单相正弦波逆变电源

摘要:本单相正弦波逆变电源的设计,以 12V 蓄电池作为输入,输出为 36V、50Hz 的标准

正弦波交流电。该电源采用推挽升压和全桥逆变两级变换,在控制电路上,前级推挽升压电

路采用 SG3525 芯片控制,闭环反馈;逆变部分采用驱动芯片 IR2110 进行全桥逆变,采用

U3990F6 完成 SPWM 的调制,后级输出采用电流互感器进行采样反馈,形成双重反馈环节,

增加了电源的稳定性;在保护上,具有输出过载、短路保护、过流保护、空载保护等多重保

护功能电路,增强了该电源的可靠性和安全性;输出交流电压通过 AD637 的真有效值转换后,

再由 STC89C52 单片机的控制进行模数转换,最终将电压值显示到液晶 12864 上,形成了良

好的人机界面。该电源很好的完成了各项指标,输入功率为 46.9W,输出功率为 43.6W,效

率达到了 93%,输出标准的 50Hz 正弦波。

关键词:单相正弦波逆变 DC-DC DC-AC SPWM

Abstract: The single-phase sine wave inverter power supply design, battery as a 12V

input and output for the 36V, 50Hz standard AC sine wave. The use of push-pull

power booster and two full-bridge inverter transform , in the control circuit, the

pre-boost push-pull circuit using SG3525 chip control, closed-loop feedback; inverter

driver IC IR2110 in part to the use of full-bridge inverter using SPWM modulation

U3990F6 completed, level after the use of current

transformer output sampling

feedback. The feedback link in the formation of a double and increase the stability of

power. In protection, with output overload, short circuit protection, over current

protection, the protection of multiple no-load protection circuit, which enhancing the

reliability of the power supply and safety. AC voltage output of the AD637 True RMS

through conversion,

single-chip STC89C52

analog-digital conversion, the final value of the voltage to the liquid crystal display

12864 on the formation of a good man-machine interface. The completion of the

power good indicators, input power to 46.9W, output power of 43.6W, the efficiency

reached 93%, 50Hz sine wave output standards.

Key words: Single-phase sine wave inverter

and then from the control of

DC-DC DC-AC SPWM

1

�

目录

1.系统设计·············································································································4

1.1 设计要求········································································································4

1.2 总体设计方案··································································································4

1.2.1 设计思路································································································· 4

1.2.2 方案论证与比较························································································5

1.2.3 系统组成································································································· 8

2.主要单元硬件电路设计·························································································· 9

2.1 DC-DC 变换器控制电路的设计 ········································································ 9

2.2 DC-AC 电路的设计······················································································· 10

2.3 SPWM 波的实现 ··························································································· 10

2.4 真有效值转换电路的设计················································································ 11

2.5 保护电路的设计···························································································· 12

2.5.1 过流保护电路的设计 ·············································································· 12

2.5.2 空载保护电路的设计················································································13

2.5.3 浪涌短路保护电路的设计········································································· 14

2.5.4 电流检测电路的设计················································································15

2.6 死区时间控制电路的设计················································································ 15

2.7 辅助电源一的设计························································································· 15

2.8 辅助电源二的设计························································································· 15

2.9 高频变压器的绕制························································································· 17

2.10 低通滤波器的设计························································································18

3.软件设计··········································································································· 18

3.1 AD 转换电路的设计························································································ 18

3.2 液晶显示电路的设计 ······················································································19

4.系统测试··········································································································· 20

4.1 测试使用的仪器····························································································· 20

4.2 指标测试和测试结果······················································································· 21

4.3 结果分析······································································································ 24

2

�

5.结论················································································································· 25

参考文献··············································································································25

附录 1 使用说明····································································································25

附录 2 主要元器件清单·························································································· 25

附录 3 电路原理图及印制板图················································································· 28

附录 4 程序清单····································································································39

3

�

1. 系统设计

1.1 设计要求

制作车载通信设备用单相正弦波逆变电源,输入单路 12V 直流,输出 220V/50Hz。满载

时输出功率大于 100W,效率不小于 80%,具备过流保护和负载短路保护等功能。

1.2 总体设计方案

1.2.1 设计思路

题目要求设计一个车载通信设备用单相正弦波逆变电源,输出电压波形为正弦波。设

计中主电路采用电气隔离、DC-DC-AC 的技术,控制部分采用 SPWM(正弦脉宽调制)技

术,利用对逆变原件电力 MOSFET 的驱动脉冲控制,使输出获得交流正弦波的稳压电源。

1.2.2 方案论证与比较

⑴ DC-DC 变换器的方案论证与选择

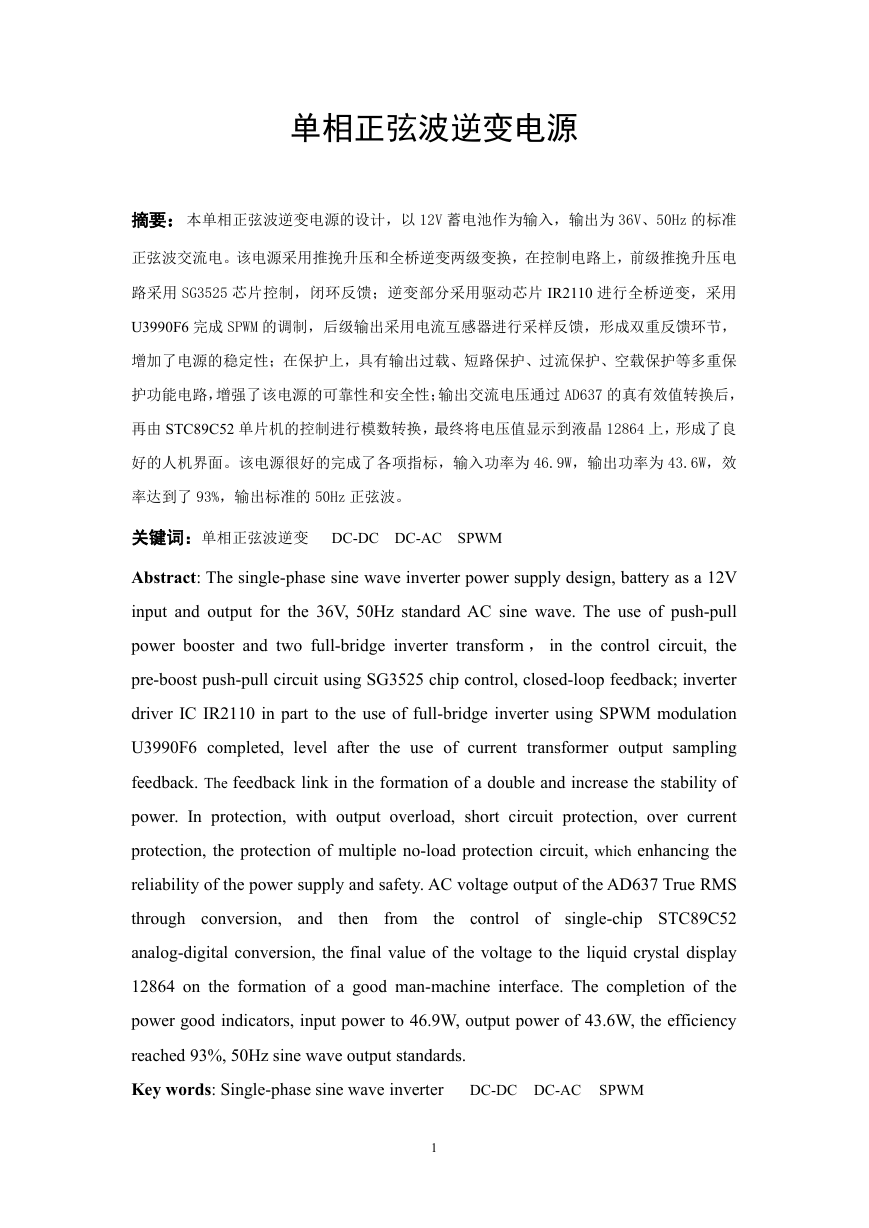

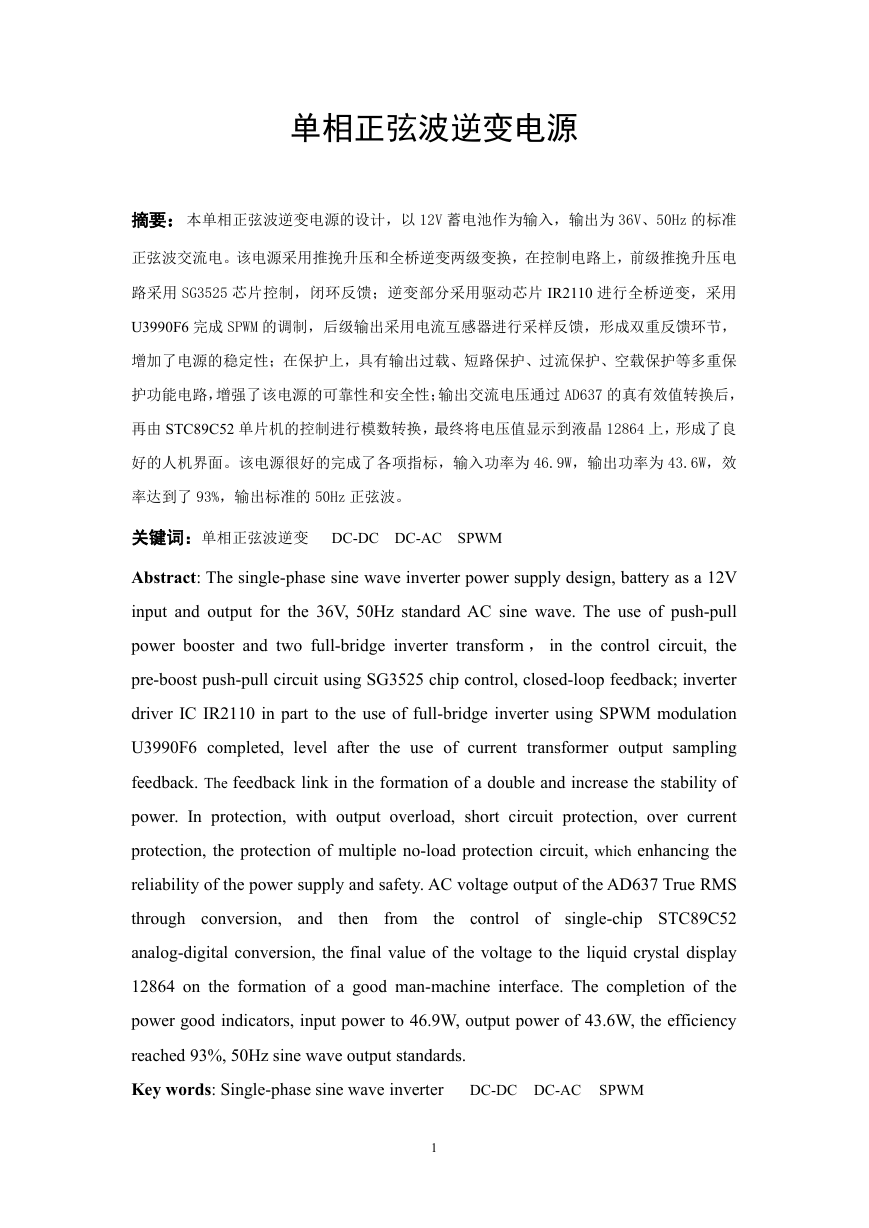

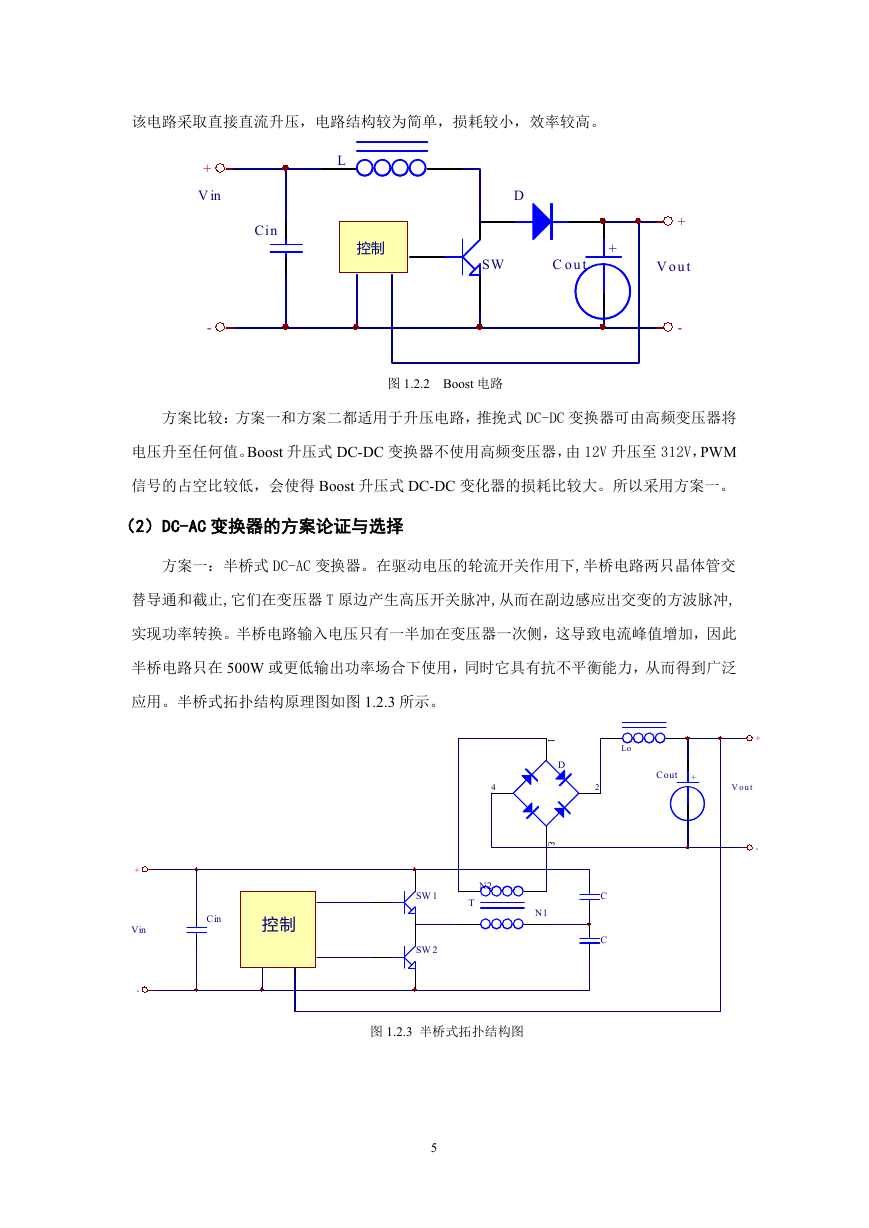

方案一:推挽式 DC-DC 变换器。推挽电路是两不同极性晶体管输出电路无输出变压

器(有 OTL、OCL 等)。是两个参数相同的功率 BJT 管或 MOSFET 管,以推挽方式存

在于电路中,各负责正负半周的波形放大任务。电路工作时,两只对称的功率开关管

每次只有一个导通,所以导通损耗小效率高。推挽输出既可以向负载灌电流,也可以

从负载抽取电流。推挽式拓扑结构原理图如图 1.2.1 所示。

+

Vin

-

SW 1

T

D1

D2

Lo

Cout

+

控 制

Cin

SW 2

反 馈

图 1.2.1 推挽式拓扑结构图

VCC

Vout

GND

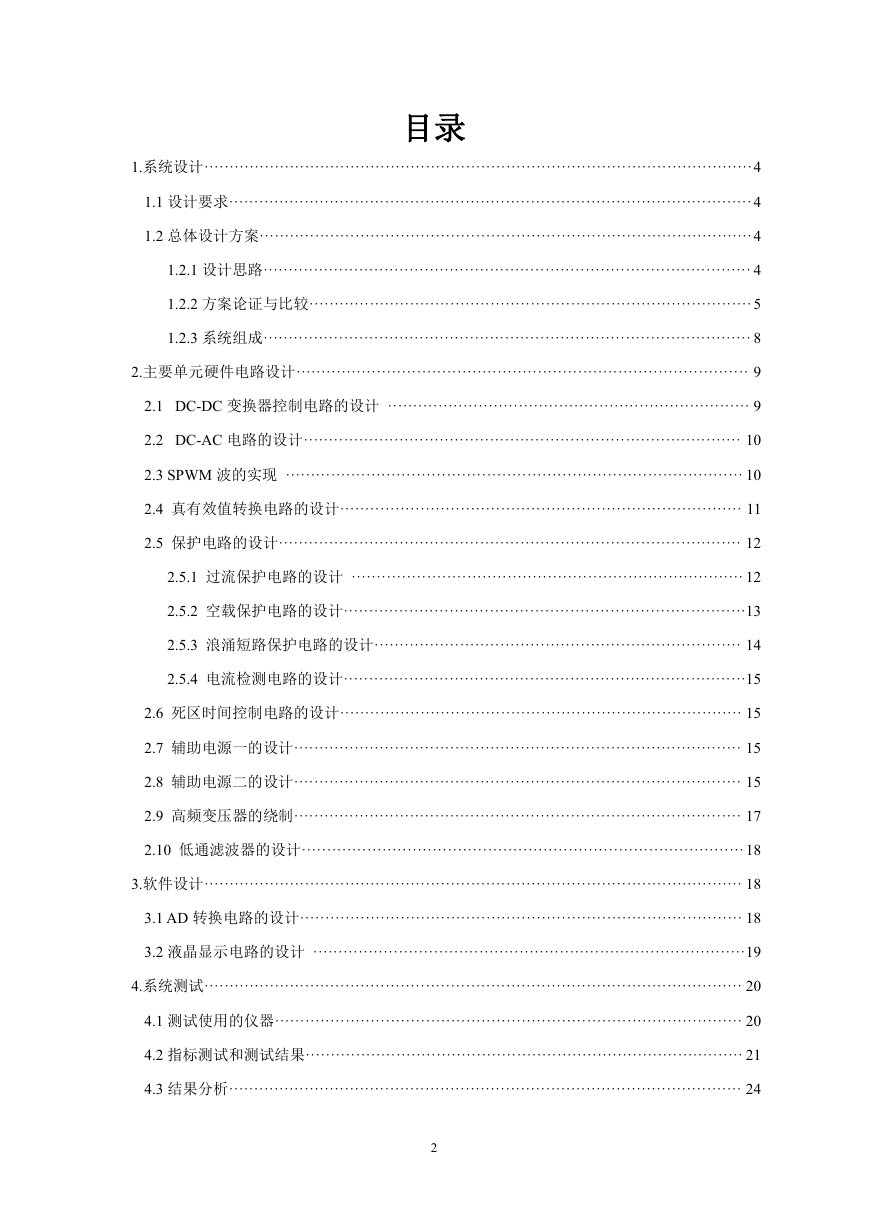

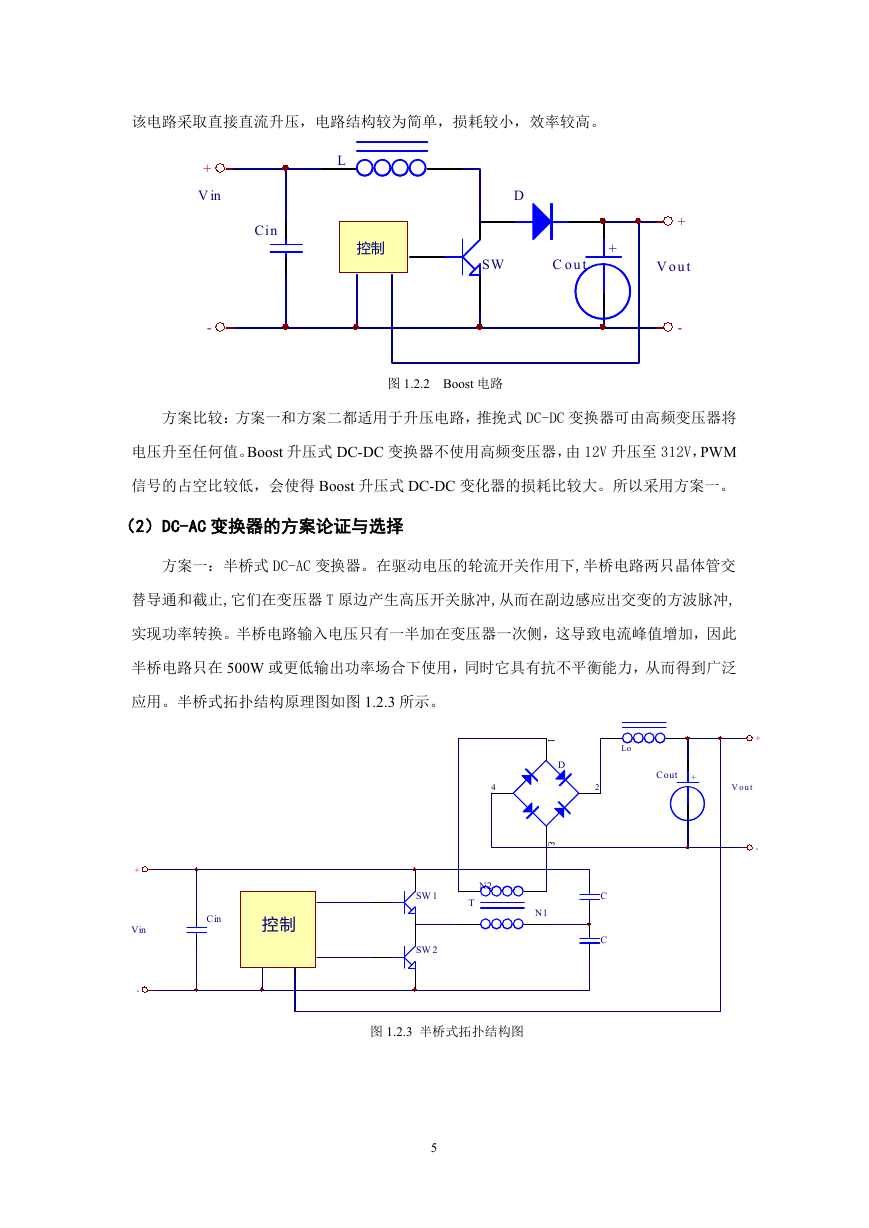

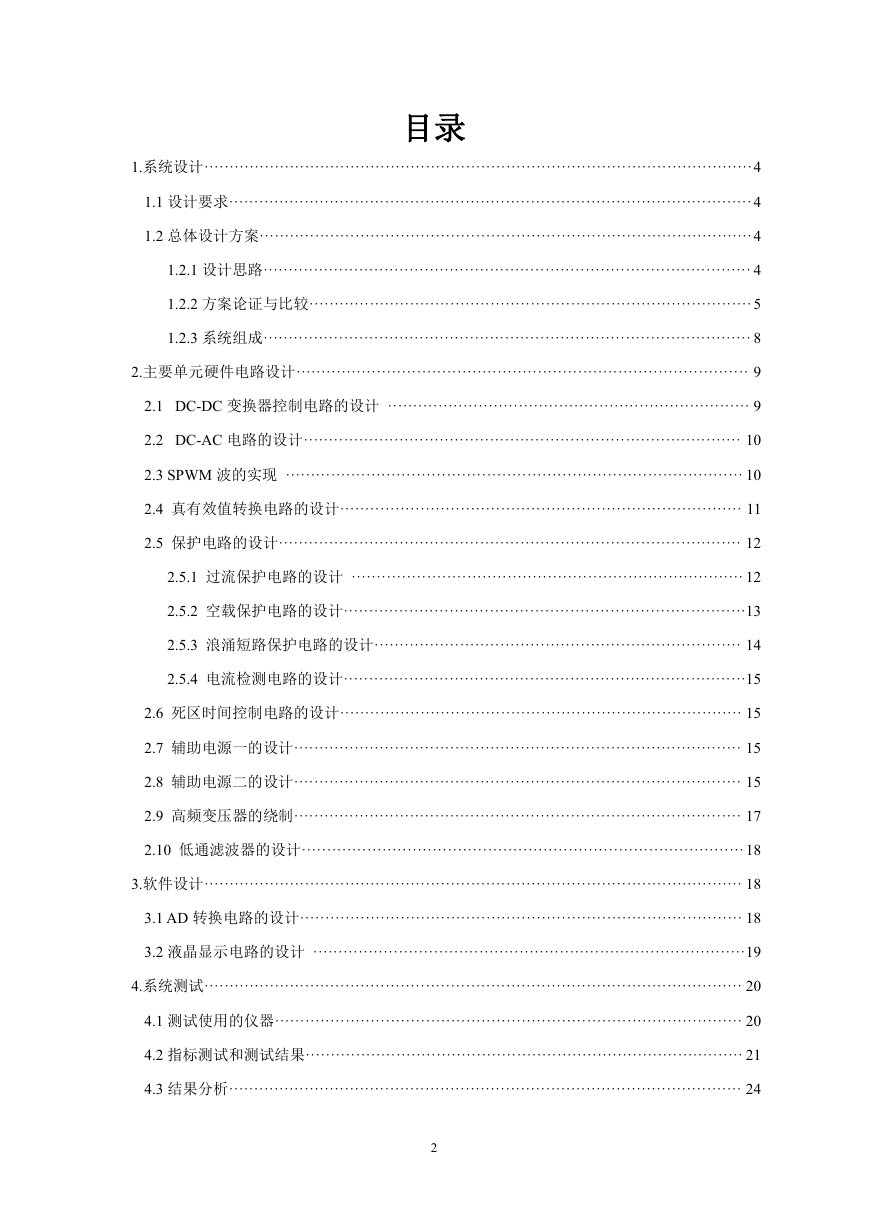

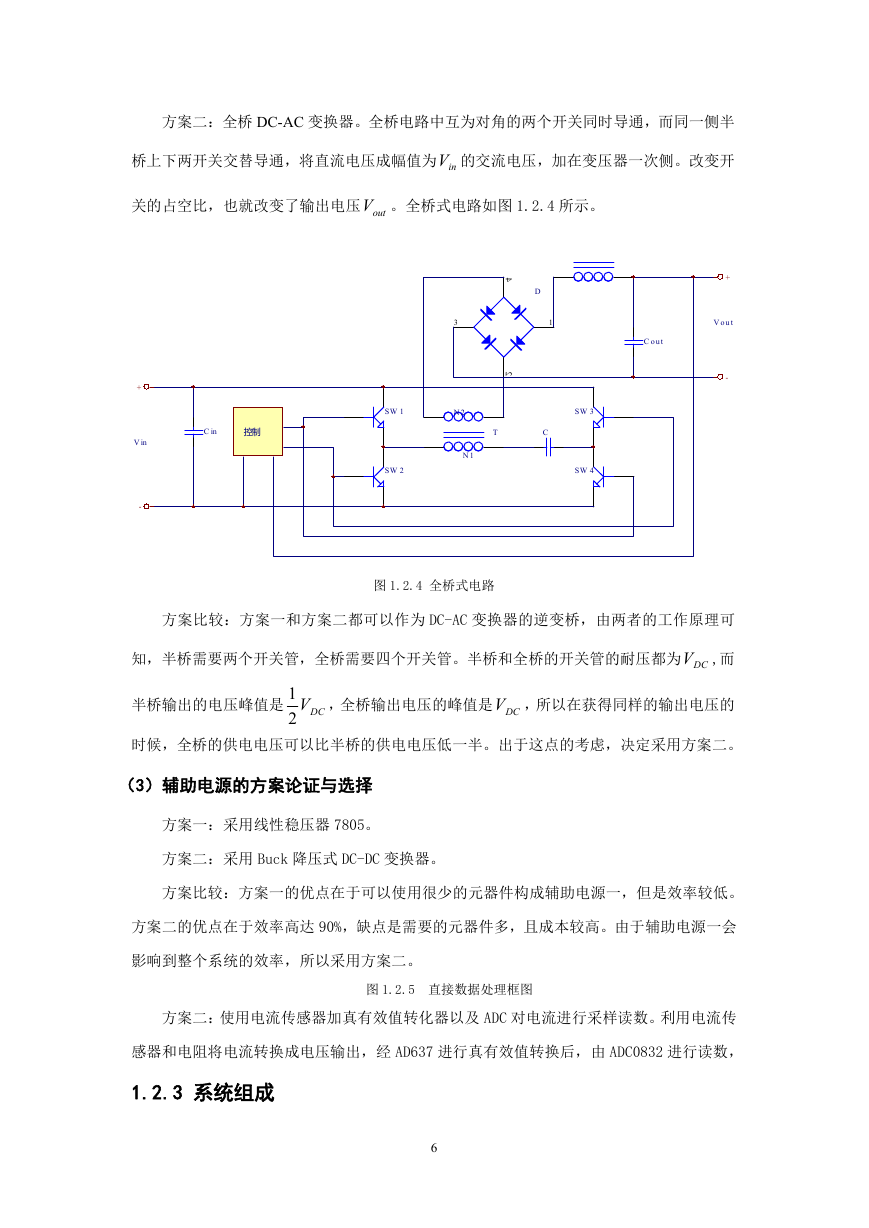

方案二:Boost 升压式 DC-DC 变换器。拓扑结构如图 1.2.2 所示。开关的开通和关断

受外部 PWM 信号控制,电感 L 将交替地存储和释放能量,电感储能后使电压泵升,而电容 outC

可将输出电压保持平稳,通过改变 PWM 控制信号的占空比可以相应实现输出电压的变化。

4

�

该电路采取直接直流升压,电路结构较为简单,损耗较小,效率较高。

L

Cin

控制

+

V in

-

D

SW

C out

+

+

V out

-

图 1.2.2 Boost 电路

方案比较:方案一和方案二都适用于升压电路,推挽式 DC-DC 变换器可由高频变压器将

电压升至任何值。Boost 升压式 DC-DC 变换器不使用高频变压器,由 12V 升压至 312V,PWM

信号的占空比较低,会使得 Boost 升压式 DC-DC 变化器的损耗比较大。所以采用方案一。

(2)DC-AC 变换器的方案论证与选择

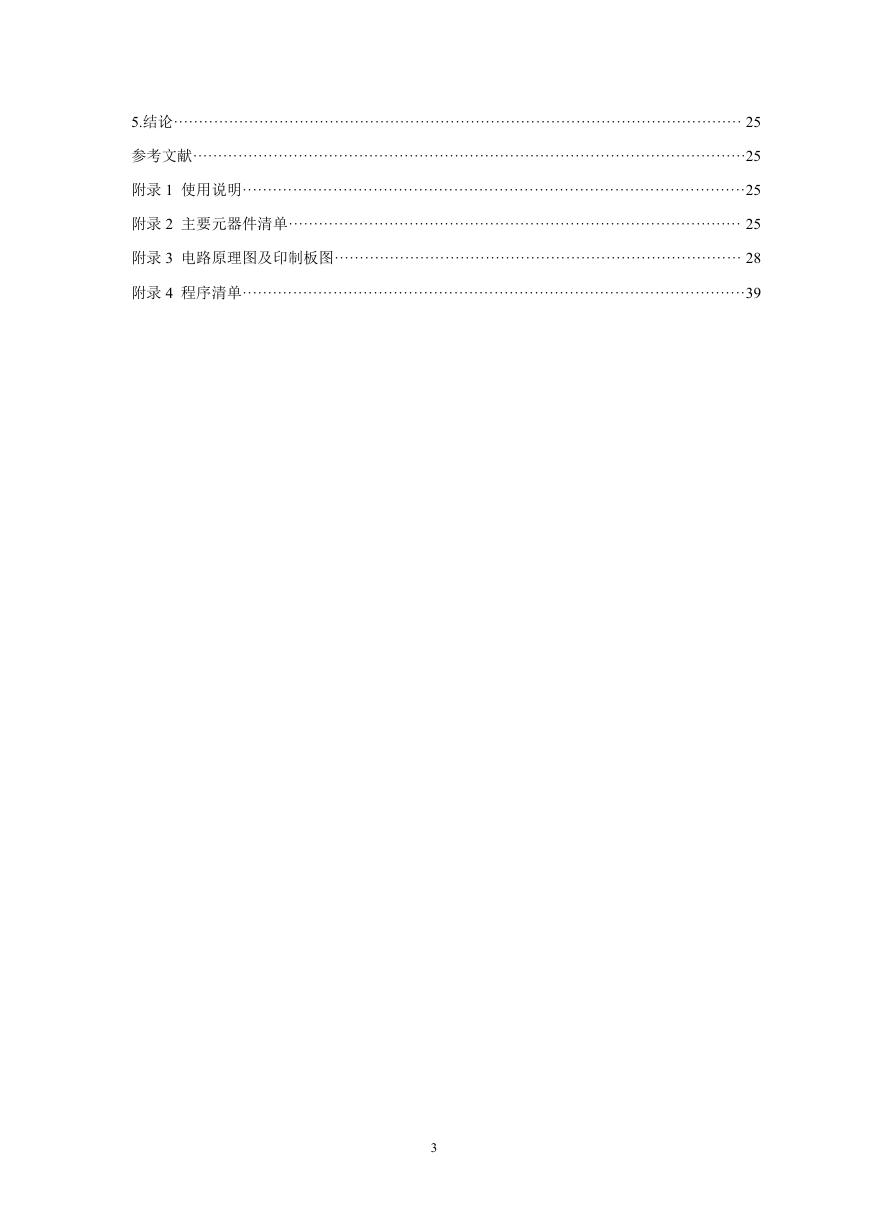

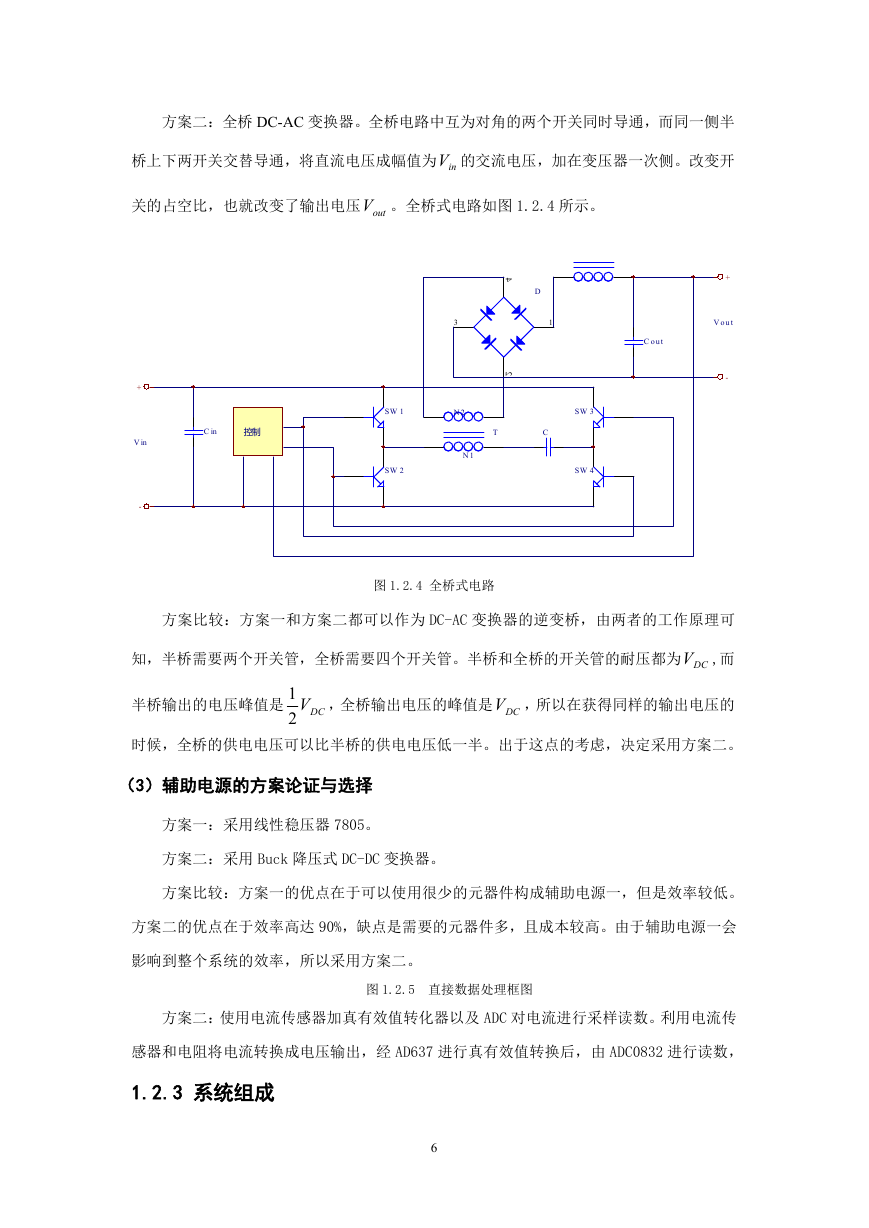

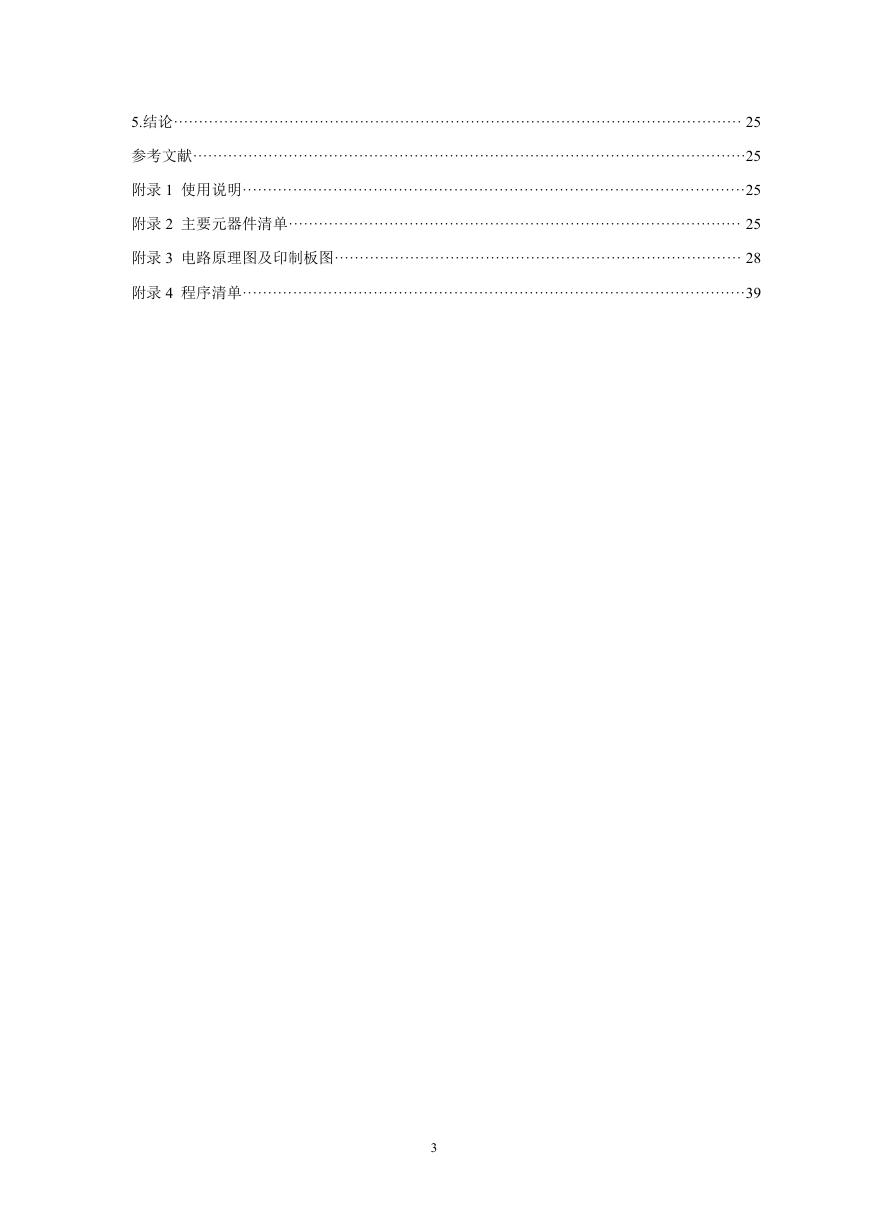

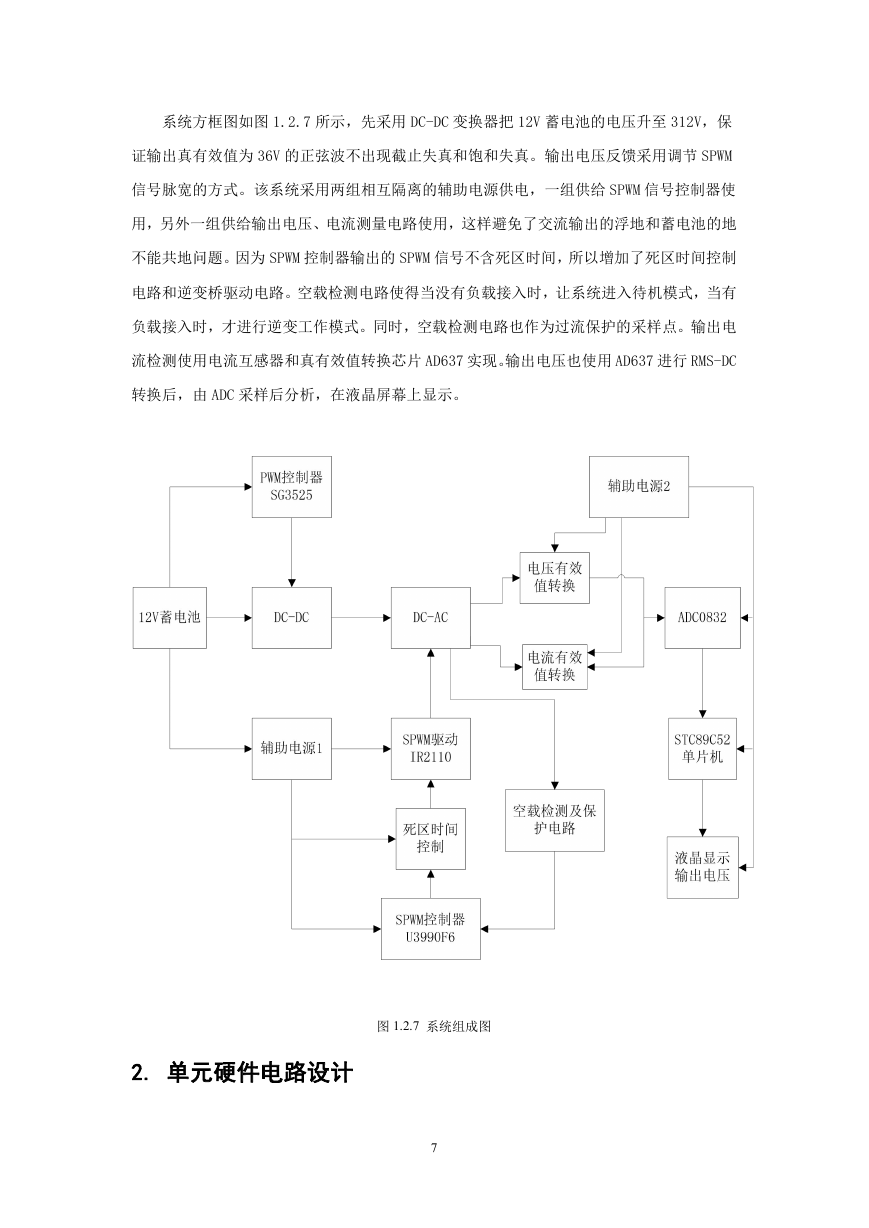

方案一:半桥式 DC-AC 变换器。在驱动电压的轮流开关作用下,半桥电路两只晶体管交

替导通和截止,它们在变压器 T 原边产生高压开关脉冲,从而在副边感应出交变的方波脉冲,

实现功率转换。半桥电路输入电压只有一半加在变压器一次侧,这导致电流峰值增加,因此

半桥电路只在 500W 或更低输出功率场合下使用,同时它具有抗不平衡能力,从而得到广泛

应用。半桥式拓扑结构原理图如图 1.2.3 所示。

1

D

Lo

4

2

Cout

+

V out

+

Vin

-

Cin

控制

3

N1

C

C

N2

T

SW 1

SW 2

+

-

图 1.2.3 半桥式拓扑结构图

5

�

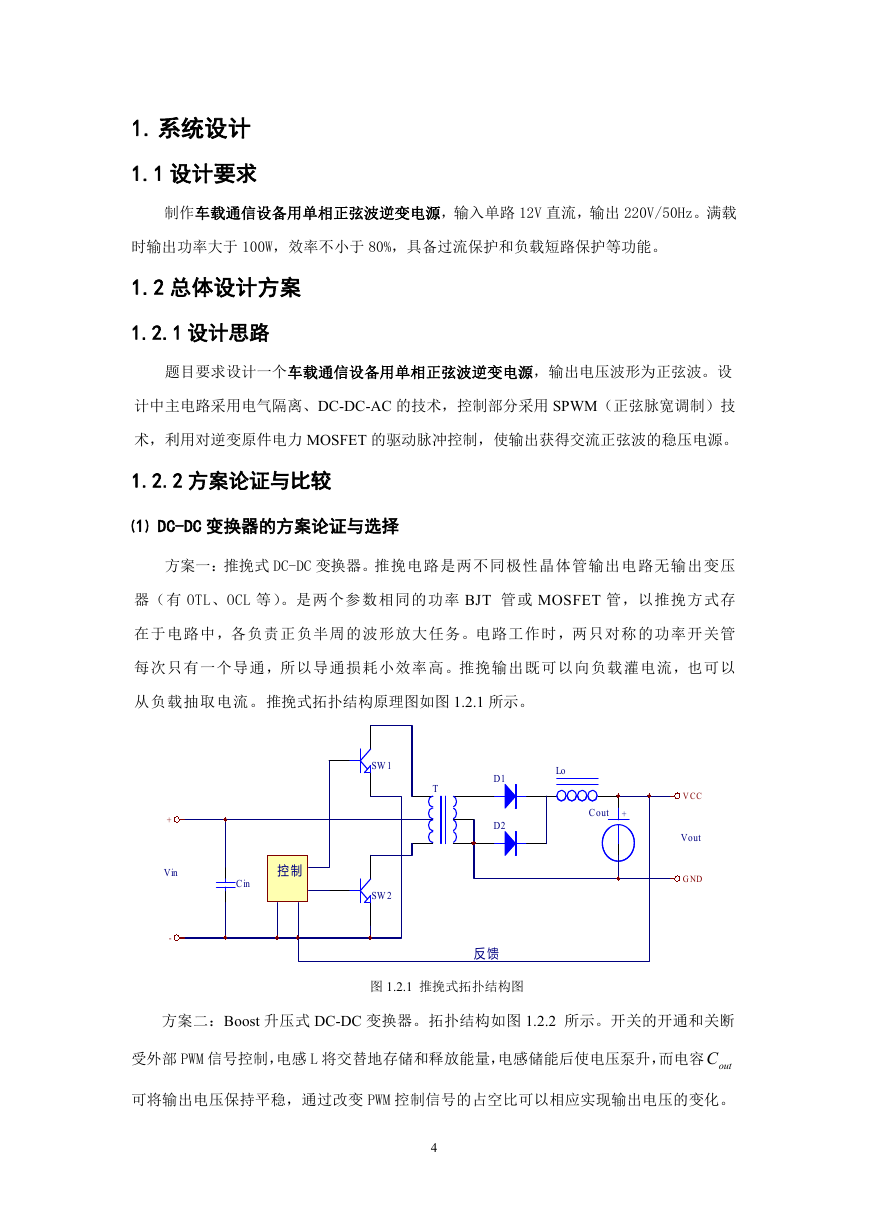

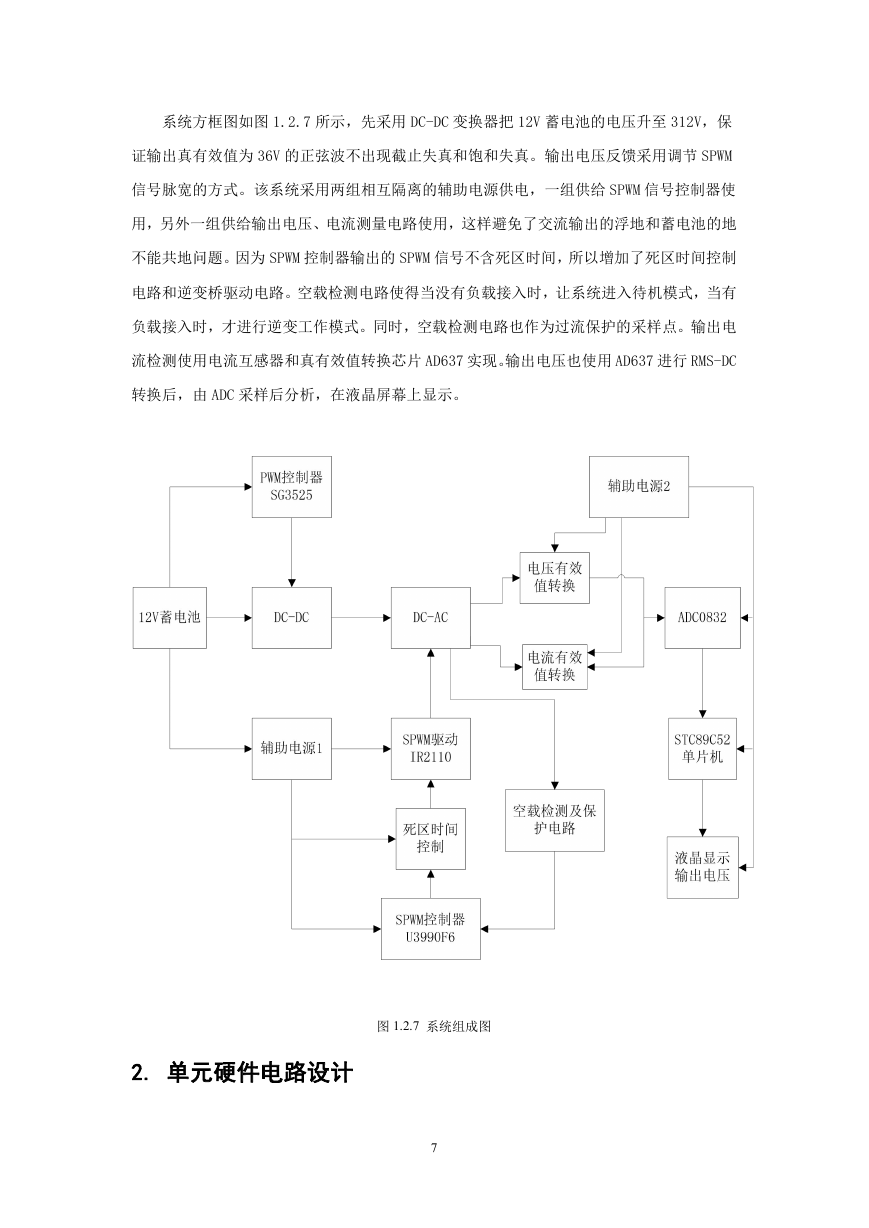

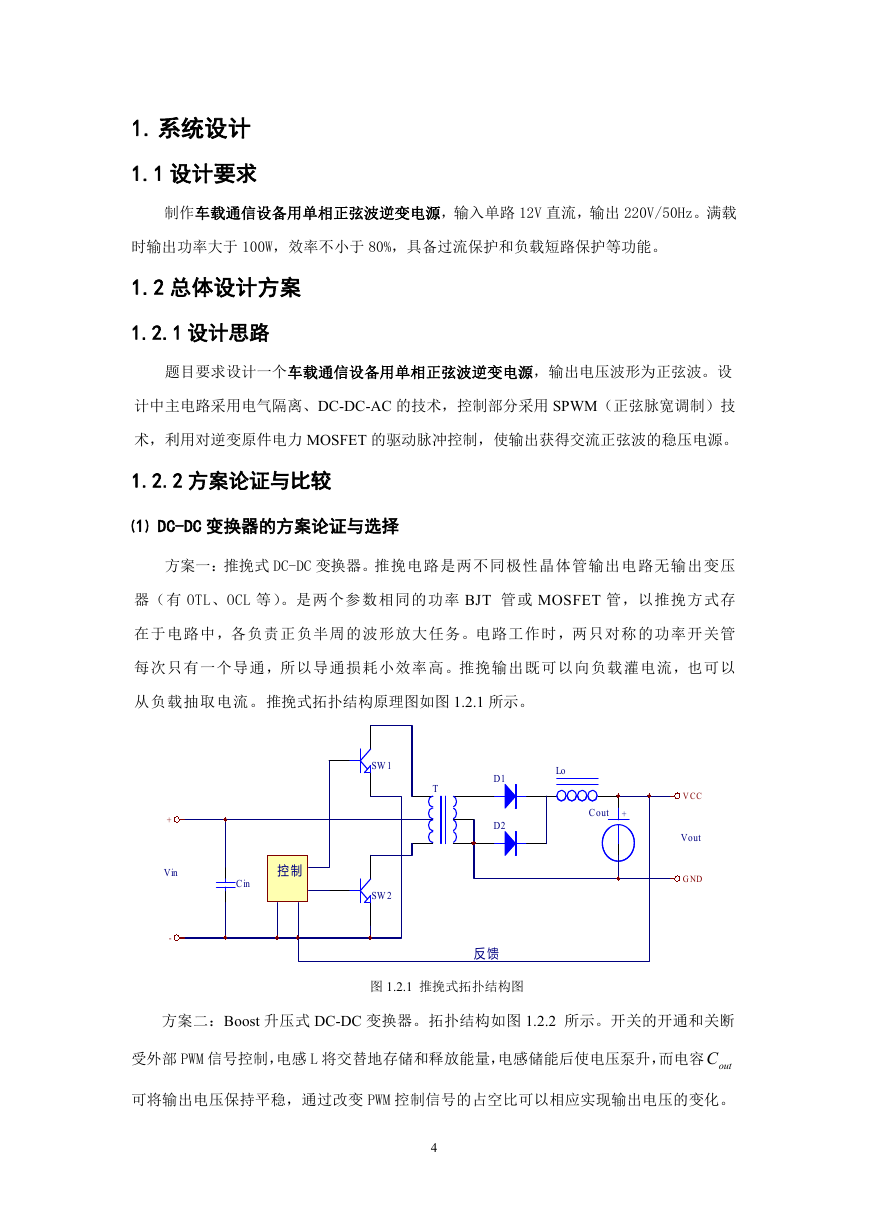

方案二:全桥 DC-AC 变换器。全桥电路中互为对角的两个开关同时导通,而同一侧半

桥上下两开关交替导通,将直流电压成幅值为 inV 的交流电压,加在变压器一次侧。改变开

关的占空比,也就改变了输出电压 outV 。全桥式电路如图 1.2.4 所示。

Lo

4

D

3

1

2

+

V out

-

C out

C in

控制

T

C

SW 1

N 2

N 1

SW 2

SW 3

SW 4

+

V in

-

图 1.2.4 全桥式电路

方案比较:方案一和方案二都可以作为 DC-AC 变换器的逆变桥,由两者的工作原理可

知,半桥需要两个开关管,全桥需要四个开关管。半桥和全桥的开关管的耐压都为 DCV ,而

半桥输出的电压峰值是 DCV

1

2

,全桥输出电压的峰值是 DCV ,所以在获得同样的输出电压的

时候,全桥的供电电压可以比半桥的供电电压低一半。出于这点的考虑,决定采用方案二。

(3)辅助电源的方案论证与选择

方案一:采用线性稳压器 7805。

方案二:采用 Buck 降压式 DC-DC 变换器。

方案比较:方案一的优点在于可以使用很少的元器件构成辅助电源一,但是效率较低。

方案二的优点在于效率高达 90%,缺点是需要的元器件多,且成本较高。由于辅助电源一会

影响到整个系统的效率,所以采用方案二。

图 1.2.5 直接数据处理框图

方案二:使用电流传感器加真有效值转化器以及 ADC 对电流进行采样读数。利用电流传

感器和电阻将电流转换成电压输出,经 AD637 进行真有效值转换后,由 ADC0832 进行读数,

1.2.3 系统组成

6

�

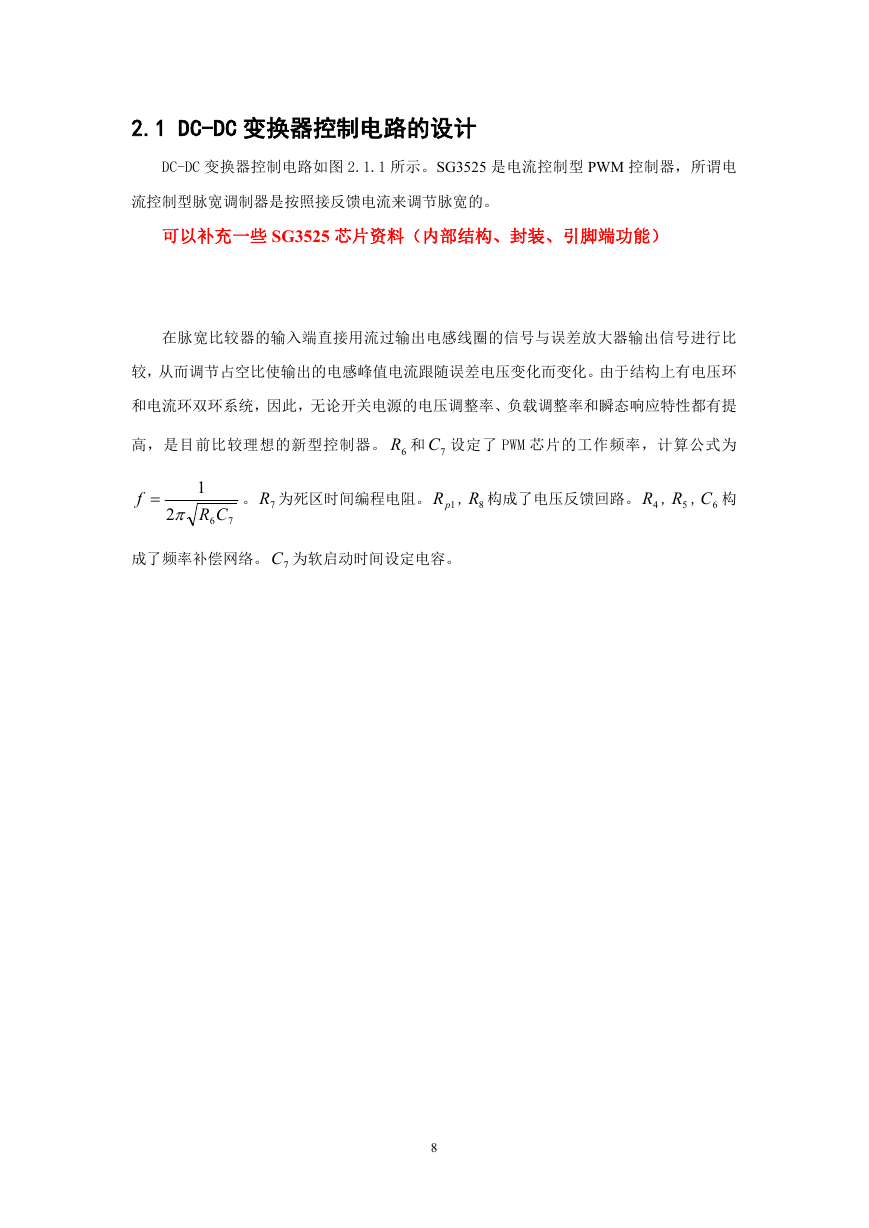

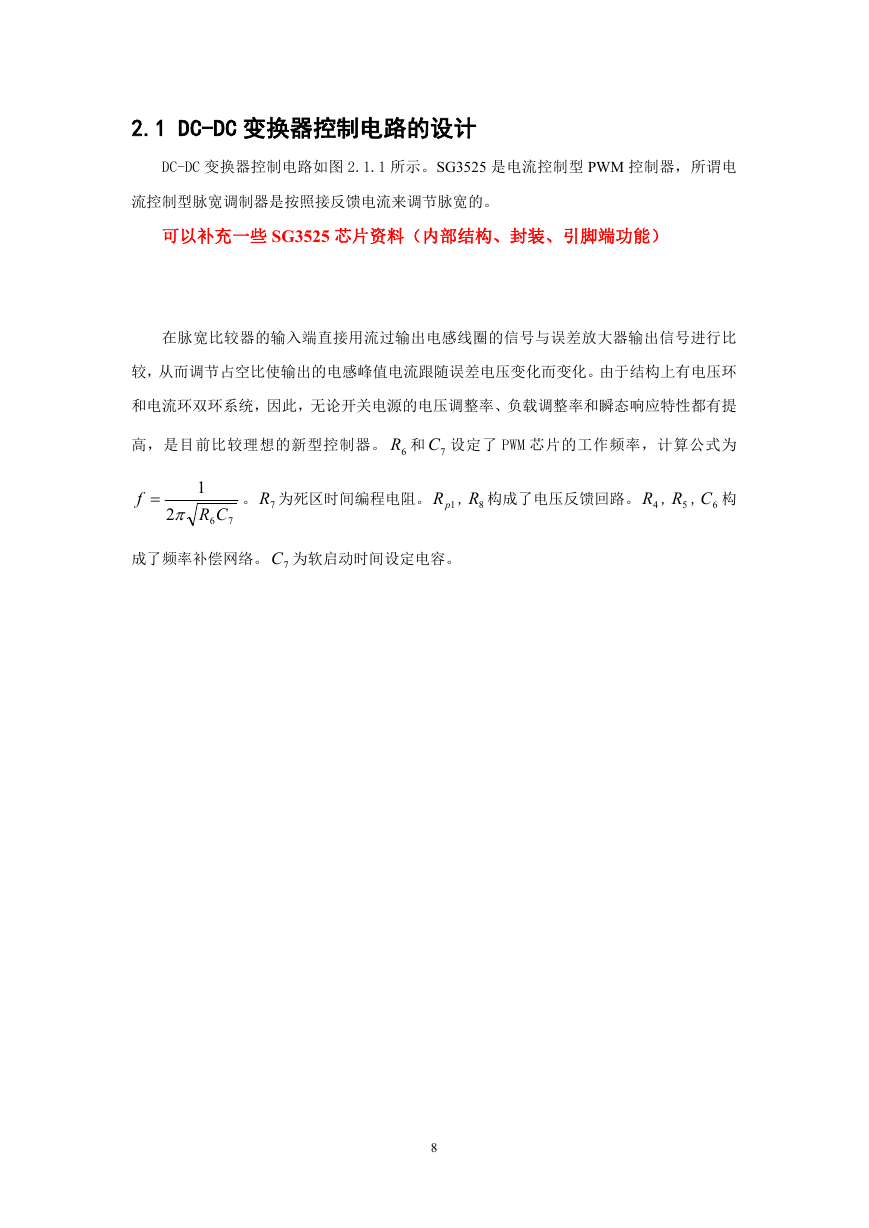

系统方框图如图 1.2.7 所示,先采用 DC-DC 变换器把 12V 蓄电池的电压升至 312V,保

证输出真有效值为 36V 的正弦波不出现截止失真和饱和失真。输出电压反馈采用调节 SPWM

信号脉宽的方式。该系统采用两组相互隔离的辅助电源供电,一组供给 SPWM 信号控制器使

用,另外一组供给输出电压、电流测量电路使用,这样避免了交流输出的浮地和蓄电池的地

不能共地问题。因为 SPWM 控制器输出的 SPWM 信号不含死区时间,所以增加了死区时间控制

电路和逆变桥驱动电路。空载检测电路使得当没有负载接入时,让系统进入待机模式,当有

负载接入时,才进行逆变工作模式。同时,空载检测电路也作为过流保护的采样点。输出电

流检测使用电流互感器和真有效值转换芯片 AD637 实现。输出电压也使用 AD637 进行 RMS-DC

转换后,由 ADC 采样后分析,在液晶屏幕上显示。

2. 单元硬件电路设计

图 1.2.7 系统组成图

7

�

2.1 DC-DC 变换器控制电路的设计

DC-DC 变换器控制电路如图 2.1.1 所示。SG3525 是电流控制型 PWM 控制器,所谓电

流控制型脉宽调制器是按照接反馈电流来调节脉宽的。

可以补充一些 SG3525 芯片资料(内部结构、封装、引脚端功能)

在脉宽比较器的输入端直接用流过输出电感线圈的信号与误差放大器输出信号进行比

较,从而调节占空比使输出的电感峰值电流跟随误差电压变化而变化。由于结构上有电压环

和电流环双环系统,因此,无论开关电源的电压调整率、负载调整率和瞬态响应特性都有提

高,是目前比较理想的新型控制器。 6R 和 7C 设定了 PWM 芯片的工作频率,计算公式为

f

2

1

CR

6

7

。 7R 为死区时间编程电阻。 1pR , 8R 构成了电压反馈回路。 4R , 5R , 6C 构

成了频率补偿网络。 7C 为软启动时间设定电容。

8

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc