Preliminary Datasheet- please see the Known Issues list

CONFIDENTIAL�

Restricted

1. Security warning

The information contained in this document is the exclusive property of GoerTek Inc. and should not be disclosed to any

third party without the written consent of GoerTek Inc.

2. Publication history

Version

Date

Description

Author

Approved

1.0

2.0

Version 2.0

2015.5.29

New design

Wiming

Sammy

2015.8.10

Update product

name

Wiming

Sammy

Page 1 / 32

CONFIDENTIAL�

Index of Contents

1. PRODUCT OVERVIEW ..........................................................................................................................................4

1.1

1.2

1.3

PRODUCT DESCRIPTION .....................................................................................................................................4

FEATURES .............................................................................................................................................................4

TYPICAL APPLICATIONS ........................................................................................................................................4

2. DEFINITIONS, ACRONYMS AND ABBREVIATIONS .......................................................................................5

2.1 DEFINITIONS .........................................................................................................................................................5

3. PIN CONFIGURATION AND BLOCK DIAGRAM ..............................................................................................6

3.1

3.2

PIN CONFIGURATION AND DESCRIPTION ...............................................................................................................6

BLOCK DIAGRAM .................................................................................................................................................7

4. SPECIFICATIONS ....................................................................................................................................................7

4.1 OPERATING RANGE ...............................................................................................................................................7

4.2 ABSOLUTE MAXIMUM RATINGS ...........................................................................................................................7

4.3

4.4

4.5

4.6

CURRENT CONSUMPTION .....................................................................................................................................8

TEMPERATURE TRANSFER FUNCTION ...................................................................................................................8

PRESSURE TRANSFER FUNCTION ..........................................................................................................................9

TIMING CHARACTERISTICS .................................................................................................................................10

5. FUNCTIONAL DESCRIPTION ............................................................................................................................10

5.1 OPERATING MODES ............................................................................................................................................10

5.2 MEASUREMENT PRECISION AND RATE ................................................................................................................ 11

5.3

5.4

5.5

5.6

SENSOR INTERFACE ............................................................................................................................................ 11

INTERRUPT .......................................................................................................................................................... 11

FIFO OPERATION ................................................................................................................................................12

CALIBRATION AND MEASUREMENT COMPENSATION ..........................................................................................12

5.6.1

5.6.2

5.6.3

How to Calculate Compensated Pressure Values ...................................................................................12

How to Calculate Compensated Temperature Values ................................................................................13

Compensation Scale Factors ......................................................................................................................13

6. APPLICATIONS ......................................................................................................................................................14

6.1 MEASUREMENT SETTINGS AND USE CASE EXAMPLES ...................................................................................14

6.2 APPLICATION CIRCUIT EXAMPLE ........................................................................................................................14

7. REGISTER MAP .....................................................................................................................................................15

8. REGISTER DESCRIPTION ..................................................................................................................................16

8.1

PRESSURE DATA (PRS_BN) ................................................................................................................................16

8.1.1

8.1.2

8.1.3

PRS_B2 ......................................................................................................................................................16

PRS_B1 ......................................................................................................................................................16

PRS_B0 ......................................................................................................................................................17

8.2

TEMPERATURE DATA (TMP_TN) ........................................................................................................................17

Version 2.0

Page 2 / 32

CONFIDENTIAL�

8.2.1

8.2.2

8.2.3

TMP_B2 .....................................................................................................................................................17

TMP_B1 .....................................................................................................................................................18

TMP_B0 .....................................................................................................................................................18

8.3

8.4

8.5

8.6

8.7

8.8

8.9

PRESSURE CONFIGURATION (PRS_CFG) ...........................................................................................................18

TEMPERATURE CONFIGURATION (TMP_CFG) ...................................................................................................20

SENSOR OPERATING MODE AND STATUS (MEAS_CFG) .................................................................................21

INTERRUPT AND FIFO CONFIGURATION (CFG_REG).........................................................................................22

INTERRUPT STATUS (INT_STS) ..........................................................................................................................23

FIFO STATUS (FIFO_STS) .................................................................................................................................24

SOFT RESET AND FIFO FLUSH (RESET).............................................................................................................25

8.10 PRODUCT AND REVISION ID (ID) ........................................................................................................................25

8.11 CALIBRATION COEFFICIENTS (COEF) ................................................................................................................26

8.12 COEFFICIENT SOURCE .........................................................................................................................................26

9. PACKAGE DIMENSIONS .....................................................................................................................................27

10.

STORAGE AND TRANSPORTATION .............................................................................................................28

11.

SOLDERING RECOMMENDATION ..............................................................................................................29

12.

PACKAGE SPECIFICATIONS .........................................................................................................................30

13. KNOWN ISSUES LIST .......................................................................................................................................31

Version 2.0

Page 3 / 32

CONFIDENTIAL�

1. Product Overview

1.1 Product Description

The SPL06-001 is a miniaturized Digital Barometric Air Pressure Sensor with a high accuracy and a low current

consumption. The SPL06-001 is both a pressure- and a temperature sensor. The pressure sensor element is based on a

capacitive sensing principle which guarantees a high precision during temperature changes. The small package makes

the SPL06-001 ideal for mobile applications and wearable devices.

The SPL06-001 ‘s internal signal processor converts the output from the pressure and temperature sensor elements to

24-bit results. Each pressure sensor has been calibrated individually and contains calibration coefficients. The

coefficients are used in the application to convert the measurement results to true pressure and temperature values.

The SPL06-001 has a FIFO that can store the latest 32 measurements. By using the FIFO, the host processor can remain

in a sleep mode for a longer period of time between readouts. This can reduce the overall system power consumption.

Sensor measurements and calibration coefficients are available through the serial I2C or SPI interface.

1.2 Features

• Operation range: Pressure: 300 – 1200 hPa. Temperature: -40 – 85 °C.

• Pressure sensor precision: ± 0.006 hPa (or ±5 cm) (high precision mode).

• Pressure sensor accuracy: ± 0.06 hPa (or ±50 cm) (non-linearity), ±1 hPa (or ±8 m) (absolute).

• Temperature accuracy: ± 0.5°C.

• Pressure temperature sensitivity: < 0.5Pa/K

• Measurement time: Typical: 28 ms. Minimum: 3 ms.

• Average current consumption: High precision: 60 µA, Low power: 3 µA, Standby: <1 µA.

• Supply voltage: VDDIO: 1.2 – 3.6 V, VDD: 1.7 – 3.6 V.

• Operating modes: Command (manual), Background (automatic), and Standby.

• Calibration: Individually calibrated with coefficients for measurement correction.

• FIFO: Stores latest 32 pressure or temperature measurements.

•

Interface: I2C and SPI (both with optional interrupt)

• Package dimensions: 8-pin LGA, 2.0 mm x 2.5 mm x 0.95mm.

1.3 Typical Applications

•

Indoor Navigation (floor detection e.g. in shopping malls and parking garages)

• Health and Sports (accurate elevation gain and vertical speed)

• Outdoor Navigation (GPS start-up time and accuracy improvement, dead-reckoning e.g. in tunnels)

• Weather Station ('Micro-weather' and local forecasts)

Version 2.0

Page 4 / 32

CONFIDENTIAL�

2. Definitions, acronyms and abbreviations

2.1 Definitions

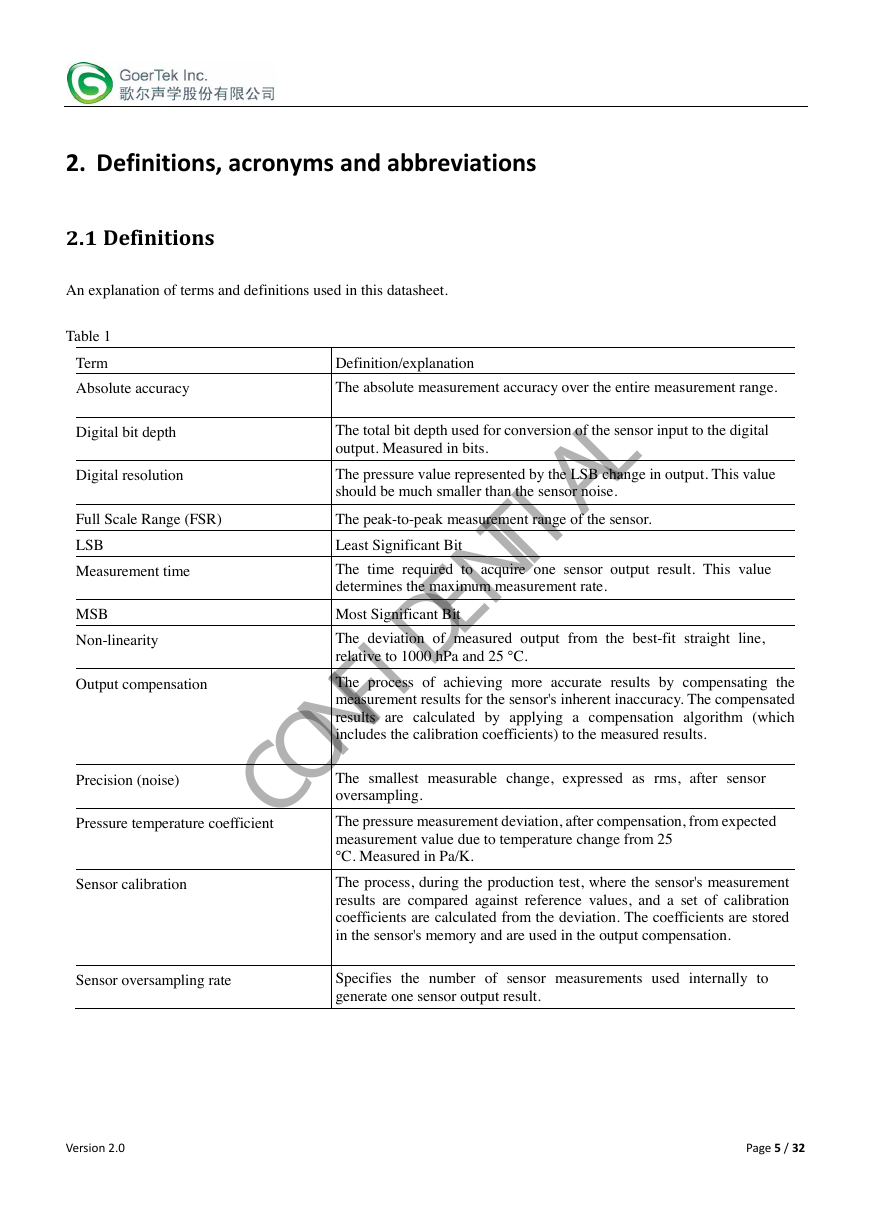

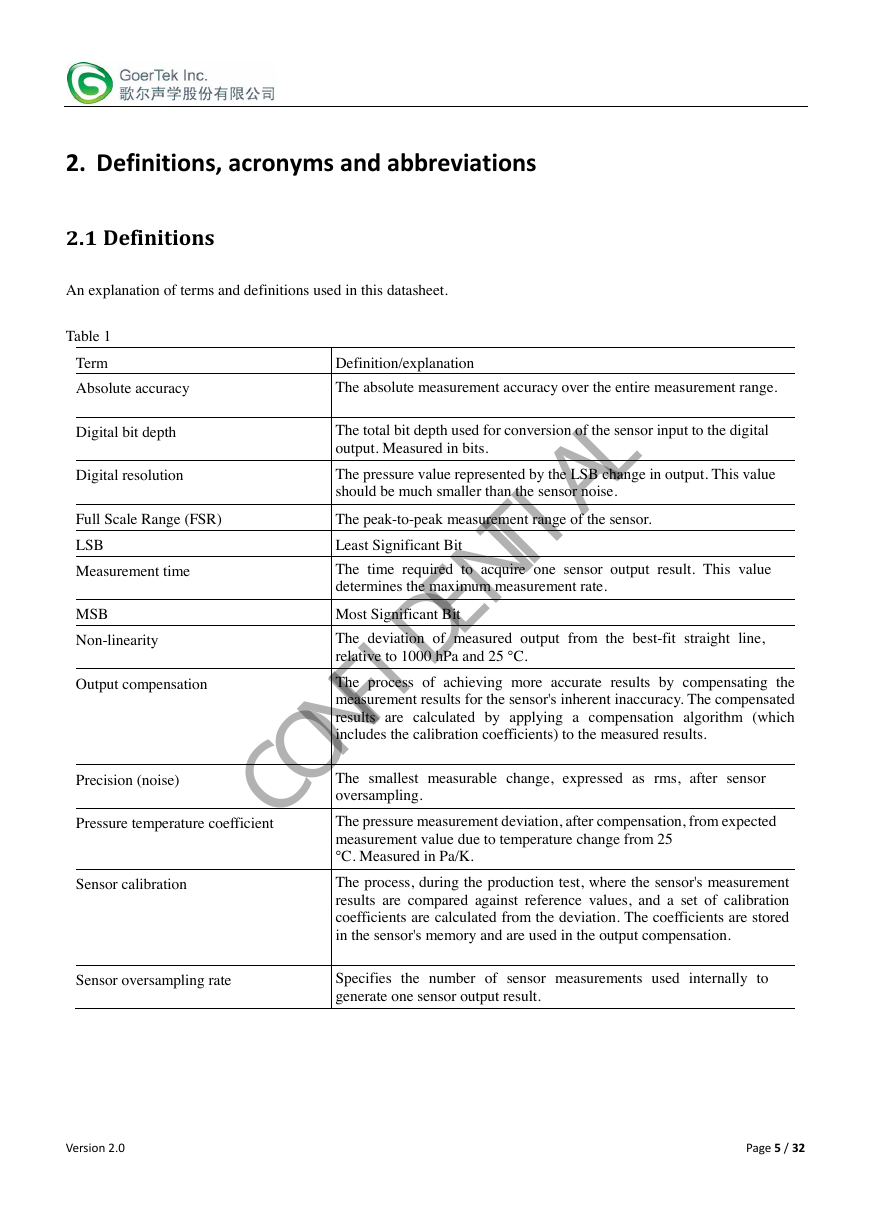

An explanation of terms and definitions used in this datasheet.

Table 1

Term

Definition/explanation

Absolute accuracy

The absolute measurement accuracy over the entire measurement range.

Digital bit depth

Digital resolution

The total bit depth used for conversion of the sensor input to the digital

output. Measured in bits.

The pressure value represented by the LSB change in output. This value

should be much smaller than the sensor noise.

Full Scale Range (FSR)

The peak-to-peak measurement range of the sensor.

LSB

Measurement time

MSB

Non-linearity

Output compensation

Precision (noise)

Pressure temperature coefficient

Sensor calibration

Least Significant Bit

The time required to acquire one sensor output result. This value

determines the maximum measurement rate.

Most Significant Bit

The deviation of measured output from the best-fit straight line,

relative to 1000 hPa and 25 °C.

The process of achieving more accurate results by compensating the

measurement results for the sensor's inherent inaccuracy. The compensated

results are calculated by applying a compensation algorithm (which

includes the calibration coefficients) to the measured results.

The smallest measurable change, expressed as rms, after sensor

oversampling.

The pressure measurement deviation, after compensation, from expected

measurement value due to temperature change from 25

°C. Measured in Pa/K.

The process, during the production test, where the sensor's measurement

results are compared against reference values, and a set of calibration

coefficients are calculated from the deviation. The coefficients are stored

in the sensor's memory and are used in the output compensation.

Sensor oversampling rate

Specifies the number of sensor measurements used internally to

generate one sensor output result.

Version 2.0

Page 5 / 32

CONFIDENTIAL�

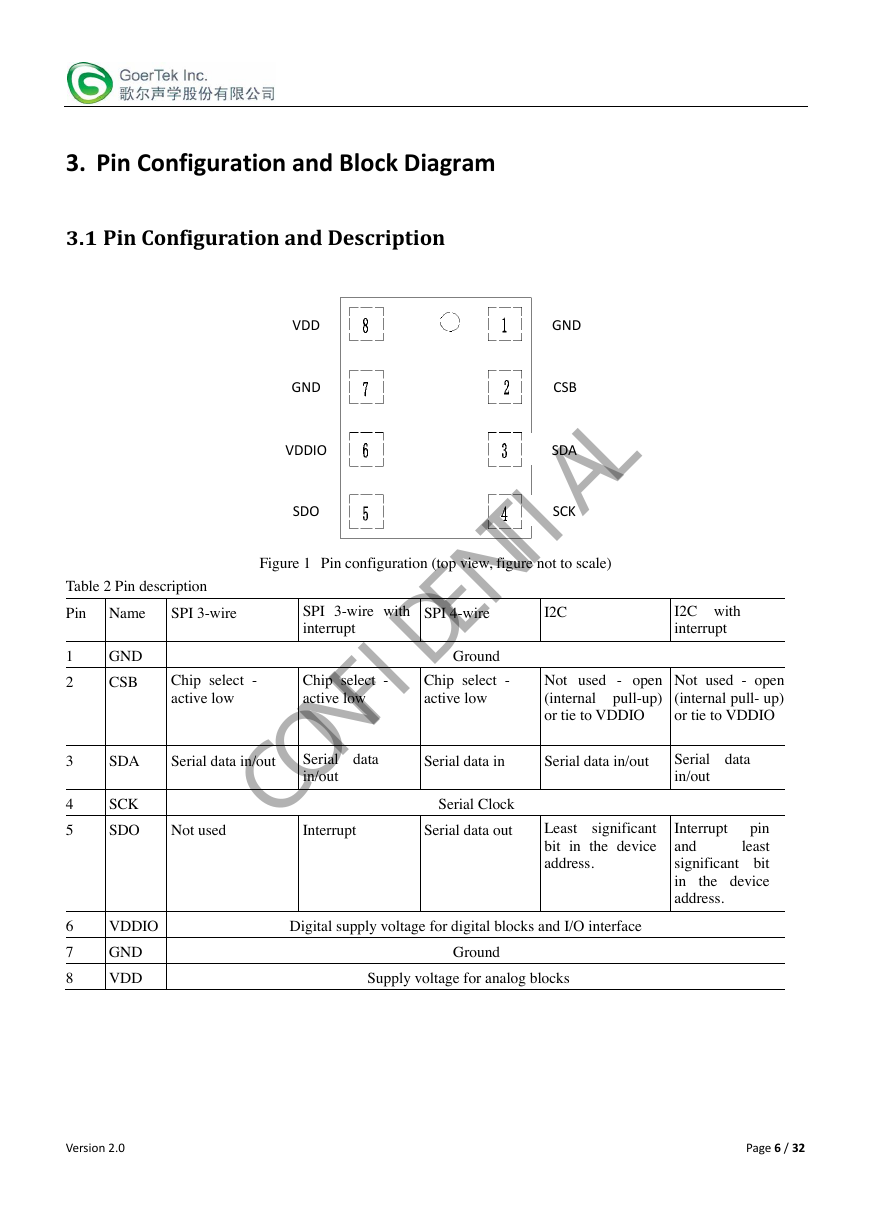

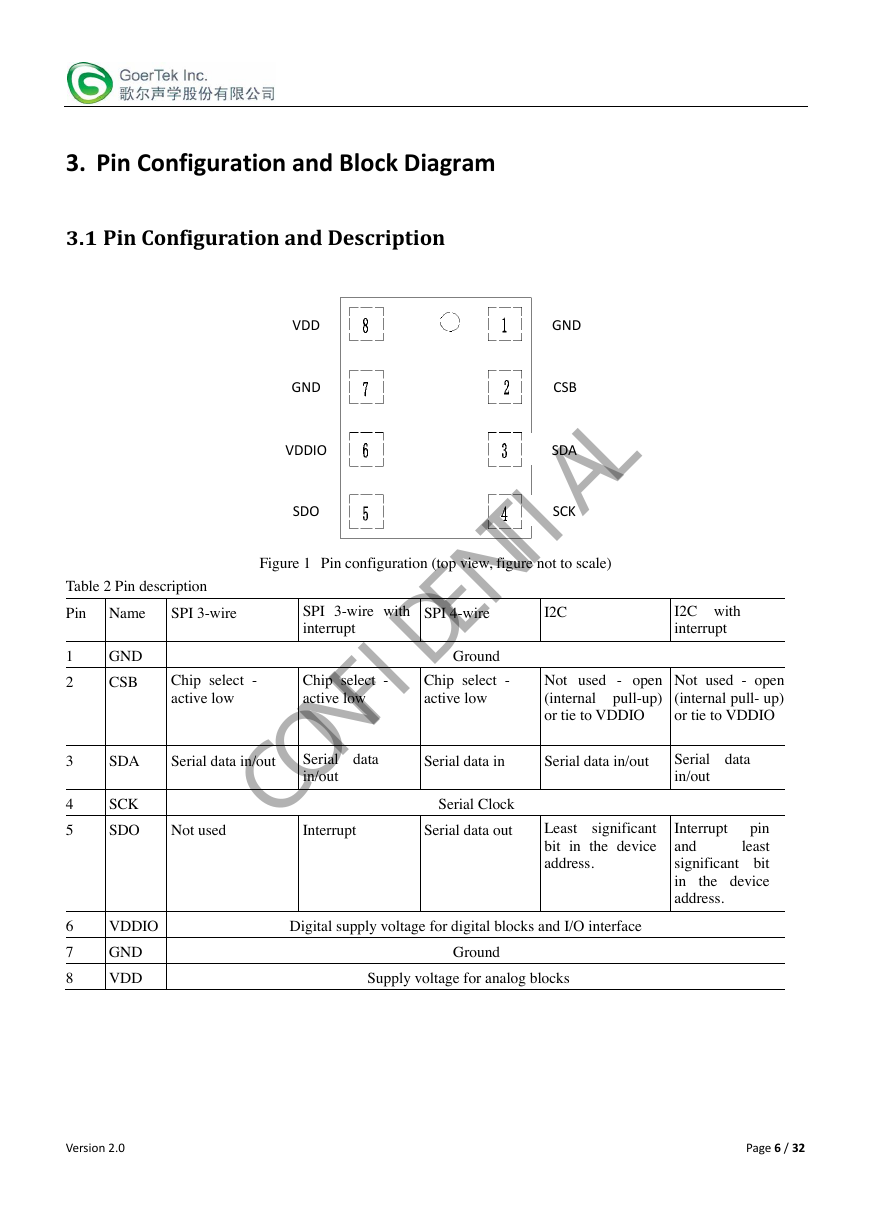

3. Pin Configuration and Block Diagram

3.1 Pin Configuration and Description

VDD

GND

VDDIO

SDO

GND

CSB

SDA

SCK

Figure 1 Pin configuration (top view, figure not to scale)

SPI 3-wire with

interrupt

SPI 4-wire

I2C

I2C with

interrupt

Ground

Chip select -

active low

Chip select -

active low

Chip select -

active low

Not used - open

(internal pull-up)

or tie to VDDIO

Not used - open

(internal pull- up)

or tie to VDDIO

SDA

Serial data in/out

Serial data

in/out

Serial data in

Serial data in/out

SCK

Serial Clock

SDO

Not used

Interrupt

Serial data out

Least significant

bit in the device

address.

Serial data

in/out

pin

Interrupt

least

and

significant bit

in

the device

address.

VDDIO

GND

VDD

Digital supply voltage for digital blocks and I/O interface

Ground

Supply voltage for analog blocks

Table 2 Pin description

Pin Name

SPI 3-wire

GND

CSB

1

2

3

4

5

6

7

8

Version 2.0

Page 6 / 32

CONFIDENTIAL�

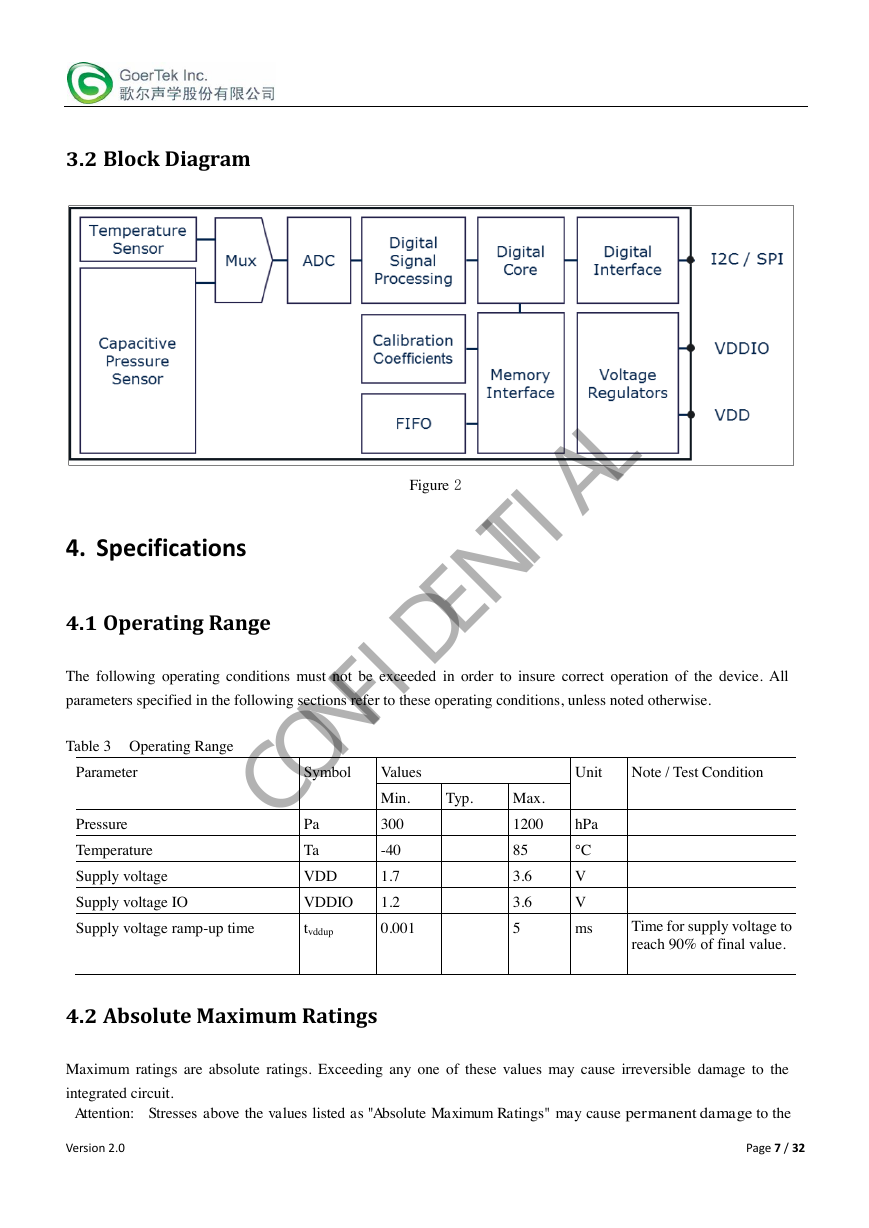

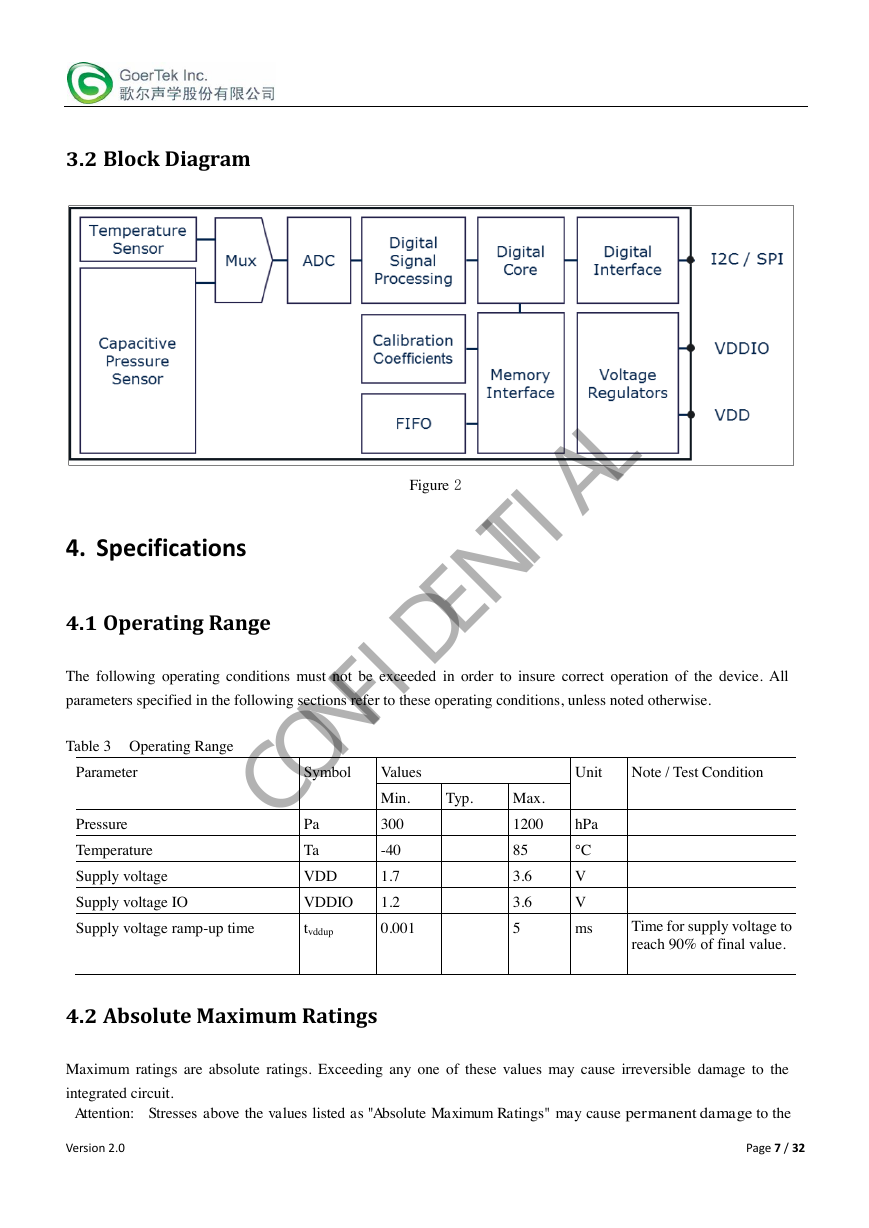

3.2 Block Diagram

4. Specifications

4.1 Operating Range

Figure 2

The following operating conditions must not be exceeded in order to insure correct operation of the device. All

parameters specified in the following sections refer to these operating conditions, unless noted otherwise.

Table 3 Operating Range

Parameter

Symbol

Values

Unit

Note / Test Condition

Min.

Typ.

Max.

Pressure

Temperature

Supply voltage

Supply voltage IO

Pa

Ta

VDD

VDDIO

300

-40

1.7

1.2

Supply voltage ramp-up time

tvddup

0.001

1200

hPa

85

3.6

3.6

5

°C

V

V

ms

Time for supply voltage to

reach 90% of final value.

4.2 Absolute Maximum Ratings

Maximum ratings are absolute ratings. Exceeding any one of these values may cause irreversible damage to the

integrated circuit.

Attention: Stresses above the values listed as "Absolute Maximum Ratings" may cause permanent damage to the

Version 2.0

Page 7 / 32

CONFIDENTIAL�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc