J. Vis. Commun. Image R. 18 (2007) 109–118

www.elsevier.com/locate/jvci

Position based dynamics q

Matthias Mu¨ ller a,*, Bruno Heidelberger a, Marcus Hennix a, John Ratcliff b

a AGEIA Technologies, Technoparkstrasse 1, 8005 Zu¨ rich, Switzerland

b AGEIA Technologies, 4041 Forest Park Avenue, St. Louis, MO 63108, USA

Received 8 January 2007; accepted 9 January 2007

Available online 12 February 2007

Abstract

The most popular approaches for the simulation of dynamic systems in computer graphics are force based. Internal and external

forces are accumulated from which accelerations are computed based on Newton’s second law of motion. A time integration method

is then used to update the velocities and finally the positions of the object. A few simulation methods (most rigid body simulators)

use impulse based dynamics and directly manipulate velocities. In this paper we present an approach which omits the velocity layer

as well and immediately works on the positions. The main advantage of a position based approach is its controllability. Overshooting

problems of explicit integration schemes in force based systems can be avoided. In addition, collision constraints can be handled easily

and penetrations can be resolved completely by projecting points to valid locations. We have used the approach to build a real time cloth

simulator which is part of a physics software library for games. This application demonstrates the strengths and benefits of the method.

Ó 2007 Elsevier Inc. All rights reserved.

Keywords: Physically based simulation; Game physics; Integration schemes; Cloth simulation

1. Introduction

Research in the field of physically based animation in

computer graphics is concerned with finding new methods

for the simulation of physical phenomena such as the

dynamics of rigid bodies, deformable objects or fluid flow.

In contrast to computational sciences where the main focus

is on accuracy, the main issues here are stability, robustness

and speed while the results should remain visually plausi-

ble. Therefore, existing methods from computational sci-

ences can not be adopted one to one. In fact, the main

justification for doing research on physically based simula-

tion in computer graphics is to come up with specialized

methods, tailored to the particular needs in the field. The

method we present falls into this category.

The traditional approach to simulating dynamic objects

has been to work with forces. At the beginning of each time

q Reprinted with permission from Proc. Virtual Reality Interactions and

Physical Simulations, Vriphys, Madrid, Spain, pp. 71–80, Nov. 6–7, 2006.

* Corresponding author. Fax: +41 44 445 2147.

E-mail address: mmueller@ageia.com (M. Mu¨ ller).

1047-3203/$ - see front matter Ó 2007 Elsevier Inc. All rights reserved.

doi:10.1016/j.jvcir.2007.01.005

step, internal and external forces are accumulated. Exam-

ples of internal forces are elastic forces in deformable

objects or viscosity and pressure forces in fluids. Gravity

and collision forces are examples of external forces. New-

ton’s second law of motion relates forces to accelerations

via the mass. So using the density or lumped masses of ver-

tices, the forces are transformed into accelerations. Any

time integration scheme can then be used to first compute

the velocities from the accelerations and then the positions

from the velocities. Some approaches use impulses instead

of

the animation. Because impulses

directly change velocities, one level of integration can be

skipped.

forces to control

In computer graphics and especially in computer games

it is often desirable to have direct control over positions of

objects or vertices of a mesh. The user might want to attach

a vertex to a kinematic object or make sure the vertex

always stays outside a colliding object. The method we pro-

pose here works directly on positions which makes such

manipulations easy. In addition, with the position based

approach it is possible to control the integration directly

thereby avoiding overshooting and energy gain problems

�

110

M. Mu¨ ller et al. / J. Vis. Commun. Image R. 18 (2007) 109–118

in connection with explicit integration. So the main fea-

tures and advantages of position based dynamics are

• Position based simulation gives control over explicit

integration and removes the typical instability problems.

• Positions of vertices and parts of objects can directly be

manipulated during the simulation.

• The formulation we propose allows the handling of gen-

eral constraints in the position based setting.

• The explicit position based solver is easy to understand

and implement.

2. Related work

The recent state of the art report ([1]) gives a good

overview of the methods used in computer graphics to

simulate deformable objects, e.g. mass-spring systems,

the finite element method or finite difference approaches.

Apart from the citation of ([2]), position based dynamics

does not appear in this survey. However, parts of the posi-

tion based approach have appeared in various papers

without naming it explicitly and without defining a com-

plete framework.

Jakobsen ([3]) built his Fysix engine on a position

based approach. His central

idea was to use a Verlet

integrator and manipulate positions directly. Because

velocities are implicitly stored by current and the previ-

ous positions, the velocities are implicitly updated by

the position manipulation. While he focused mainly on

distance constraints, he only gave vague hints on how

more general constraints could be handled. In this paper

we present a fully general approach which handles

general constraints. We also focus on the important issue

of conservation of linear and angular momenta by posi-

tion projection. We work with explicit velocities instead

of storing previous positions which makes damping and

friction simulation much easier.

Desbrun ([4]) and Provot ([5]) use constraint projection

in mass spring systems to prevent springs from overstret-

ching. In contrast to a full position based approach, projec-

tion is only used as a polishing process for those springs

that are stretched too much and not as the basic simulation

method.

Bridson et al. use a traditional force based approach

for cloth simulation ([6]) and combine it with a geomet-

ric collision resolving algorithm based on positions to

make sure that the collision resolving impulses are kept

within stable bounds. The same holds for the kinemati-

cal collision correction step proposed by Volino et al.

([7]).

A position based approach has been used by Clavet

et al. ([8]) to simulate viscoelastic fluids. Their approach

is not fully position based because the time step appears

in various places of their position projections. Thus, the

integration is only conditionally stable as regular explicit

integration.

Mu¨ ller et al.

([2]) simulate deformable objects by

moving points towards certain goal positions which are

found by matching the rest state to the current state of

the object. Their integration method is the closest to

the one we propose here. They only treat one specialized

global constraint and, therefore, do not need a position

solver.

Fedor ([9]) uses Jakobsen’s approach to simulate char-

acters in games. His method is tuned to the particular prob-

lem of simulating human characters. He uses several

skeletal

them in sync via

projections.

representations and keeps

Faure ([10]) uses a Verlet integration scheme by modify-

ing the positions rather than the velocities. New positions

are computed by linearizing the constraints while we work

with the non linear constraint functions directly.

We define general constraints via a constraint function

as ([11]) and ([12]). Instead of computing forces as the

derivative of a constraint function energy, we directly solve

for the equilibrium configuration and project positions.

With our method we derive a bending term for cloth which

is similar to the one proposed in ([13]) and ([14]) but

adopted to the point based approach.

In Section 4 we use the position based dynamics

approach for the simulation of cloth. Cloth simulation

has been an active research field in computer graphics in

recent years. Instead of citing the key papers of the field

individually we refer the reader to ([1]) for a comprehensive

survey.

3. Position based simulation

In this section we will formulate the general position

based approach. With cloth simulation, we will give a par-

ticular application of the method in the subsequent and in

the results section. We consider a three dimensional world.

However,

in two

dimensions.

the approach works equally well

3.1. Algorithm overview

We represent a dynamic object by a set of N vertices and

M constraints. A vertex i 2 [1, . . . , N] has a mass mi, a posi-

tion xi and a velocity vi.

A constraint j 2 [1, . . . , M] consists of

• a cardinality nj,

• a function Cj : R3nj ! R,

• a set of indices fi1; . . . injg, ik 2 [1, . . . N],

• a stiffness parameter kj 2 [0 . . . 1] and

• a type of either equality or inequality.

equality

is

Constraint

j with type

satisfied if

Cjðxi1 ; . . . ; xinjÞ ¼ 0. If its type is inequality then it is satis-

fied if Cjðxi1 ; . . . ; xinjÞ P 0. The stiffness parameter kj

defines the strength of the constraint in a range from zero

to one.

�

M. Mu¨ ller et al. / J. Vis. Commun. Image R. 18 (2007) 109–118

111

Based on this data and a time step Dt, the dynamic

object is simulated as follows:

initialize xi ¼ x0

i , vi ¼ v0

i , wi = 1/mi

(1) forall vertices i

(2)

(3) endfor

(4) loop

(5)

(6)

(7)

(8)

forall vertices i do vi ‹ vi + Dtwifext(xi)

dampVelocities(v1, . . . , vN)

forall vertices i do pi ‹ xi + Dtvi

forall

vertices

i

generateCollisionConstraints(xi fi pi)

do

loop solverIterations times

projectConstraints(C1; . . . ; CMþM coll ; p1; . . . ; pN )

(9)

(10)

(11)

(12)

(13)

(14)

(15)

(16)

(17) endloop

endloop

forall vertices i

vi ‹ (pi � xi)/Dt

xi ‹ pi

endfor

velocityUpdate(v1, . . . , vN)

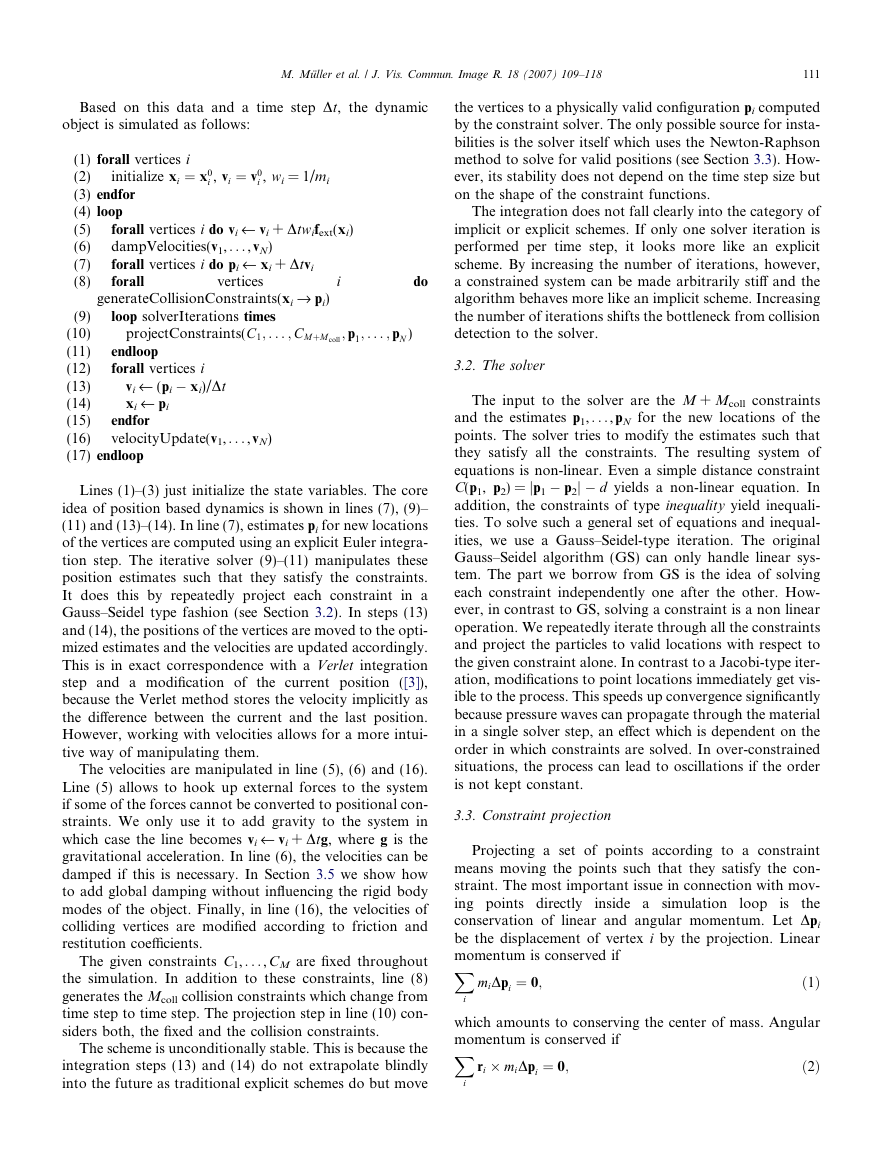

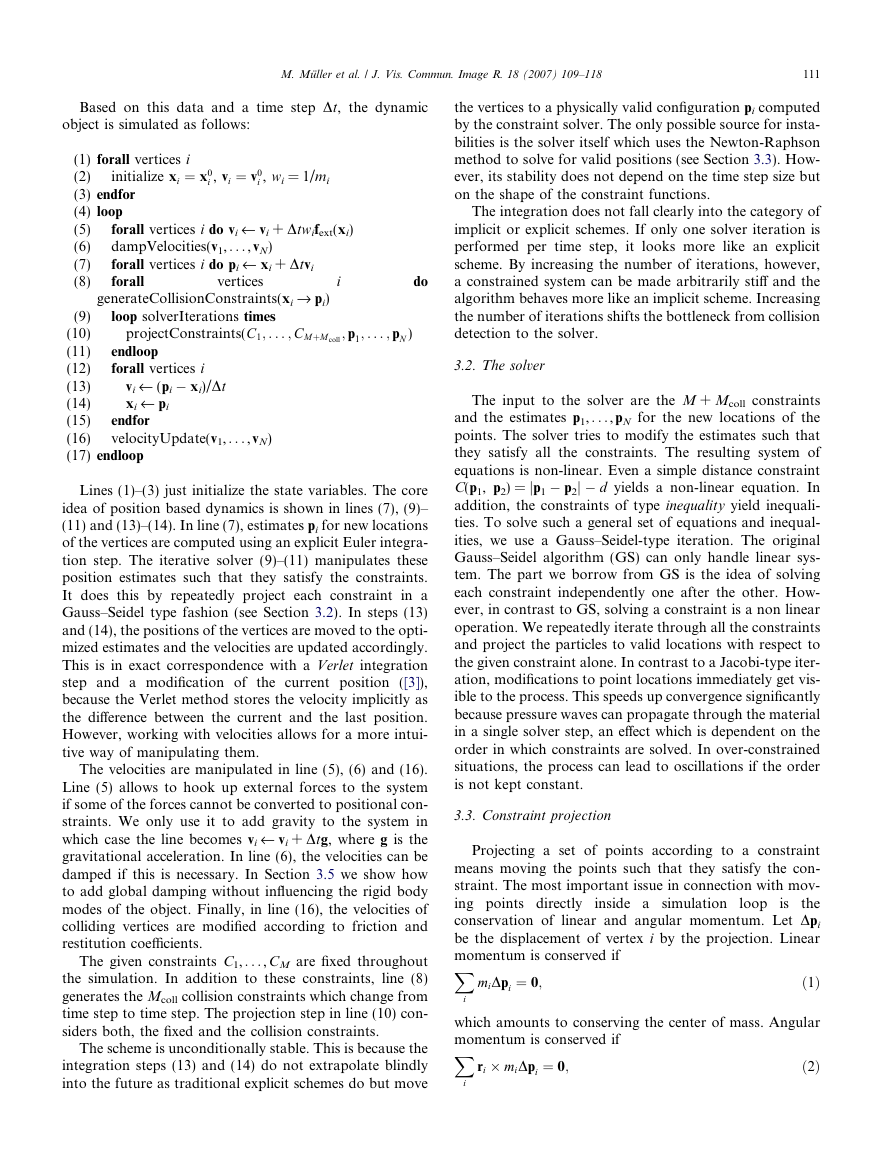

Lines (1)–(3) just initialize the state variables. The core

idea of position based dynamics is shown in lines (7), (9)–

(11) and (13)–(14). In line (7), estimates pi for new locations

of the vertices are computed using an explicit Euler integra-

tion step. The iterative solver (9)–(11) manipulates these

position estimates such that they satisfy the constraints.

It does this by repeatedly project each constraint in a

Gauss–Seidel type fashion (see Section 3.2). In steps (13)

and (14), the positions of the vertices are moved to the opti-

mized estimates and the velocities are updated accordingly.

This is in exact correspondence with a Verlet integration

step and a modification of the current position ([3]),

because the Verlet method stores the velocity implicitly as

the difference between the current and the last position.

However, working with velocities allows for a more intui-

tive way of manipulating them.

The velocities are manipulated in line (5), (6) and (16).

Line (5) allows to hook up external forces to the system

if some of the forces cannot be converted to positional con-

straints. We only use it to add gravity to the system in

which case the line becomes vi ‹ vi + Dtg, where g is the

gravitational acceleration. In line (6), the velocities can be

damped if this is necessary. In Section 3.5 we show how

to add global damping without influencing the rigid body

modes of the object. Finally, in line (16), the velocities of

colliding vertices are modified according to friction and

restitution coefficients.

The given constraints C1, . . . , CM are fixed throughout

the simulation. In addition to these constraints, line (8)

generates the Mcoll collision constraints which change from

time step to time step. The projection step in line (10) con-

siders both, the fixed and the collision constraints.

The scheme is unconditionally stable. This is because the

integration steps (13) and (14) do not extrapolate blindly

into the future as traditional explicit schemes do but move

the vertices to a physically valid configuration pi computed

by the constraint solver. The only possible source for insta-

bilities is the solver itself which uses the Newton-Raphson

method to solve for valid positions (see Section 3.3). How-

ever, its stability does not depend on the time step size but

on the shape of the constraint functions.

The integration does not fall clearly into the category of

implicit or explicit schemes. If only one solver iteration is

performed per time step, it looks more like an explicit

scheme. By increasing the number of iterations, however,

a constrained system can be made arbitrarily stiff and the

algorithm behaves more like an implicit scheme. Increasing

the number of iterations shifts the bottleneck from collision

detection to the solver.

3.2. The solver

The input to the solver are the M + Mcoll constraints

and the estimates p1, . . . , pN for the new locations of the

points. The solver tries to modify the estimates such that

they satisfy all the constraints. The resulting system of

equations is non-linear. Even a simple distance constraint

C(p1, p2) = jp1 � p2j � d yields a non-linear equation. In

addition, the constraints of type inequality yield inequali-

ties. To solve such a general set of equations and inequal-

ities, we use a Gauss–Seidel-type iteration. The original

Gauss–Seidel algorithm (GS) can only handle linear sys-

tem. The part we borrow from GS is the idea of solving

each constraint independently one after the other. How-

ever, in contrast to GS, solving a constraint is a non linear

operation. We repeatedly iterate through all the constraints

and project the particles to valid locations with respect to

the given constraint alone. In contrast to a Jacobi-type iter-

ation, modifications to point locations immediately get vis-

ible to the process. This speeds up convergence significantly

because pressure waves can propagate through the material

in a single solver step, an effect which is dependent on the

order in which constraints are solved. In over-constrained

situations, the process can lead to oscillations if the order

is not kept constant.

3.3. Constraint projection

Projecting a set of points according to a constraint

means moving the points such that they satisfy the con-

straint. The most important issue in connection with mov-

ing points directly inside a simulation loop is

the

conservation of linear and angular momentum. Let Dpi

be the displacement of vertex i by the projection. Linear

momentum is conserved if

X

miDpi ¼ 0;

i

ð1Þ

X

which amounts to conserving the center of mass. Angular

momentum is conserved if

ri � miDpi ¼ 0;

i

ð2Þ

�

112

M. Mu¨ ller et al. / J. Vis. Commun. Image R. 18 (2007) 109–118

Fig. 1. A known deformation benchmark test, applied here to a cloth character under pressure.

P

s ¼

where the ri are the distances of the pi to an arbitrary com-

mon rotation center. If a projection violates one of these

constraints, it introduces so called ghost forces which act

like external forces dragging and rotation the object. How-

ever, only internal constraints need to conserve the

momenta. Collision or attachment constraints are allowed

to have global effects on the object.

1 ; . . . ; pT

The method we propose for constraint projection con-

serves both momenta for internal constraints. Again, the

point based approach is more direct in that we can directly

use the constraint function while force based methods

derive forces via an energy term (see ([11,12])). Let us look

at a constraint with cardinality n on the points p1, . . . , pn

with constraint function C and stiffness k. We let p be the

concatenation ½pT

nT . For internal constraints, C is

independent of rigid body modes, i.e. translation and rota-

tion. This means that rotating or translating the points

does not change the value of the constraint function.

Therefore, the gradient $pC is perpendicular to rigid body

modes because it is the direction of maximal change. If the

correction Dp is chosen to be along $Cp both momenta are

automatically conserved if all masses are equal (we handle

different masses later). Given p we want to find a correction

Dp such that C(p + Dp) = 0. This equation can be approx-

imated by

Cðp þ DpÞ � CðpÞ þ rpCðpÞ � Dp ¼ 0:

Restricting Dp to be in the direction of $pC means choosing

a scalar k such that

Dp ¼ krpCðpÞ:

Substituting Eq. (4) into Eq. (3), solving for k and substi-

tuting it back into Eq. (4) yields the final formula for Dp

ð5Þ

Dp ¼ � CðpÞ

ð3Þ

ð4Þ

jrpCðpÞj2 rpCðpÞ;

which is a regular Newton-Raphson step for the iterative

solution of the non-linear equation given by a single con-

straint. For the correction of an individual point pi we have

Dpi ¼ �srpiCðp1; . . . ; pnÞ;

ð6Þ

where the scaling factor

Cðp1; . . . ; pnÞ

jjrpjCðp1; . . . ; pnÞj2

ð7Þ

is the same for all points. If the points have individual

masses, we extend the Newton–Raphson process by weight-

ing the corrections proportional to the inverse masses wi = 1/mi

Dpi ¼ �s

ð8Þ

rpiCðp1; . . . ; pnÞ;

n � wiP

jwj

to

points

To give an example, let us consider the distance constraint

function C(p1,p2) = jp1 � p2j � d. The derivative with re-

are rp1Cðp1; p2Þ ¼ n

spect

the

and

rp2Cðp1; p2Þ ¼ �n with n ¼ p1�p2

jp1�p2j. The scaling factor s is,

thus, s ¼ jp1�p2j�d

1þ1

Dp1 ¼ � w1

w1 þ w2

Dp2 ¼ þ w2

w1 þ w2

ðjp1 � p2j � dÞ p1 � p2

jp1 � p2j ;

ðjp1 � p2j � dÞ p1 � p2

jp1 � p2j ;

and the final corrections

ð9Þ

ð10Þ

which are the formulas proposed in ([3]) for the projection

of distance constraints (see Fig. 2). They pop up as a spe-

cial case of the general constraint projection method.

We have not considered the type and the stiffness k of

the constraint so far. Type handling is straight forward.

If the type is equality we always perform a projection. If

the type is inequality, the projection is only performed if

C(p1, . . ., pn) < 0. There are several ways of incorporating

the stiffness parameter. The simplest variant is to multiply

the corrections Dp by k 2 [0 . . . 1]. However, for multiple

iteration loops of the solver, the effect of k is non-linear.

The remaining error for a single distance constraint after

ns solver iterations is Dpð1 � kÞns . To get a linear relation-

ship we multiply the corrections not by k directly but by

k0 ¼ 1 � ð1 � kÞ1=ns. With this transformation the error

becomes Dpð1 � k0Þns ¼ Dpð1 � kÞ and, thus, becomes line-

arly dependent on k and independent of ns as desired. How-

2pΔ

2m

2p

1pΔ

d

1m

1p

Fig. 2. Projection of the constraint C(p1, p2) = jp1 � p2j � d. The correc-

tions Dpi are weighted according to the inverse masses wi = 1/mi.

�

M. Mu¨ ller et al. / J. Vis. Commun. Image R. 18 (2007) 109–118

113

ever, the resulting material stiffness is still dependent on the

time step of the simulation. Real time environments typi-

cally use fixed time steps in which case this dependency is

not problematic.

3.4. Collision detection and response

the simulation,

One advantage of the position based approach is how

simply collision response can be realized. In line (8) of the

simulation algorithm the Mcoll collision constraints are gen-

erated. While the first M constraints given by the object rep-

resentation are fixed throughout

the

additional Mcoll constraints are generated from scratch at

each time step. The number of collision constraints Mcoll

varies and depends on the number of colliding vertices.

Both, continuous and static collisions can be handled. For

continuous collision handling, we test for each vertex i the

ray xi fi pi. If this ray enters an object, we compute the entry

point qc and the surface normal nc at this position. An

inequality constraint with constraint

function C(p) =

(p � qc) Æ nc and stiffness k = 1 is added to the list of con-

straints. If the ray xi fi pi lies completely inside an object,

continuous collision detection has failed at some point. In

this case we fall back to static collision handling. We com-

pute the surface point qs which is closest to pi and the surface

normal ns at this position. An inequality constraint with con-

straint function C(p) = (p � qs) Æ ns and stiffness k = 1 is

added to the list of constraints. Collision constraint genera-

tion is done outside of the solver loop. This makes the sim-

ulation much faster. There are certain scenarios, however,

where collisions can be missed if the solver works with a fixed

collision constraint set. Fortunately, according to our

experience, the artifacts are negligible.

Friction and restitution can be handled by manipulating

the velocities of colliding vertices in step (16) of the algo-

rithm. The velocity of each vertex for which a collision con-

straint has been generated is dampened perpendicular to

the collision normal and reflected in the direction of the

collision normal.

The collision handling discussed above is only correct

for collisions with static objects because no impulse is

transferred to the collision partners. Correct response for

two dynamic colliding objects can be achieved by simulat-

ing both objects with our simulator, i.e. the N vertices and

M constraints which are the input to our algorithm simply

represent two or more independent objects. Then, if a point

q of one objects moves through a triangle p1, p2, p3 of

another object, we insert an inequality constraint with con-

straint function C(q, p1, p2, p3) = ±(q � p1) Æ [(p2 � p1) ·

(p3 � p1)] which keeps the point q on the correct side of

the triangle. Since this constraint function is independent

of rigid body modes, it will correctly conserve linear and

angular momentum. Collision detection gets slightly more

involved because the four vertices are represented by rays

xi fi pi. Therefore the collision of a moving point against

a moving triangle needs to be detected (see section about

cloth self collision).

3.5. Damping

�

�

�

P

�

P

�

�

i mi

imi

imi

iximi

ivimi

In line (6) of the simulation algorithm the velocities are

dampened before they are used for the prediction of the

new positions. Any form of damping can be used and many

methods for damping have been proposed in the literature

�

(see ([1])). Here we propose a new method with some inter-

P

�

esting properties:

P

P

(1) xcm ¼

=

P

(2) vcm ¼

=

iri · (mivi)

(3) L =

(4) I ¼

i~ri~rT

�1L

(5) x = I

(6) forall vertices i

(7)

(8)

(9) endfor

Here ri = xi � xcm, ~ri is the 3 by 3 matrix with the prop-

erty ~riv ¼ ri � v, and kdamping 2 [0 . . . 1] is the damping

coefficient. In lines (1)–(5) we compute the global linear

velocity xcm and angular velocity x of the system. Lines

(6)–z(9) then only damp the individual deviations Dvi of

the velocities vi from the global motion vcm + x · ri. Thus,

in the extreme case kdamping = 1, only the global motion

survives and the set of vertices behaves like a rigid body.

For arbitrary values of kdamping, the velocities are globally

dampened but without influencing the global motion of the

vertices.

Dvi = vcm + x · ri � vi

vi ‹ vi + kdamping Dvi

3.6. Attachments

With the position based approach, attaching vertices to

static or kinematic objects is quite simple. The position of

the vertex is simply set to the static target position or

updated at every time step to coincide with the position

of the kinematic object. To make sure other constraints

containing this vertex do not move it, its inverse mass wi

is set to zero.

4. Cloth simulation

We have used the point based dynamics framework to

implement a real time cloth simulator for games. In this

section we will discuss cloth specific issues thereby giving

concrete examples of the general concepts introduced in

the previous section.

4.1. Representation of cloth

Our cloth simulator accepts as input arbitrary triangle

meshes. The only restriction we impose on the input mesh

is that it represents a manifold, i.e. each edge is shared by at

most two triangles. Each node of the mesh becomes a sim-

ulated vertex. The user provides a density q given in mass

per area [kg/m2]. The mass of a vertex is set to the sum

�

114

M. Mu¨ ller et al. / J. Vis. Commun. Image R. 18 (2007) 109–118

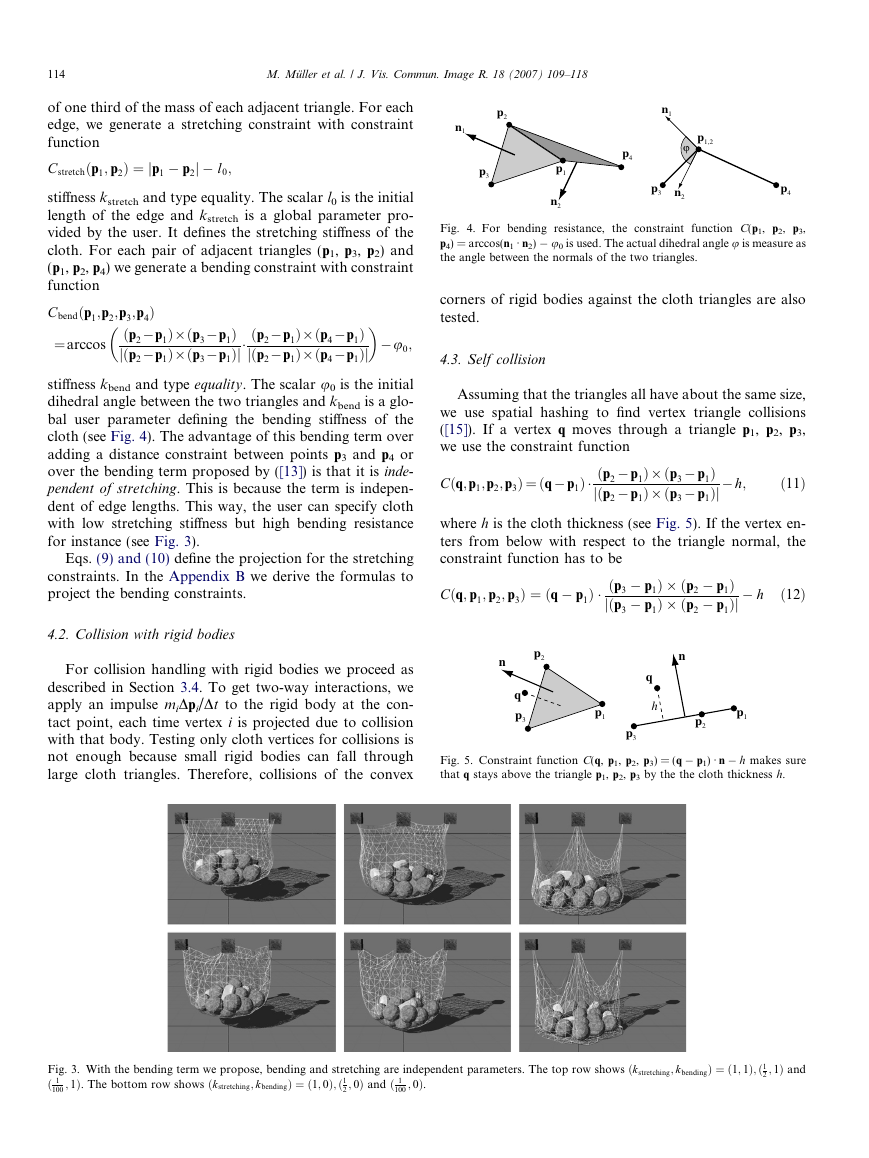

of one third of the mass of each adjacent triangle. For each

edge, we generate a stretching constraint with constraint

function

Cstretchðp1; p2Þ ¼ jp1 � p2j � l0;

stiffness kstretch and type equality. The scalar l0 is the initial

length of the edge and kstretch is a global parameter pro-

vided by the user. It defines the stretching stiffness of the

cloth. For each pair of adjacent triangles (p1, p3, p2) and

(p1, p2, p4) we generate a bending constraint with constraint

function

Cbendðp1;p2;p3;p4Þ

¼arccos

�

jðp2�p1Þ�ðp3�p1Þj� ðp2�p1Þ�ðp4�p1Þ

ðp2�p1Þ�ðp3�p1Þ

jðp2�p1Þ�ðp4�p1Þj

�u0;

�

stiffness kbend and type equality. The scalar u0 is the initial

dihedral angle between the two triangles and kbend is a glo-

bal user parameter defining the bending stiffness of the

cloth (see Fig. 4). The advantage of this bending term over

adding a distance constraint between points p3 and p4 or

over the bending term proposed by ([13]) is that it is inde-

pendent of stretching. This is because the term is indepen-

dent of edge lengths. This way, the user can specify cloth

with low stretching stiffness but high bending resistance

for instance (see Fig. 3).

Eqs. (9) and (10) define the projection for the stretching

constraints. In the Appendix B we derive the formulas to

project the bending constraints.

4.2. Collision with rigid bodies

For collision handling with rigid bodies we proceed as

described in Section 3.4. To get two-way interactions, we

apply an impulse miDpi/Dt to the rigid body at the con-

tact point, each time vertex i is projected due to collision

with that body. Testing only cloth vertices for collisions is

not enough because small rigid bodies can fall through

large cloth triangles. Therefore, collisions of the convex

2p

1n

3p

1p

2n

1n

1,2p

ϕ

4p

3p

2n

4p

Fig. 4. For bending resistance, the constraint function C(p1, p2, p3,

p4) = arccos(n1 Æ n2) � u0 is used. The actual dihedral angle u is measure as

the angle between the normals of the two triangles.

corners of rigid bodies against the cloth triangles are also

tested.

4.3. Self collision

Assuming that the triangles all have about the same size,

we use spatial hashing to find vertex triangle collisions

([15]). If a vertex q moves through a triangle p1, p2, p3,

we use the constraint function

Cðq; p1; p2; p3Þ¼ðq� p1Þ� ðp2 � p1Þ�ðp3 � p1Þ

jðp2 � p1Þ�ðp3 � p1Þj� h;

ð11Þ

where h is the cloth thickness (see Fig. 5). If the vertex en-

ters from below with respect to the triangle normal, the

constraint function has to be

Cðq; p1; p2; p3Þ ¼ ðq � p1Þ � ðp3 � p1Þ � ðp2 � p1Þ

jðp3 � p1Þ � ðp2 � p1Þj � h

ð12Þ

2p

n

q

3p

n

q

h

1p

3p

1p

2p

Fig. 5. Constraint function C(q, p1, p2, p3) = (q � p1) Æ n � h makes sure

that q stays above the triangle p1, p2, p3 by the the cloth thickness h.

Fig. 3. With the bending term we propose, bending and stretching are independent parameters. The top row shows ðkstretching; kbendingÞ ¼ ð1; 1Þ;ð1

100 ; 1Þ. The bottom row shows ðkstretching; kbendingÞ ¼ ð1; 0Þ;ð1

ð 1

2 ; 0Þ and ð 1

100 ; 0Þ.

2 ; 1Þ and

�

M. Mu¨ ller et al. / J. Vis. Commun. Image R. 18 (2007) 109–118

115

experiments have been carried out to analyze the character-

istics and the performance of the proposed method. All test

scenarios presented in this section have been performed on

a PC Pentium 4, 3 GHz.

5.1. Independent bending and stretching

Our bending term only depends on the dihedral angle of

adjacent triangles, not on edge lengths, so bending and

stretching resistances can be chosen independently. Fig. 3

shows a cloth bag with various stretching stiffnesses, first

with bending resistance enabled and then disabled. As the

top row shows, bending does not influence stretching

resistance.

5.2. Attachments with two way interaction

We can simulate both, one way and two way coupled

attachment constraints. The cloth stripes in Fig. 8 are

attached via one way constraints to the static rigid bodies

at the top. In addition, two way interaction is enabled

between the stripes and the bottom rigid bodies. This con-

figuration results in realistically looking swing and twist

motions of the stripes. The scene features 6 rigid bodies

and 3 pieces of cloth which are simulated and rendered

with more than 380 fps.

Fig. 6. This folded configuration demonstrates stable self collision and

response.

to keep the vertex on the original side. Projecting these con-

straints conserves linear and angular momentum which is

essential for cloth self collision since it is an internal pro-

cess. Fig. 6 shows a rest state of a piece of cloth with self

collisions. Testing continuous collisions is insufficient if

cloth gets into a tangled state, so methods like the ones

proposed by ([16]) have to be applied.

4.4. Cloth balloons

For closed triangle meshes, overpressure inside the mesh

can easily be modeled (see Fig. 7). We add an equality con-

straint concerning all N vertices of the mesh with constraint

function

!

X

ntriangles

i¼1

Cðp1; . . . ; pNÞ ¼

ðpti

1

� pti

2

Þ � pti

3

� kpressureV 0

ð13Þ

5.3. Real time self collision

1, ti

and stiffness k = 1 to the set of constraints. Here ti

2 and

ti

3 are the three indices of the vertices belonging to triangle

i. The sum computes the actual volume of the closed mesh.

It is compared against the original volume V0 times the

overpressure factor kpressure. This constraint function yields

the gradients

ðptj

rpiC ¼

X

X

X

� ptj

� ptj

Þ:

ð14Þ

Þþ

� ptj

3

Þþ

2

ðptj

1

ðptj

3

2

1¼i

j:t j

2¼i

j:t j

1

3¼i

j:t j

These gradients have to be scaled by the scaling factor gi-

ven in Eq. (7) and weighted by the masses according to

Eq. (8) to get the final projection offsets Dpi.

5. Results

We have integrated our method into Rocket ([17]), a

game-like environment for physics simulation. Various

The piece of cloth shown in Fig. 6 is composed of 1364

vertices and 2562 triangles. The simulation runs at 30 fps

on average including self collision detection, collision han-

dling and rendering. The effect of friction is shown in

Fig. 9, where the same piece of cloth is tumbling in a rotat-

ing barrel.

5.4. Tearing and stability

Fig. 10 shows a piece of cloth consisting of 4264 vertices

and 8262 triangles that is torn open by an attached cube

and finally ripped apart by a thrown ball. This scene is sim-

ulated and rendered with 47 fps on average. Tearing is sim-

ulated by a simple process: whenever the stretching of an

edge exceeds a specified threshold value, we select one of

the edge’s adjacent vertices. We then put a split plane

through that vertex perpendicular to the edge direction

Fig. 7. Simulation of overpressure inside a character.

�

116

M. Mu¨ ller et al. / J. Vis. Commun. Image R. 18 (2007) 109–118

Fig. 8. Cloth stripes are attached via one way interaction to static rigid bodies at the top and via two way constraints to rigid bodies at the bottom.

Fig. 9. Influenced by collision, self collision and friction, a piece of cloth tumbles in a rotating barrel.

Fig. 10. A piece of cloth is torn open by an attached cube and ripped apart by a thrown ball.

Fig. 11. Three inflated characters experience multiple collisions and self collisions.

and split the vertex. All triangles above the split plane are

assigned to the original vertex while all triangles below are

assigned to the duplicate. Our method remains stable even

in extreme situations as shown in Fig. 1, a scene inspired by

([18]). An inflated character model is squeezed through

rotating gears resulting in multiple constraints, collisions

and self collisions acting on single cloth vertices (Fig. 11).

5.5. Complex simulation scenarios

The presented method is especially suited for complex

simulation environments (see Fig. 12). Despite the exten-

sive interaction with animated characters and geometrically

complex game levels, simulation and rendering of multiple

pieces of cloth can still be done at interactive speed.

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc