RELIABILITY REPORT 57

1H 2014

�

Copyright © 2014 Altera Corporation. All rights reserved. Altera, The Programmable Solutions Company, the

stylized Altera logo, specific device designations, and all other words and logos that are identified as trademarks

and/or service marks are, unless noted otherwise, the trademarks and service marks of Altera Corporation in the

U.S. and other countries. All other product or service names are the property of their respective holders. Altera

products are protected under numerous U.S. and foreign patents and pending applications, maskwork rights,

and copyrights. Altera warrants performance of its semiconductor products to current specifications in

accordance with Altera's standard warranty, but reserves the right to make changes to any products and services

at any time without notice. Altera assumes no responsibility or liability arising out of the application or use of

any information, product, or service described herein except as expressly agreed to in writing by Altera

Corporation. Altera customers are advised to obtain the latest version of device specifications before relying on

any published information and before placing orders for products or services.

2

�

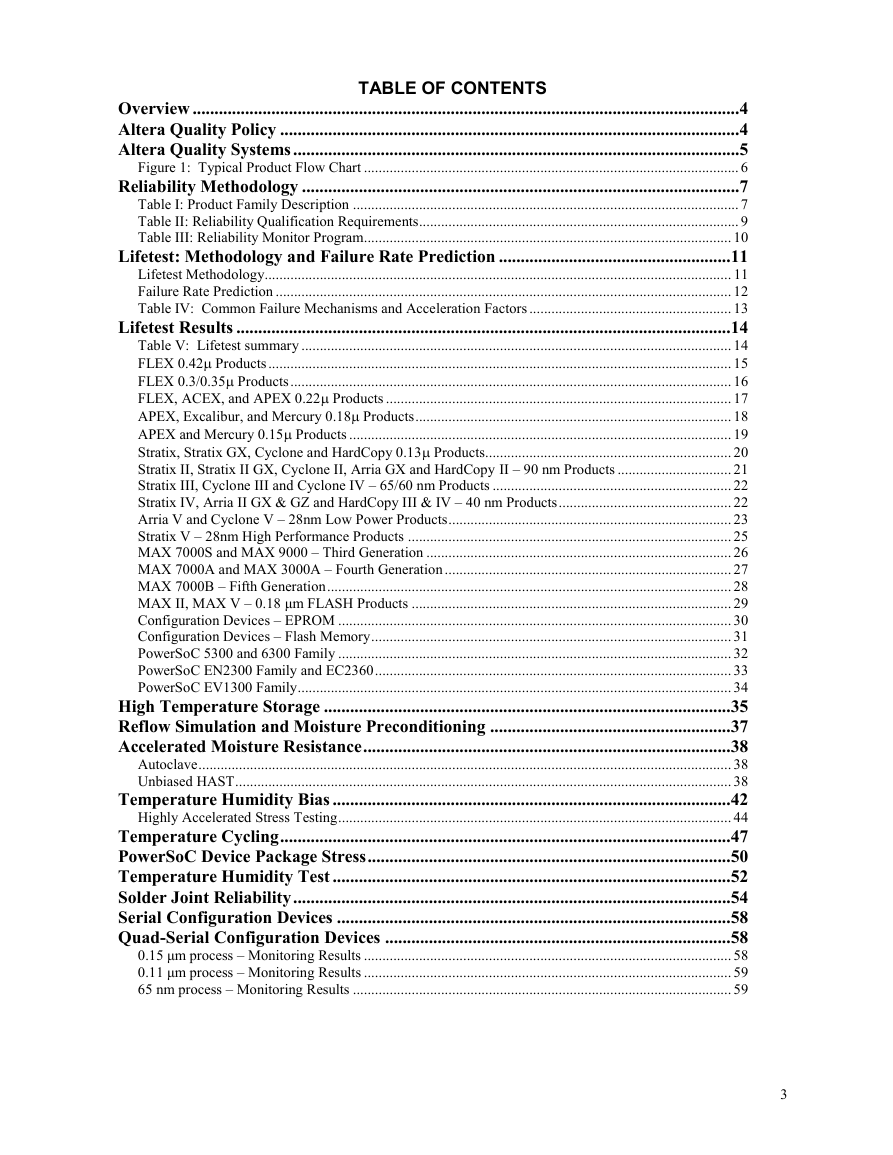

TABLE OF CONTENTS

Overview .............................................................................................................................4

Altera Quality Policy .........................................................................................................4

Altera Quality Systems ......................................................................................................5

Figure 1: Typical Product Flow Chart ...................................................................................................... 6

Reliability Methodology ....................................................................................................7

Table I: Product Family Description ......................................................................................................... 7

Table II: Reliability Qualification Requirements....................................................................................... 9

Table III: Reliability Monitor Program.................................................................................................... 10

Lifetest: Methodology and Failure Rate Prediction .....................................................11

Lifetest Methodology............................................................................................................................... 11

Failure Rate Prediction ............................................................................................................................ 12

Table IV: Common Failure Mechanisms and Acceleration Factors ....................................................... 13

Lifetest Results .................................................................................................................14

Table V: Lifetest summary ..................................................................................................................... 14

FLEX 0.42 Products .............................................................................................................................. 15

FLEX 0.3/0.35 Products ........................................................................................................................ 16

FLEX, ACEX, and APEX 0.22 Products .............................................................................................. 17

APEX, Excalibur, and Mercury 0.18 Products ...................................................................................... 18

APEX and Mercury 0.15 Products ........................................................................................................ 19

Stratix, Stratix GX, Cyclone and HardCopy 0.13 Products................................................................... 20

Stratix II, Stratix II GX, Cyclone II, Arria GX and HardCopy II – 90 nm Products ............................... 21

Stratix III, Cyclone III and Cyclone IV – 65/60 nm Products ................................................................. 22

Stratix IV, Arria II GX & GZ and HardCopy III & IV – 40 nm Products ............................................... 22

Arria V and Cyclone V – 28nm Low Power Products ............................................................................. 23

Stratix V – 28nm High Performance Products ........................................................................................ 25

MAX 7000S and MAX 9000 – Third Generation ................................................................................... 26

MAX 7000A and MAX 3000A – Fourth Generation .............................................................................. 27

MAX 7000B – Fifth Generation .............................................................................................................. 28

MAX II, MAX V – 0.18 μm FLASH Products ....................................................................................... 29

Configuration Devices – EPROM ........................................................................................................... 30

Configuration Devices – Flash Memory .................................................................................................. 31

PowerSoC 5300 and 6300 Family ........................................................................................................... 32

PowerSoC EN2300 Family and EC2360 ................................................................................................. 33

PowerSoC EV1300 Family ...................................................................................................................... 34

High Temperature Storage .............................................................................................35

Reflow Simulation and Moisture Preconditioning .......................................................37

Accelerated Moisture Resistance ....................................................................................38

Autoclave ................................................................................................................................................. 38

Unbiased HAST ....................................................................................................................................... 38

Temperature Humidity Bias ...........................................................................................42

Highly Accelerated Stress Testing ........................................................................................................... 44

Temperature Cycling .......................................................................................................47

PowerSoC Device Package Stress ...................................................................................50

Temperature Humidity Test ...........................................................................................52

Solder Joint Reliability ....................................................................................................54

Serial Configuration Devices ..........................................................................................58

Quad-Serial Configuration Devices ...............................................................................58

0.15 μm process – Monitoring Results .................................................................................................... 58

0.11 μm process – Monitoring Results .................................................................................................... 59

65 nm process – Monitoring Results ....................................................................................................... 59

3

�

Overview

Altera® Corporation is the pioneer of programmable logic solutions, enabling system and

semiconductor companies to rapidly and cost effectively innovate, differentiate, and win in their

markets. Altera offers FPGAs, SoCs with embedded processor systems, and CPLDs in combination

with software tools, intellectual property, embedded processors and customer support to provide high-

value programmable solutions.

This report shows reliability results on each product family from Altera's product catalog. All results

successfully meet Altera quality and reliability standards. Altera ensures that standards are constantly

met through continuous monitoring.

Altera Quality Commitment

DRIVE Quality in everything we do

to ensure the Customer’s total quality experience!

D Deliver defect-free products and services on time

R Requirements are met at all times for internal and external customers

I

Improve continuously

V Verify effectiveness

E Every Altera employee is responsible!

Altera’s corporate mission is to be the preferred fabless supplier of FPGAs, SoCs with embedded

processor systems, CPLDs, ASICs and PowerSoCs in combination with software tools, intellectual

property, embedded processors and customer support, in order to provide high-value programmable

solutions. Altera will use this advantage to gain market share penetration into the larger Logic IC

market.

To achieve and maintain this preferred supplier status, we must provide cost–effective, state–of–the–art

solutions to our customers, in a timely manner, while consistently meeting their quality, reliability, and

service requirements. We ensure that all products and services receive optimum attention to detail, from

conception to delivery.

We are committed to sustaining a corporate culture that strives for risk management, defect-free

performance, verification of effectiveness and continuous improvement, and which extends to all our

activities as well as to our supply chain partners.

Achieving Quality is the responsibility of all Altera employees, managers, directors, and officers. To

achieve our corporate goals, we must:

conform to all applicable procedures and specifications,

produce quality work,

monitor the performance of our business processes against current quality goals,

derive and implement quality improvements from this performance analysis.

4

�

Altera Quality Systems

Altera has a closed-loop quality and reliability system that conforms to the requirements of ISO

9001:2008, MIL-I-45208 and JEDEC® standards. Altera and all of its major suppliers are ISO 9000

certified. Altera’s Reliability qualification and monitoring programs are also governed by internal

specifications, which define procedures, pass/fail requirements, and corrective actions. Altera has been

ISO9001 certified since October, 1994.

Altera is able to provide the automotive supply chain with the highest levels of quality and

reliability because all of Altera’s foundry, assembly and test partners are certified and registered to the

ISO/TS 16949 automotive industry quality standard.

Altera conducts automotive product qualification which complies with requirements listed in the AEC-

Q100 document.

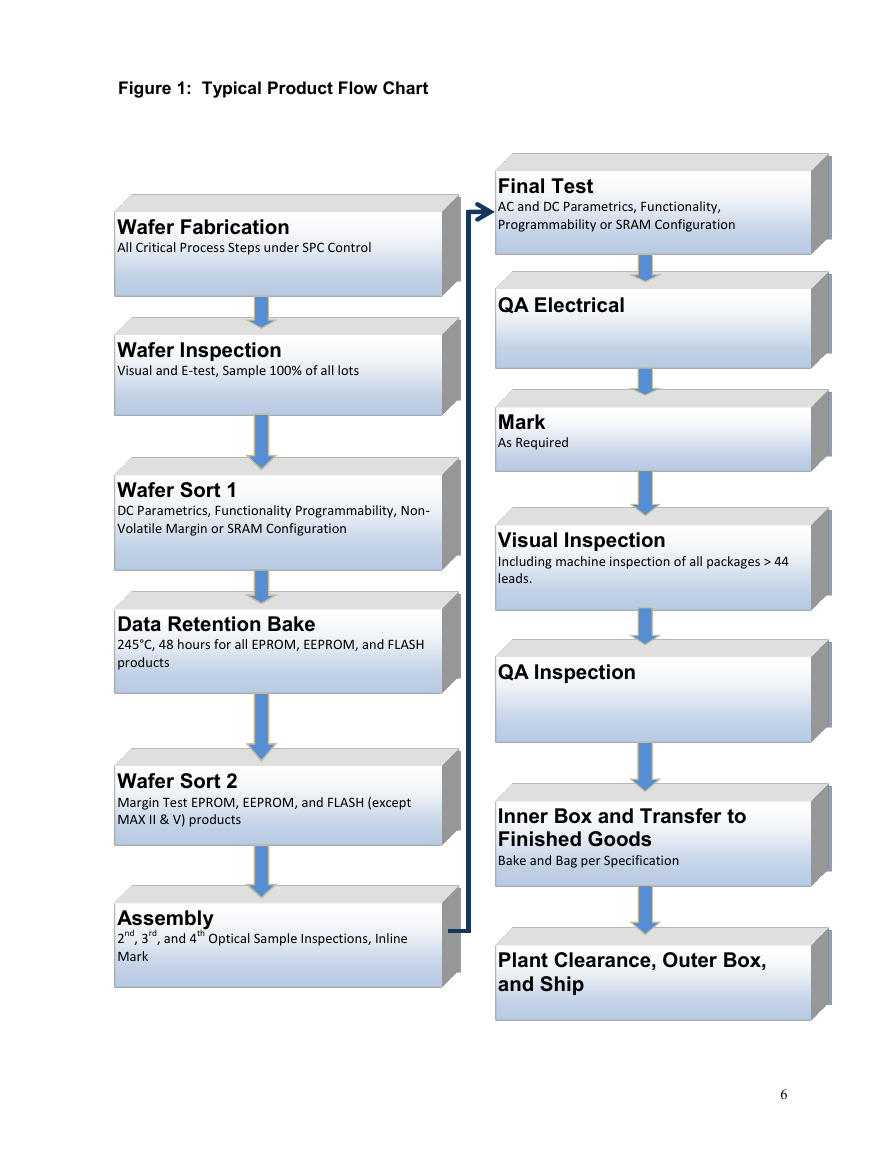

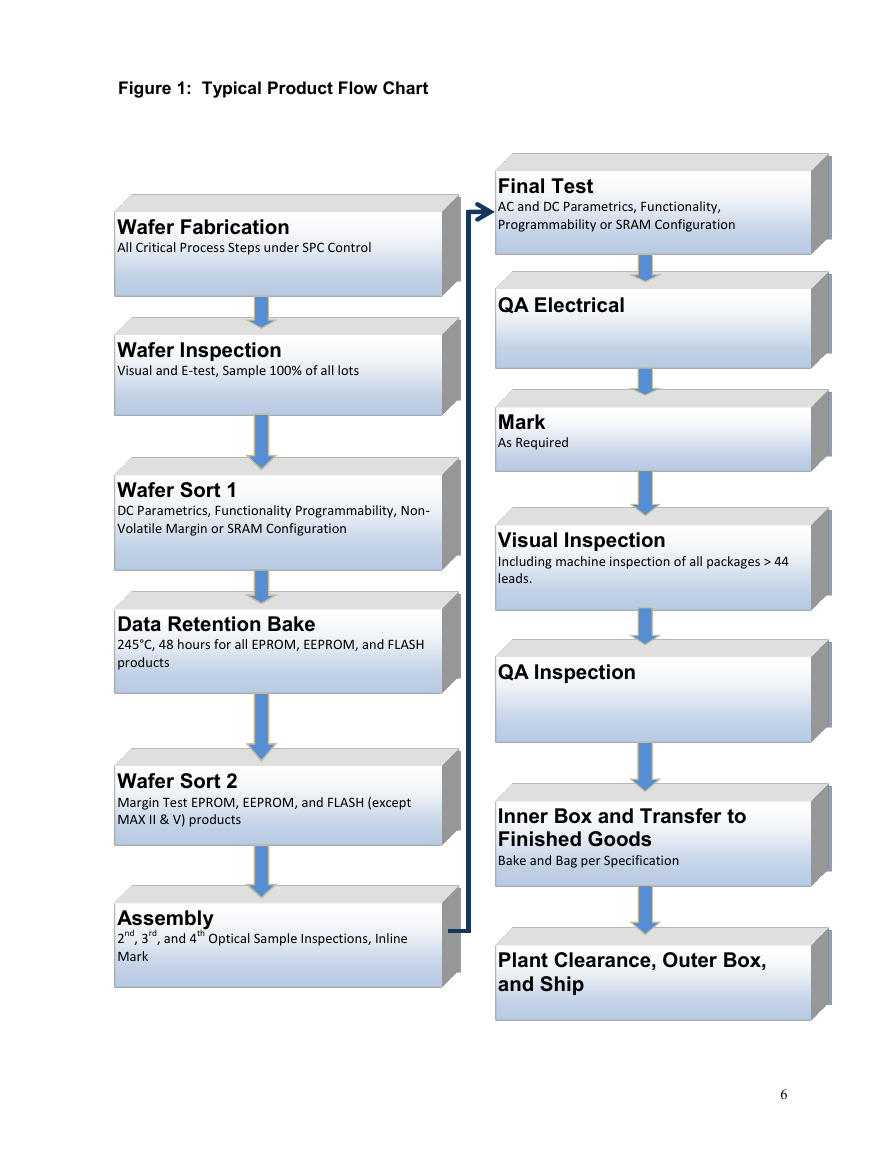

Altera performs comprehensive testing and manufacturing controls on all its products. Figure 1 shows a

typical product manufacturing flow.

5

�

Figure 1: Typical Product Flow Chart

Wafer Fabrication

All Critical Process Steps under SPC Control

Wafer Inspection

Visual and E-test, Sample 100% of all lots

Wafer Sort 1

DC Parametrics, Functionality Programmability, Non-

Volatile Margin or SRAM Configuration

Data Retention Bake

245°C, 48 hours for all EPROM, EEPROM, and FLASH

products

Wafer Sort 2

Margin Test EPROM, EEPROM, and FLASH (except

MAX II & V) products

Assembly

2nd, 3rd, and 4th Optical Sample Inspections, Inline

Mark

Final Test

AC and DC Parametrics, Functionality,

Programmability or SRAM Configuration

QA Electrical

Mark

As Required

Visual Inspection

Including machine inspection of all packages > 44

leads.

QA Inspection

Inner Box and Transfer to

Finished Goods

Bake and Bag per Specification

Plant Clearance, Outer Box,

and Ship

6

�

Reliability Methodology

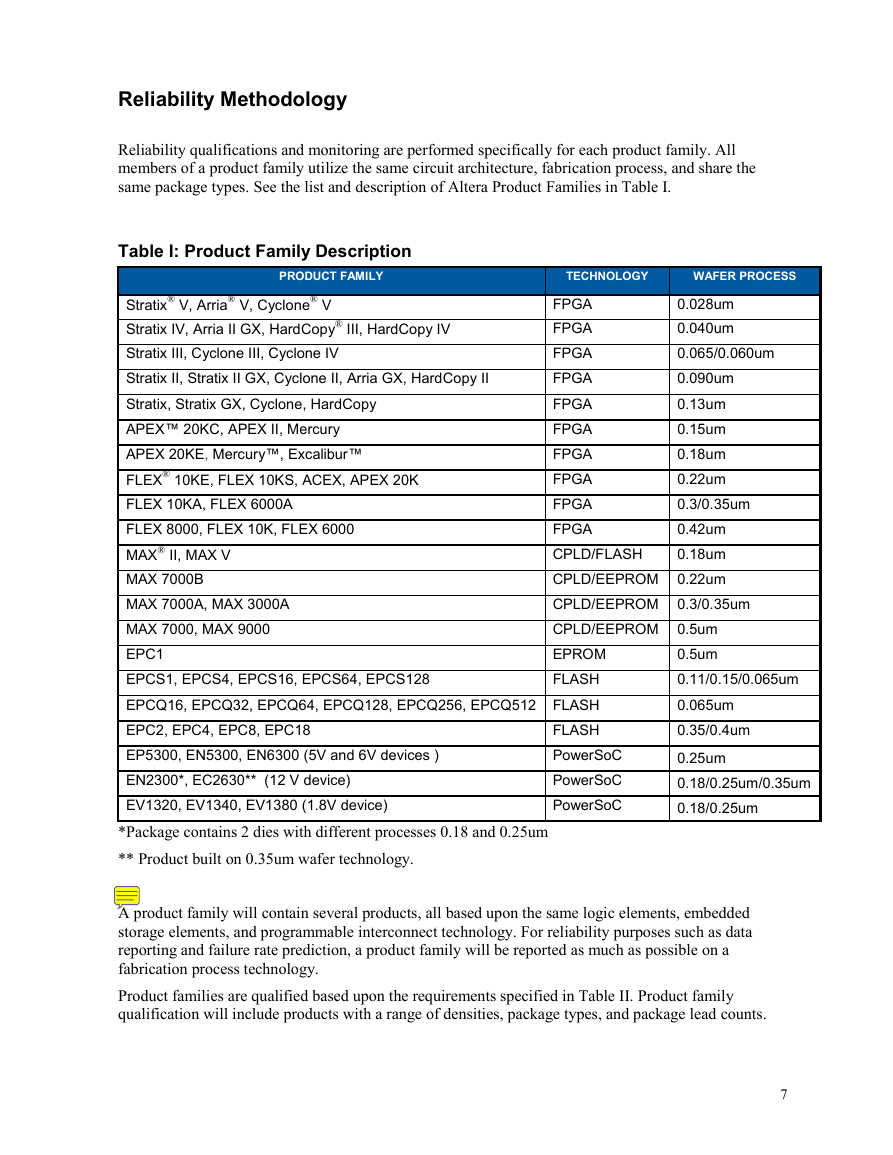

Reliability qualifications and monitoring are performed specifically for each product family. All

members of a product family utilize the same circuit architecture, fabrication process, and share the

same package types. See the list and description of Altera Product Families in Table I.

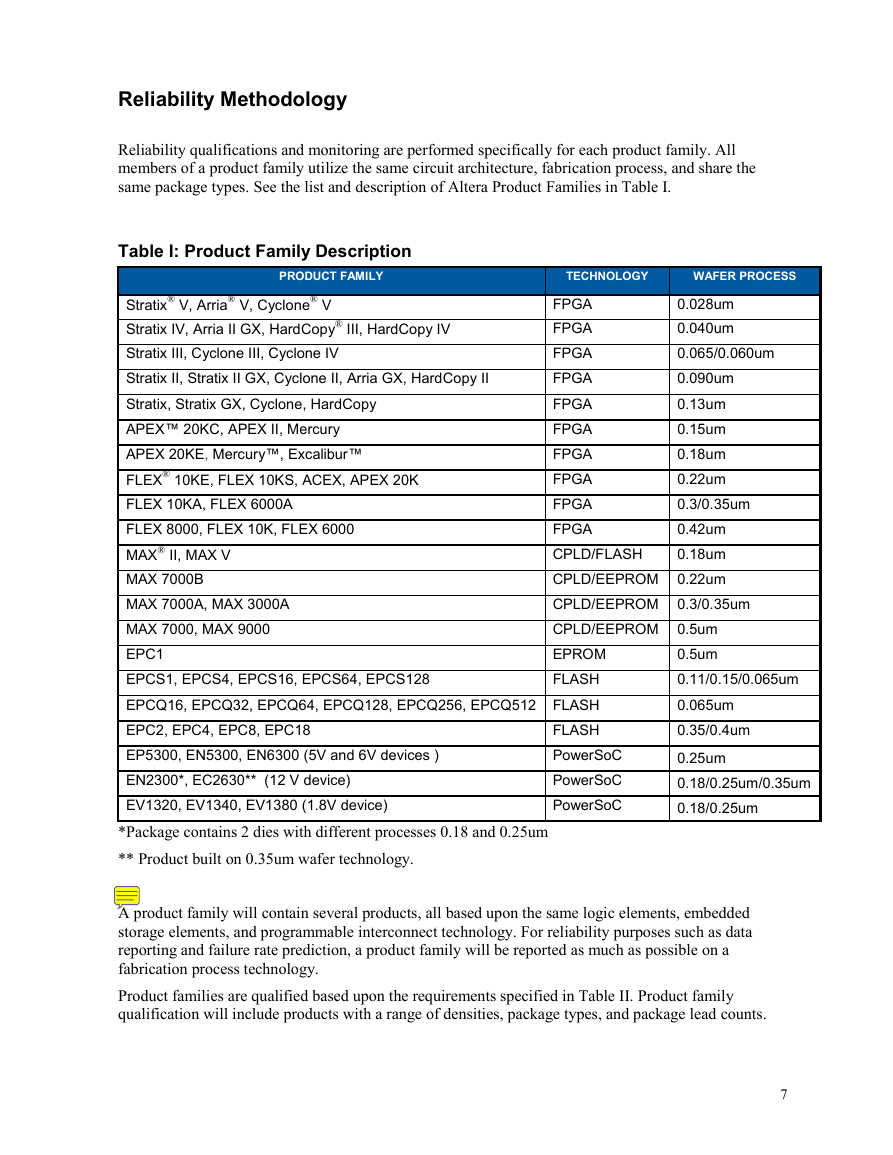

Table I: Product Family Description

PRODUCT FAMILY

TECHNOLOGY

WAFER PROCESS

Stratix® V, Arria® V, Cyclone® V

FPGA

0.028um

Stratix IV, Arria II GX, HardCopy® III, HardCopy IV

FPGA

0.040um

FPGA

0.065/0.060um

Stratix III, Cyclone III, Cyclone IV

FPGA

0.090um

Stratix II, Stratix II GX, Cyclone II, Arria GX, HardCopy II

FPGA

0.13um

Stratix, Stratix GX, Cyclone, HardCopy

FPGA

0.15um

APEX™ 20KC, APEX II, Mercury

FPGA

0.18um

APEX 20KE, Mercury™, Excalibur™

FLEX® 10KE, FLEX 10KS, ACEX, APEX 20K

FPGA

0.22um

FPGA

0.3/0.35um

FLEX 10KA, FLEX 6000A

FPGA

0.42um

FLEX 8000, FLEX 10K, FLEX 6000

MAX® II, MAX V

CPLD/FLASH

0.18um

CPLD/EEPROM 0.22um

MAX 7000B

CPLD/EEPROM 0.3/0.35um

MAX 7000A, MAX 3000A

CPLD/EEPROM 0.5um

MAX 7000, MAX 9000

0.5um

EPROM

EPC1

0.11/0.15/0.065um

EPCS1, EPCS4, EPCS16, EPCS64, EPCS128

FLASH

EPCQ16, EPCQ32, EPCQ64, EPCQ128, EPCQ256, EPCQ512 FLASH

0.065um

0.35/0.4um

FLASH

EPC2, EPC4, EPC8, EPC18

PowerSoC

EP5300, EN5300, EN6300 (5V and 6V devices )

0.25um

EN2300*, EC2630** (12 V device)

PowerSoC

0.18/0.25um/0.35um

EV1320, EV1340, EV1380 (1.8V device)

PowerSoC

0.18/0.25um

*Package contains 2 dies with different processes 0.18 and 0.25um

** Product built on 0.35um wafer technology.

A product family will contain several products, all based upon the same logic elements, embedded

storage elements, and programmable interconnect technology. For reliability purposes such as data

reporting and failure rate prediction, a product family will be reported as much as possible on a

fabrication process technology.

Product families are qualified based upon the requirements specified in Table II. Product family

qualification will include products with a range of densities, package types, and package lead counts.

7

�

If a new product is added to the product family with a significant increase (more than 50%) in logic

elements, a product qualification will be performed.

Reliability monitors are performed on a regular basis in order to assure that Altera’s normal production

testing and process control methodologies produce reliable products. The reliability monitor program is

also based upon a product family methodology.

Altera has a product reliability goal for long term failure rate. The long term failure rate is listed as

<200 FIT’s at 55°C use condition. Inherent in this requirement are two key components:

Product needs to meet lifetime goal of 100,000 hrs of useful life

The wear-out mechanisms are outside of the useful life of the product.

Different products and package types are procured from normal production on a Last in First out

(LIFO) schedule to monitor product reliability. Results in this report cover data gathered at least in the

last 36 months. For life-test, the report covers a much larger period to assess FIT numbers more

accurately.

Reliability monitor sampling is defined in Table III. Reliability monitor schedules depend on the

maturity of the product:

A) Minimum of 1 lot per quarter for new product in production since less than 5 years

B) Minimum of 1 lot per year for mature products in production for more than 5 years.

All new results shown in this reliability report compared to previous version appear upfront in each

table of results and are highlighted in a different color and font.

8

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc