplanes, and connectors.

This standard was revised from IEEE Std 1101.1-1991.

At the time that the revision was completed, the P1101.1 Working Group had the following membership:

Ralf Behrens

Martin Blake

Robert Downing

Jean-Jacques Dumont

Eike Waltz,

Chair

Frank Hom,

Secretary

Wayne P. Fischer

Tad Kubic

Paul Mazura

Michael Munroe

Joe P. Norris

Elwood T. Parsons

Holly Shernsky

Michael G. Thompson

Sue Wong

The following persons were on the balloting committee that approved this document for submission to the

IEEE-SA Standards Board:

Ghassan A. Abbas

Malcolm J. Airst

Ray S. Alderman

Keith D. Anthony

Edmund H. Baulsir

Martin Blake

Ralf Bokaemper

David Brearley

Charles Brill

C. H. Chen

Jean-Jacques Dumont

Jean Paul Emard

Wayne P. Fischer

Kenneth C. Heck

Roger Hinsdale

Frank Hom

Jing Kwok

Conrad A. Laurvick

Gerald E. Laws

Rollins Linser

Gary S. Manchester

Joseph R. Marshall

Thanos Mentzelopoulos

Gene E. Milligan

Klaus-Dieter Mueller

Michael Munroe

Joe P. Norris

Peter G. Odell

Elwood T. Parsons

Hermann H. Strass

Michael G. Thompson

Robert C. Tripi

Bruce Wallace

David L. Wright

Copyright ' 1998 IEEE. All rights reserved.

iii

�

The nal conditions for approval of this standard were met on 28 September 1998. This standard was condi-

tionally approved by the IEEE-SA Standards Board on 16 September 1998, with the following membership:

Richard J. Holleman,

Chair

Donald N. Heirman,

Vice Chair

Judith Gorman,

Secretary

Satish K. Aggarwal

Clyde R. Camp

James T. Carlo

Gary R. Engmann

Harold E. Epstein

Jay Forster*

Thomas F. Garrity

Ruben D. Garzon

*Member Emeritus

James H. Gurney

Jim D. Isaak

Lowell G. Johnson

Robert Kennelly

E. G. Al Kiener

Joseph L. Koepnger*

Stephen R. Lambert

Jim Logothetis

Donald C. Loughry

L. Bruce McClung

Louis-Franois Pau

Ronald C. Petersen

Gerald H. Peterson

John B. Posey

Gary S. Robinson

Hans E. Weinrich

Donald W. Zipse

Catherine Berger

IEEE Standards Project Editor

iv

Copyright ' 1998 IEEE. All rights reserved.

�

Contents

1.

Scope.................................................................................................................................................... 1

1.1 Basic dimensions of subracks ...................................................................................................... 1

1.2 Dimensions of plug-in units......................................................................................................... 1

1.3 Environmental requirements of subracks..................................................................................... 1

Purpose................................................................................................................................................. 1

References............................................................................................................................................ 1

General arrangement............................................................................................................................ 3

Euroboard matrix ................................................................................................................................. 4

Euroboard sizes.................................................................................................................................... 5

6.1 Euroboard height.......................................................................................................................... 5

6.2 Euroboard depth........................................................................................................................... 5

6.3 Euroboard thickness..................................................................................................................... 5

6.4 Conductive elements and guide rails ........................................................................................... 5

Position of plug-in unit mounted connectors, board-type and box-type.............................................. 9

Plug-in unit description...................................................................................................................... 12

Plug-in unit dimensions ..................................................................................................................... 12

9.1 Board-type plug-in units ............................................................................................................ 12

9.2 Box-type, box/board-type plug-in units..................................................................................... 12

2.

3.

4.

5.

6.

7.

8.

9.

10.

Backplane design and mounting positions......................................................................................... 13

10.1 Rigidity ...................................................................................................................................... 13

10.2 Dimensions ................................................................................................................................ 13

11.

Subracks............................................................................................................................................. 34

12.

Environmental specifications............................................................................................................. 42

12.1 Introduction................................................................................................................................ 42

12.2 Climatic tests.............................................................................................................................. 42

12.3 Mechanical load ......................................................................................................................... 42

12.4 Vibration .................................................................................................................................... 44

12.5 Shock.......................................................................................................................................... 44

12.6 Safety tests ................................................................................................................................. 44

Annex A (informative) Bibliography .......................................................................................................... 47

Copyright ' 1998 IEEE. All rights reserved.

v

�

IEEE Standard for Mechanical Core

Specications for Microcomputers

Using IEC 60603-2 Connectors

1. Scope

1.1 Basic dimensions of subracks

This standard covers the basic dimensions of a range of modular subracks conforming to IEC 60297-3

(1984-01) and IEC 60297-4 (1995-03) for mounting in equipment according to IEC 60297-1 (1986-09) and

ANSI/EIA 310-D-1992, together with the basic dimensions of a compatible range of plug-in units, printed

boards, and backplanes.

1.2 Dimensions of plug-in units

This standard will give the dimensions of associated plug-in units and connector-mounting details together

with applicable detail dimensions of the subrack.

1.3 Environmental requirements of subracks

This standard will state environmental requirements of subracks and their associated plug-in units.

2. Purpose

The purpose of this standard is the specication of dimensions that will ensure the mechanical interchange-

ability and environmental requirements of subracks and of plug-in units.

3. References

The following publications shall be used in conjunctions with this standard. When they are superseded by an

approved revision, the revision shall apply.

1

ANSI/EIA 310-D-1992: Racks, Panels, and Associated Equipment.

1

ANSI publications are available from the Sales Department, American National Standards Institute, 11 West 42nd Street, 13th Floor,

New York, NY 10036, USA (www.ansi.org/).

Copyright ' 1998 IEEE. All rights reserved.

1

�

IEEE

Std 1101.1-1998

IEEE STANDARD FOR MECHANICAL CORE SPECIFICATIONS

CFR (Code of Federal Regulations), Title 47: Telecommunications, Part 15J, published by Ofce of the Fed-

2

eral Register (FCC Rules and Regulations are contained within this document).

3

IEC 60068-2-1 (1990-05), Environmental testingPart 2: Tests. Tests A: Cold.

IEC 60068-2-2 (1974-01), Environmental testingPart 2: Tests. Test B: Dry Heat.

IEC 60068-2-6 (1995-03), Environmental testingPart 2: Tests. Test Fc: Vibration (sinusoidal).

IEC 60068-2-11 (1981-01), Environmental testingPart 2: Tests. Test Ka: Salt mist.

IEC 60068-2-27 (1987-06), Environmental testingPart 2: Tests. Test Ea and guidance: Shock.

IEC 60097 (1991-05), Grid systems for printed circuits.

IEC 60249-2-1 (1985-01), Base materials for printed circuits. Part 2: Specications. Specication No. 1:

Phenolic cellulose paper copper-clad laminated sheet, high electrical quality.

IEC 60249-2-2 (1985-01), Base materials for printed circuits. Part 2: Specications. Specication No. 2:

Phenolic cellulose paper copper-clad laminated sheet, economic quality.

IEC 60249-2-3 (1987-04), Base materials for printed circuits. Part 2: Specications. Specication No. 3:

Epoxide cellulose paper copper-clad laminated sheet of dened ammability (vertical burning test).

IEC 60249-2-4 (1987-06), Base materials for printed circuits. Part 2: Specications. Specication No. 4:

Epoxide woven glass fabric copper-clad laminated sheet, general purpose grade.

IEC 60249-2-5 (1987-06), Base materials for printed circuits. Part 2: Specications. Specication No. 5:

Epoxide woven glass fabric copper-clad laminated sheet of dened ammability (vertical burning test).

IEC 60297-1 (1986-09), Dimensions of mechanical structures of the 482.6 mm (19 in) series. Part 1: Panels

and racks.

IEC 60297-3 (1984-01), Dimensions of mechanical structures of the 482.6 mm (19 in) series. Part 3: Sub-

racks and associated plug-in units.

IEC 60297-4 (1995-03), Mechanical structures of electronic equipmentDimensions of mechanical struc-

tures of the 482.6 mm (19 in) series. Part 4: Subracks and associated plug-in unitsAdditional dimensions.

IEC 60603-2 (1995-09), Connectors for frequencies below 3 MHz for use with printed boardsPart 2:

Detail specication for two-part connectors with assessed quality, for printed boards, for basic grid of

2.54 mm (0.1 in), with common mounting features.

IEC 60651 (1979-01), Sound level meters.

IEC 60707 (1981-01), Methods of test for the determination of the ammability of solid electrical insulating

materials when exposed to an igniting source.

IEC 61010-1 (1990-09), Safety requirements for electrical equipment for measurement, control, and labora-

4

tory usePart 1: General requirements.

2

CFR publications are available from the Superintendent of Documents, U.S. Government Printing Ofce, P.O. Box 37082, Washing-

ton, DC 20013-7082, USA.

3

IEC publications are available from the Sales Department of the International Electrotechnical Commission, Case Postale 131, 3, rue

de Varemb, CH-1211, Genve 20, Switzerland/Suisse (www.iec.ch/). IEC publications are also available from the Sales Department,

American National Standards Institute, 11 West 42nd Street, 13th Floor, New York, NY 10036, USA (www.ansi.org/).

4

IEC 61010-1 (1990-09) replaces withdrawn standard IEC 60348 (1978).

2

Copyright ' 1998 IEEE. All rights reserved.

�

FOR MICROCOMPUTERS USING IEC 60603-2 CONNECTORS

IEEE

Std 1101.1-1998

IEEE Std 1101.10-1996, IEEE Standard for Additional Mechanical Specications for Microcomputers

5

Using the IEEE 1101.1-1991 Equipment Practice.

IEEE 1101.11-1998, IEEE Standard for Mechanical Rear Plug-in Units Specications for Microcomputers

Using the IEEE 1101.1 and the IEEE 1101.10 Equipment Practice.

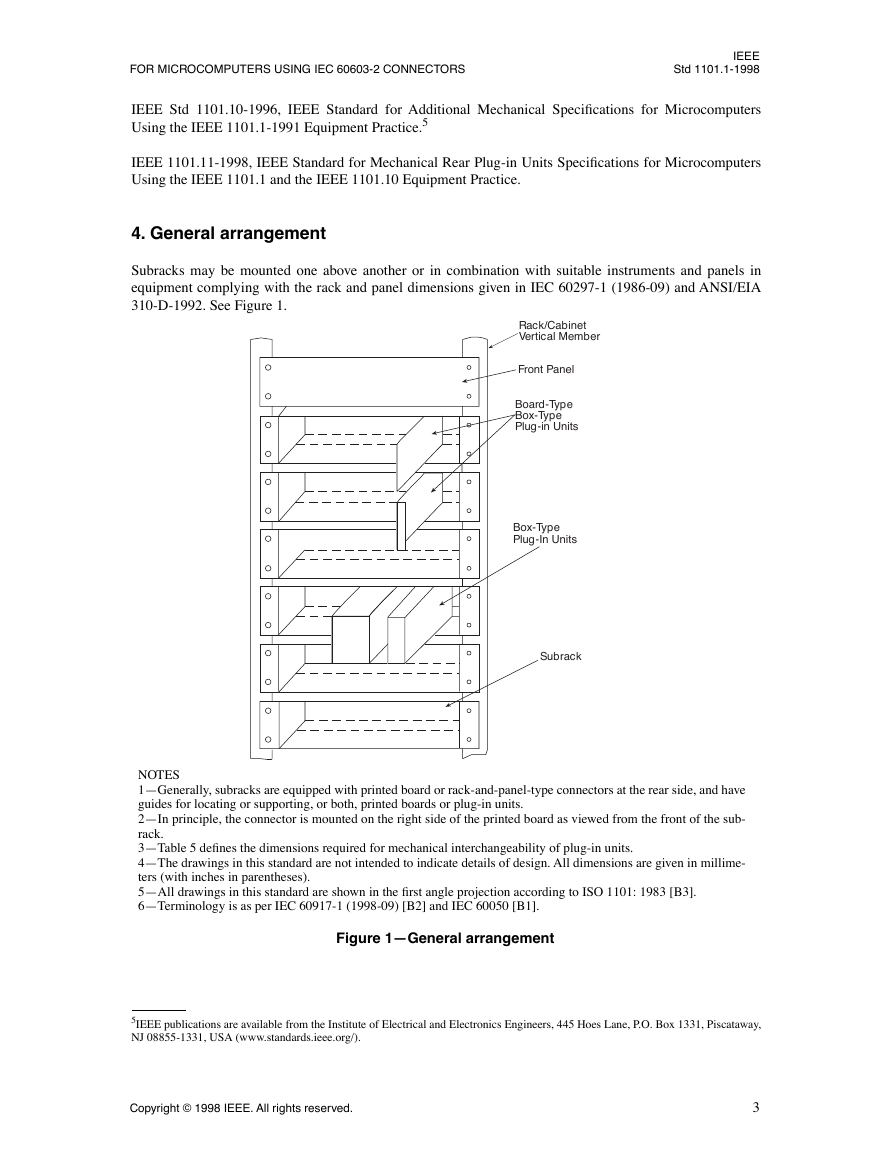

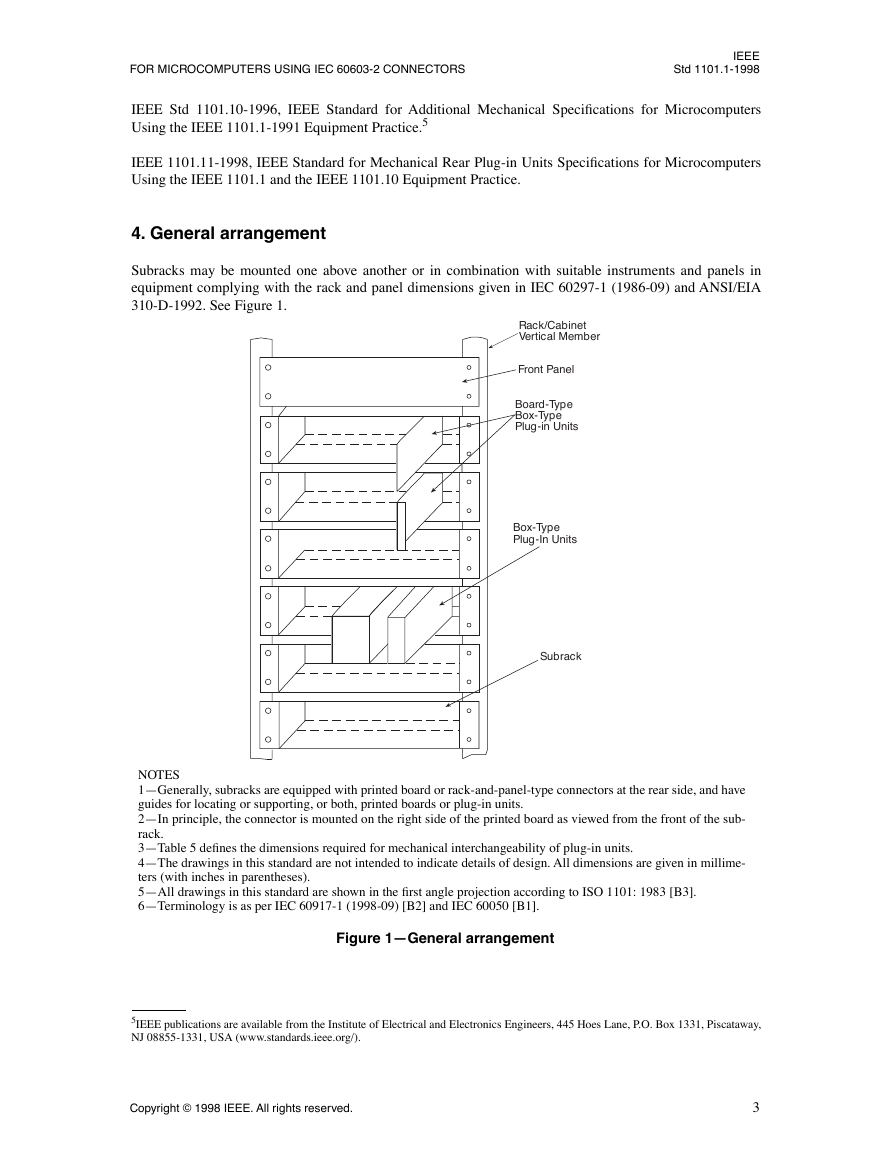

4. General arrangement

Subracks may be mounted one above another or in combination with suitable instruments and panels in

equipment complying with the rack and panel dimensions given in IEC 60297-1 (1986-09) and ANSI/EIA

310-D-1992. See Figure 1.

Rack/Cabinet

Vertical Member

Front Panel

Board-Type

Box-Type

Plug-in Units

Box-Type

Plug-In Units

Subrack

NOTES

1Generally, subracks are equipped with printed board or rack-and-panel-type connectors at the rear side, and have

guides for locating or supporting, or both, printed boards or plug-in units.

2In principle, the connector is mounted on the right side of the printed board as viewed from the front of the sub-

rack.

3Table 5 denes the dimensions required for mechanical interchangeability of plug-in units.

4The drawings in this standard are not intended to indicate details of design. All dimensions are given in millime-

ters (with inches in parentheses).

5All drawings in this standard are shown in the rst angle projection according to ISO 1101: 1983 [B3].

6Terminology is as per IEC 60917-1 (1998-09) [B2] and IEC 60050 [B1].

Figure 1General arrangement

5

IEEE publications are available from the Institute of Electrical and Electronics Engineers, 445 Hoes Lane, P.O. Box 1331, Piscataway,

NJ 08855-1331, USA (www.standards.ieee.org/).

Copyright ' 1998 IEEE. All rights reserved.

3

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc