Hollow Rotary Geared Actuator

Hollow Rotary Index Table

Accurate Gear Driven

High Precision

High Rigidity

High Torque

Easy to Use

�

HG60

HG100

HG130

HG200

Hollow Rotary Geared Actuator

High performance of Hollow Rotary Actuator, Ezi-Actuator HG Series, is extremely low

backlash gear is driven directly into the hollow rotary table combines to high speed,

high accuracy of closed loop stepping control system, Ezi-SERVO

�

HOLLOW ROTARY TABLE

Large Diameter hollow bore to penetrate the output table equipped HG Series ensure

flexibility and convenience in the design of equipment when install complex wiring and piping.

Ø75mm

□200mm

ex) only HG275 series

Model Name

Size of plinth (Frame Size)

Hollow Bore Diameter

HG60

HG100

HG130

HG200

HG275

60mm

100mm

130mm

200mm

200mm

20mm

29mm

40mm

40mm

75mm

ACCURATE GEAR DRIVEN

Extremely low backlash gear direct drive, so that repetitive positioning accuracy from a

single direction is ±15sec, lost motion by positioning from two directions for less than

2min. and the precise positioning can be determined. And Belt and Pulley are not used in

this system so it enables cost saving, unnecessary of maintenance and repair service

without adjustment of belt-tensioning

HIGH RIGIDITY

High rigidity of taper roller bearing and Ball Bearing integrated HG Series maximizes

allowable thrust load and moment load ( But, Deep Groove ball bearings applied in

HG60 Series )

Output Table

Ball Bearing

Taper Roller

Bearing

Taper Roller Bearing

Ball Bearing

HG275

�

Feature

FAST

RESPONSE

Speed

Speed

High rigidity Rotary table fixed to the closed loop

stepping control system, Ezi-SERVO can shorten

positioning time for big inertia applications.

Settling Time

Time

Time

SUPPORTING SUDDEN LOAD FLUCTUATION AND RAPID ACCELERATION

Adopting a closed loop stepping control system, Ezi-SERVO designed to maintain synchronism and does not have

step-out problem, Ezi-Actuator HG series can be driven by rapid acceleration or sudden load fluctuation because

the situation in a typical servo system that is prone to fluctuation, Hunting does not occur. For sudden load

fluctuatoin with a servo system is essential to improve the control performance does not need to gain adjustment

is gain Tuning Free Actuator.

Complete stop

Hunting

Load variations are concerned

about the equipment without

having to adjust the gain,

HG Series enables stable

operation.

VARIETY OF CONTROLLER WITH HIGH PERFORMANCE AND MULTI-TASKING

Ezi-SERVO, high performance closed loop stepping

control system by adopting, pulse train input drives

and controller integrated drives are possible to use.

Pulse Input drive

Controller Embedded Drive

(Enable to operate Multi-Axes

based on Network)

NETWORK BASED MOTION CONTROL

PC

A maximum of 16 axis can be operated from a PC

through RS-485 communications. All of the Motion

conditions are set through the network and saved in

Flash ROM as a parameter. Motion Library (DLL) is

provided for programming under Windows 2000/XP.

�

POSITION TABLE FUNCTION

PLC

Ezi-Actuator HG _ 4 / 5

Position Table can be used for motion control by

digital input and output signals of host controller.

You can operate the motor directly by sending the

position table number, start/stop, origin search and

other digital input values from a PLC. The PLC can

monitor The In-Position, origin search, moving/stop,

servo ready and other digital output signals from a

drive. A maximum of 256 positioning points can be

set from PLC.

SIMPLE RETURN TO HOME FUNCTION

Rotary table drive from home return often necessary

to simplify the return to home operation has been

equipped with the optional Home-sensor Set. The

sensor set comes with all the parts required for the

return to home operation, meaning you will spend

less time for designing, assembling and procuring

parts related to sensor installation.

Sensor Dog

Origin Sensor

Example of Sensor

Installation on HG130

EXTENSIVE INPUT/OUTPUT SIGNALS AND USER-DEFINED FUNCTIONS

Input 9 points / 9 points signal output according to the needs of users can be defined. Therefore, various

functions depending on the needs of the user input / output wiring must be used without changing.

Examples of Ezi-Actuator HG Applications

Applications support to

changing load intertia fluctuation

Applications for high

precision positining

Applications support moment load

Applications for optical

applications using hollow bore

Applications for air

absorption using hollow bore

Applications for a precise

positioning using hollow bore

�

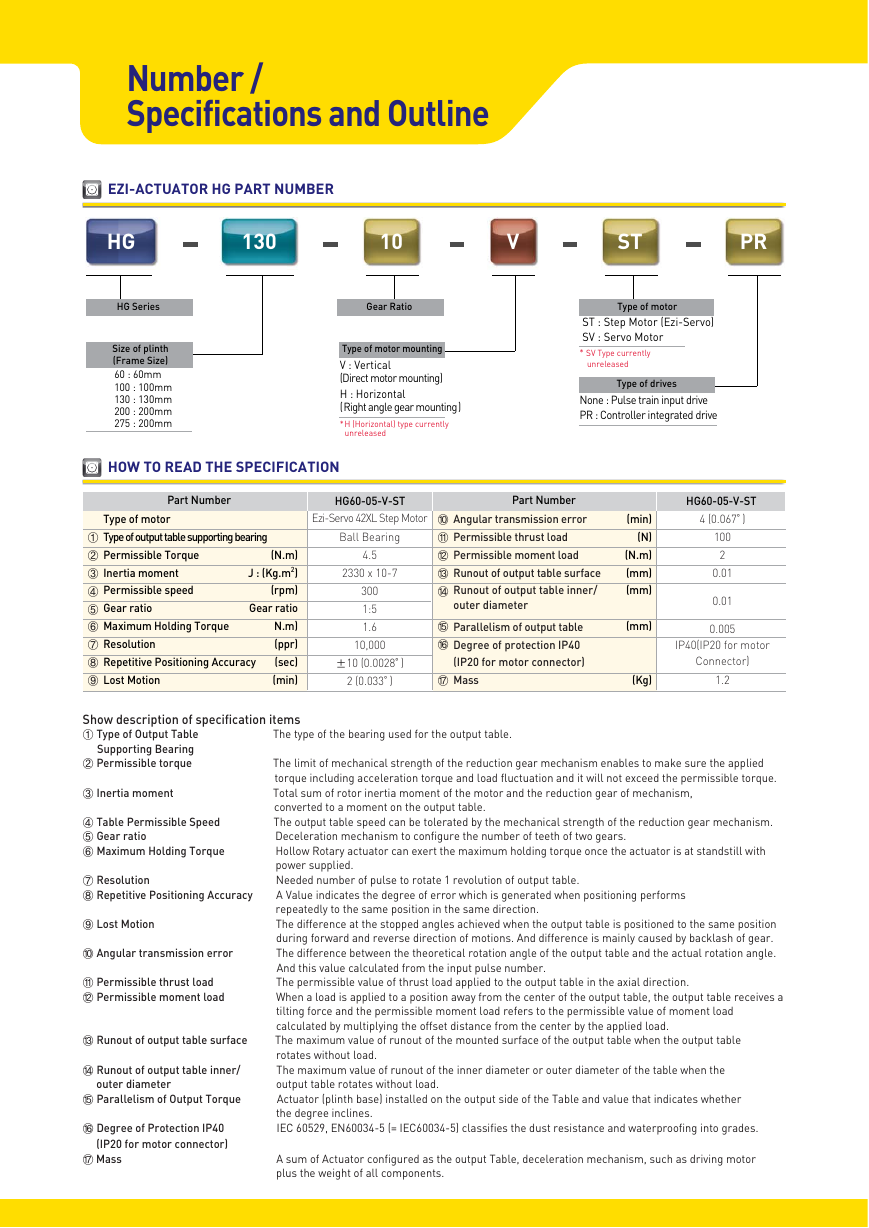

Number /

Specifications and Outline

EZI-ACTUATOR HG PART NUMBER

HG

130

10

V

ST

PR

HG Series

Size of plinth

(Frame Size)

60 : 60mm

100 : 100mm

130 : 130mm

200 : 200mm

275 : 200mm

Gear Ratio

Type of motor mounting

V : Vertical

(Direct motor mounting)

H : Horizontal

(Right angle gear mounting)

* H (Horizontal) type currently

unreleased

Type of motor

ST : Step Motor (Ezi-Servo)

SV : Servo Motor

* SV Type currently

unreleased

Type of drives

None : Pulse train input drive

PR : Controller integrated drive

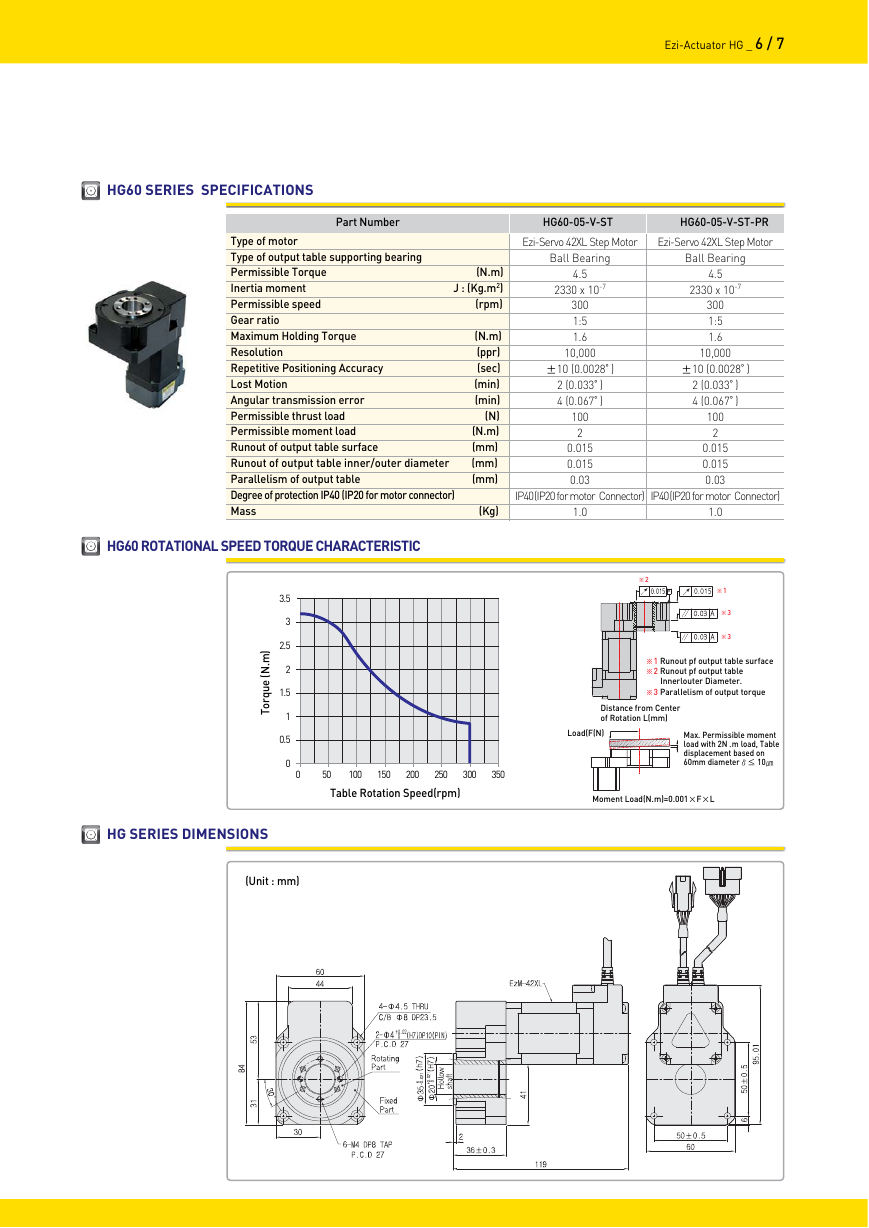

HOW TO READ THE SPECIFICATION

Part Number

Type of motor

Type of output table supporting bearing

Permissible Torque

Inertia moment

Permissible speed

Gear ratio

Maximum Holding Torque

Resolution

Repetitive Positioning Accuracy

Lost Motion

①

②

③

④

⑤

⑥

⑦

⑧

⑨

(N.m)

J : (Kg.m2)

(rpm)

Gear ratio

N.m)

(ppr)

(sec)

(min)

HG60-05-V-ST

Ezi-Servo 42XL Step Motor

Ball Bearing

4.5

2330 x 10-7

300

1:5

1.6

10,000

±10 (0.0028)

2 (0.033)

Part Number

Angular transmission error

Permissible thrust load

Permissible moment load

Runout of output table surface

Runout of output table inner/

outer diameter

Parallelism of output table

Degree of protection IP40

(IP20 for motor connector)

Mass

⑩

⑪

⑫

⑬

⑭

⑮

⑯

⑰

HG60-05-V-ST

4 (0.067)

100

2

0.01

0.01

0.005

IP40(IP20 for motor

Connector)

1.2

(min)

(N)

(N.m)

(mm)

(mm)

(mm)

(Kg)

Show description of specification items

① Type of Output Table The type of the bearing used for the output table.

Supporting Bearing

② Permissible torque

③ Inertia moment

④ Table Permissible Speed

⑤ Gear ratio

⑥ Maximum Holding Torque

⑦ Resolution

⑧ Repetitive Positioning Accuracy

⑨ Lost Motion

⑩ Angular transmission error

⑪ Permissible thrust load

⑫ Permissible moment load

⑬ Runout of output table surface

⑭ Runout of output table inner/

outer diameter

⑮ Parallelism of Output Torque

⑯ Degree of Protection IP40

(IP20 for motor connector)

⑰ Mass

The limit of mechanical strength of the reduction gear mechanism enables to make sure the applied

torque including acceleration torque and load fluctuation and it will not exceed the permissible torque.

Total sum of rotor inertia moment of the motor and the reduction gear of mechanism,

converted to a moment on the output table.

The output table speed can be tolerated by the mechanical strength of the reduction gear mechanism.

Deceleration mechanism to configure the number of teeth of two gears.

Hollow Rotary actuator can exert the maximum holding torque once the actuator is at standstill with

power supplied.

Needed number of pulse to rotate 1 revolution of output table.

A Value indicates the degree of error which is generated when positioning performs

repeatedly to the same position in the same direction.

The difference at the stopped angles achieved when the output table is positioned to the same position

during forward and reverse direction of motions. And difference is mainly caused by backlash of gear.

The difference between the theoretical rotation angle of the output table and the actual rotation angle.

And this value calculated from the input pulse number.

The permissible value of thrust load applied to the output table in the axial direction.

When a load is applied to a position away from the center of the output table, the output table receives a

tilting force and the permissible moment load refers to the permissible value of moment load

calculated by multiplying the offset distance from the center by the applied load.

The maximum value of runout of the mounted surface of the output table when the output table

rotates without load.

The maximum value of runout of the inner diameter or outer diameter of the table when the

output table rotates without load.

Actuator (plinth base) installed on the output side of the Table and value that indicates whether

the degree inclines.

IEC 60529, EN60034-5 (= IEC60034-5) classifies the dust resistance and waterproofing into grades.

A sum of Actuator configured as the output Table, deceleration mechanism, such as driving motor

plus the weight of all components.

�

Ezi-Actuator HG _ 6 / 7

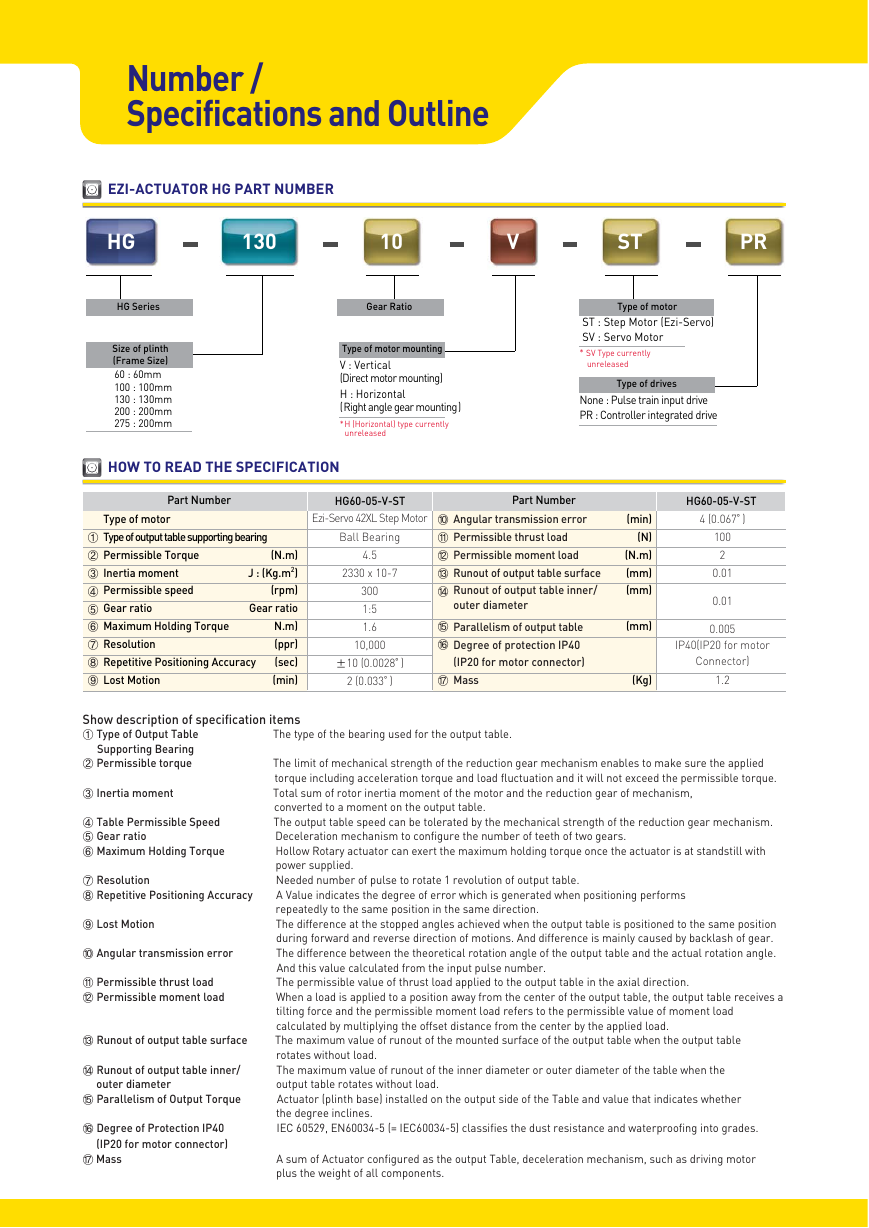

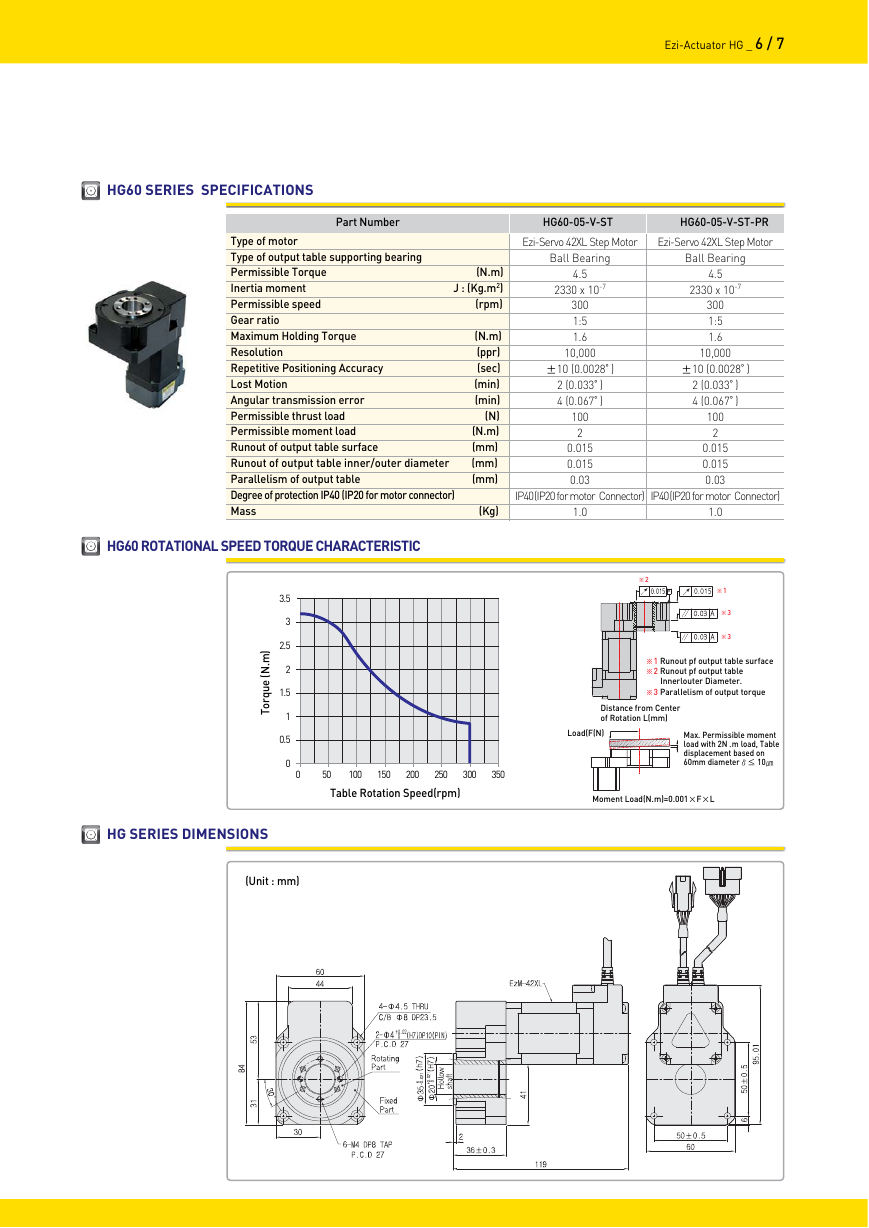

HG60-05-V-ST

Ezi-Servo 42XL Step Motor

HG60-05-V-ST-PR

Ezi-Servo 42XL Step Motor

Ball Bearing

4.5

2330 x 10-7

300

1:5

1.6

10,000

±10 (0.0028)

2 (0.033)

4 (0.067)

100

2

0.015

0.015

0.03

Ball Bearing

4.5

2330 x 10-7

300

1:5

1.6

10,000

±10 (0.0028)

2 (0.033)

4 (0.067)

100

2

0.015

0.015

0.03

IP40(IP20 for motor Connector)

IP40(IP20 for motor Connector)

1.0

1.0

※2

※1

※3

※3

※1 Runout pf output table surface

※2 Runout pf output table

Innerlouter Diameter.

※3 ParalIelism of output torque

Distance from Center

of Rotation L(mm)

Load(F(N)

Max. Permissible moment

load with 2N m load, Table

displacement based on

60mm diameter δ≤ 10㎛

Moment Load(N.m)=0.001×F×L

HG60 SERIES SPECIFICATIONS

Part Number

Type of motor

Type of output table supporting bearing

Permissible Torque

Inertia moment

Permissible speed

Gear ratio

Maximum Holding Torque

Resolution

Repetitive Positioning Accuracy

Lost Motion

Angular transmission error

Permissible thrust load

Permissible moment load

Runout of output table surface

Runout of output table inner/outer diameter

Parallelism of output table

Degree of protection IP40 (IP20 for motor connector)

Mass

(N.m)

J : (Kg.m2)

(rpm)

(N.m)

(ppr)

(sec)

(min)

(min)

(N)

(N.m)

(mm)

(mm)

(mm)

(Kg)

HG60 ROTATIONAL SPEED TORQUE CHARACTERISTIC

m

N

.

)

(

e

u

q

r

o

T

3.5

3

2.5

2

1.5

1

0.5

0

0

50

100

150

200

250

300

350

Table Rotation Speed(rpm)

HG SERIES DIMENSIONS

(Unit : mm)

�

Specifications and Outline

HG100 SERIES SPECIFICATIONS

Part Number

Type of motor

Type of output table supporting bearing

Permissible Torque

Inertia moment

Permissible speed

Gear ratio

Maximum Holding Torque

Resolution

Repetitive Positioning Accuracy

Lost Motion

Angular transmission error

Permissible thrust load

Permissible moment load

Runout of output table surface

Runout of output table inner/outer diameter

Parallelism of output table

Degree of protection IP40 (IP20 for motor connector)

Mass

(N.m)

J : (Kg.m2)

(rpm)

(N.m)

(ppr)

(sec)

(min)

(min)

(N)

(N.m)

(mm)

(mm)

(mm)

(Kg)

HG100 ROTATIONAL SPEED TORQUE CHARACTERISTIC

m

N

.

)

(

e

u

q

r

o

T

14

12

10

8

6

4

2

0

0

25

50

75 100 125 150 175 200

Table Rotation Speed(rpm)

225

250

HG SERIES DIMENSIONS

(Unit : mm)

HG100-08-V-ST

Ezi-Servo 60L Step Motor

Taper Roller Bearing + Ball Bearing

HG100-08-V-ST-PR

Ezi-Servo 60L Step Motor

Taper Roller Bearing + Ball Bearing

12

3898 x 10-6

200

1:8

10

10,000

±10 (0.0028)

2 (0.033)

4 (0.067)

500

10

0.01

0.01

0.01

12

3898 x 10-6

200

1:8

10

10,000

±10 (0.0028)

2 (0.033)

4 (0.067)

500

10

0.01

0.01

0.01

IP40(IP20 for motor Connector)

IP40(IP20 for motor Connector)

4.0

※2

4.0

※1

※3

※1 Runout pf output table surface

※2 Runout pf output table

Innerlouter Diameter.

※3 Parallelism of outqut torgue

Distance from Center

of Rotation L(mm)

Load(F(N)

Max. Permissible moment

load with 2N m load, Table

displacement based on

60mm diameter δ≤ 10㎛

Moment Load(N.m)=0.001×F×L

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc