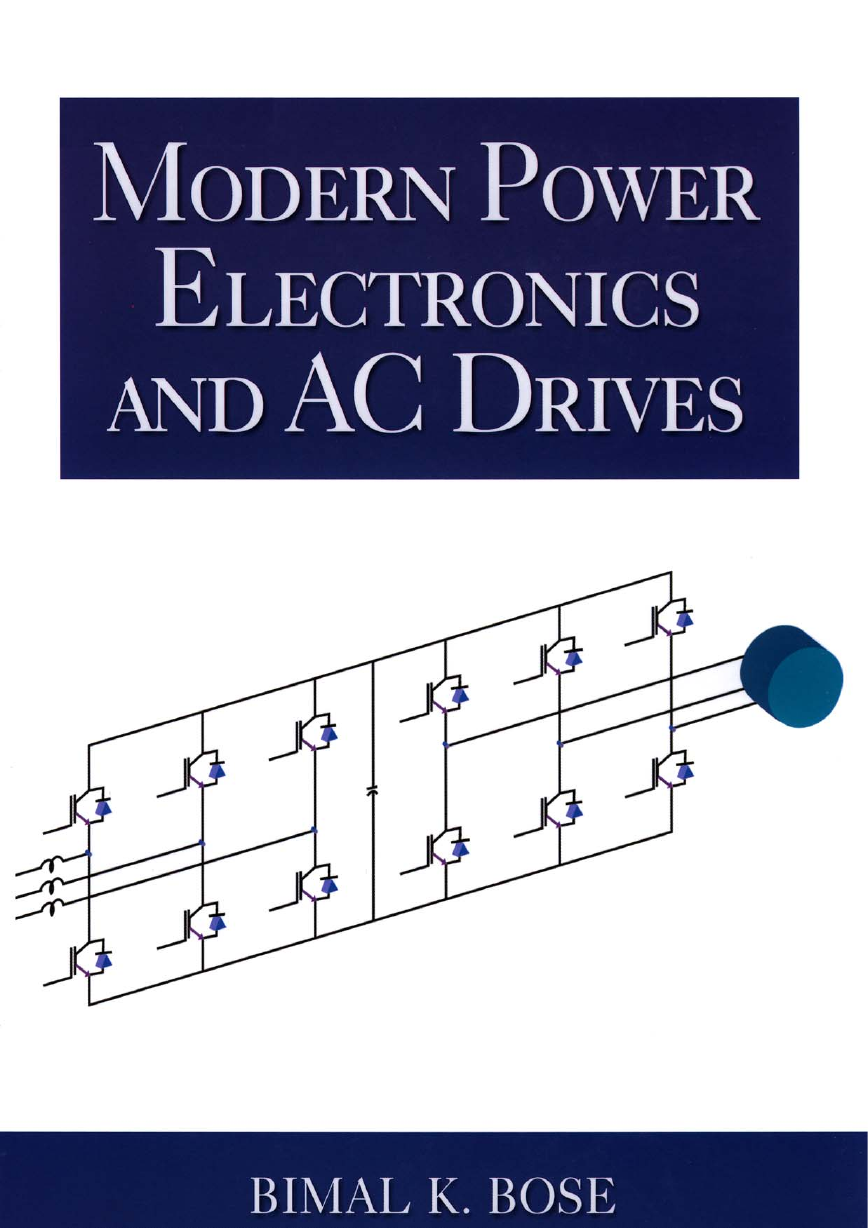

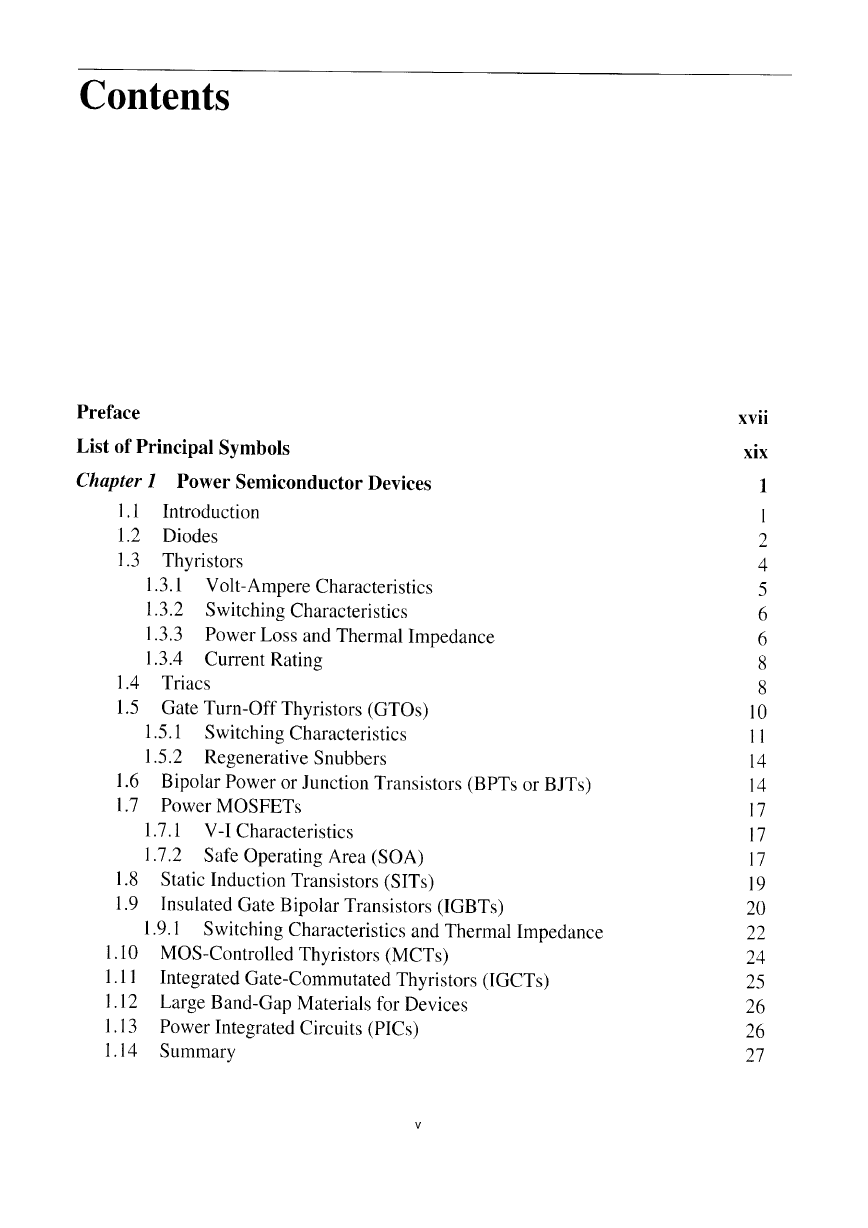

Modern Power Electronics and AC Drives

Preface

List of Principal Symbols

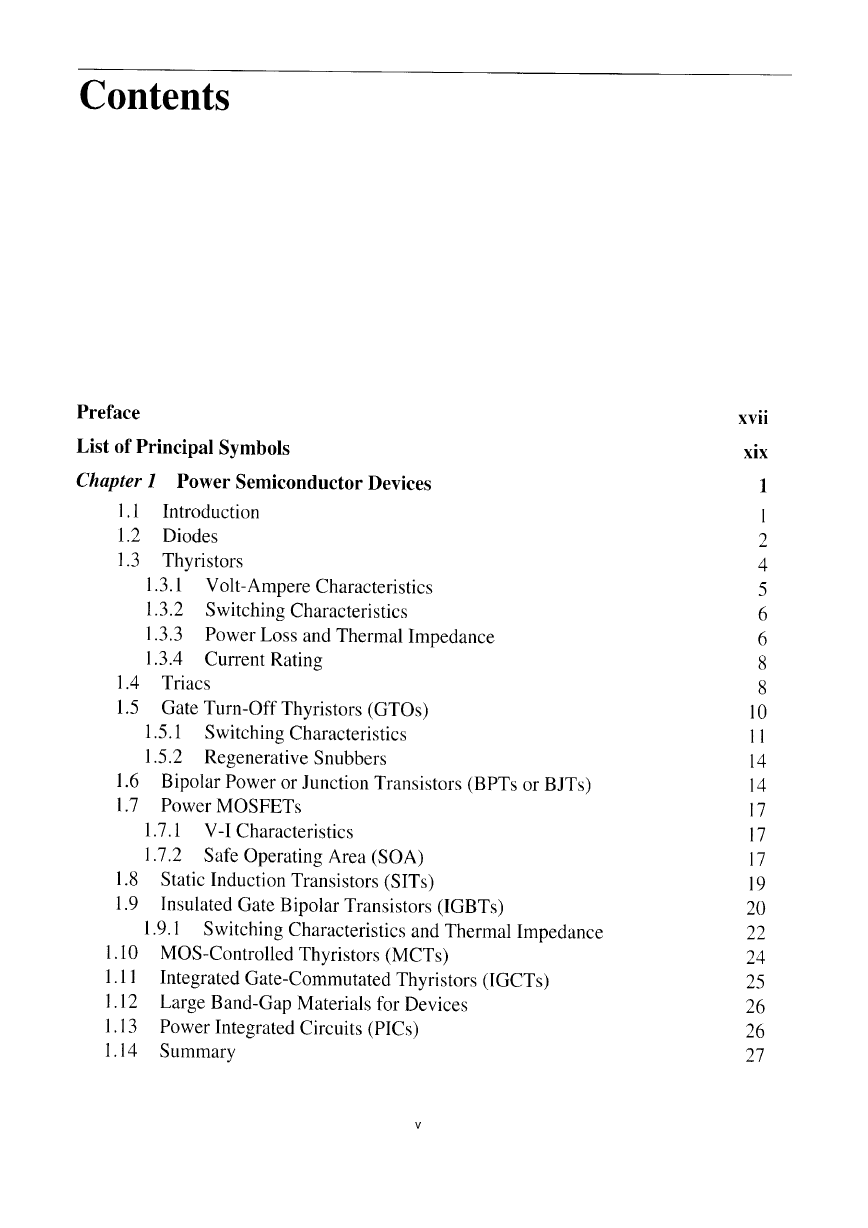

Chapter 1 Power Semiconductors Devices

1.2 Diodes

1.1 Introduction

1.3 Thyristors

1.3.1 Volt Ampere Characteristics

1.3.2 Switching Characteristics

1.3.3 Power Loss and Thermal Impedance

1.3.4 Current Rating

1.4 Triacs

1.5 Gate Turn-Off Thyristors (GTOs)

1.5.1 Switching Characteristics

1.5.2 Regenerative Snubbers

1.6 Bipolar Power or Junction Transistors (BPTs or BJTs)

1.7 Power MOSFETs

1.7.1 V-I Characteristics

1.7.2 Safe Operating Area (SOA)

1.8 Static Induction Transistors (SITs)

1.9 Insulated Gate Bipolar Transistors (IGBTs)

1.9.1 Switching Cgaracteristics and Thermal Impedance

1.10 MOS-Controlled Thyristors (MCTs)

1.11 Integrated Gate-Commutated Thyristors (IGCTs)

1.12 Large Band-Gap Materials for Devices

1.13 Power Integrated Circuits (PICs)

1.14 Summary

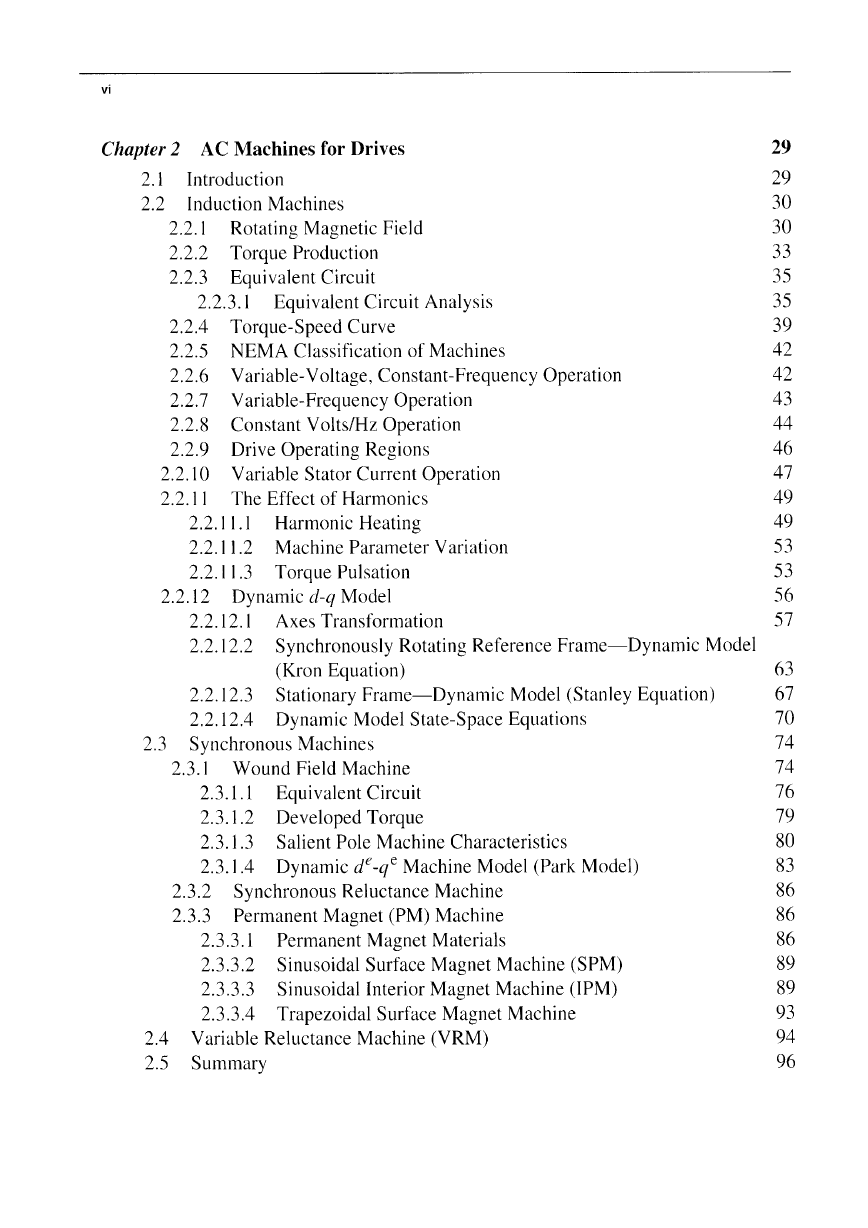

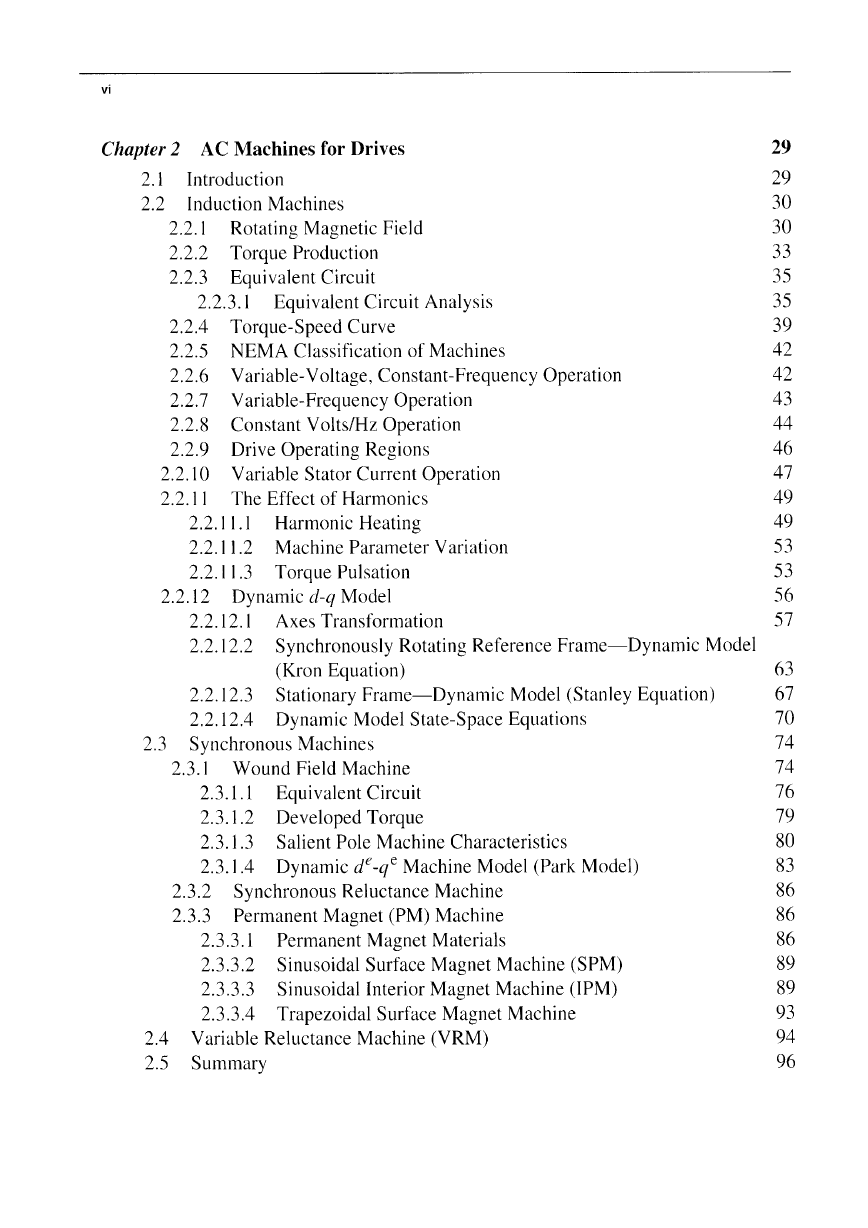

Chapter 2 AC Machines for Drivers

2.1 Introduction

2.2 Induction Machines

2.2.1 Rotating Magnetic Field

2.2.2 Torque Production

2.2.3 Equivalent Circuit

2.2.4 Torque-Speed Curve

2.2.5 NEMA Classification of Machines

2.2.6 Variable-Voltage, Constant-Frequency Operation

2.2.7 Variable-Frequency Operation

2.2.8 Constant Volts/Hz Operation

2.2.9 Drive Operating Regions

2.2.10 Variable Stator Current Operation

2.2.11 The Effect of Harmonics

2.2.11.1 Harmonic Heating

2.2.11.2 Machine Parameter Variation

2.2.11.3 Torque Pulsation

2.2.12 Dynamic d-q Model

2.2.12.1 Axes Transformation

2.2.12.2 Synchronously Rotating Reference Frame - Dynamic Model (Kron Equation)

2.2.12.3 Stationary Frame - Dynamic Model (Stanley Equation)

2.2.12.4 Dynamic Model State-Space Equations

2.3 Synchronous Machines

2.3.1 Wound Field Machine

2.3.1.1 Equivalent Circuit

2.3.1.2 Developed Torque

2.3.1.3 Salient Pole Machine Characteristics

2.3.1.4 Dynamic d-q Machine Model (Park Model)

2.3.2 Synchronous Reluctance Machine

2.3.3 Permanent Magnet (PM) Machine

2.3.3.1 Permanent Magnet Materials

2.3.3.2 Sinusoidal Surface Magnet Machine (SPM)

2.3.3.3 Sinusoidal Interior Magnet Machine (IPM)

2.3.3.4 Trapezoidal Surface Magnet Machine

2.4 Variable Reluctance Machine (VRM)

2.5 Summary

Chapter 3 Diodes and Phase-Controlled Converters

3.1 Introduction

3.2 Diode Rectifiers

3.2.1 Single-Phase Bridge - R, RL Load

3.2.2 Effect of Source Inductance

3.2.3 Single-Phase Bridge - RL, CEMF Load

3.2.4 Single-Phase Bridge - CR Load

3.2.5 Distortion, Displacement, and Power Factors

3.2.6 Distortion Factor (DF)

3.2.7 Displacement Power Factor (DPF)

3.2.8 Power Factor (PF)

3.2.9 Three-Phase Full Bridge - RL Load

3.2.10 Three-Phase Bridge - CR Load

3.3 Thristor Converters

3.3.1 Single-Phase Bridge - RL, CEMF Load

3.3.2 Discontinuous Conduction

3.3.3 Three-Phase Converter - RL, CEMF Load

3.3.4 Three-Phase, Half-Wave Converter

3.3.5 Analysis for Line Leakage Inductance (Lc)

3.3.6 Three-Phase Bridge Converter

3.3.7 Discontinuous Conduction

3.3.8 Three-Phase Dual Converter

3.3.9 Six-Pulse, Center-Tap Converter

3.3.10 12-Pulse Converter

3.3.11 Concurrent and Sequential Control of bridge Converters

3.4 Converter Control

3.4.1 Linear Firing Angle Control

3.4.2 Cosine Wave Crossing Control

3.4.3 Phase-Locked Oscillator Principle

3.5 EMI and Line Power Quality Problems

3.5.1 EMI Problems

3.5.2 Line Harmonic Problems

3.6 Summary

Chapter 4 Cycloconverters

4.1 Introduction

4.2 Phase-Controlled Cycloconverters

4.2.1 Operation Principles

4.2.2 A Three-Phase Dual Converter as Cycloconverter

4.2.3 Cycloconverter Circuits

4.2.3.1 Three-Phase, Half-Wave Cycloconverter

4.2.3.2 Three-Phase Bridge Cycloconverter

4.2.3.2.1 Modulation Factor

4.2.4 Circulating vs. Non-Circulating Current Mode

4.2.4.1 Circulating Current Mode

4.2.4.2 Blocking Mode

4.2.5 Load an Line Harmonics

4.2.5.1 Load Voltage Harmonics

4.2.5.2 Line Current Harmonics

4.2.6 Line Displacement Power Factor

4.2.6.1 Theoretical Derivation of Line DPF

4.2.7 Control of Cycloconverter

4.2.8 DPF Improvement Methods

4.2.8.1 Square-Wave Operation

4.2.8.2 Asymmetrical Firing Angle Control

4.2.8.3 Circulating Current Control

4.3 Matrix Converters

4.4 High-Frequency Cycloconverters

4.4.1 High-Frequency, Phase-Controlled Cycloconverter

4.4.2 High-Frequency, Integral-Pulse Cycloconverter

4.4.2.1 Sinusoidal Supply

4.4.2.2 Quasi-Square-Wave Supply

4.5 Summary

Chapter 5 Voltage-Fed Converters

5.1 Introduction

5.2 Single-Phase Inverters

5.2.1 Half-Bridge and Center-Tapped Inverters

5.2.2 Full, or H-Bridge, Inverter

5.2.2.1 Phase-Shift Voltage Control

5.3 Three-Phase Bridge Inverters

5.3.1 Square-Wave, or Six-Step, Operation

5.3.2 Motoring and Regenerative Modes

5.3.3 Input Ripple

5.3.4 Device Voltage and Current Ratings

5.3.5 Phase-Shift Voltage Control

5.3.6 Voltage and Frequency Control

5.4 Multi-Stepped Inverters

5.4.1 12-Step Inverter

5.4.2 18-Step Inverter by Phase-Shift Control

5.5 Pulse Width Modulation Techniques

5.5.1 PWM Principle

5.5.1.1 PWM Classification

5.5.1.1.1 Sinusoidal PWM

5.5.1.1.2 Selected Harmonic Elimination PWM

5.5.1.1.3 Minimum Ripple Current PWM

5.5.1.1.4 Space-Vector PWM

5.5.1.1.5 Sinusoidal PWM with Instantaneous Current Control

5.5.1.1.6 Hysteresis-Band Current Control PWM

5.5.1.1.7 Sigma-Delta Modulation

5.6 Three-Level Inverters

5.6.1 Control of Neutral Point Voltage

5.7 Hard Switching Effects

5.8 Resonant Inverters

5.9 Soft-Switched Inverters

5.9.1 Soft Switching Principle

5.9.1.1 Inverter Circuits

5.10 Dynamic and Regenerative Drive Braking

5.10.1 Dynamic Braking

5.10.2 Regenerative Braking

5.11 PWM Rectifiers

5.11.1 Diode Rectifier with Boost Chopper

5.11.1.1 Single-Phase

5.11.1.2 Three-Phase

5.11.2 PWM Converter as Line-Side Rectifier

5.11.2.1 Single-Phase

5.11.2.2 Three-Phase

5.12 Static VAR Compensators and Active Harmonic Filters

5.13 Introduction to Simulation - MATLAB/SIMULINK

5.14 Summary

Chapter 6 Current-Fed Converters

6.1 Introduction

6.2 General Operation of Six-Step Thyristor Inverter

6.2.1 Inverter Opereation Modes

6.2.1.1 Mode 1: Load-Commutated Rectifier

6.2.1.2 Mode 2: Load-Commutated Inverter

6.2.1.3 Mode 3: Force-Commutated Inverter

6.2.1.4 Mode 4: Force-Commutated Rectifier

6.3 Load-Commutated Inverters

6.3.1 Single-Phase Resonant Inverter

6.3.1.1 Circuit Analysis

6.3.2 Three-Phase Inverter

6.3.2.1 Lagging Power Factor Load

6.3.2.2 Over-Excited Synchronous Machine Load

6.3.2.3 Synchronous Motor Starting

6.4 Force-Commutated Inverters

6.4.1 Auto-Sequential Current-Fed Inverter (ASCI)

6.5 Harmonic Heating and Torque Pulsation

6.6 Multi-Stepped Inverters

6.7 Inverters with Self-Commutated Devices

6.7.1 Six-Step Inverter

6.7.1.1 Load Harmonic Resonance Problem

6.7.2 PWM Inverters

6.7.2.1 Trapezoidal PWM

6.7.2.2 Selected Harmonic Elimination PWM (SHE-PWM)

6.7.3 Double-Sided PWM Converter System

6.7.4 PWM Rectifier Applications

6.7.4.1 Static VAR Compensator/Active Filter

6.7.4.2 Superconducting Magnet Energy Storage (SMES)

6.7.4.3 DC Motor Speed Control

6.8 Current-Fed vs. Voltage-Fed Converters

6.9 Summary

Chapter 7 Induction Motor Slip-Power Recovery Drives

7.1 Introduction

7.2 Doubly-Fed Machine Speed Control by Rotor Rheostat

7.3 Static Kramer Drive

7.3.1 Phasor Diagram

7.3.2 AC Equivalent Circuit

7.3.3 Torque Expression

7.3.4 Harmonics

7.3.5 Speed Control of a Kramer Drive

7.3.6 Power Factor Improvement

7.4 Static Scherius Drive

7.4.1 Modef of Operation

7.4.2 Modified Scherbius Drive for VSCF Power Generation

7.5 Summary

Chapter 8 Control and Estimation of Induction Motor Drives

8.1 Introduction

8.2 Induction Motor Control with Small Signal Model

8.2.1 Small-Signal Model

8.3 Scalar Control

8.3.1 Voltage-Fed Inverter Control

8.3.1.1 Open Loop Volts/Hz Control

8.3.1.2 Energy Conservation Effect by Variable Frequency Drive

8.3.1.3 Speed Control with Slip Regulation

8.3.1.4 Speed Control with Torque and Flux Control

8.3.1.5 Current-Controlled Voltage-Fed Inverter Drive

8.3.1.6 Traction Drives with Parallel Machines

8.3.2 Current-Fed Inverter Control

8.3.2.1 Independent Current and Frequency Control

8.3.2.2 Speed and Flux Control in Current-Fed Inverter Drive

8.2.2.3 Volts/Hz Control of Current-Fed Inverter Drive

8.3.3 Efficiency Optimization Control by Flux Program

8.4 Vector or Field-Oriented Control

8.4.1 DC Drive Analogy

8.4.2 Equivalent Circuit and Phasor Diagram

8.4.3 Principles of Vector Control

8.4.4 Direct or Feedback Vector Control

8.4.5 Flux Vector Estimation

8.4.5.1 Voltage Model

8.4.5.2 Current Model

8.4.6 Indirect or Feedforward Vector Control

8.4.6.1 Indirect Vector Control Slip Gain (Ks) Tuning

8.4.7 Vector Control of Line-Side PWM Rectifier

8.4.8 Stator Flux-Oriented Vector Control

8.4.9 Vector Control of Current-Fed Inverter Drive

8.4.10 Vector Control of Cycloconverter Drive

8.5 Sensorless Vector Control

8.5.1 Speed Estimation Methods

8.5.1.1 Slip Calculation

8.5.1.2 Direct Synthesis from State Equations

8.5.1.3 Model Referencing Adaptive System (MRAS)

8.5.1.4 Speed Adaptive Flux Observer (Luenberger Observer)

8.5.1.5 Extended Kalman Filter (EKS)

8.5.1.6 Slot Harmonics

8.5.1.7 Injection of Auxiliary Signal on Salient Rotor

8.5.2 Direct Vector Control without Speed Signal

8.5.2.1 Programmable Cascaded Low-Pass Filter (PCLPF) Stator Flux Estimation

8.5.2.2 Drive Machine Start-up with Current Model Equations

8.6 Direct Torque and Flux Control (DTC)

8.6.1 Torque Expression with Stator and Rotor Fluxes

8.6.2 Control Strategy of DTC

8.7 Adaptive Control

8.7.1 Self-Tuning Control

8.7.1.1 Load Torque Disturbance (Tl) Compensation

8.7.2 Model Referencing Adaptive Control (MRAC)

8.7.3 Sliding Mode Control

8.7.3.1 Control Principle

8.7.3.2 Sliding Trajectory Control of a Vector Drive

8.8 Self-Commissioning of Drive

8.9 Summary

Chapter 9 Control and Estimation of Synchronous Motor Drives

9.1 Introduction

9.2 Sinusoidal SPM Machine Drives

9.2.1 Open Loop Volts/Hertz Control

9.2.2 Self-Control Model

9.2.3 Absolute Position Encoder

9.2.3.1 Optical Encoder

9.2.3.2 Analog Resolver with Decoder

9.2.4 Vector Control

9.2.4.1 Field-Weakening Mode

9.3 Synchronous Reluctance Machine Drives

9.3.1 Current Vector Control of SyRM Drive

9.3.1.1 Constant d - Axis Current Control

9.3.1.2 Fast Torque Response Control

9.3.1.3 Maximum Torque/Ampere Control

9.3.1.4 Maximum Power Factor Control

9.4 Sinusoidal IPM Machine Drives

9.4.1 Current Vector Control with Maximum Torque/Ampere

9.4.2 Field-Weakening Control

9.4.3 Vector Control with Stator Flux Orientation

9.4.3.1 Feedback Signal Processing

9.4.3.2 Square-Wave (SW) Mode Field-Weakening Control

9.4.3.3 PWM - Square-Wave Sequencing

9.5 Trapezoidal SPM Machine Drives

9.5.1 Drive Operation with Inverter

9.5.1.1 Angle Switch-on Mode

9.5.1.2 PWM Voltage and Current Control Mode

9.5.2 Torque-Speed Curve

9.5.3 Machine Dynamic Model

9.5.4 Drive Control

9.5.4.1 Close Loop Speed Control in Feedback Mode

9.5.4.2 Close Loop Current Control in Freewheeling Mode

9.5.5 Torque Pulsation

9.5.6 Extended Speed Operation

9.6 Wound-Field Synchronous Machine Drives

9.6.1 Brush and Brushless dc Excitation

9.6.2 Load-Commutated Inverter (LCI) Drive

9.6.2.1 Control of LCI Drive with Constant Angle

9.6.2.2 Delay angle or Angle control

9.6.2.3 Control with Machine Terminal Voltage Signals

9.6.2.4 Phase-Locked Loop (PLL) Angle Control

9.6.3 Scalar Control of Cycloconverter Drive

9.6.4 Vector Control of Cycloconverter

9.6.5 Vector Control with Voltage-Fed Inverter

9.7 Sensorless Control

9.7.1 Trapezoidal SPM Machine

9.7.1.1 Terminal Voltage Sensing

9.7.1.2 Stator Third Harmonic Voltage Detection

9.7.2 Sinusoidal PM Machine (PMSM)

9.7.2.1 Terminal Voltage and Current Sensing

9.7.2.2 Inductance Variation (sailency) Effect

9.7.2.3 Extended Kalman Filter (EKF)

9.8 Switched Reluctance Motor (SRM) Drives

9.9 Summary

Chapter 10 Expert System Principles and Applications

10.1 Introduction

10.2 Expert System Principles

10.2.1 Knowledge Base

10.2.1.1 Frame Structure

10.2.1.2 Meta-Knowledge

10.2.1.3 ES Language

10.2.2 Inference Engine

10.2.3 User Interface

10.3 Expert System Shell

10.3.1 Shell Features

10.3.2 External Interface

10.3.3 Program Development Steps

10.4 Design Methodology

10.5 Application

10.5.1 P-I Tuning of a Drive

10.5.2 Fault Diagnostics

10.5.3 Selection of Commercial ac Drive Product

10.5.4 Configuration Selection, Design, and Simulation of a Drive System

10.5.4.1 Configuration Selection

10.5.4.2 Motor Ratings Design

10.5.4.3 Converter Design

10.5.4.4 Control Design and Simulation Study

10.6 Glossary

10.7 Summary

Chapter 11 Fuzzy Logic Principles and Applications

11.1 Introduction

11.2 Fuzzy Sets

11.2.1 Membership Functions

11.2.2 Operations on Fuzzy Sets

11.3 Fuzzy System

11.3.1 Implication Methods

11.3.1.1 Mamdani Type

11.3.1.2 Lusing Larson Type

11.3.1.3 Sugeno Type

11.3.2 Defuzzification Methods

11.3.2.1 Center of Area (COA) Method

11.3.2.2 Height Method

11.3.2.3 Mean of Maxima (MOM) Method

11.3.2.4 Sugeno Method

11.4 Fuzzy Control

11.4.1 Why Fuzzy Control

11.4.2 Historical Perspective

11.4.3 Control Principle

11.4.4 Control Implementation

11.5 General design Methotology

11.6 Applications

11.6.1 Induction Motor Speed Control

11.6.2 Flux Programming Efficiency Improvement of Induction Motor Drive

11.6.2.1 Pulsating Torque Compensation

11.6.3 Wind Generation System

11.6.3.1 Wind Turbine Characteristics

11.6.3.2 System Description

11.6.3.3 Fuzzy Control

11.6.4 Slip Gain Tuning of Indirect Vector Control

11.6.4.1 Derivation of Q and v

11.6.5 Stator Resistance Rs Estimation

11.6.6 Estimation of Distorted Waves

11.6.6.2 Sugeno Method

11.6.6.1 Mandami Method

11.7 Fuzzy Logic Toolbox

11.7.1 FIS Editor

11.7.2 Membership Function Editor

11.7.3 Rule Editor

11.7.4 Rule Viewer

11.7.5 Surface Viewer

11.7.6 Demo Program for Synchronous Current Control

11.8 Glossary

11.9 Summary

Chapter 12 Neural Network Principles and Applications

12.1 Introduction

12.2 The Structure of a Neuron

12.2.1 The Concept of a Biological Neuron

12.2.2 Artificial Neuron

12.2.2.1 Activation Functions of a Neuron

12.3 Artificial Neural Network

12.3.1 Application: Y = Asin X

12.3.2 Training of Feedforward Neural Network

12.3.2.1 Learning Methods

12.3.2.2 Alphabet Character Recognition by an ANN

12.3.3 Back Propagation Training

12.3.4 Back propagation Algorithm for Three-Layer Network

12.3.4.1 Weight Calculation for Output Layer Neurons

12.3.4.2 Weight Calculation for Hidden Layer Neurons

12.3.5 On-Line Training

12.4 Other Networks

12.4.1 Radial Basis Function Network

12.4.2 Kohonen's Self-Organizing Feature Map Network

12.4.3 Recurrent Neural Network for Dynamic System

12.4.3.1 Training an RNN by EKF Algorithm

12.5 Neural Network in Identification and Control

12.5.1 Time-Delayed Neural Network

12.5.2 Dynamic System Models

12.5.3 ANN Identification of Dynamic Models

12.5.4 Inverse Dynamics Model

12.5.5 Neural Network-Based Control

12.6 General Design Methodology

12.7 Applications

12.7.1 PWM Controller

12.7.1.1 Selected Harmonic Elimination (SHE) PWM

12.7.1.2 Instantaneous Current Control PWM

12.7.1.3 Space Vector PWM

12.7.2 Vector-Controlled Drive Feedback Signal Estimation

12.7.3 Estimation of Distorted Waves

12.7.4 Model Identification and Adaptive Drive Control

12.7.5 Speed Estimation by RNN

12.7.6 Adaptive Flux Estimation by RNN

12.8 Neuro-Fuzzy Systems

12.8.1 Adaptive Network-Based Fuzzy Inference System (ANFIS)

12.9 Demo Program With Neural Network Toolbox

12.9.1 Introduction to Neural Network Toolbox

12.9.2 Demo Program

12.10 Glossary

12.11 Summary

Index

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc