KUKA System Software 8.3

6.16

Torque mode

6.16.1 Overview of torque mode

Description

Restriction

The torque mode function consists of the sub-functionalities torque limita-

tion and deactivation of monitoring functions.

Torque limitation:

The torques, i.e. the motor current, can be limited for individual axes or multi-

ple axes. Torque limitation enables the following applications:

The axis can push or pull with a defined torque against a resistance.

Example:

application of a defined pressure on the workpiece by an electric motor-

driven spot welding gun.

The axis can be set to soft. It can then be moved by application of an ex-

ternal force. It can be pushed away, for example.

Examples:

The robot must grip a workpiece in a press that is then ejected by the

press. In order for the robot to be able to yield and absorb the ejector

stroke, the affected axis is set to soft.

The robot must set a workpiece down at a point from which it can be pulled

into exactly the right position by means of clamps. The robot must be com-

pliant for this.

Deactivation of monitoring functions:

The torque limitation generally results in a relatively large deviation between

the command position and the actual position. Certain monitoring functions

are triggered by this deviation, although this is undesirable with torque limita-

tion. These regular monitoring functions can thus be deactivated.

The following restriction must be taken into consideration if axes are to absorb

ejector motions:

A diagonal ejector motion cannot generally be absorbed by switching a single

axis to soft. Remedy:

In the case of slightly diagonal ejector motions, a possible remedy is to in-

stall the robot with a slight inclination.

Or contact KUKA Roboter GmbH.

Inclined installation of the robot is only permissible up to a certain an-

gle of inclination. Further information is contained in the robot operat-

ing or assembly instructions.

6.16.1.1 Using torque mode

Torque mode is only possible in program mode, not in manual mode.

204 / 477

Issued: 24.01.2014 Version: KSS 8.3 SI V2

�

6 Configuration

By default, the robot controller is configured so that only

limits that exceed the holding torque of the axis

($HOLDING_TORQUE) can be set. It is nonetheless possible that the axis

with limited torque is no longer able to achieve the necessary torque for brak-

ing, holding or moving the axis. This can be the case, for example, if the de-

fault configuration of the robot controller has been changed or incorrect load

data are used.

Incorrectly set values can result in unexpected behavior of the robot control-

ler, e.g. motion in a different direction or with different acceleration.

For this reason:

Only ever limit the torque in small steps, gradually approaching the re-

quired limit.

Do not limit the torque further than necessary.

Failure to take this precaution into consideration may result in death, injuries

or damage to property.

If an application requires torque limits that no longer exceed the hold-

ing torque of the axis, KUKA Roboter GmbH must be contacted.

1. Set the torque limits for the desired axis and/or deactivate the regular mon-

itoring functions.

(>>> 6.16.2 "Activating torque mode: SET_TORQUE_LIMITS()"

Page 207)

If the regular monitoring functions are deactivated, other monitoring func-

tions specially adapted to torque mode are automatically activated.

(>>> "Monitoring functions" Page 206)

If the axis is to be set to soft: move the axis so that the torque limit be-

comes active. At the end of the motion, the brakes of this axis remain

open.

Alternatively, a motion to the current position can be executed. The robot

does not move, but the brakes are released.

2.

3. Optionally: generate a signal indicating that the axis is stationary (e.g. sig-

nal to an injection molding machine).

4. Perform the desired action, e.g. move to workpiece and build up pressure

or push the axis away.

5. Optionally: wait for a signal to end torque mode.

6. Deactivate torque mode again.

(>>> 6.16.3 "Deactivating torque mode: RESET_TORQUE_LIMITS()"

Page 210)

The torque limits are canceled and the regular monitoring functions are re-

activated. Furthermore, the command position is adjusted to the actual po-

sition.

Torque mode is considered to be activated in the following case:

If the upper torque limit is less than or equal to the upper value of the

$TORQUE_AXIS_MAX interval.

(>>> 6.16.5.3 "$TORQUE_AXIS_MAX" Page 212)

And/or: If the lower torque limit is greater than or equal to the lower value

of the $TORQUE_AXIS_MAX interval.

And/or: If the regular monitoring functions are deactivated.

Torque mode is considered to be deactivated in the following case:

If no limits are set or if the limits are invalid. A limit is invalid if it is outside

the $TORQUE_AXIS_MAX interval.

Procedure

Activated/deacti-

vated

Issued: 24.01.2014 Version: KSS 8.3 SI V2

205 / 477

�

KUKA System Software 8.3

Automatic deacti-

vation

Monitoring

functions

And: If the regular monitoring functions are deactivated.

Torque mode is automatically deactivated in the following cases:

End of program

Program reset

Program deselection

Block selection (but no deactivation if the target of the block selection is in

an interrupt program)

RESUME (but no deactivation if the RESUME statement returns to an in-

terrupt program)

Manual mode is activated. Planning is carried out from the current actual

position and motion is resumed with full torque.

Torque mode generally results in a relatively large deviation between the com-

mand position and the actual position. Certain monitoring functions are trig-

gered by this deviation, although this is undesirable in torque mode. These

regular monitoring functions can thus be deactivated using

SET_TORQUE_LIMITS().

If the regular monitoring functions are deactivated, other monitoring functions

specially adapted to torque mode are automatically activated for the actual ve-

locity and following error. If required, user-defined values can be set for these

special monitoring functions using SET_TORQUE_LIMITS().

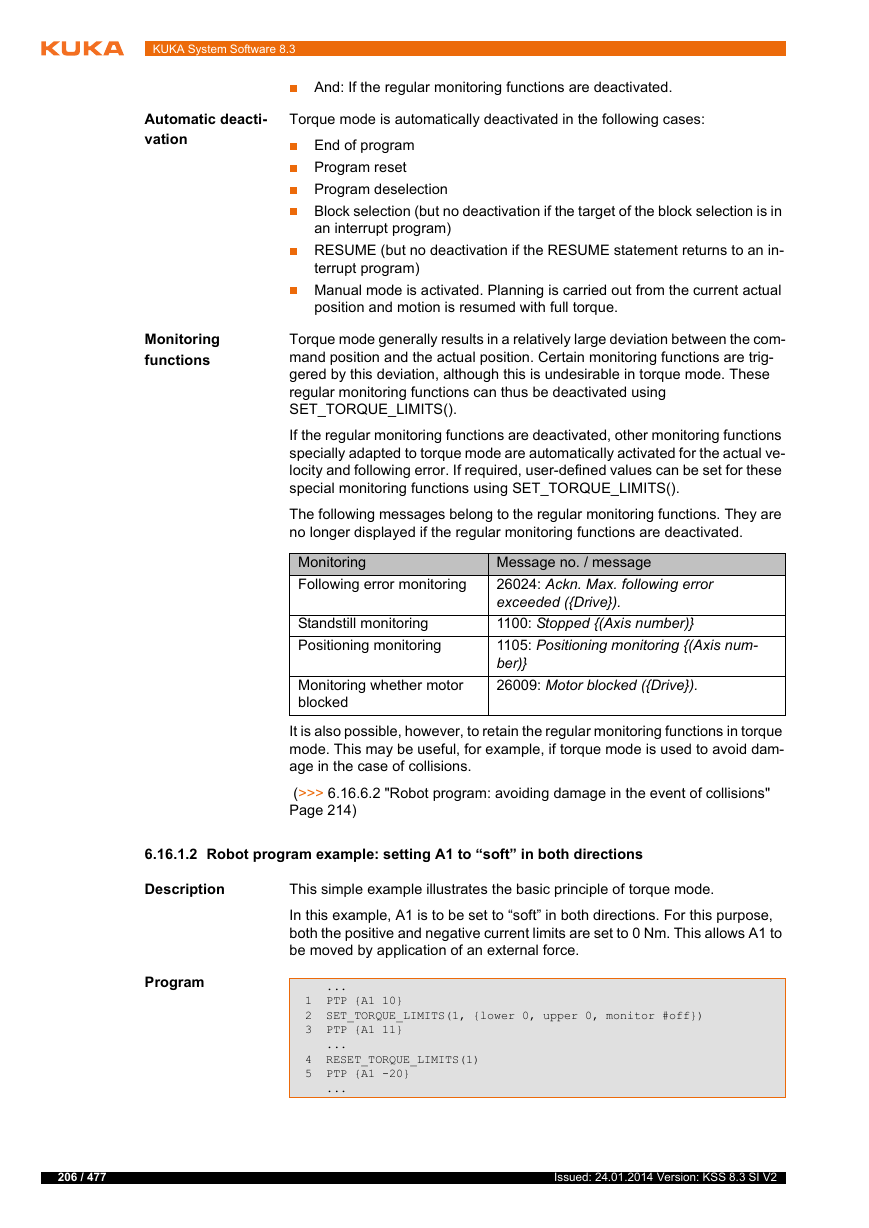

The following messages belong to the regular monitoring functions. They are

no longer displayed if the regular monitoring functions are deactivated.

Monitoring

Following error monitoring

Standstill monitoring

Positioning monitoring

Monitoring whether motor

blocked

Message no. / message

26024: Ackn. Max. following error

exceeded ({Drive}).

1100: Stopped {(Axis number)}

1105: Positioning monitoring {(Axis num-

ber)}

26009: Motor blocked ({Drive}).

It is also possible, however, to retain the regular monitoring functions in torque

mode. This may be useful, for example, if torque mode is used to avoid dam-

age in the case of collisions.

(>>> 6.16.6.2 "Robot program: avoiding damage in the event of collisions"

Page 214)

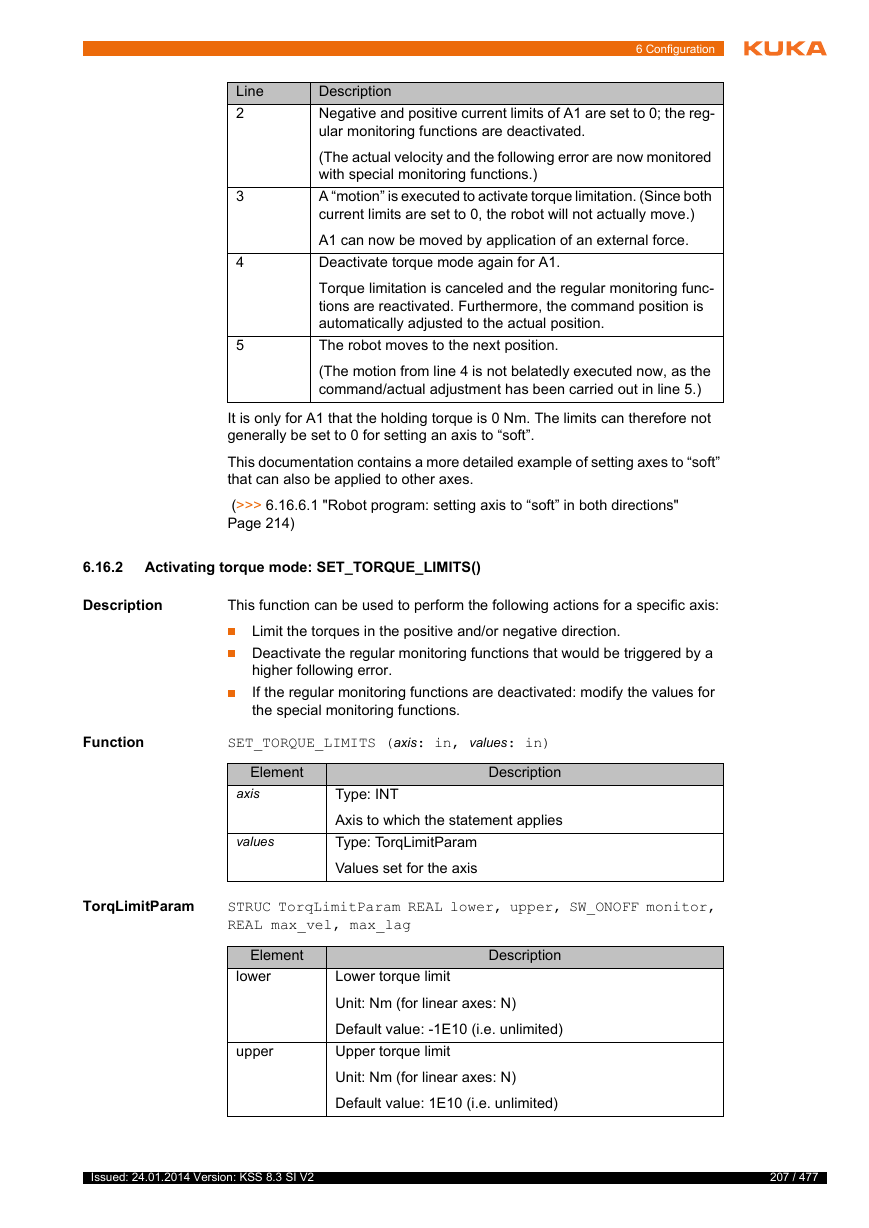

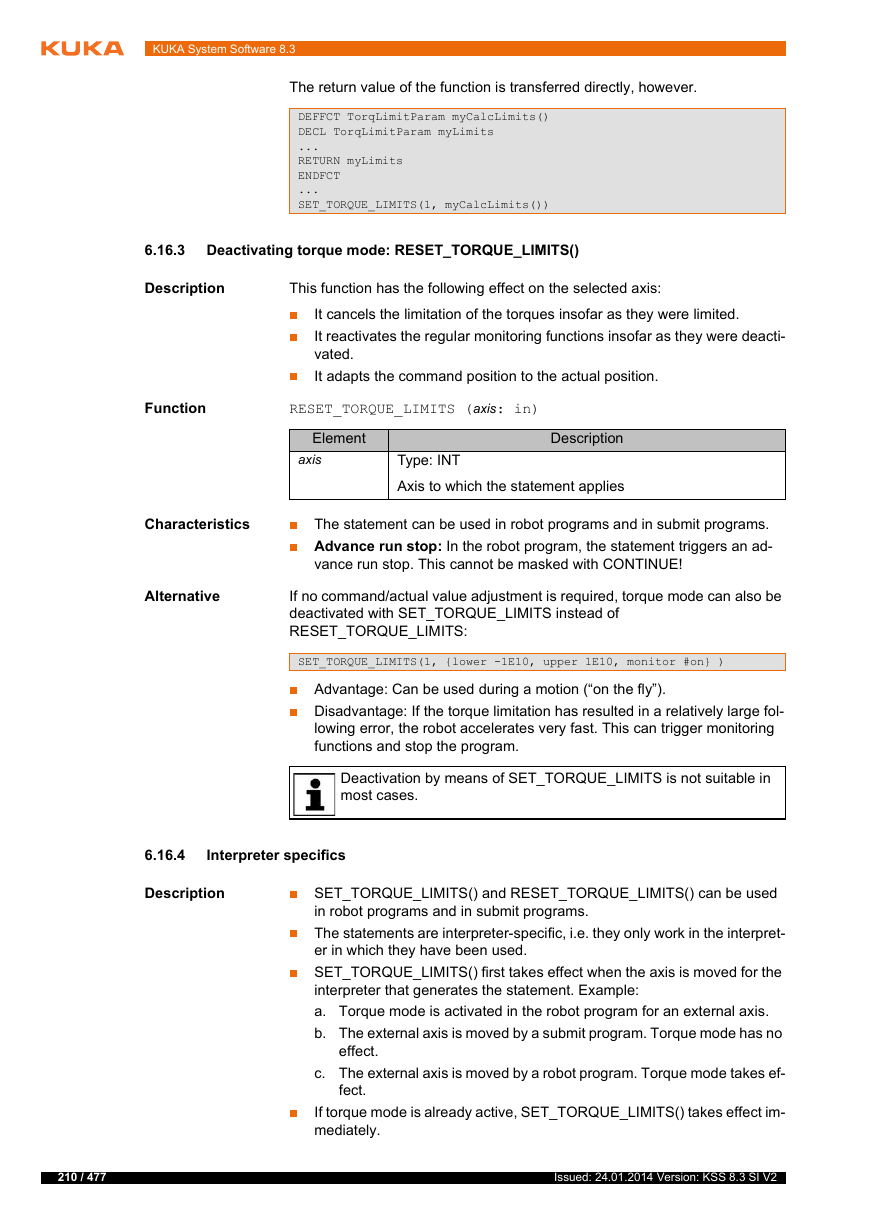

6.16.1.2 Robot program example: setting A1 to soft in both directions

Description

Program

This simple example illustrates the basic principle of torque mode.

In this example, A1 is to be set to soft in both directions. For this purpose,

both the positive and negative current limits are set to 0 Nm. This allows A1 to

be moved by application of an external force.

...

1 PTP {A1 10}

2 SET_TORQUE_LIMITS(1, {lower 0, upper 0, monitor #off})

3 PTP {A1 11}

...

4 RESET_TORQUE_LIMITS(1)

5 PTP {A1 -20}

...

206 / 477

Issued: 24.01.2014 Version: KSS 8.3 SI V2

�

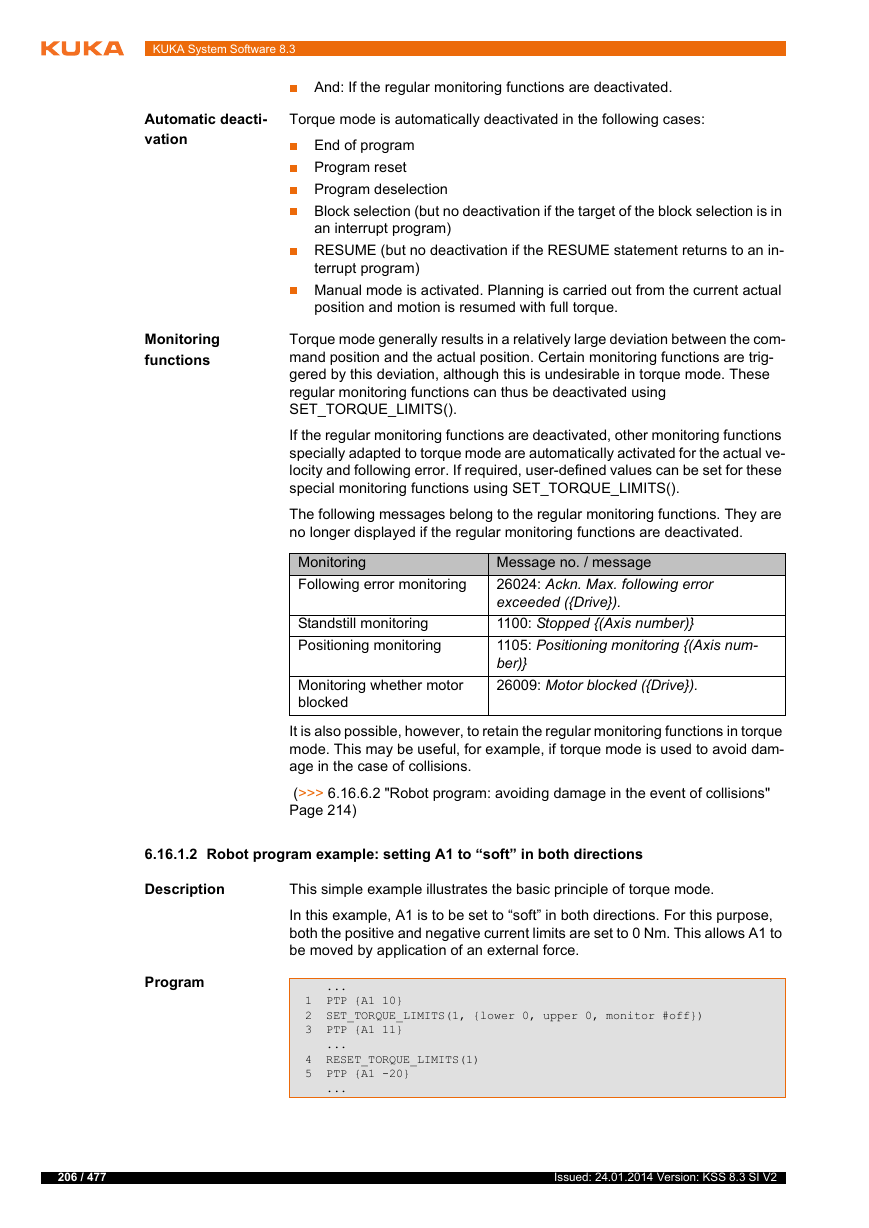

Line

2

3

4

5

6 Configuration

Description

Negative and positive current limits of A1 are set to 0; the reg-

ular monitoring functions are deactivated.

(The actual velocity and the following error are now monitored

with special monitoring functions.)

A motion is executed to activate torque limitation. (Since both

current limits are set to 0, the robot will not actually move.)

A1 can now be moved by application of an external force.

Deactivate torque mode again for A1.

Torque limitation is canceled and the regular monitoring func-

tions are reactivated. Furthermore, the command position is

automatically adjusted to the actual position.

The robot moves to the next position.

(The motion from line 4 is not belatedly executed now, as the

command/actual adjustment has been carried out in line 5.)

It is only for A1 that the holding torque is 0 Nm. The limits can therefore not

generally be set to 0 for setting an axis to soft.

This documentation contains a more detailed example of setting axes to soft

that can also be applied to other axes.

(>>> 6.16.6.1 "Robot program: setting axis to soft in both directions"

Page 214)

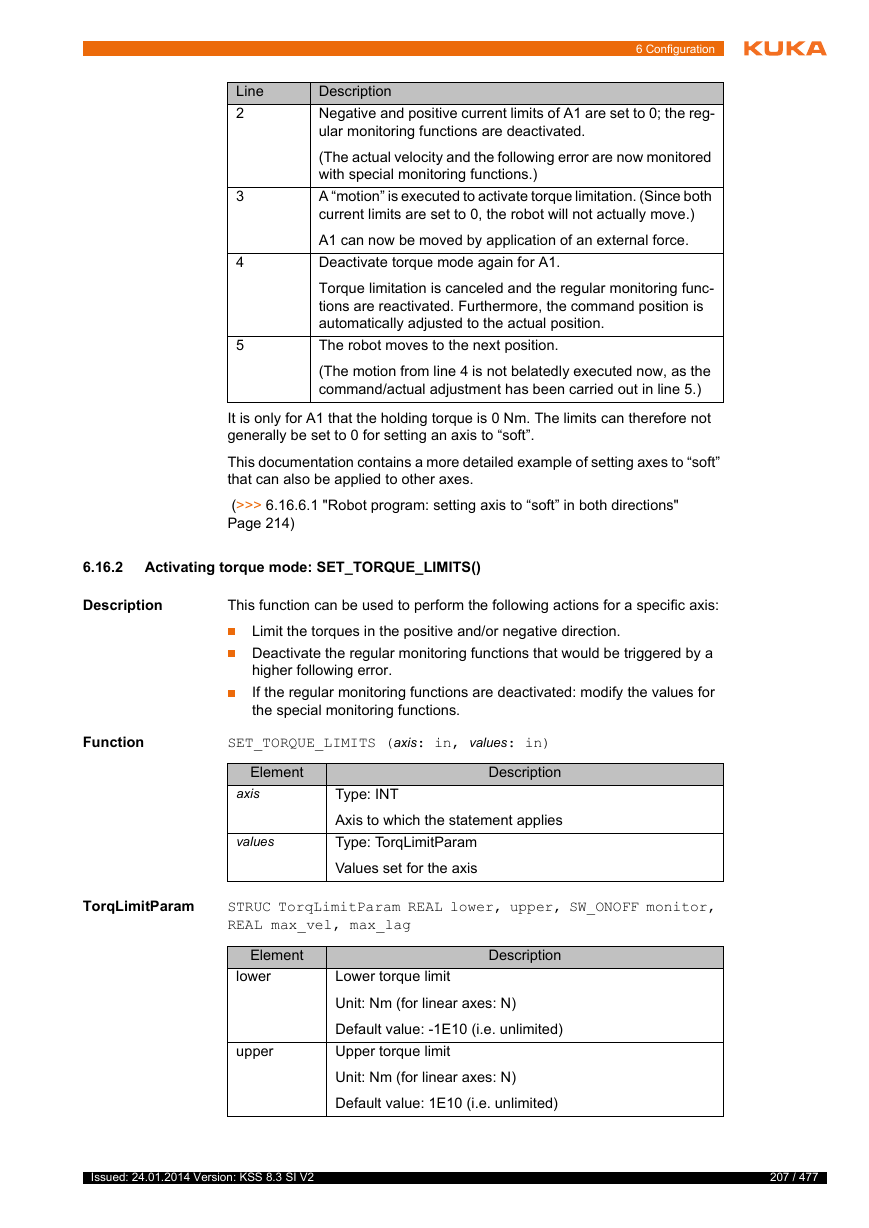

6.16.2

Activating torque mode: SET_TORQUE_LIMITS()

Description

This function can be used to perform the following actions for a specific axis:

Limit the torques in the positive and/or negative direction.

Deactivate the regular monitoring functions that would be triggered by a

higher following error.

If the regular monitoring functions are deactivated: modify the values for

the special monitoring functions.

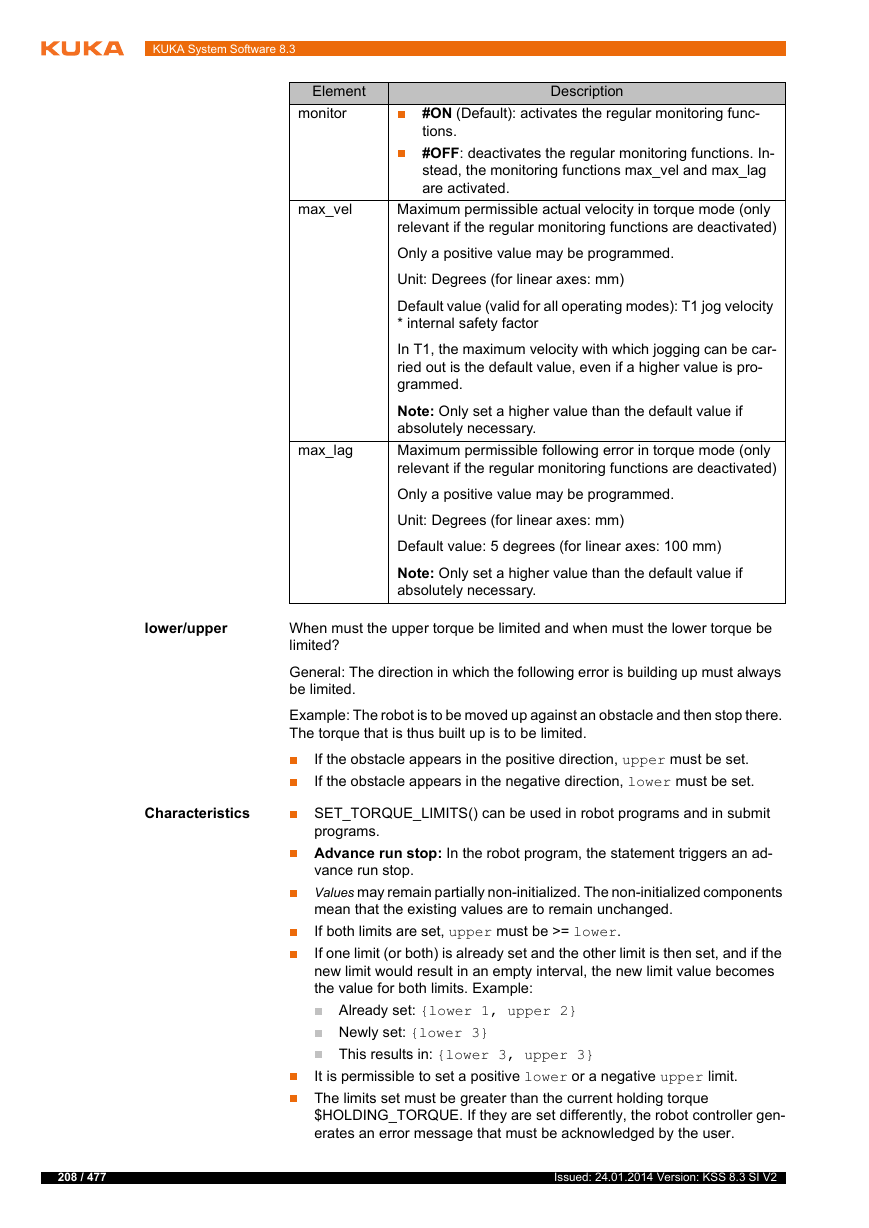

Function

SET_TORQUE_LIMITS (axis: in, values: in)

Description

Element

axis

values

Type: INT

Axis to which the statement applies

Type: TorqLimitParam

Values set for the axis

TorqLimitParam

STRUC TorqLimitParam REAL lower, upper, SW_ONOFF monitor,

REAL max_vel, max_lag

Element

lower

upper

Description

Lower torque limit

Unit: Nm (for linear axes: N)

Default value: -1E10 (i.e. unlimited)

Upper torque limit

Unit: Nm (for linear axes: N)

Default value: 1E10 (i.e. unlimited)

Issued: 24.01.2014 Version: KSS 8.3 SI V2

207 / 477

�

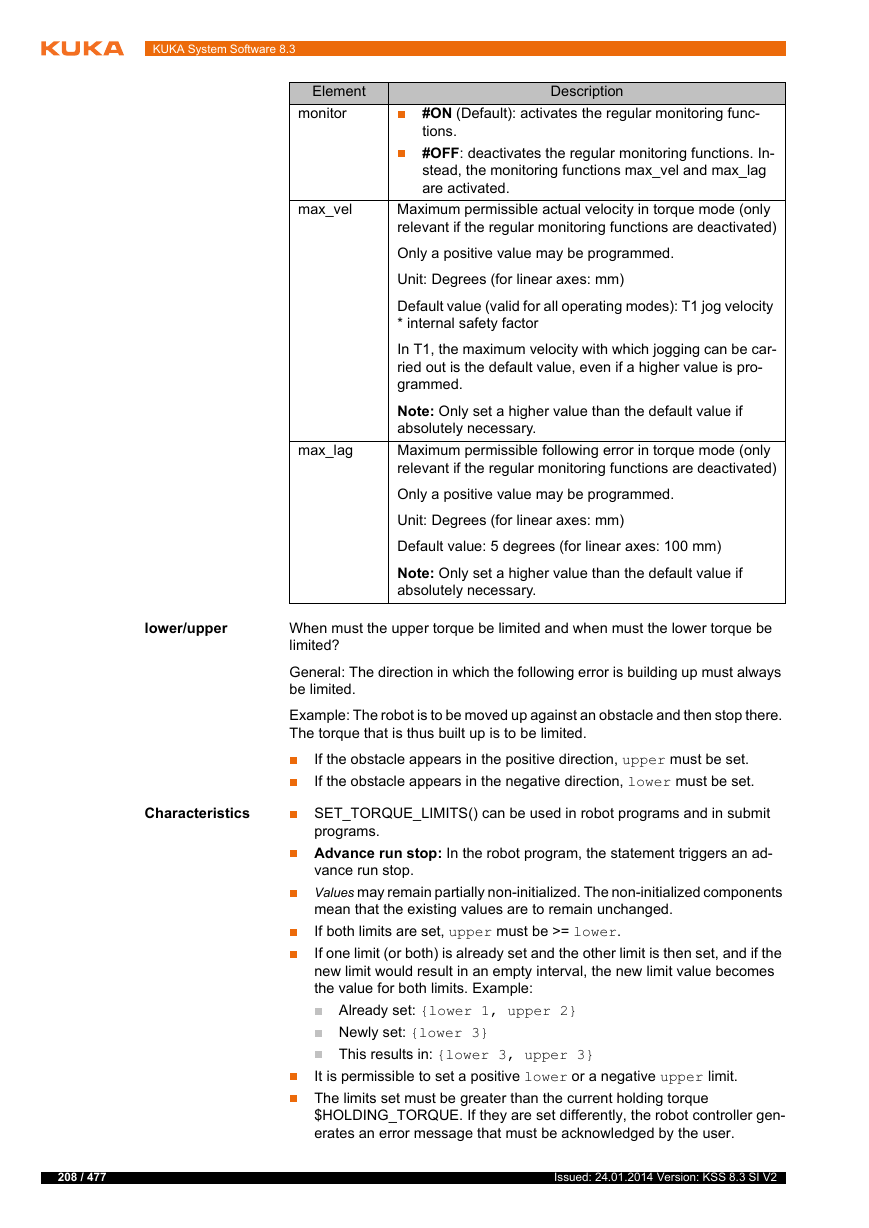

KUKA System Software 8.3

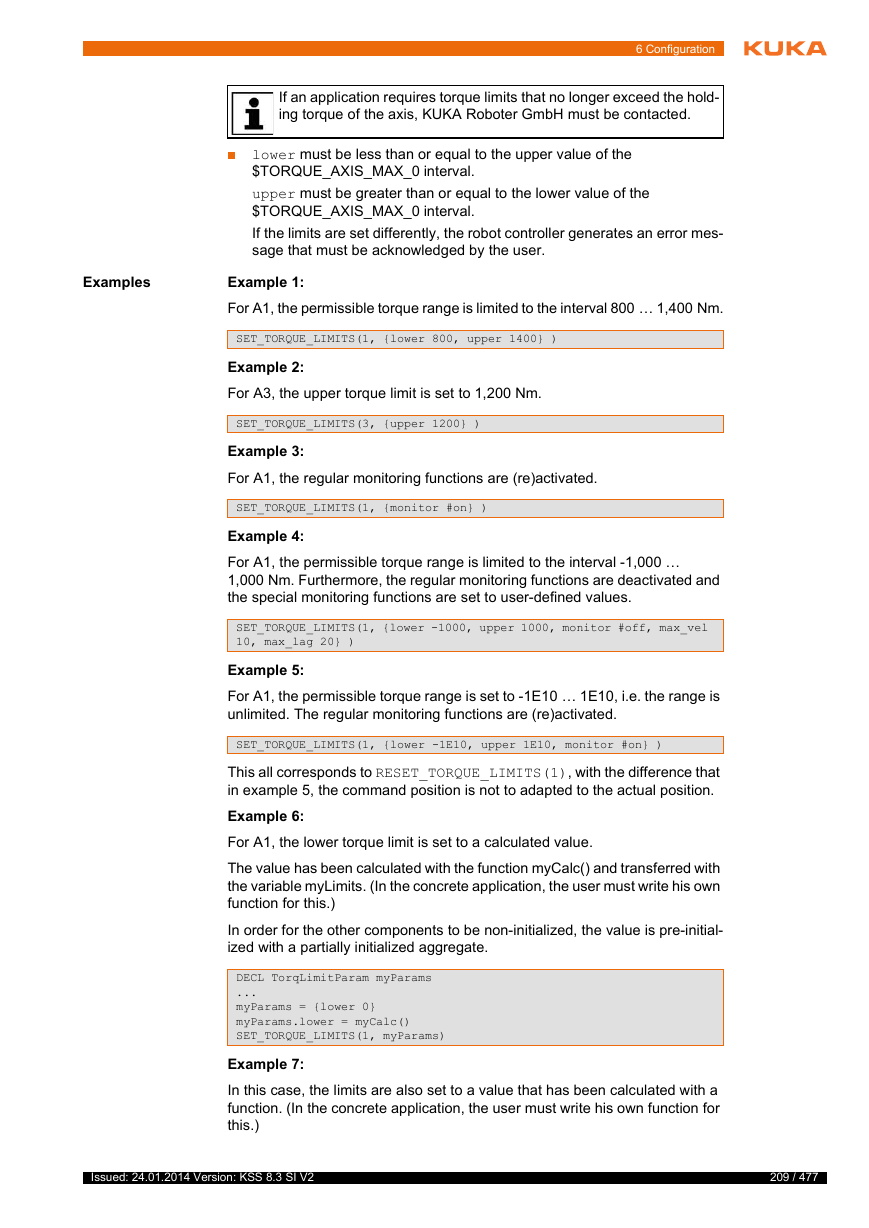

Element

monitor

max_vel

max_lag

Description

#ON (Default): activates the regular monitoring func-

tions.

#OFF: deactivates the regular monitoring functions. In-

stead, the monitoring functions max_vel and max_lag

are activated.

Maximum permissible actual velocity in torque mode (only

relevant if the regular monitoring functions are deactivated)

Only a positive value may be programmed.

Unit: Degrees (for linear axes: mm)

Default value (valid for all operating modes): T1 jog velocity

* internal safety factor

In T1, the maximum velocity with which jogging can be car-

ried out is the default value, even if a higher value is pro-

grammed.

Note: Only set a higher value than the default value if

absolutely necessary.

Maximum permissible following error in torque mode (only

relevant if the regular monitoring functions are deactivated)

Only a positive value may be programmed.

Unit: Degrees (for linear axes: mm)

Default value: 5 degrees (for linear axes: 100 mm)

Note: Only set a higher value than the default value if

absolutely necessary.

When must the upper torque be limited and when must the lower torque be

limited?

General: The direction in which the following error is building up must always

be limited.

Example: The robot is to be moved up against an obstacle and then stop there.

The torque that is thus built up is to be limited.

If the obstacle appears in the positive direction, upper must be set.

If the obstacle appears in the negative direction, lower must be set.

SET_TORQUE_LIMITS() can be used in robot programs and in submit

programs.

Advance run stop: In the robot program, the statement triggers an ad-

vance run stop.

Values may remain partially non-initialized. The non-initialized components

mean that the existing values are to remain unchanged.

If both limits are set, upper must be >= lower.

If one limit (or both) is already set and the other limit is then set, and if the

new limit would result in an empty interval, the new limit value becomes

the value for both limits. Example:

Already set: {lower 1, upper 2}

Newly set: {lower 3}

This results in: {lower 3, upper 3}

It is permissible to set a positive lower or a negative upper limit.

The limits set must be greater than the current holding torque

$HOLDING_TORQUE. If they are set differently, the robot controller gen-

erates an error message that must be acknowledged by the user.

lower/upper

Characteristics

208 / 477

Issued: 24.01.2014 Version: KSS 8.3 SI V2

�

6 Configuration

If an application requires torque limits that no longer exceed the hold-

ing torque of the axis, KUKA Roboter GmbH must be contacted.

lower must be less than or equal to the upper value of the

$TORQUE_AXIS_MAX_0 interval.

upper must be greater than or equal to the lower value of the

$TORQUE_AXIS_MAX_0 interval.

If the limits are set differently, the robot controller generates an error mes-

sage that must be acknowledged by the user.

Examples

Example 1:

For A1, the permissible torque range is limited to the interval 800

1,400 Nm.

SET_TORQUE_LIMITS(1, {lower 800, upper 1400} )

Example 2:

For A3, the upper torque limit is set to 1,200 Nm.

SET_TORQUE_LIMITS(3, {upper 1200} )

Example 3:

For A1, the regular monitoring functions are (re)activated.

SET_TORQUE_LIMITS(1, {monitor #on} )

Example 4:

For A1, the permissible torque range is limited to the interval -1,000

1,000 Nm. Furthermore, the regular monitoring functions are deactivated and

the special monitoring functions are set to user-defined values.

SET_TORQUE_LIMITS(1, {lower -1000, upper 1000, monitor #off, max_vel

10, max_lag 20} )

Example 5:

For A1, the permissible torque range is set to -1E10

1E10, i.e. the range is

unlimited. The regular monitoring functions are (re)activated.

SET_TORQUE_LIMITS(1, {lower -1E10, upper 1E10, monitor #on} )

This all corresponds to RESET_TORQUE_LIMITS(1), with the difference that

in example 5, the command position is not to adapted to the actual position.

Example 6:

For A1, the lower torque limit is set to a calculated value.

The value has been calculated with the function myCalc() and transferred with

the variable myLimits. (In the concrete application, the user must write his own

function for this.)

In order for the other components to be non-initialized, the value is pre-initial-

ized with a partially initialized aggregate.

DECL TorqLimitParam myParams

...

myParams = {lower 0}

myParams.lower = myCalc()

SET_TORQUE_LIMITS(1, myParams)

Example 7:

In this case, the limits are also set to a value that has been calculated with a

function. (In the concrete application, the user must write his own function for

this.)

Issued: 24.01.2014 Version: KSS 8.3 SI V2

209 / 477

�

KUKA System Software 8.3

The return value of the function is transferred directly, however.

DEFFCT TorqLimitParam myCalcLimits()

DECL TorqLimitParam myLimits

...

RETURN myLimits

ENDFCT

...

SET_TORQUE_LIMITS(1, myCalcLimits())

6.16.3

Deactivating torque mode: RESET_TORQUE_LIMITS()

Description

This function has the following effect on the selected axis:

It cancels the limitation of the torques insofar as they were limited.

It reactivates the regular monitoring functions insofar as they were deacti-

vated.

It adapts the command position to the actual position.

Function

RESET_TORQUE_LIMITS (axis: in)

Element

axis

Description

Type: INT

Axis to which the statement applies

Characteristics

Alternative

The statement can be used in robot programs and in submit programs.

Advance run stop: In the robot program, the statement triggers an ad-

vance run stop. This cannot be masked with CONTINUE!

If no command/actual value adjustment is required, torque mode can also be

deactivated with SET_TORQUE_LIMITS instead of

RESET_TORQUE_LIMITS:

SET_TORQUE_LIMITS(1, {lower -1E10, upper 1E10, monitor #on} )

Advantage: Can be used during a motion (on the fly).

Disadvantage: If the torque limitation has resulted in a relatively large fol-

lowing error, the robot accelerates very fast. This can trigger monitoring

functions and stop the program.

Deactivation by means of SET_TORQUE_LIMITS is not suitable in

most cases.

6.16.4

Interpreter specifics

Description

SET_TORQUE_LIMITS() and RESET_TORQUE_LIMITS() can be used

in robot programs and in submit programs.

The statements are interpreter-specific, i.e. they only work in the interpret-

er in which they have been used.

SET_TORQUE_LIMITS() first takes effect when the axis is moved for the

interpreter that generates the statement. Example:

a. Torque mode is activated in the robot program for an external axis.

b. The external axis is moved by a submit program. Torque mode has no

effect.

c. The external axis is moved by a robot program. Torque mode takes ef-

fect.

If torque mode is already active, SET_TORQUE_LIMITS() takes effect im-

mediately.

210 / 477

Issued: 24.01.2014 Version: KSS 8.3 SI V2

�

Example

6 Configuration

SET_TORQUE_LIMITS() works immediately if a motion is active. For this

reason, the torque limits can be set at any time in robot programs, both in-

side and outside an interrupt, and the monitoring functions can be activat-

ed and deactivated.

It is also possible to use torque mode inside an interrupt program only. (If

RESET_TORQUE_LIMITS() is used, it may subsequently be necessary to

return to the interrupt position with PTP $AXIS_RET.)

(>>> 6.16.6.3 "Robot program: torque mode in the interrupt" Page 216)

When a torque-driven axis changes owner, the command position is ad-

justed to the actual position.

Change of owner means: an interpreter has moved the axis in torque

mode (and thus owns it). While torque mode is active, the axis is moved

by a different interpreter.

The main application here is: jogging after a program has been interrupted

in torque mode.

The following example shows when SET_TORQUE_LIMITS() is effective, de-

pending on whether torque mode is already active or not.

Initial situation (default): the monitoring functions are activated.

1 SET_TORQUE_LIMITS(1, {monitor #off})

2 HALT

3 PTP_REL {A1 10}

4 HALT

5 SET_TORQUE_LIMITS(1, {monitor #on})

6 HALT

7 PTP_REL {A1 15}

Line

1

2

3

4

5

6

Description

The monitoring functions for A1 are deactivated.

Here the monitoring functions are still activated.

The axis is moved. From here on, the statement

SET_TORQUE_LIMITS is effective.

The monitoring functions are deactivated.

The monitoring functions are activated.

Here the monitoring functions are already activated. Because

torque limitation was already active, the statement took effect

immediately and not just after the next motion of this axis.

6.16.5

Diagnostic variables for torque mode

All these variables and constants are write-protected.

Their value is not dependent on the interpreter.

6.16.5.1 $TORQUE_AXIS_ACT

Variable

Description

$TORQUE_AXIS_ACT[axis number]

Data type: REAL

Current motor torque for axis [axis number]

Unit: Nm (for linear axes: N)

The value is only relevant if the brakes are released. If the brakes are applied,

it is virtually zero.

Advance run stop: In the robot program, the variable triggers an advance run

stop.

Issued: 24.01.2014 Version: KSS 8.3 SI V2

211 / 477

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc