组合 3

组合 2

组合 1

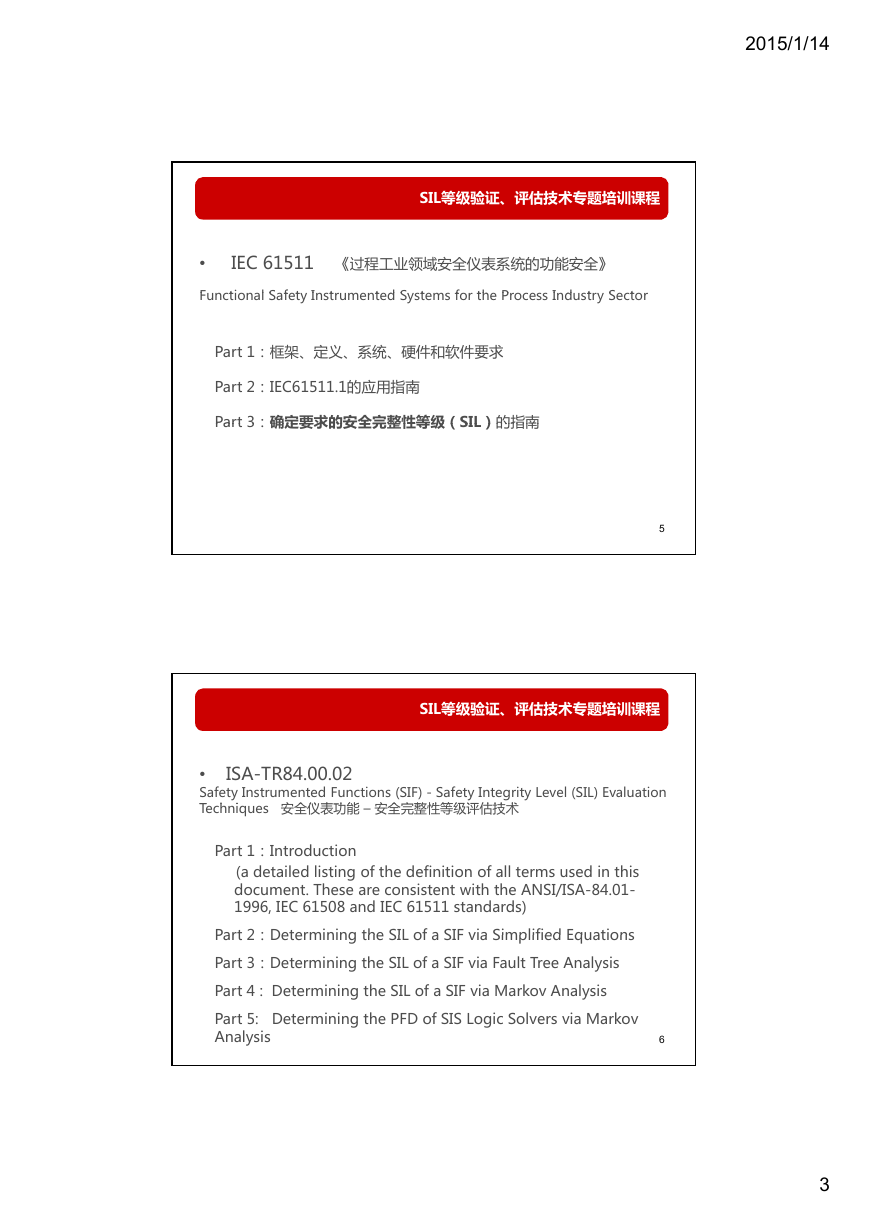

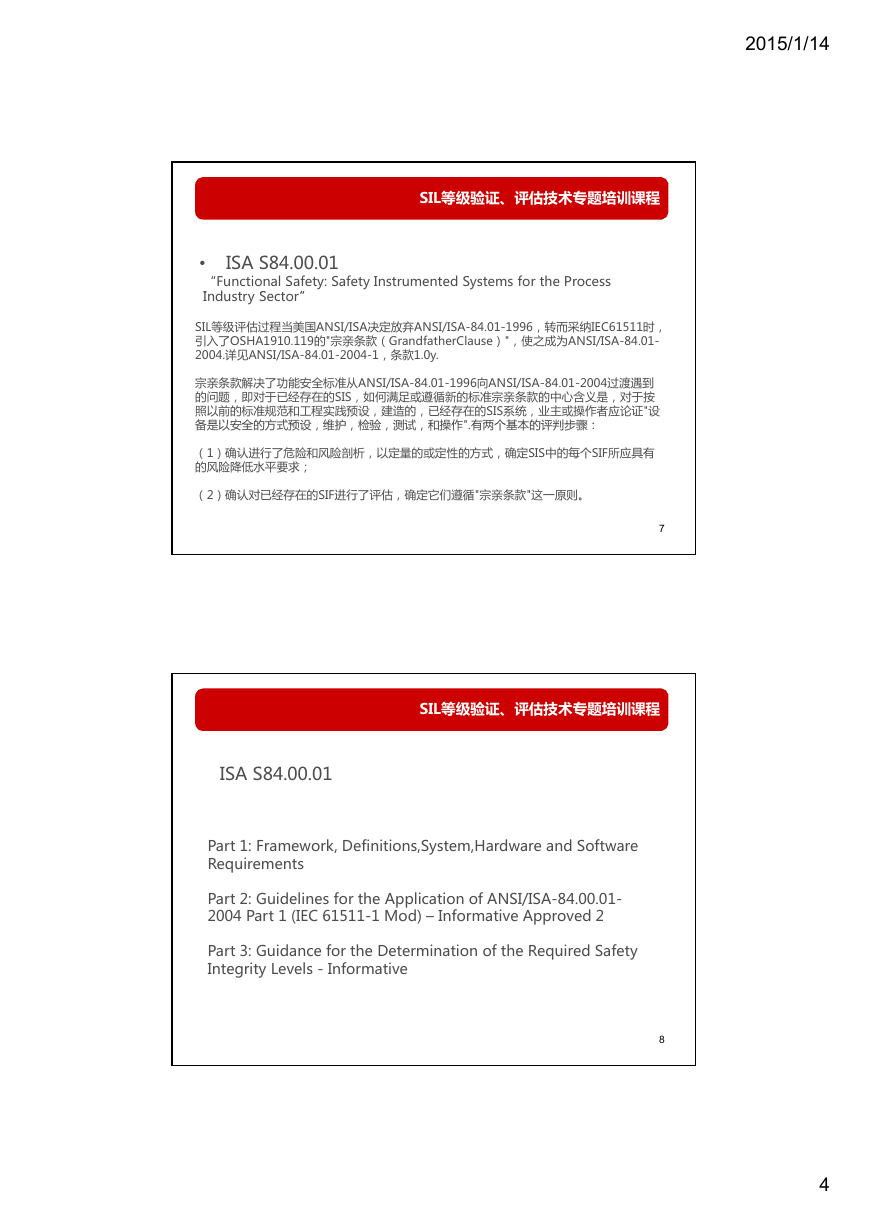

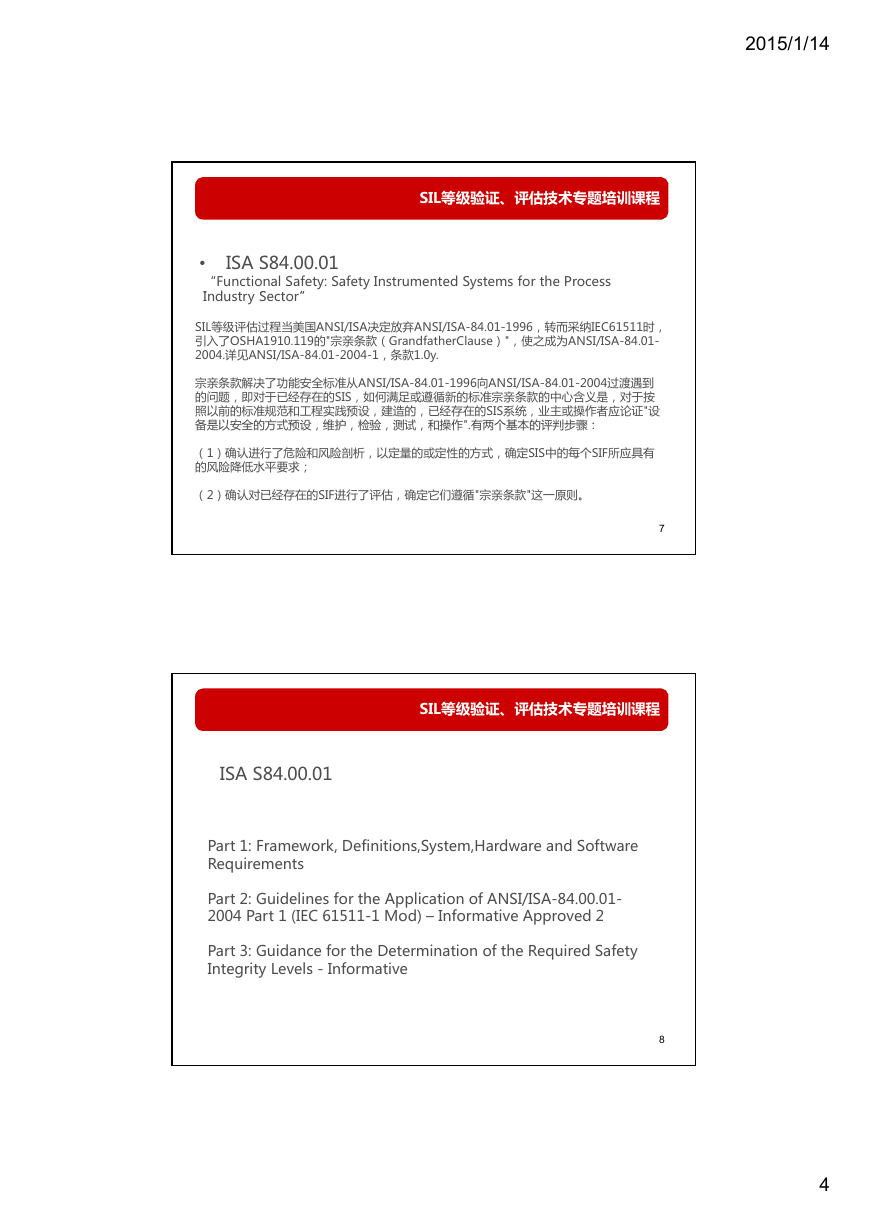

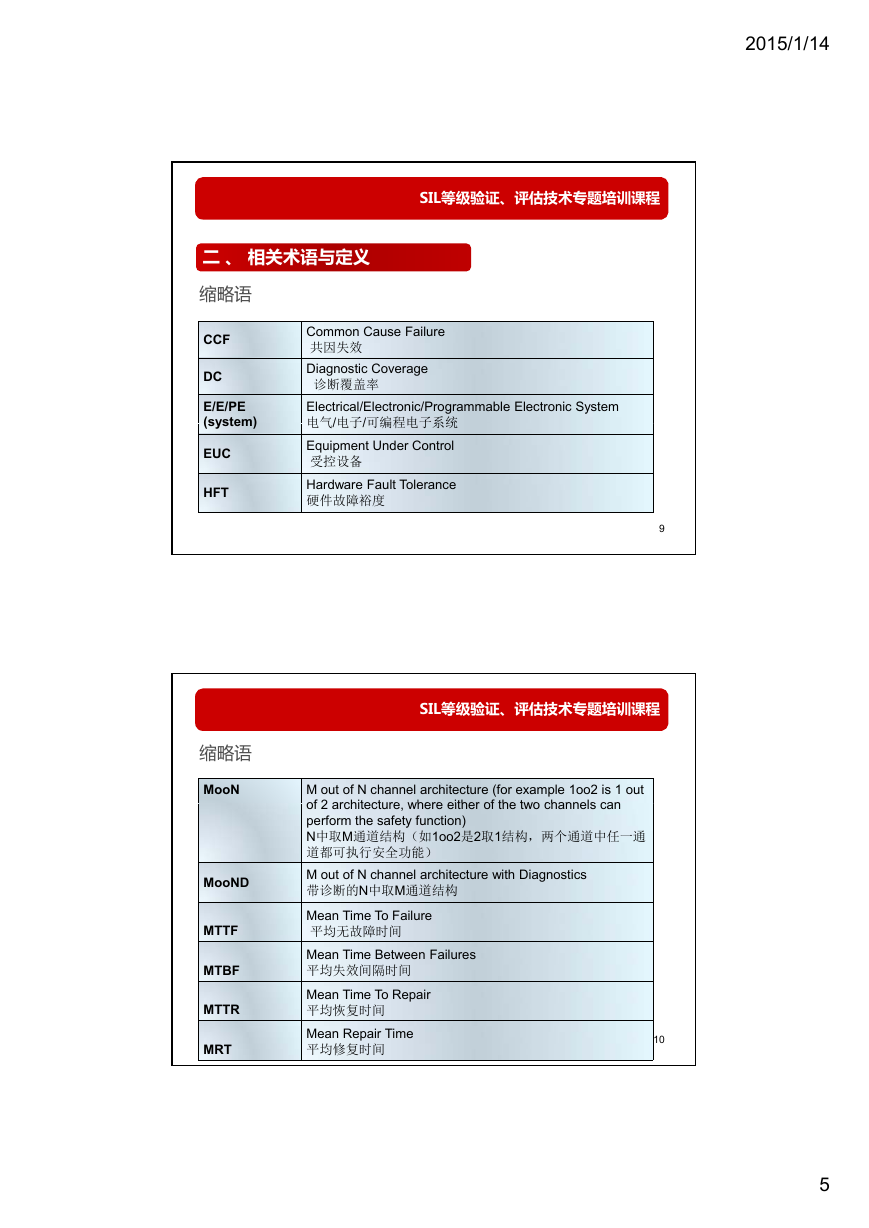

第一讲 SIL等级验证、评估技术专题培训课程

第二讲 确定SIL等级的简化方程

第三讲 SIL等级验证方法

第四讲 SIL等级验证方法

附录B-应用指南最终版打印

ISA TR84.00.02 PART 2-2002

ISA TR84.00.02 PART 3-2002

Preface

Contents

Foreword

Introduction

1 Scope

2 References

3 Introduction to Fault Tree Analysis

4 Definition of terms and symbols

5 Assumptions for Fault Tree calculations for a SIF

6 Procedure

7 Base case example calculation for an SIF using FTA - without common cause failures and systematic failures

8 Example FTA calculations for an SIF including common cause and systematic failure

Annex A (informative) — Fault tree symbols and logic

Annex B (informative) — Mathematics

Annex C — Index

FIGURES

Figure I.1 — Safety lifecycle model

Figure I.2 — Definition of Safety Instrumented System (SIS)

Figure I.3 — ISA-TR84.00.02-2002 overall framework

Figure 7.1 — Base case example process diagram

Figure 7.2 — Base case example SIF configuration

Figure 7.3 — Fault tree for the determination of PFDavg

Figure 7.4 — Fault tree for the determination of MTTFspurious

Figure 8.1 — Fault tree for the determination of PFDavg transmitter miscalibrated

Figure 8.2 — Case 8.2 fault tree for the determination of PFDavg transmitter calibration with procedural safeguard

Figure A.1 — Examples of fault tree symbols

Figure B.1 — Intersection of PFDPT101A and PFDPT101B

Figure B.2 — The union of PFDPT101A and PFDPT101B

Figure B.3 — Representation of the states of a device

TABLES

Table 7.1 — Data used in fault tree analysis

Table 7.2 — Fault tree cut sets

Table 7.3 — Calculated data for each component

Table 7.4 — Percent contribution to PFDavg base case 7.1

Table 7.5 — Calculated data for each component

Table 7.6 — Average after logic solution time series (excerpt)

Table 7.7 — Percent contribution to MTTFspurious

Table 7.8 — Case 7.2 percent contribution to PFDavg (temperature switches tested every 3 months instead of annually)

Table 7.9 — Case 7.3 percent contribution to PFDavg (logic solver with higher MTTFD)

Table 8.1 — Case 8.1 percent contribution to PFDavg transmitter miscalibrated

Table 8.2 — Percent contribution to PFDavg

Table B.1 — PFDavg comparison of average before logic and average after logic

ISA TR84.00.02 PART 4-2002

Preface

Contents

Foreword

Introduction

1 Scope

2 References

3 Definitions

4 Introduction to Markov

5 Modeling and calculation procedures

6 Assumptions for Markov calculations for an SIF

7 Overview examples

8 Example 1

9 Quantifying a Markov model

10 Results Example 1

11 Example 2

12 Results Example 2

13 Example 3

14 Base example calculation for an SIF using Markov models

15 Results base example

16 Index

FIGURES

Figure I.1 — Safety life cycle model

Figure I.2 — Definition of Safety Instrumented System (SIS)

Figure I.3 — ISA-TR84.00.02-2002 overall framework

Figure 4.1 — Simple Markov model

Figure 8.1 — Example 1 (demand mode process)

Figure 8.2 — Fully developed Markov model - Example 1

Figure 8.3 — Simplified Markov model - Example 1

Figure 10.1 — PFD and sensitivity plot - Example 1

Figure 10.2 — Probability of spurious trip and sensitivity plot - Example 1

Figure 11.1 — Simplified Markov model with diagnostics - Example 2

Figure 12.1 — Probability of fail on demand and sensitivity plot with diagnostics - Example 2

Figure 12.2 — PFS and sensitivity plot with diagnostics - Example 2

Figure 13.1 — PFD before and after periodic and imperfect testing

Figure 14.1 — SIS process diagram - Base example

Figure 14.2 — SIS configuration - Base example

Figure 14.3 — Simplified Markov model - Base example

Figure 15.1 — Probability of failure on demand - Base example

Figure 15.2 — Probability of spurious trip - Base example

TABLES

Table 7.1 — Overview results examples

Table 8.1 — Resulting state after single failure - Example 1

Table 8.2 — Description of the different states of the SIS - Example 1

Table 11.1 — Resulting state after single failure with diagnostic capabilities - Examples 2

Table 11.2 — Description of the different states of the SIS - Example 2

Table 14.1 — Resulting state after single failure - Base example

Table 14.2 — Description of the different states of the SIS - Base example

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc