Technical Product Information

Y 258 E00 015e

Seite/Page 1 von/of 13

Datum/Date 14.6.2005

Produkt / Product:

Typ / Type:

Bemerkung / Comment:

Nr.

Index

1

Seite

Page

-

Änderung

Revision

Erstausgabe / First Edition

translation to English

Planar Wide Band Lambda Sensor

LSU4.9

All data given in this document are nominal values

and might be subject of change at all time.

Datum

Date

14.6.05

26.8.05

GS-EX/ENG6-

Ham

gez Hamann

GS-EX/ENG6 GS-EX/ENG

gez Meier

gez.

Stanglmeier

1.

2.

3.

4.

5.

Contents

Characteristics

Application conditions

Functional values

Installation instructions

General operating instructions

2

5

7

9

12

©Alle Rechte bei Robert Bosch GmbH, auch für den Fall von Schutzrechtsanmeldungen. Jede Verfügungsbefugnis, wie Kopier- und Weitergaberecht, bei uns.

©Robert Bosch GmbH reserves all rights even in the event of industrial property.We reserve all rights of disposal such as copying and passing on to third parties

�

Technical Product Information

Y 258 E00 015e

Seite/Page 2 von/of 13

Datum/Date 14.6.2005

1.

1.1

1.2

General

The wide band lambda sensor LSU is a planar ZrO2 dual cell limiting current

sensor with an integrated heater. It is used to measure the oxygen content

and the λ-value of exhaust gases in automotive engines (gasoline and die-

sel). Its monotonic output signal in the range of λ=0.65 to air makes the

LSU capable of being used as an universal sensor for λ=1 measurement as

well as for other λ ranges.

The connector module contains a trimming resistor, which defines the

characteristics of the sensor and is necessary for the sensor function.

The wide band sensor LSU operates only in combination with a special

LSU control unit (e.g. AWS control box, LA4 or CJ125 IC).

Characteristics

Circuit of LSU and control unit

APE

← Ip

red

Trimming Resistor

30-300 Ohm

green

AWS

← Ipmeas

Measuring

Resistance 61.9 Ohm

IP

IA

+

−

IPN

yellow

VM=2,5V

RE

UN

+

−

Reference

Voltage

450 mV

VCC

RV

Sensor Cell

O2, CO, HC, H2

O2−

O2−

H-

H+

20 µA Reference Pump Current

Ri-control

−

+

black

white

grey

red

yellow

white

grey

green

black

Electrical connection:

Pin1: Pumping Current APE

Pin2: Virtual Ground IPN

Pin3: Heater Minus H-

Pin4: Heater Vbatt H+

Pin5: Trim Current RT

Pin6: Nernst Voltage RE+

©Alle Rechte bei Robert Bosch GmbH, auch für den Fall von Schutzrechtsanmeldungen. Jede Verfügungsbefugnis, wie Kopier- und Weitergaberecht, bei uns.

©Robert Bosch GmbH reserves all rights even in the event of industrial property.We reserve all rights of disposal such as copying and passing on to third parties

�

Technical Product Information

Y 258 E00 015e

Seite/Page 3 von/of 13

Datum/Date 14.6.2005

Sensor element

The heater supply voltage must be controlled, so that the temperature of

the sensor is kept at the operation point. The temperature is measured by

measuring the internal resistance of the sensor’s Nernst cell Ri,N

Nominal internal resistance of λ=1 Nernst cell Ri,N

for new sensors (operating and calibration point)

(measured with AC f = 1...4 kHz)

300 Ω

Max. current load of λ=1 Nernst cell

Continuous AC (f = 1...4 kHz)

for RI,N measurement

≤ 250 µA

Recommended value for reference pumping current

continuous

= 20 µA

Max. pumping current into pump cell (Ip)

- for rich gas signal (λ≥0,65)

- for lean gas signal (air)

≥ -9 mA

≤ 6 mA

Isolation resistance

(all values for new sensors in static air, heater off)

- between housing and each heater- and

sensor circuit connector pin at room

temperature

- between sensor signal circuit and heater

circuit at 600°C hexagon temperature

- between sensor signal pin APE and housing

at 600°C hexagon temperature:

≥ 30 MΩ

≥ 1 MΩ

≥ 100 kΩ

1.3

1.4

©Alle Rechte bei Robert Bosch GmbH, auch für den Fall von Schutzrechtsanmeldungen. Jede Verfügungsbefugnis, wie Kopier- und Weitergaberecht, bei uns.

©Robert Bosch GmbH reserves all rights even in the event of industrial property.We reserve all rights of disposal such as copying and passing on to third parties

�

Technical Product Information

Y 258 E00 015e

Seite/Page 4 von/of 13

Datum/Date 14.6.2005

Heater supply

Nominal voltage:

7.5 V

Nominal heater power at 7.5 V heater supply

at thermal equilibrium in air:

approx. 7.5 W

Nominal heater cold resistance at room temp.

for new sensor, including cable and connector

Minimum heater cold resistance at -40°C:

3.2 Ω

1.8 Ω

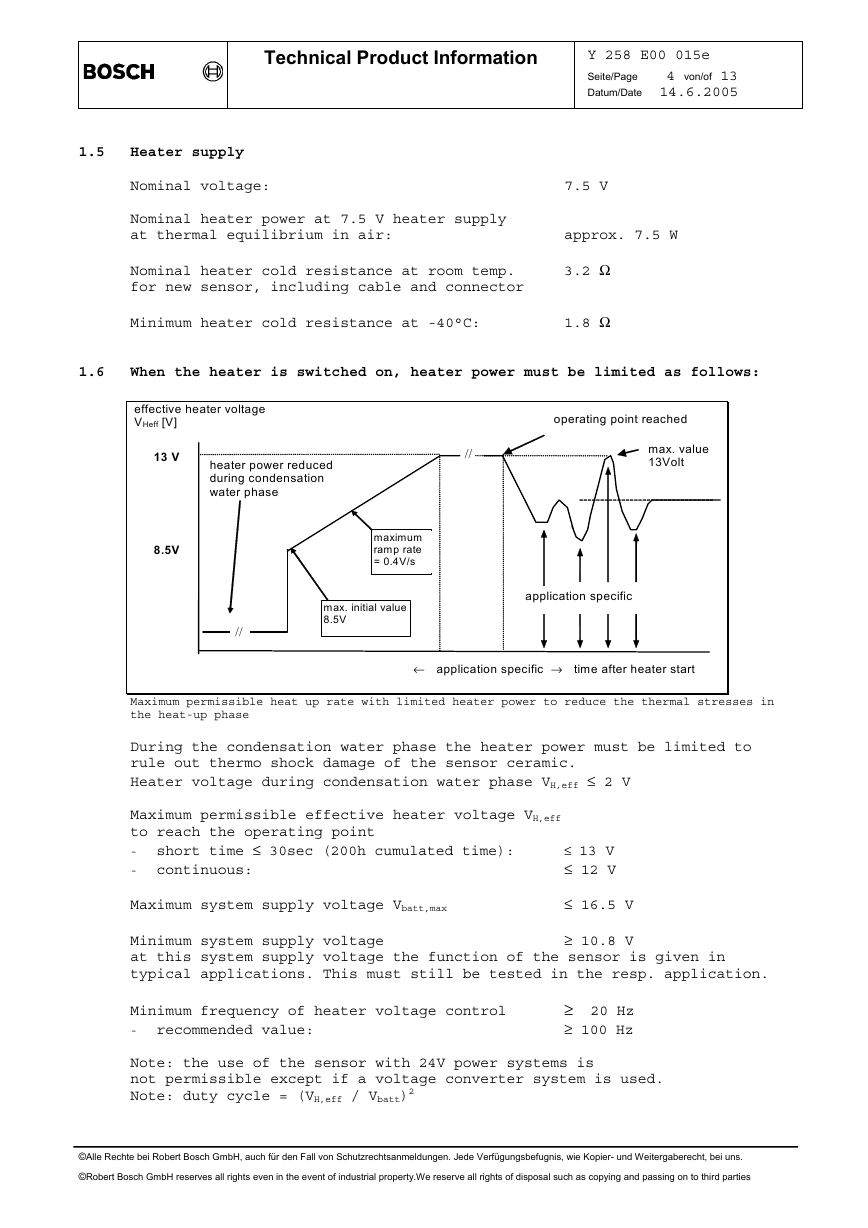

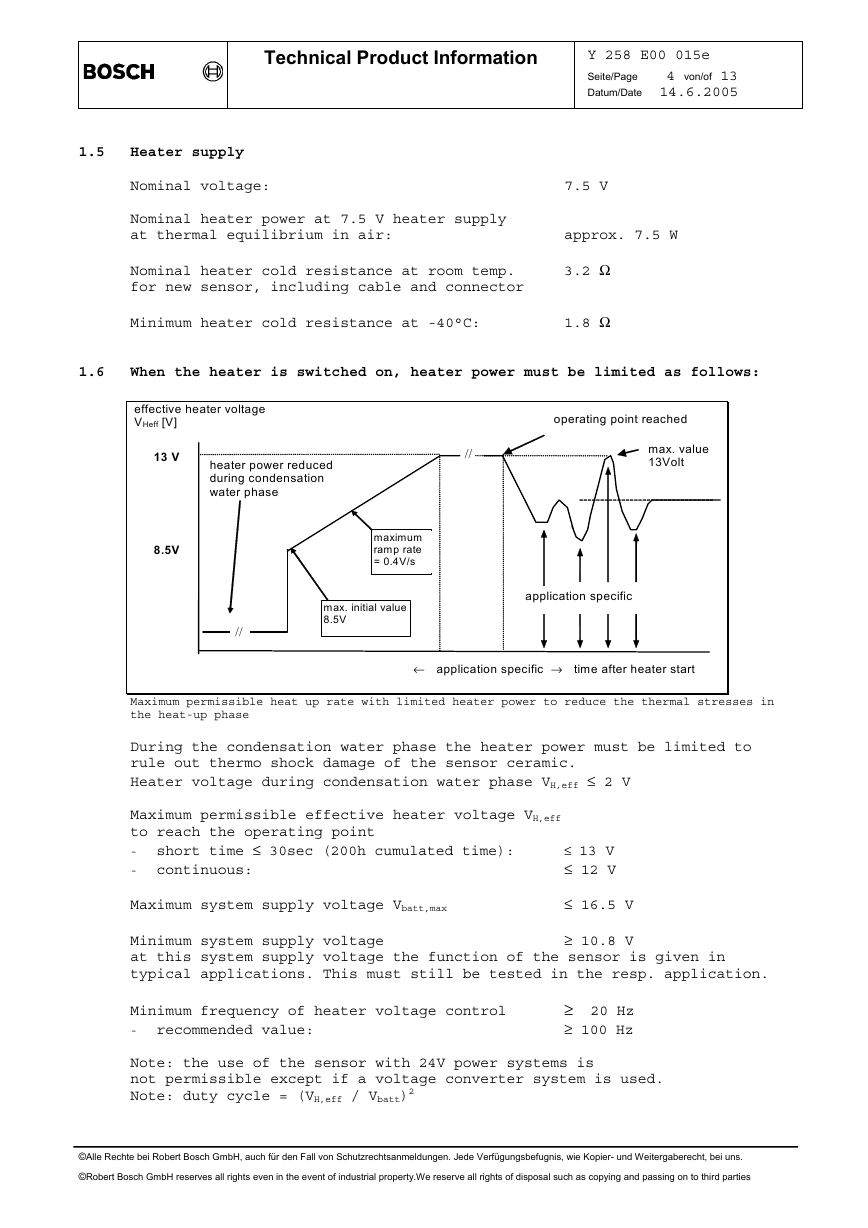

When the heater is switched on, heater power must be limited as follows:

1.5

1.6

effective heater voltage

VHeff [V]

operating point reached

//

max. value

13Volt

13 V

8.5V

heater power reduced

during condensation

water phase

maximum

ramp rate

= 0.4V/s

max. initial value

8.5V

//

application specific

← application specific → time after heater start

Maximum permissible heat up rate with limited heater power to reduce the thermal stresses in

the heat-up phase

During the condensation water phase the heater power must be limited to

rule out thermo shock damage of the sensor ceramic.

Heater voltage during condensation water phase VH,eff ≤ 2 V

Maximum permissible effective heater voltage VH,eff

to reach the operating point

- short time ≤ 30sec (200h cumulated time):

- continuous:

≤ 13 V

≤ 12 V

Maximum system supply voltage Vbatt,max

≤ 16.5 V

Minimum system supply voltage

at this system supply voltage the function of the sensor is given in

typical applications. This must still be tested in the resp. application.

≥ 10.8 V

Minimum frequency of heater voltage control

- recommended value:

≥ 20 Hz

≥ 100 Hz

Note: the use of the sensor with 24V power systems is

not permissible except if a voltage converter system is used.

Note: duty cycle = (VH,eff / Vbatt)2

©Alle Rechte bei Robert Bosch GmbH, auch für den Fall von Schutzrechtsanmeldungen. Jede Verfügungsbefugnis, wie Kopier- und Weitergaberecht, bei uns.

©Robert Bosch GmbH reserves all rights even in the event of industrial property.We reserve all rights of disposal such as copying and passing on to third parties

�

Technical Product Information

Y 258 E00 015e

Seite/Page 5 von/of 13

Datum/Date 14.6.2005

Application conditions

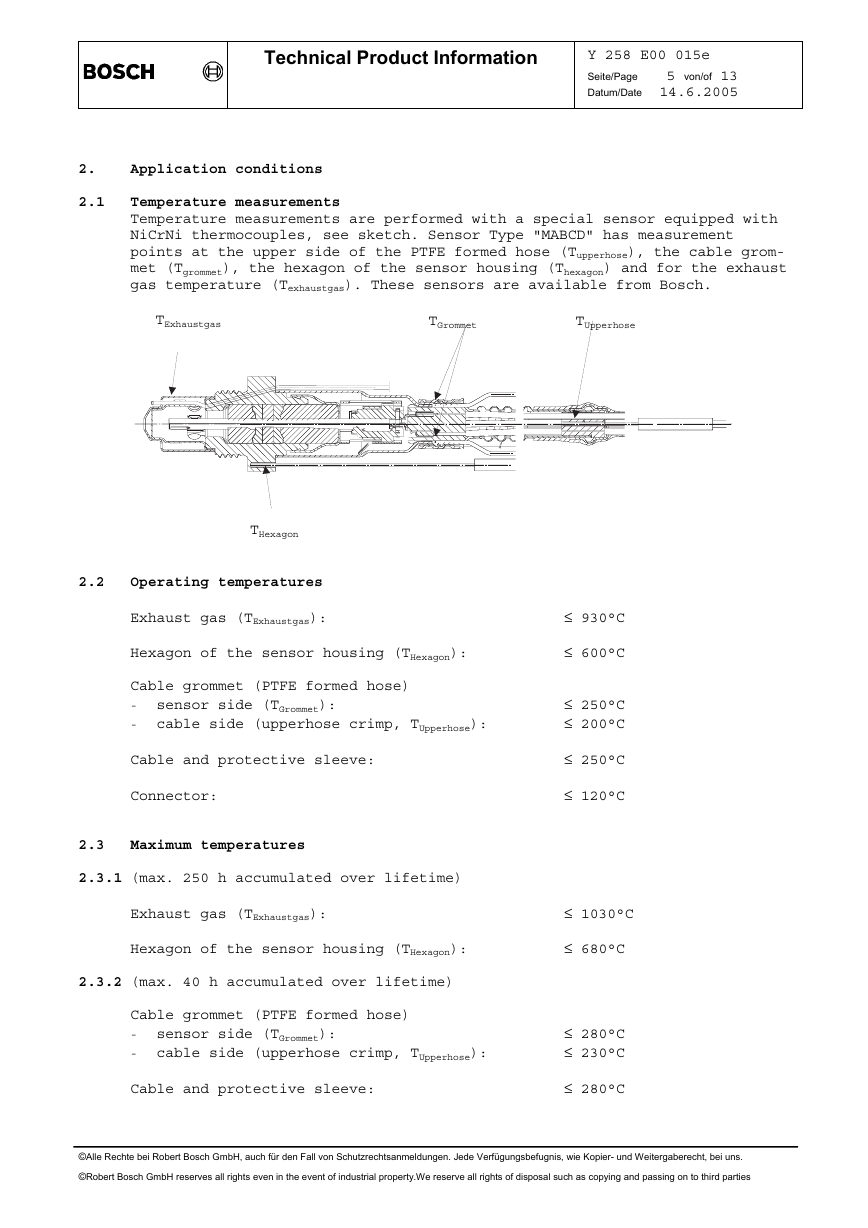

Temperature measurements

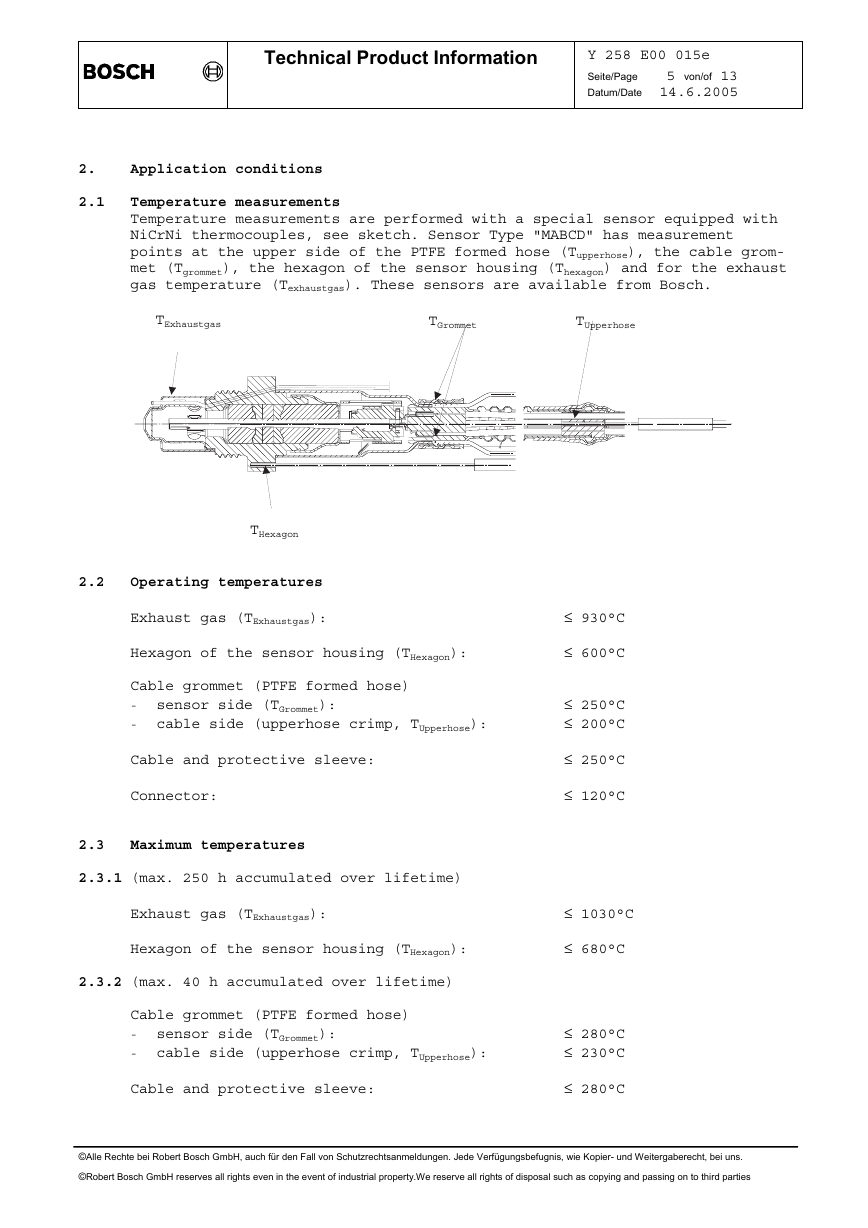

Temperature measurements are performed with a special sensor equipped with

NiCrNi thermocouples, see sketch. Sensor Type "MABCD" has measurement

points at the upper side of the PTFE formed hose (Tupperhose), the cable grom-

met (Tgrommet), the hexagon of the sensor housing (Thexagon) and for the exhaust

gas temperature (Texhaustgas). These sensors are available from Bosch.

TExhaustgas

TGrommet

TUpperhose

2.

2.1

2.2

THexagon

Operating temperatures

Exhaust gas (TExhaustgas):

Hexagon of the sensor housing (THexagon):

Cable grommet (PTFE formed hose)

- sensor side (TGrommet):

- cable side (upperhose crimp, TUpperhose):

≤ 930°C

≤ 600°C

≤ 250°C

≤ 200°C

≤ 250°C

≤ 120°C

≤ 1030°C

≤ 680°C

≤ 280°C

≤ 230°C

≤ 280°C

Cable and protective sleeve:

2.3

2.3.1 (max. 250 h accumulated over lifetime)

Connector:

Maximum temperatures

Exhaust gas (TExhaustgas):

2.3.2 (max. 40 h accumulated over lifetime)

Hexagon of the sensor housing (THexagon):

Cable grommet (PTFE formed hose)

- sensor side (TGrommet):

- cable side (upperhose crimp, TUpperhose):

Cable and protective sleeve:

©Alle Rechte bei Robert Bosch GmbH, auch für den Fall von Schutzrechtsanmeldungen. Jede Verfügungsbefugnis, wie Kopier- und Weitergaberecht, bei uns.

©Robert Bosch GmbH reserves all rights even in the event of industrial property.We reserve all rights of disposal such as copying and passing on to third parties

�

Technical Product Information

Y 258 E00 015e

Seite/Page 6 von/of 13

Datum/Date 14.6.2005

2.4

2.5

2.6

2.7

Exhaust gas pressure (absolute pressure)

- continuous:

- short time, max. 250h cumulated over lifetime ≤ 4 bar

≤ 2.5 bar

Notes:

If the operating temperature ( 2.2) or the max. continuous exhaust gas

pressure ( 2.4) is exceeded, the sensor accuracy might be limited during

this time.

Permissible vibrations

Stochastic vibrations: (peak level)

Sinusoidal vibrations:

≤ 1000 m/s2

≤ 300 m/s2

Corrosion, humidity

The lambda sensor has been developed and tested for use in automotive vehi-

cles, e.g.

- damp heat cycling acc. to IEC 68-2-30 test Db (21 days, 40°C)

- salt mist test acc. to IEC 68-2-11 test Ka, test time 288 h

- temperature cycling test acc. to IEC 68-2-14 test Na,

250 cycles -40°C / 130°C

- sulfur dioxide test with general condensation of moisture acc. to DIN EN

ISO 6988, 6 cycles of 24h

- submergence test IPx7 acc. to IEC 529

Permissible fuel additives

In accordance with DIN EN228 for commercially available unleaded fuel or

EN590 for diesel fuel.

Contamination by other fuels, additives or oil consumption must be deter-

mined by the customer by the way of adequate large-scale tests.

©Alle Rechte bei Robert Bosch GmbH, auch für den Fall von Schutzrechtsanmeldungen. Jede Verfügungsbefugnis, wie Kopier- und Weitergaberecht, bei uns.

©Robert Bosch GmbH reserves all rights even in the event of industrial property.We reserve all rights of disposal such as copying and passing on to third parties

�

Technical Product Information

Y 258 E00 015e

Seite/Page 7 von/of 13

Datum/Date 14.6.2005

3.

3.1

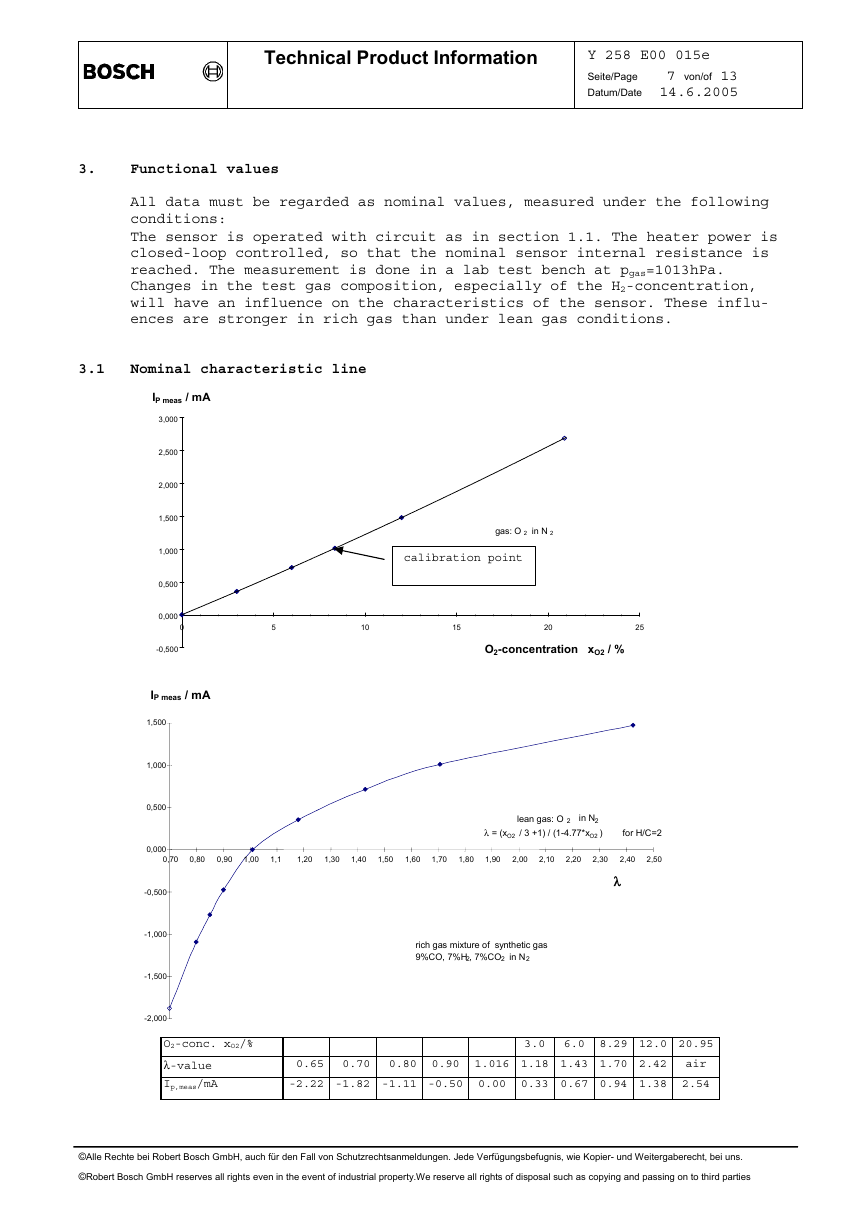

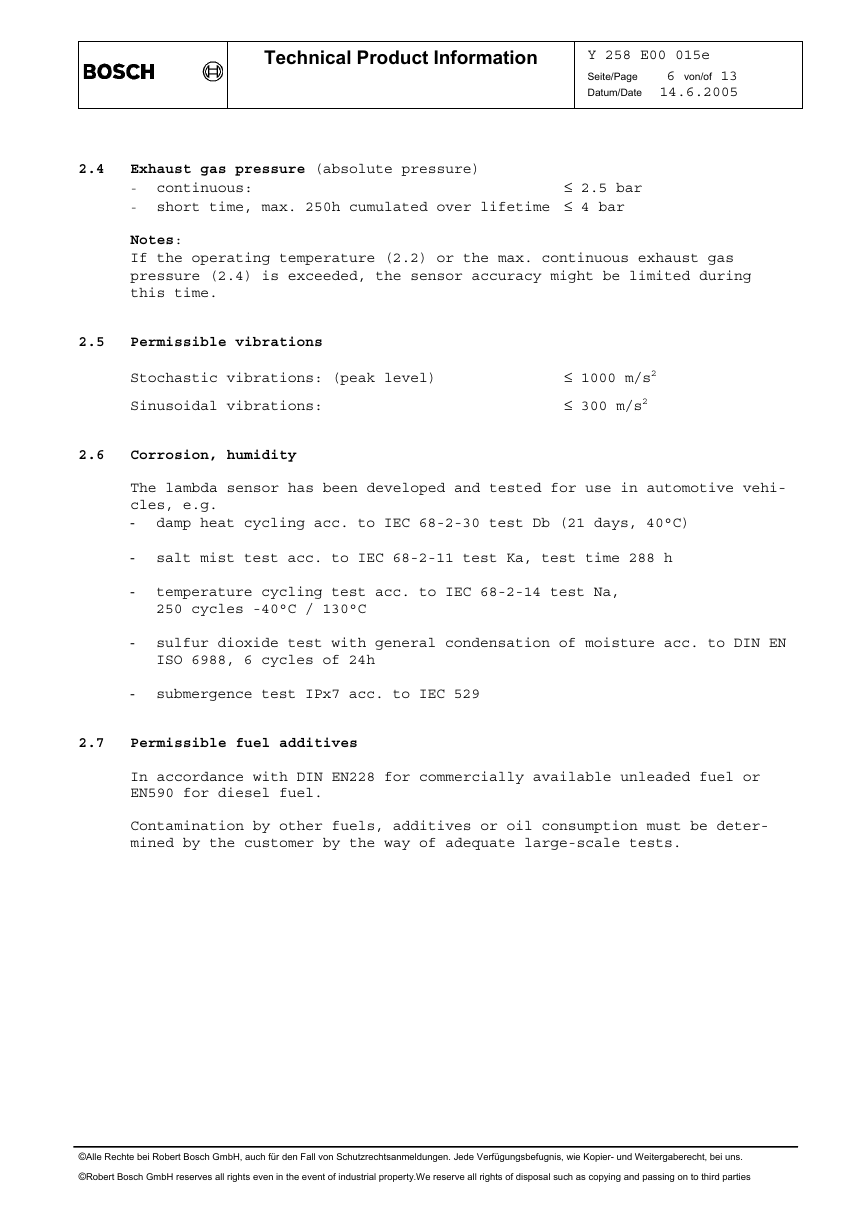

Functional values

All data must be regarded as nominal values, measured under the following

conditions:

The sensor is operated with circuit as in section 1.1. The heater power is

closed-loop controlled, so that the nominal sensor internal resistance is

reached. The measurement is done in a lab test bench at pgas=1013hPa.

Changes in the test gas composition, especially of the H2-concentration,

will have an influence on the characteristics of the sensor. These influ-

ences are stronger in rich gas than under lean gas conditions.

Nominal characteristic line

IP meas / mA

3,000

2,500

2,000

1,500

1,000

0,500

0,000

0

-0,500

IP meas / mA

gas: O 2 in N 2

calibration point

5

10

15

20

25

O2-concentration xO2 / %

1,500

1,000

0,500

0,000

0,70

-0,500

-1,000

-1,500

-2,000

0,80

0,90

1,00

1,1

1,20

1,30

1,40

1,50

1,60

1,70

1,80

1,90

2,00

2,10

2,20

2,30

2,50

2,40

λ

lean gas: O 2 in N2

λ = (xO2 / 3 +1) / (1-4.77*xO2 ) for H/C=2

rich gas mixture of synthetic gas

9%CO, 7%H2, 7%CO2 in N2

O2-conc. xO2/%

λ-value

Ip,meas/mA

3.0 6.0 8.29 12.0 20.95

0.65 0.70 0.80

0.90 1.016 1.18 1.43 1.70 2.42 air

-2.22 -1.82 -1.11 -0.50

0.00 0.33 0.67 0.94 1.38 2.54

©Alle Rechte bei Robert Bosch GmbH, auch für den Fall von Schutzrechtsanmeldungen. Jede Verfügungsbefugnis, wie Kopier- und Weitergaberecht, bei uns.

©Robert Bosch GmbH reserves all rights even in the event of industrial property.We reserve all rights of disposal such as copying and passing on to third parties

�

Technical Product Information

Y 258 E00 015e

Seite/Page 8 von/of 13

Datum/Date 14.6.2005

3.2

3.3

Time to activity (light-off time)

Guide value for the time to activity after switching

on the sensor heater (“light-off time”)

≤ 10 s

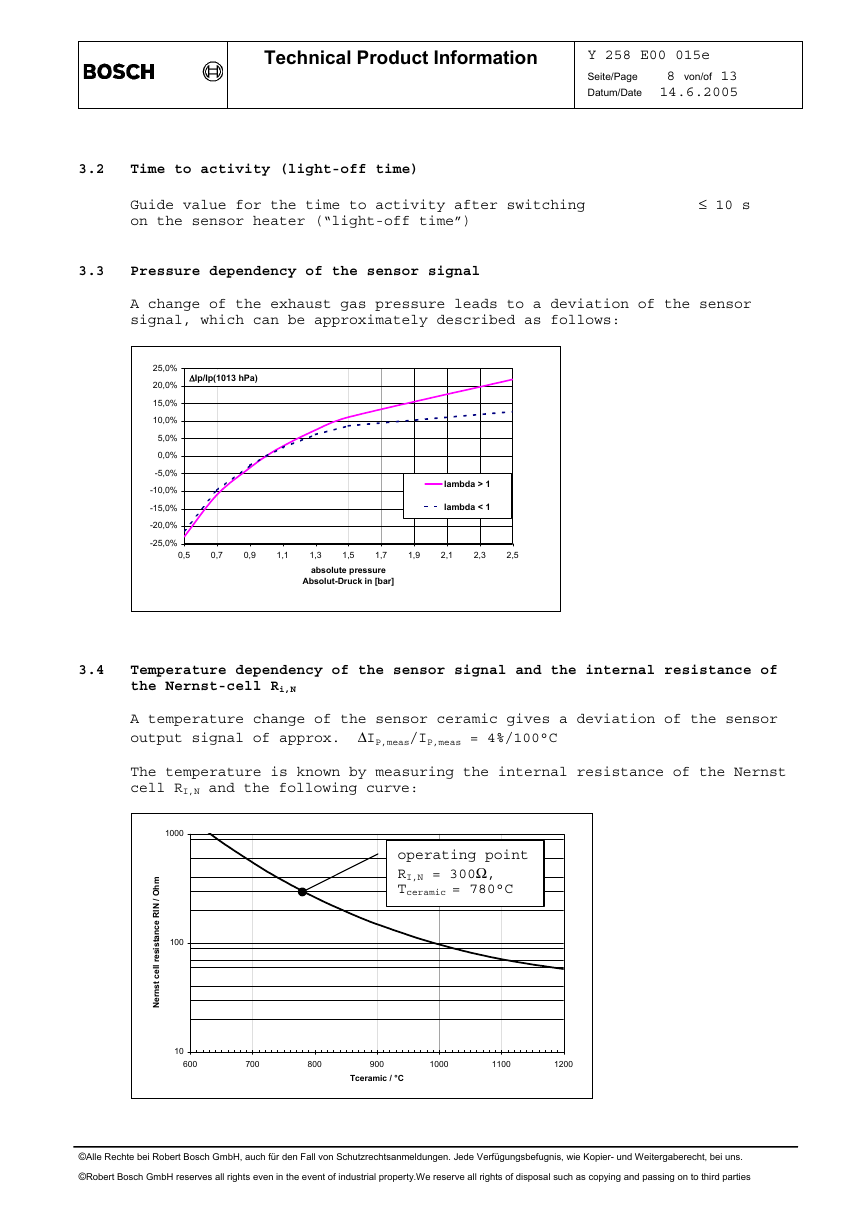

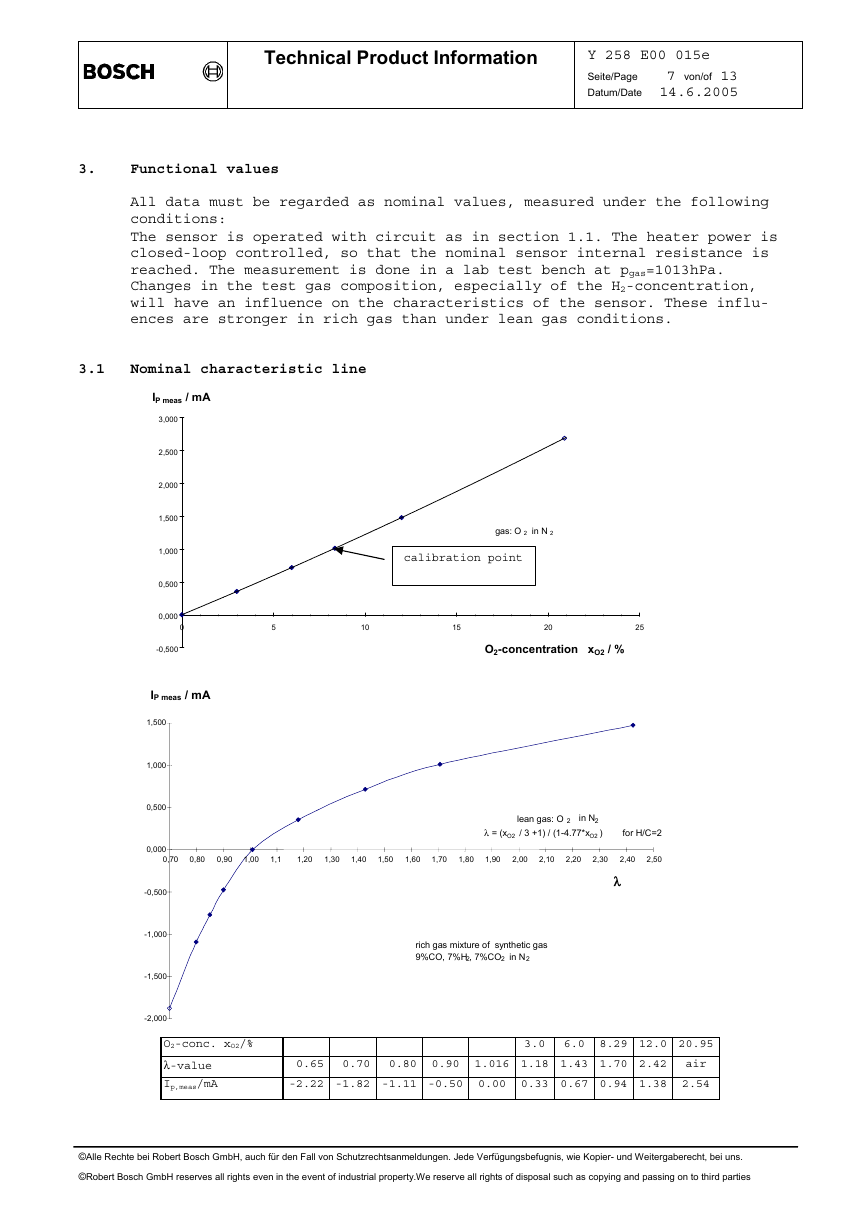

Pressure dependency of the sensor signal

A change of the exhaust gas pressure leads to a deviation of the sensor

signal, which can be approximately described as follows:

∆Ip/Ip(1013 hPa)

25,0%

20,0%

15,0%

10,0%

5,0%

0,0%

-5,0%

-10,0%

-15,0%

-20,0%

-25,0%

0,5

0,7

0,9

1,1

lambda > 1

lambda < 1

1,9

2,1

2,3

2,5

1,5

1,7

1,3

absolute pressure

Absolut-Druck in [bar]

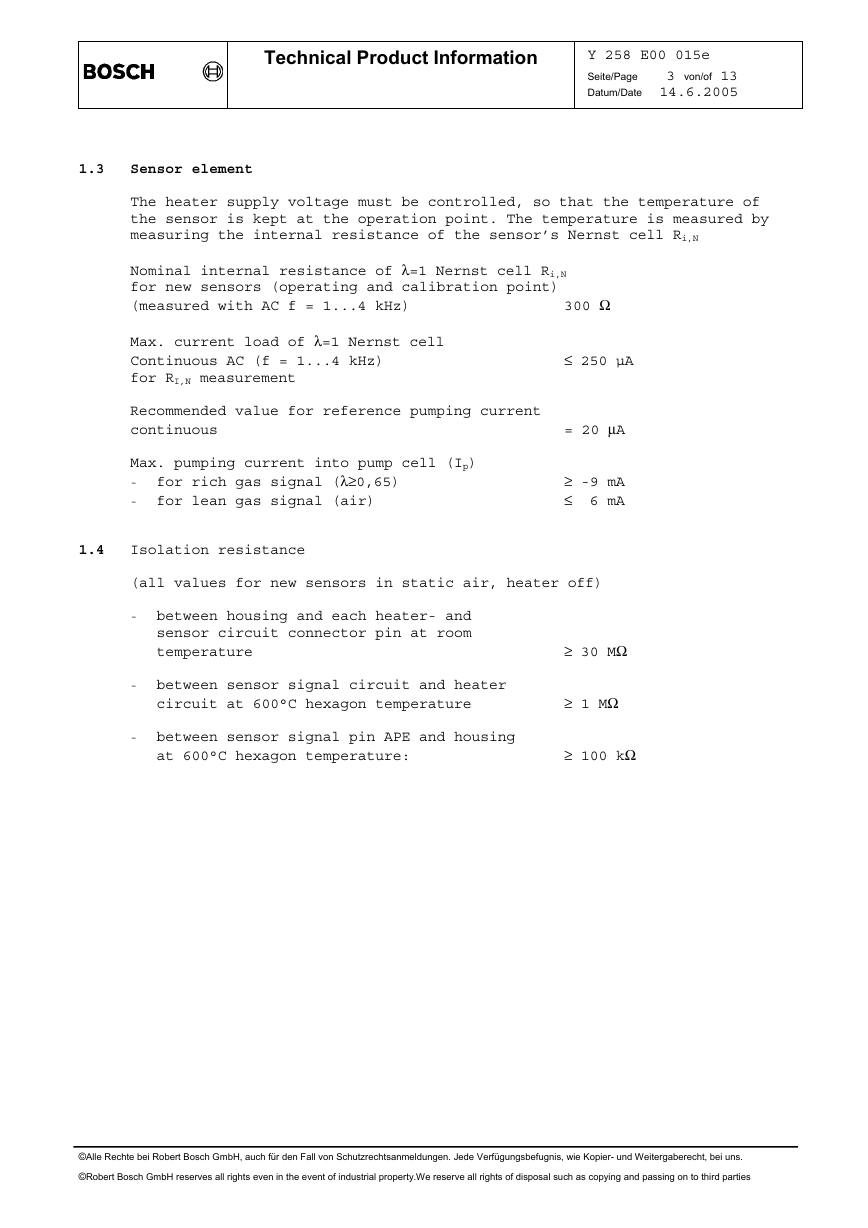

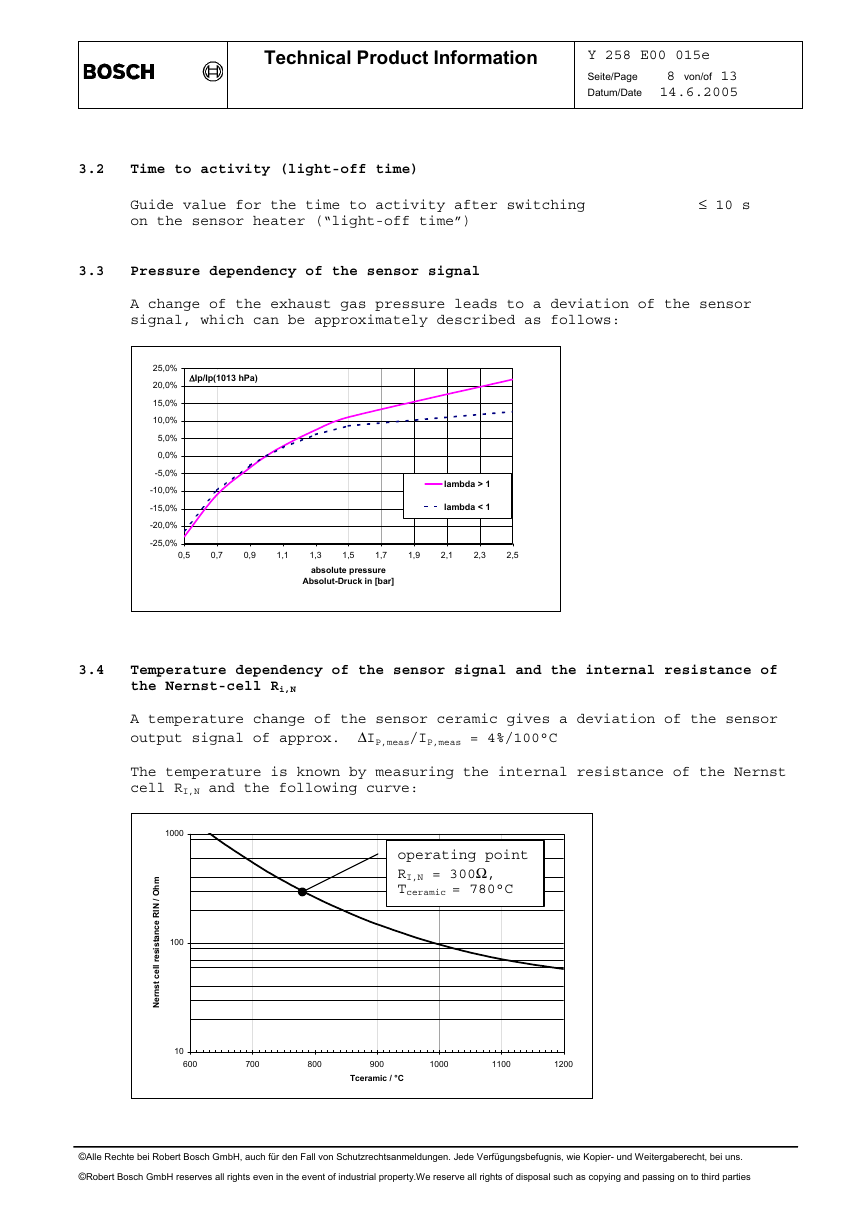

Temperature dependency of the sensor signal and the internal resistance of

the Nernst-cell Ri,N

A temperature change of the sensor ceramic gives a deviation of the sensor

output signal of approx. ∆IP,meas/IP,meas = 4%/100°C

The temperature is known by measuring the internal resistance of the Nernst

cell RI,N and the following curve:

1000

100

operating point

RI,N = 300Ω,

Tceramic = 780°C

m

h

O

/

I

N

R

e

c

n

a

t

s

i

s

e

r

l

l

e

c

t

s

n

r

e

N

10

600

700

800

900

1000

1100

1200

Tceramic / °C

3.4

©Alle Rechte bei Robert Bosch GmbH, auch für den Fall von Schutzrechtsanmeldungen. Jede Verfügungsbefugnis, wie Kopier- und Weitergaberecht, bei uns.

©Robert Bosch GmbH reserves all rights even in the event of industrial property.We reserve all rights of disposal such as copying and passing on to third parties

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc