SMTC

上海汽车集团股份有限公司技术中心企业标准

Enterprise Standard of SAIC MOTOR Technical Center

SMTC 3 800 001 -2012(V2)

代替 SMTC 3 800 001-2010(V1)

电子电器零部件通用测试要求

General test requirements for electric electronic component

2012-11-29 发布/Issue 2012-11-30 实施/Implementation

上 汽 集 团 技 术 中 心 技 术 标 准 化 委 员 会

Technical Standardization Committee of SAIC MOTOR Technical Center

发布

Issue

© 上汽集团版权所有 秘密文件 注意保密 Copyright SAIC MOTOR Confidential

�

SMTC 3 800 001—2012(V2)

目次/Contents

前言 Foreword ...................................................................................................................................... III

1 范围 Scope......................................................................................................................................... 1

2 规范性引用文件 Normative reference ................................................................................................ 1

3 术语和缩略语 Terms and abbreviations ........................................................................................... 2

3.1 缩略语 Abbreviations ..................................................................................................................... 2

3.2 测试仪器的标准误差 Standard tolerance for test instruments. ...................................................... 3

3.3 测试环境标准值 Standard values for test environment .................................................................. 3

3.4 工作电压范围 Operating volrage range ......................................................................................... 4

3.5 功能状态 Functional status ............................................................................................................ 4

3.6 工作模式 Operating mode ............................................................................................................. 5

3.7 样件分级定义 Sample grade description ........................................................................................ 6

4 文档及总体要求 Documents and general requirements .................................................................. 7

4.1 电子电器零部件规范性文档 Specification documents of electrical component ............................. 7

4.2 验证文档及认可报告 Documents and report of qualification .......................................................... 6

4.3 总体要求 General requirements ...................................................................................................... 7

5 电气测试要求 Electrical test requirements ...................................................................................... 8

5.1 长时间过电压 Long-term overvoltage .............................................................................................. 8

5.2 瞬时过电压 Transient overvoltage ................................................................................................... 9

5.3 瞬时低电压 Transient undervoltage .............................................................................................. 10

5.4 跳变电压启动 Jump start ............................................................................................................... 11

5.5 负载跌落 Load dump ..................................................................................................................... 12

5.6 发电机叠加纹波电压 Superimposed alternating voltage ............................................................... 13

5.7 工作电压的缓慢下降/缓慢上升 Slow decrease/increase of operating voltage .............................. 15

5.8 电源缓慢下降/快速上升 Slow decrease, quick increase of the supply voltage ............................ 16

5.9 复位测试 Reset behavior test ....................................................................................................... 17

5.10 发动机启动时脉冲电压 Voltage pulses when starting engine .................................................... 19

5.11 引脚中断 Pin interruption ............................................................................................................ 22

5.12 接插件中断 Connector interruption ............................................................................................. 24

5.13 反极性测试 Reverse polarity....................................................................................................... 24

5.14 地偏移 Ground offset .................................................................................................................. 25

5.15 信号线与驱动电路的短路保护 Short circuit in signal circuit and load circuits ............................ 26

5.16 绝缘阻抗测试 Insulation resistance ............................................................................................ 27

5.17 过电流测试 Over current test ...................................................................................................... 28

5.18 静态电流测试 Quiescent current ................................................................................................ 29

6 环境测试要求 Environmental test requirements ............................................................................ 31

6.1 总体描述-零部件在整车上安装区域的分类代码 General description- vehicle installation area clas-

sification codes .................................................................................................................................... 31

6.2 高低温存放试验 High-/low temperature storage........................................................................... 36

6.3 阶梯温度变化试验 Stepped temperature test ............................................................................... 36

6.4 低温工作试验 Operating at low temperature ................................................................................ 38

6.5 高温工作试验 Operating at high temperature ............................................................................... 38

© 上汽集团版权所有 秘密文件 注意保密 Copyright SAIC MOTOR Confidential

I

�

SMTC 3 800 001—2012(V2)

6.6 温度交变试验 Change of temperature test .................................................................................. 38

6.7 重新喷漆的温度试验 Re-spray oven stoving temperature test .................................................... 40

6.8 热冲击试验 Thermal shock test .................................................................................................... 40

6.9 稳态湿热试验 Damp heat, steady state ........................................................................................ 43

6.10 湿热循环试验 Damp heat, cyclic ................................................................................................ 43

6.11 抗粉尘侵蚀试验 Protection against dust test .............................................................................. 44

6.12 喷水试验 Spraying water ............................................................................................................ 45

6.13 喷射热水试验 Hot water jet ......................................................................................................... 46

6.14 浸渍试验 Immersion in water ...................................................................................................... 46

6.15 抗有害气体试验 Noxious gases .................................................................................................. 47

6.16 盐雾试验 Salt spray .................................................................................................................... 47

6.17 化学试剂耐抗性 Resistance of chemical fluids........................................................................... 48

6.18 机械试验 Mechanical tests ......................................................................................................... 50

7 寿命测试 Life test ........................................................................................................................... 60

7.1 寿命测试-操作循环耐久试验 Life test – operation cycle endurance test ...................................... 60

7.2 寿命测试-高温耐久测试 Life test - high-temperature endurance test .......................................... 61

7.3 寿命试验-温度循环测试 Life test - temperature cycle test ........................................................... 63

附录 ...................................................................................................................................................... 67

© 上汽集团版权所有 秘密文件 注意保密 Copyright SAIC MOTOR Confidential

II

�

SMTC 3 800 001—2012(V2)

前言

Foreword

为规范 SMTC 电子电器零部件试验项目,试

验条件及试验方法,特制定此标准。

本标准是对 SMTC 3 800 001—2010(V1)《通

用电器零部件测试方法》的修订,自本标准实施

之日起废除 SMTC 3 800 001—2010(V1)。

本标准与 SMTC 3 800 001—2010(V1)相

比主要变化如下:

——增加 3.3 节测试环境标准值;

——修订 3.4 节工作电压范围定义;

——增加 3.5 节功能状态定义;

——增加 3.6 节工作模式定义;

——增加 5.2 节瞬时过电压;

——增加 5.9 节复位测试;

——增加 5.10 节发动机启动时脉冲电压;

——增加 5.11 节引脚中断试验/5.12 节接

插件中断试验参数;

——增加 5.14 节地偏移;

——增加 5.15 节信号线与驱动电路的短路

保护;

——修订 5.19 静态电流测试;

——增加 6.2 节高低温存放试验;

——修订第 7 章寿命测试。

请注意本标准的某些内容可能涉及专利,上

汽集团不承担识别这些专利的责任。

当中英文产生疑义时,以中文为准。

本标准由电子电器分标委提出。

本标准由 SMTC 技术标准化委员会批准。

本标准由标准化工作组负责标准化审核及

归口管理。

本标准起草部门:电子电器部。

本标准主要起草人:王文建、辛长宇、朱德

康、张海涛。

本标准于 2010 年 11 月 22 日首次批准发布,

2010 年 11 月 23 日实施。本次为第 1 次修订。

本版本所代替标准的历次版本发布情况为:

——SMTC 3 800 001-V1

This standard is established for the premise to

specify the test items, test conditions and test

methods for SMTC electrical electronic com-

ponents.

This standard is a revision for SMTC 3 800 001

– 2010 (V1)《Generic Electrical Component

Test Methods》. This standard will replace

SMTC 3 800 001– 2010 (V1) from the imple-

mentation date.

The main changes between this standard and

SMTC 3 800 001– 2010 (V1)are as follows:

——Add 3.3 Standard values for test envi-

ronment

——Revise 3.4 Operating voltage ranges

——Add 3.5 Functional statuses

——Add 3.6 Operating mode

——Add 5.2 Transient overvoltage

——Add 5.9 Reset behavior test

——Add 5.10 Voltage Pulses when Starting

Engine

——Describe in more detail 5.11 Pin interrup-

tion and 5.12 Connector interruption

——Add 5.14 Ground offset

——Add 5.15 Short circuit in signal circuit and

load circuits

——Add 5.19 Quiescent Current

——Add 6.2 High-/Low Temperature Storage

——Revise 7 Life test

Please note that some contents in this stan-

dard may relate to patent rights, which SAIC

Motor shall not be held responsible for identi-

fying any or all such patent rights.

This standard is in Chinese and English. If in

doubt, the Chinese version is the Master.

This standard was proposed by Electrical

Electronic sub-committee.

This standard was approved by the SMTC

Technical Standardization Committee.

The Standardization Work Team is responsible

for the standardization approval and overall

management of this standard.

The drafting department of this standard is EE

Dept.

The main drafters of this standard are Wang

Wenjian, Xin Changyu, Zhu dekang and Zhang

Haitao.

This standard was

first published on

10,15,2012 and implemented on 10 18, 2012.

III

© 上汽集团版权所有 秘密文件 注意保密 Copyright SAIC MOTOR Confidential

�

SMTC 3 800 001—2012(V2)

This standard is the 1st revision.

The versions superseded by this standard:

——SMTC 3 800 001-V1

© 上汽集团版权所有 秘密文件 注意保密 Copyright SAIC MOTOR Confidential

IV

�

电子电器零部件通用测试要求

SMTC 3 800 001—2012(V2)

General test requirements

for electric/electronic com-

ponent

1 范围

1 Scope

本标准规定了电子电器零部件验证试验的

This standard specifies the general test re-

一般要求,测试条件及测试方法。

本标准适用于所有汽车电子电器零部件组

件及总成件。

quirement, test condition and test method for

electrical electronic component.

This standard applies to all the vehicle elec-

trical electronic component and assembly

本标准是制订零部件试验大纲的基础,在工

parts.

程认可签署前,供应商必须提交一份符合所有验

证或有偏差许可的最终验证报告。任何与本标准

的偏差,都必须得到上汽集团乘用车公司电子电

器部系统集成测试的批准。

This standard is the basis for establishing test

plan of the component.The supplier must

submit a final qualification report showing full

compliance, or any authorized deviations,

before any engineering Sign-Off is agreed.

Any deviations from this standard must be

fully authorized by the SAIC Motor EE De-

partment system integration test section.

2 规范性引用文件

2 Normative reference

下列文件对于本标准的应用是必不可少的。

The following referenced documents are in-

凡是注日期的引用文件,仅注日期的版本适用于

本文件。凡是不注日期的引用文件,其最新版本

(包括所有的修改单)适用于本标准。

SMTC 2 800 001 车辆电源管理规范

ISO 16750-2-2010 道路车辆-电子电器零件的

环境条件和测试方法

ISO 12103-1 灰尘过滤试验-第一部分

dispensable for the application of this stan-

dard. For dated references, only the edition

cited applies. For undated references, the lat-

est edition of the referenced standard (includ-

ing any amendments) applies.

SMTC 2 800 001 Vehicle Power Management

Specification

ISO 16750-2-2010 Road vehicles — Envi-

ronmental conditions and testing for electrical

DIN 40050-9 抗外来物质侵蚀试验

and electronic equipment

DIN 53509-1 橡胶测试 - 臭氧裂化耐受性确定

DIN EN 60068-2-14 空气中热冲击试验

DIN EN 60068-2-29 冲击试验

DIN EN 60068-2-32 跌落试验

DIN EN 60068-2-47 振动试验

DIN EN 60068-2-52 盐雾试验

DIN EN 60068-2-60 抗有害气体试验

ISO 12103-1 Road vehicles - Test dust for filter

evaluation - Part 1

DIN 40050-9 Protection against Foreign

Objects; Water and Contact;

DIN 53509-1 Testing of rubber –Deter

-mination of resistance to ozone cracking;

DIN EN 60068-2-14 Thermal shock in air;

DIN EN 60068-2-29 Mechanical Shock Test

DIN EN 60068-2-32 Free Fall Test

© 上汽集团版权所有 秘密文件 注意保密 Copyright SAIC MOTOR Confidential

1

�

DIN EN 60068-2-78 湿热试验

SAE J400 表面涂层的耐剥落试验

SMTC 3 800 001—2012(V2)

DIN EN 60068-2-47 Vibration Test

DIN EN 60068-2-52 Salt Spray

DIN EN 60068-2-60 Protection against Nox-

ious Gases

DIN EN 60068-2-78:2001 Damp Heat;

SAE J400 Gravelometer Test

3 术语和缩略语

3 Terms and abbreviations

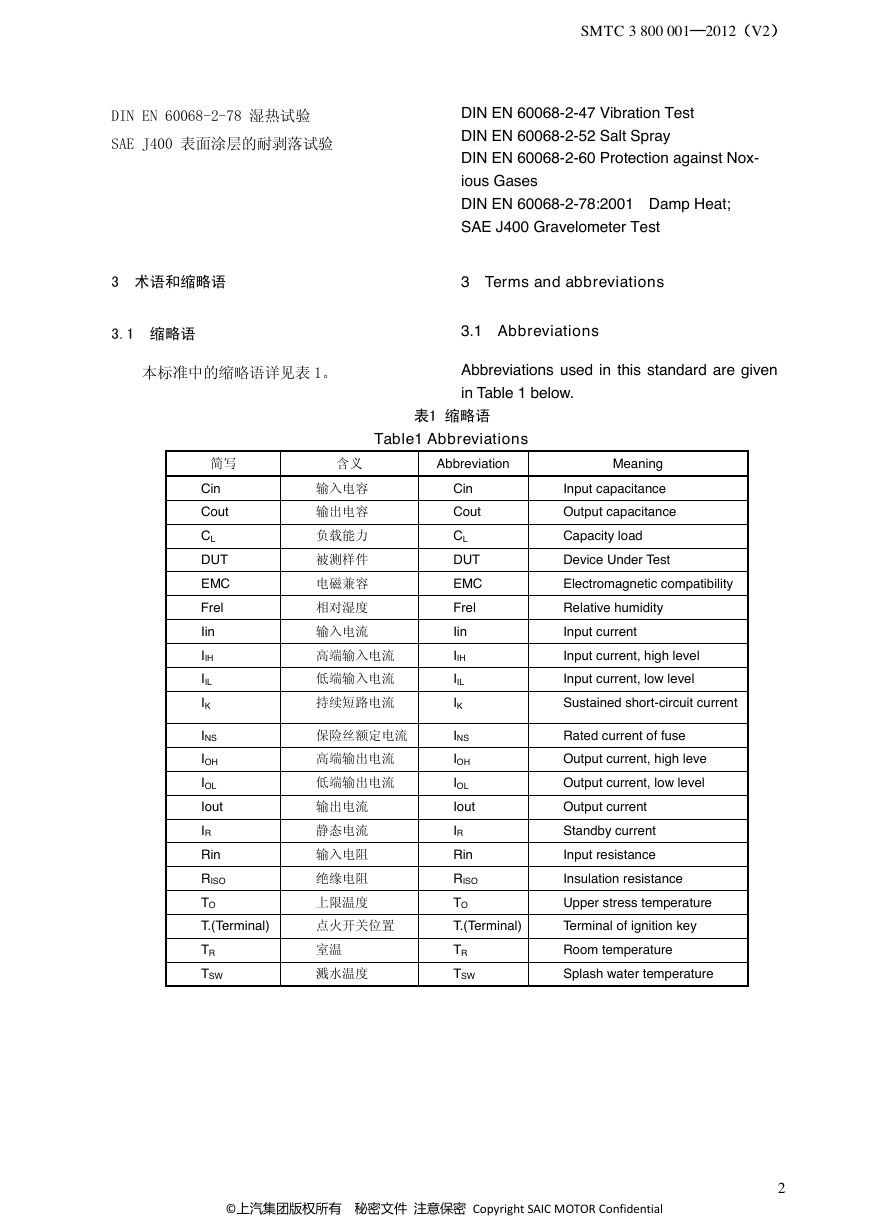

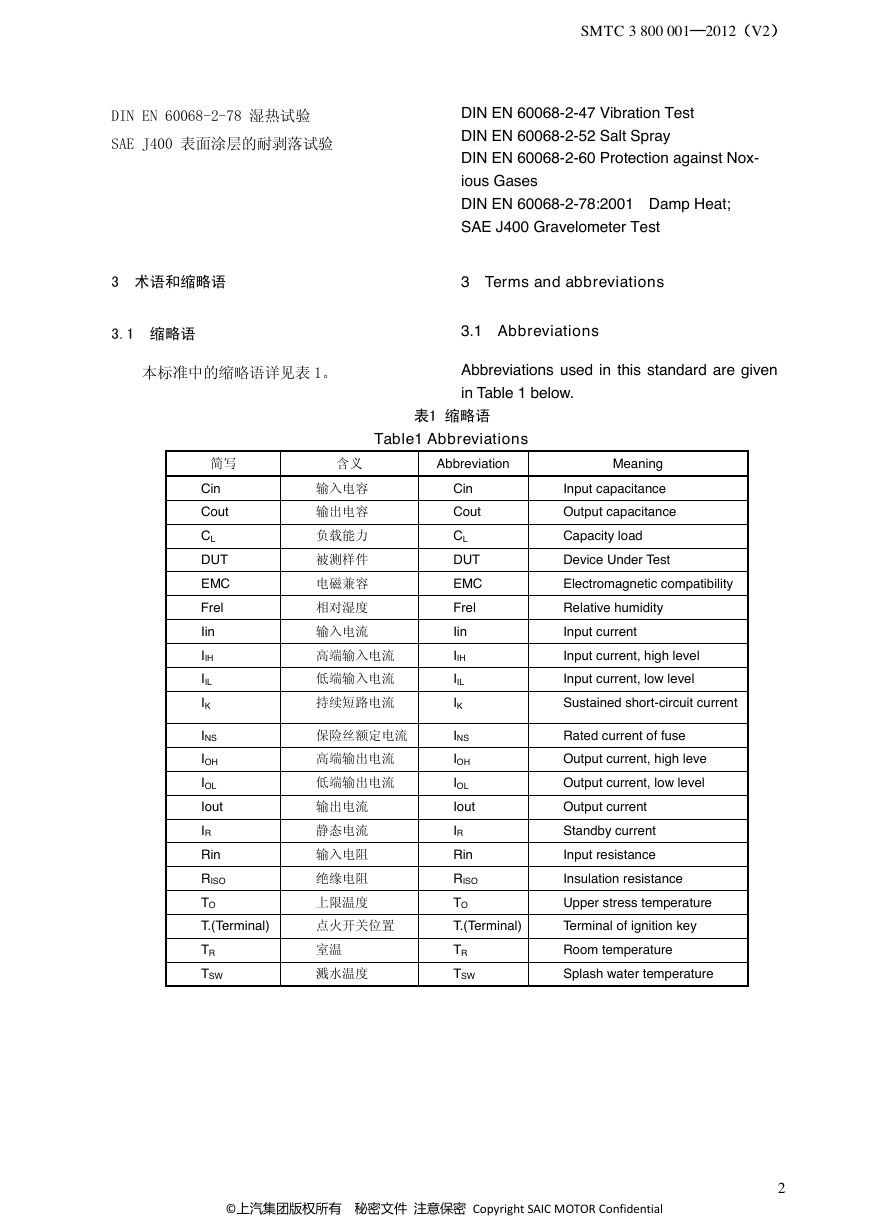

3.1 缩略语

3.1 Abbreviations

本标准中的缩略语详见表 1。

Abbreviations used in this standard are given

in Table 1 below.

表1 缩略语

Table1 Abbreviations

简写

Cin

Cout

CL

DUT

EMC

Frel

Iin

IIH

IIL

IK

INS

IOH

IOL

Iout

IR

Rin

RISO

TO

含义

输入电容

输出电容

负载能力

被测样件

电磁兼容

相对湿度

输入电流

高端输入电流

低端输入电流

持续短路电流

保险丝额定电流

高端输出电流

低端输出电流

输出电流

静态电流

输入电阻

绝缘电阻

上限温度

Abbreviation

Meaning

Cin

Cout

CL

DUT

EMC

Frel

Iin

IIH

IIL

IK

INS

IOH

IOL

Iout

IR

Rin

RISO

TO

Input capacitance

Output capacitance

Capacity load

Device Under Test

Electromagnetic compatibility

Relative humidity

Input current

Input current, high level

Input current, low level

Sustained short-circuit current

Rated current of fuse

Output current, high leve

Output current, low level

Output current

Standby current

Input resistance

Insulation resistance

Upper stress temperature

T.(Terminal)

点火开关位置

T.(Terminal)

Terminal of ignition key

TR

TSW

室温

溅水温度

TR

TSW

Room temperature

Splash water temperature

© 上汽集团版权所有 秘密文件 注意保密 Copyright SAIC MOTOR Confidential

2

�

SMTC 3 800 001—2012(V2)

表1 缩略语(续)

Table1 Abbreviations(Continued)

简写

TU

tf

tPB

tPS

tr

tw

UB

UBatt

UBmax.

UBmin.

Uin

UN

UIH

UIL

UOH

UOL

Uout

UP

Zout

含义

下限温度

下降时间

工作时间

休眠时间模拟

上升时间

脉冲宽度

工作电压

蓄电池电压

最大工作电压

最低工作电压

输入电压

额定电压

高端输入电压

低端输入电压

高端输出电压

低端输出电压

输出电压

测试电压

输出阻抗

Abbreviation

Meaning

TU

tf

tPB

tPS

tr

tw

UB

UBatt

UBmax.

UBmin.

Uin

UN

UIH

UIL

UOH

UOL

Uout

UP

Zout

Lower stress temperature

Fall time

Operating time simulation

Dormant time simulation

Rise time

Pulse width

Operating voltage

Battery voltage

Operating voltage, max.

Operating voltage, min.

Input voltage

Rated voltage

Input voltage, high level

Input voltage, low level

Output voltage, high level

Output voltage, low level

Output voltage

Test voltage

Output impedance

3.2 测试仪器的标准误差

3.1.1.2 Standard tolerance for test instru-

ments.

除非另有特殊定义,测试仪器的偏差限于

表 2 所示。

Unless otherwise stated, the accuracy of in-

struments is to be within the following Table2.

Table2 Standard Tolerance for Test Instruments

表2 测试仪器的标准误差

名称 / Item

电压/Voltage

电流/ Current

电阻/ Resistant

温度/ Temperature

相对湿度/ Relative Humidity

时间/ Time

频率/ Frequency

3.3 测试环境标准值

误差 / Tolerance

±1.5 %

±1.0 %

±2.0 %

±2.0 ℃

±5.0 % RH

±2.0 %

±1.0 %

3.3 Standard values for test environment

除非另有特殊定义,测试环境的标准值如

表 3 所示。

Unless otherwise stated, the standard values

for test environment is listed in the following

© 上汽集团版权所有 秘密文件 注意保密 Copyright SAIC MOTOR Confidential

3

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc