A RAPID METHOD FOR OPTIMIZATION OF LINEAR SYSTEMS

WITH STORAGE

Intelligent Energy Systems Ltd., Crows Nest, New South Wales, Australia

C. H. BANNISTER

R. J. KAYE

University of New South Wales, Kensington, New South Wales, Australia

(Received March 1989; revision received January 1990; accepted January 1990)

A new method for optimizing the operation of a single storage connected to a general linear memoryless system is presented.

The model is shown to cover a wide variety of practical situations where a deterministic approximation is valid. The method

combines linear and dynamic programming concepts to produce a fast but exact optimization.

Storage devices can be used for commodities with

costs or availabilities that change with time. Eco-

nomic benefits are gained by storing the commodity

when

* its cost is low, or

* demand for it is low

for use at other times when

* the cost is higher, or

* it is in demand.

For example, storage is commonly used in large-scale

power systems in the form of dams with generation and

pumping facilities, in small-scale remote area power

supply systems (batteries) and in many types of industrial

and commercial activities.

The systems considered in this paper consist of a

single store and a production facility. In the case of an

electric power system, the production facility consists of

the model of, inter alia, the generating units, the loads

and dam spillages and inflows. In the absence of storage,

the thermal generation units are dispatched using the

merit order rule: the units are loaded in increasing order

of variable cost until the demand is satisfied. Storage

significantly complicates this process because it links

operations between time periods, so that optimization of

operations cannot be carried out independently in each

time period.

In this paper, a new exact optimization technique is

presented. Combining linear programming and dynamic

programming concepts, the technique optimizes the op-

eration of the storage by solving a sequence of small

linear programming problems rather than the much

larger, time-staged problem. By exploiting specific fea-

tures of the single-stage problem, a very rapid solution

method has been devised.

A number of mathematical methods have been applied

to the operational optimization problem, including dy-

namic programming (Lukic 1982), the maximum princi-

ple of optimal control (Martin and Dillon 1977) and

linear, nonlinear and mixed integer programming

(Meliopoulos and Skordilis 1979, Halliburton and

Sirisena 1982, Habibollahzadeh and Bubenko 1986).

However, the applicability of these methods to practical

problems has been limited by their computational bur-

den. For example, the number of constraints in a simple

linear programming formulation of a storage optimiza-

tion will be proportional to the number of time steps.

Solution time will vary approximately as the cube of the

number of time steps. This places a relatively small

practical limit on the size and duration of problems that

can be solved.

Dechamps, Nuytten and Lee (1980) derived the

Kuhn-Tucker necessary conditions for the solution of a

particular deterministic single storage problem. These

conditions were then used to develop a heuristic solution

Subject classifications: Dynamic programming, deterministic: rapid, exact dynamic programming. Production/scheduling: optimal utilization of

storage. Programming, linear: fast optimization of linear systems.

Operations Research

Vol. 39, No. 2, March-April 1991

220

0030-364X/9 1/3902-0220 $01.25

(D 1991 Operations Research Society of America

�

method, avoiding the need to solve the very large linear

program directly. The method was reported to be some

ten times faster than a dynamic programming approach.

However, the solutions exhibited some departure from

optimality, presumably because the heuristics did not

lead to the Kuhn-Tucker conditions being satisfied

exactly.

In the work of Daryanian (1986), the optimization

ofthe operation of a simple production process with stor-

age was formulated as a time-sequenced network. A spe-

cial purpose solution procedure for this problem was

developed and tested. It performed much faster than a

standard simplex routine. However, this algorithm can-

not handle complex production facilities that exhibit

time-variation in the inputs, outputs, production pro-

cesses or costs.

In this paper, we present a new, efficient and exact

method for solving a very general class of deterministic

problems with a single storage. In Section 1, the model

of systems to be optimized is described. It consists of a

single storage and a production facility, which is de-

scribed by a piecewise linear production cost function.

This function is constant within a number of time inter-

vals that make up the study period. Some examples, also

presented in Section 1, illustrate how this model can be

used to describe a wide range of industrial situations.

One contribution of this paper is the recognition that the

modeling of the production facility and the optimization

of the storage operation can be separated.

In Section 2, the storage optimization problem is

formulated as a linear program. This formulation is used

in Section 3 to derive certain general properties of the

optimal solution which, therefore, also apply to the

dynamic programming solution. Key among these is the

central role played by the Kuhn-Tucker multiplier asso-

ciated with the continuity equation, which describes the

operation of the storage. This multiplier can be shown

to equal the incremental value of commodity in the

storage.

These properties are exploited in Section 4 to develop

the solution method, which amounts to solving a small

linear program at each time step. However, by further

exploiting the special properties of the problem, a solu-

tion technique that is much faster than the simplex

method has been developed. In Sections 5 and 6, illustra-

tive examples are detailed and discussed.

The procedure gives exact results because it systemati-

cally and explicitly satisfies the Kuhn-Tucker necessary

and sufficient conditions for the solution of the linear

program. Although the method uses dynamic program-

ming concepts, no discretization of the storage space is

required, thus avoiding the usual approximations associ-

ated with dynamic programming.

Rapid Optimization of Linear Systems / 221

1. SYSTEM DESCRIPTION

1.1. The Production and Storage Model

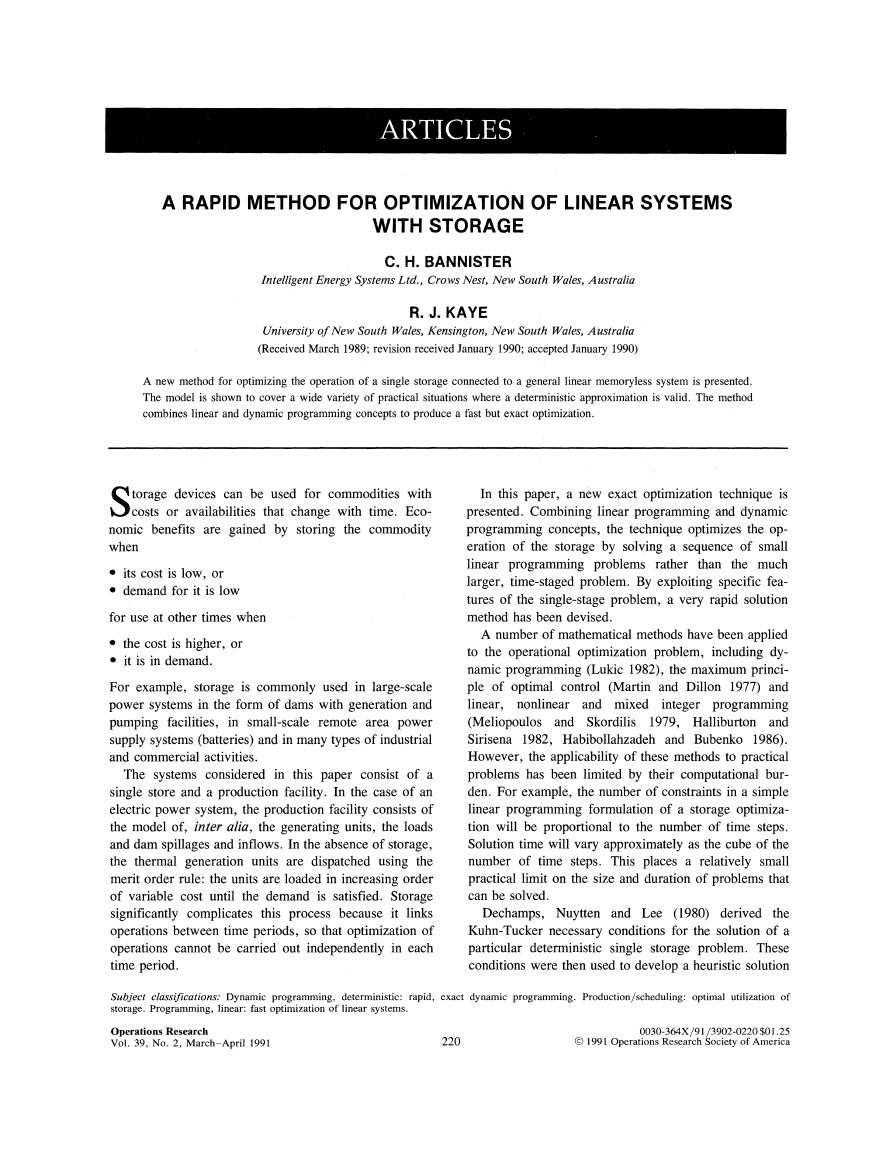

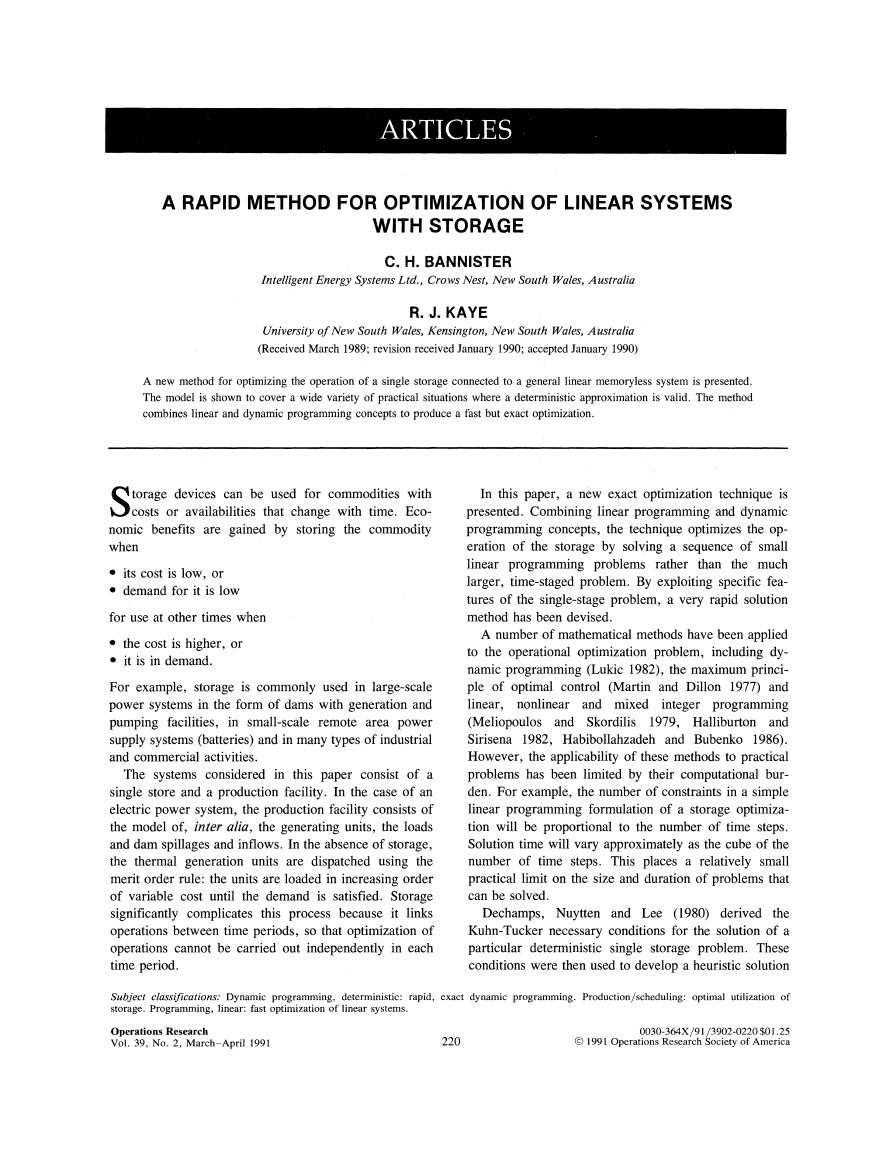

The system whose operation is to be optimized consists

of two components: a storage and a general, memoryless

production facility which feeds material into and out of

the storage, as shown in Figure 1. The time period under

study, to < t < T, is partitioned into K time intervals. It

is assumed that the flow rate of material, the state of the

production facility and the constraints on the amount of

storage are constant over each interval.

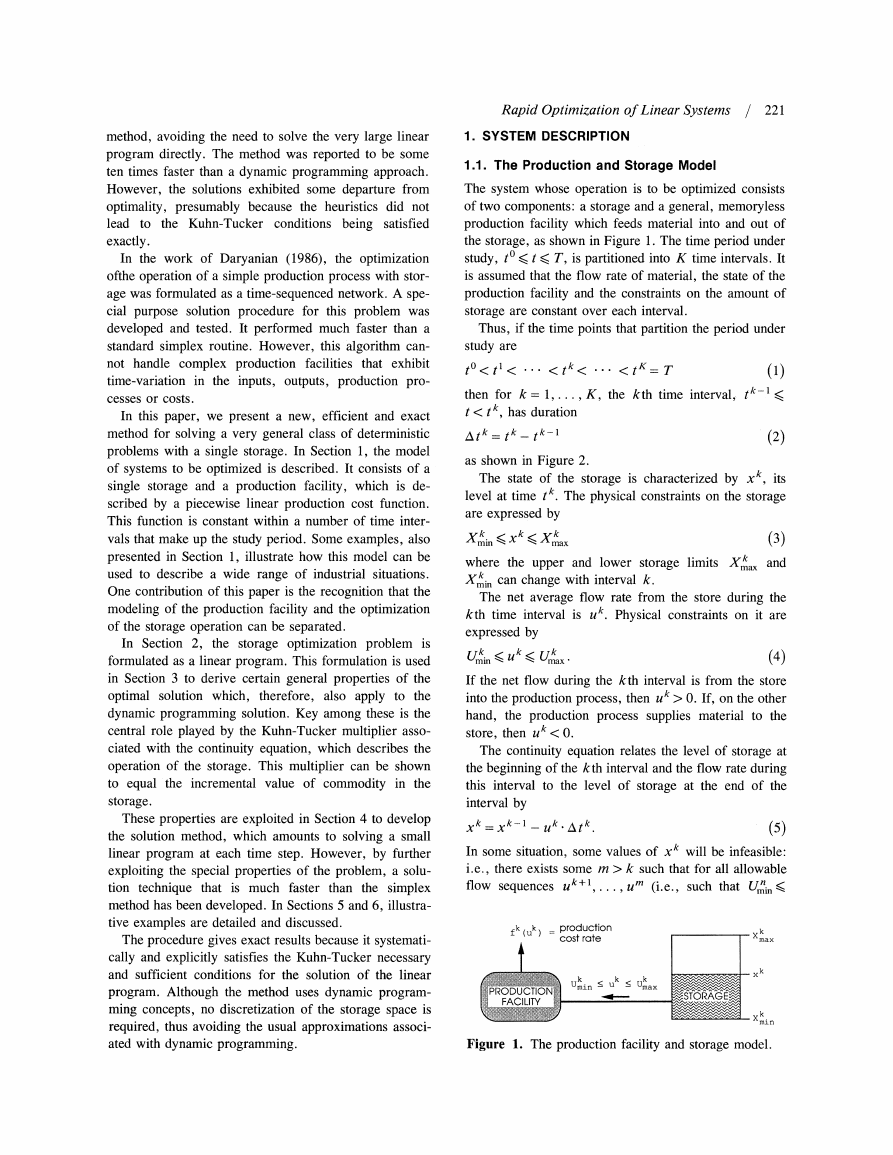

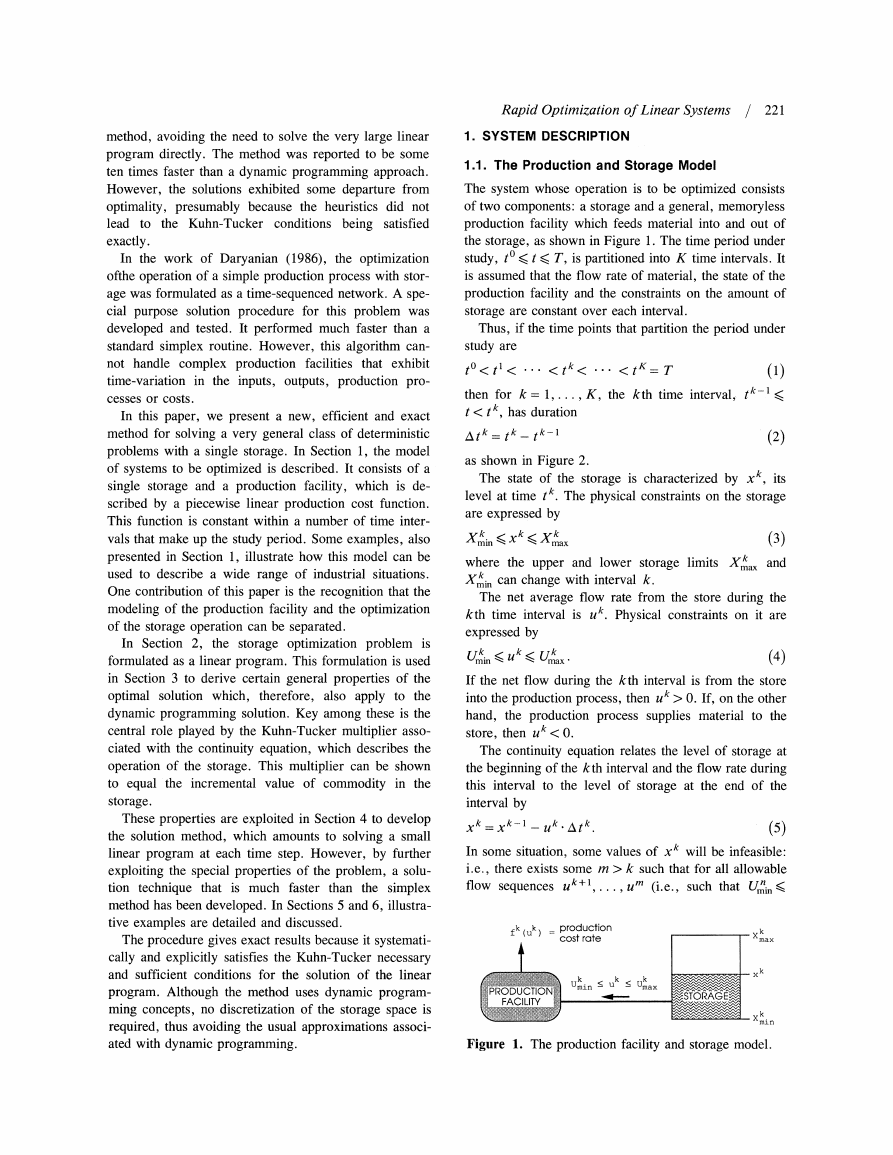

Thus, if the time points that partition the period under

study are

t1 <

. . . < tk <

t 0<

then for k = 1, ...

t < tk', has duration

< tK= T

, K, the kth time interval, tk-l <

k-i

'A tk = t k-

as shown in Figure 2.

(2)

The state of the storage is characterized by x k, its

level at time tk. The physical constraints on the storage

are expressed by

Xk.

Xk < Xax

(3)

where the upper and lower storage limits Xmk and

min can change with interval k.

The net average flow rate from the store during the

kth time interval is uk. Physical constraints on it are

expressed by

Umax.

(4)

Umk~l? 0. If, on the other

hand, the production process supplies material to the

store, then uk< O.

The continuity equation relates the level of storage at

the beginning of the kth interval and the flow rate during

this interval to the level of storage at the end of the

interval by

k-i

- Uk.5Atk)

Xk =

In some situation, some values of x k will be infeasible:

i.e., there exists some m > k such that for all allowable

flow sequences uk+1,...

(i.e., such that Ut in?

, U f

fk(Uk)

= production

cost ratema

u

Um

< k < Uk

max

RODUCTION<

FACILITY

Figure

1.

The

production

facility

and

storage

Xka

k

modlin

Figure 1. The production facility and storage model.

�

222

/ BANNISTER AND KAYE

At

At k

At

time,t

0

U3

Uk

U

a2

u~ 1

u~

u~1 ~k

U

t?

t 1

tk-

tk

tK

tK

T

k

k

-

k

k k

k

k

k

kth

interval

Figure 2. Partition of the time period into K intervals.

1<

6k

=03-

k

k

6Tu3k=IO

Figure 4. Definition of 6 ujk

flow

~~~~~~~~rate

for n = k + 1, . , m), the level of storage at

Un Um

time tm obtained by repeated application of (5), xm,

will not obey the storage level limits (3),

either xm > Xmax or xm < Xmn.

(6)

If the net flow rate from the storage during the kth

interval is uk, then the net cost per unit time incurred in

the production facility is denoted as f k(Uk). Note that

f k(Uk) can be negative, denoting a net profit. The total

net production cost during the kth interval is f k(Uk)A tk.

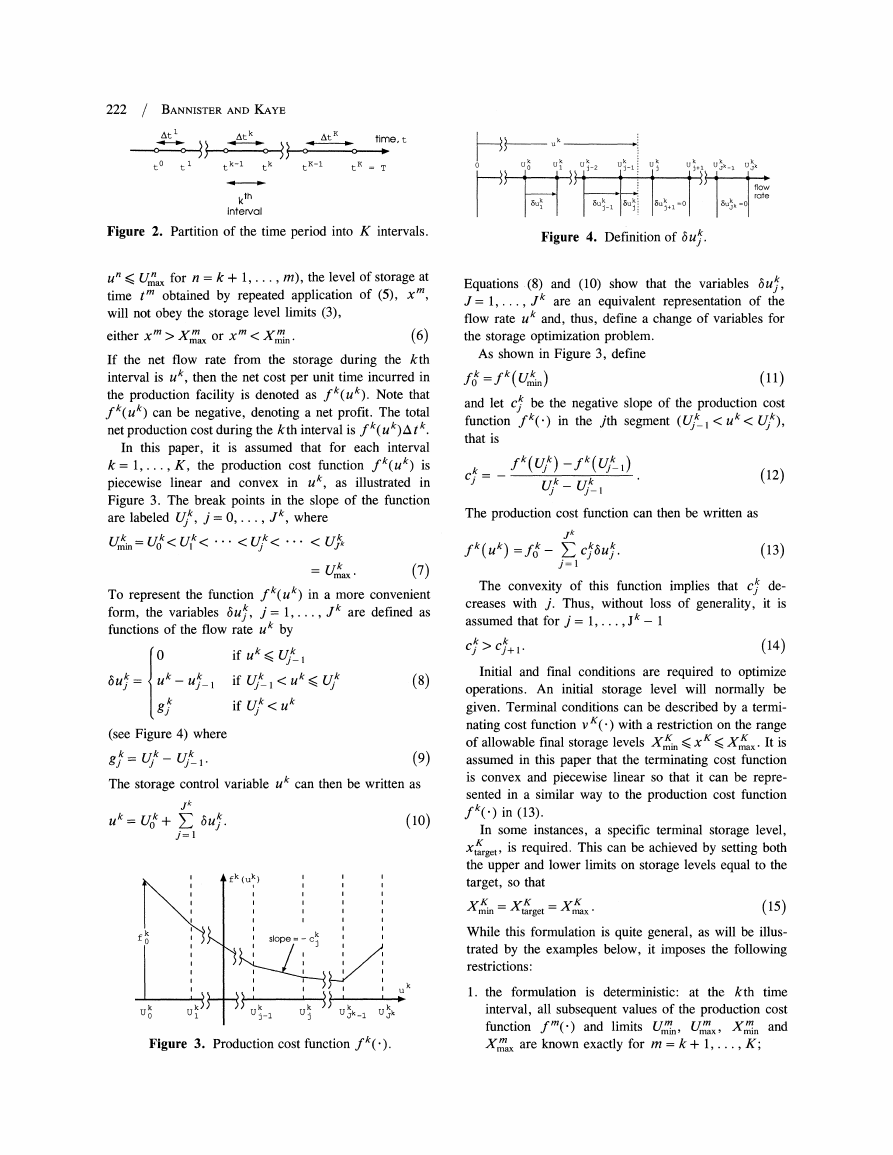

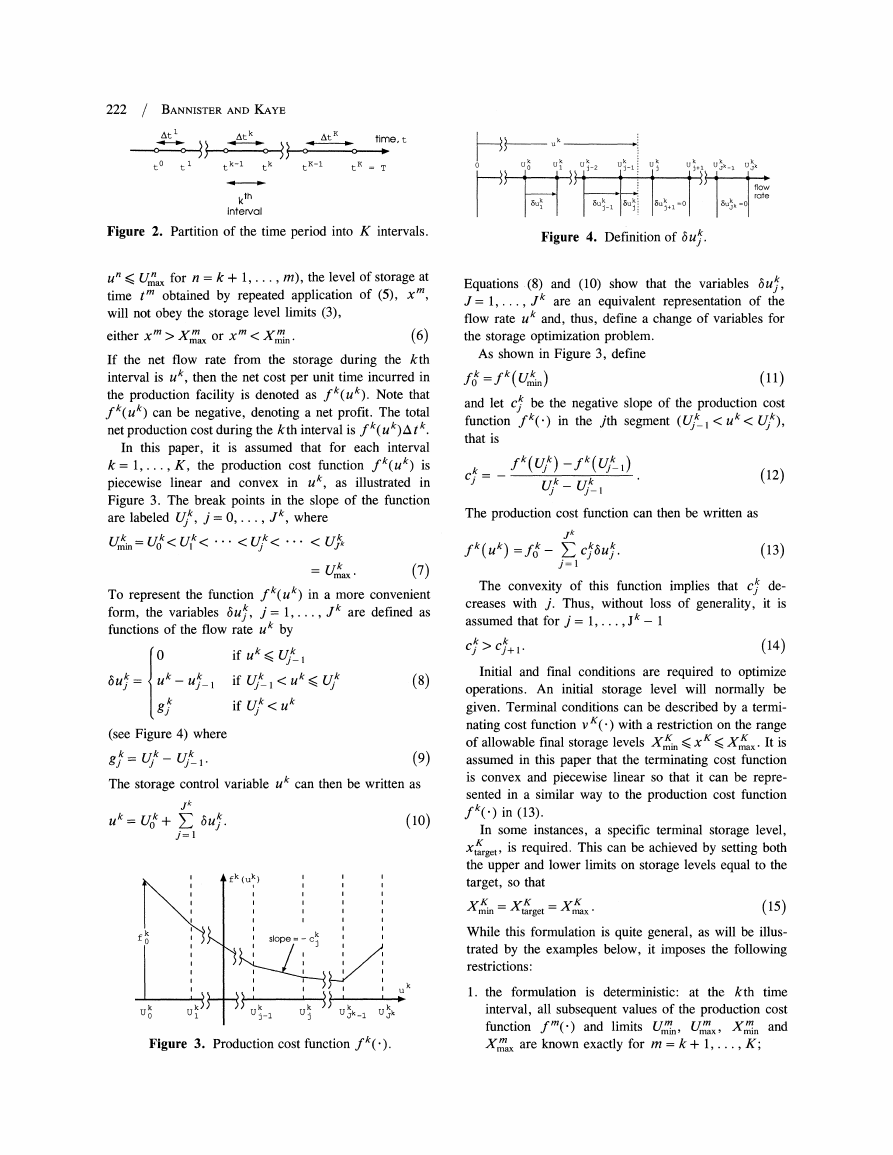

In this paper, it is assumed that for each interval

k = 1, . . . , K, the production cost function fk(uk)

is

piecewise linear and convex in uk, as illustrated in

Figure 3. The break points in the slope of the function

are labeled Uk, j= 0,. . . , jk, where

Uk=wk< Ulk<

...

< U

<

...

< U~k

= Uk.

(7)

To represent the function f k(Uk) in a more convenient

jk are defined as

form, the variables 6uj/, ]=1,...,

functions of the flow rate uk by

r

Uk

Uk-Uk

gk

if Uk< Y/?-i

if U1 < Uk< Uk

if Uk < uk

(8)

(see Figure 4) where

gI%41k

Uk1

(9)

The storage control variable uk can then be written as

jk

U

Uok + E u$.k(10)

j=1

,Ki

fk (uk)

I

I

I

fk

siope

C

i

L:

X

,L

Figure 3. Production cost function f k( *).

Equations (8) and (10) show that the variables 6uk

jk are an equivalent representation of the

J = 1,...,

flow rate uk and, thus, define a change of variables for

the storage optimization problem.

As shown in Figure 3, define

fk

fk(Uk)

(11)

and let

function fk(.)

that is

be the negative slope of the production cost

in the jth segment (Uj

k Cy+1

(14)

Initial and final conditions are required to optimize

operations. An initial storage level will normally be

given. Terminal conditions can be described by a termi-

nating cost function v K(.) with a restriction on the range

of allowable final storage levels X4i < x < XK . It is

assumed in this paper that the terminating cost function

is convex and piecewise linear so that it can be repre-

sented in a similar way to the production cost function

fk(.)

in (13).

In some instances, a specific terminal storage level,

XtaKrget is required. This can be achieved by setting both

the upper and lower limits on storage levels equal to the

target, so that

Xm

target

Xmax,*(1

While this formulation is quite general, as will be illus-

trated by the examples below, it imposes the following

restrictions:

1. the formulation is deterministic: at the kth time

interval, all subsequent values of the production cost

function fm(*) and limits Umin Ummx, Xmin and

Xmax are known exactly for m = k + 1, ... ., K;

�

2. the production cost does not depend on the level of

storage;

3. losses from the store do not depend on the storage

level;

4. there is only one storage device.

1.2. Convex Piecewise Linear Production Facilities

In the above formulation, the operation of the production

facility is represented by the production cost function

and limits on the flow rate Uk. This model cap-

fk(.)

tures a wide variety of production facilities made up of

connections of components with:

a. limits on the rate of output, input or throughput;

b. variable costs which can change as linear or piece-

wise linear functions of output, input or throughput;

and

c. operating characteristics in each time interval which

are not affected by operations in other time intervals

(i.e., memoryless).

For a given flow rate from the store, u k, a least cost

solution to the storage optimization problem requires that

operating costs within the production process also be

minimized. It follows that for each value of uk in the

feasible range, f k(Uk) is the sum of the variable costs of

each component, given that the facility is operated to

minimize this total variable cost, and that the flow rate

from the store is uk. Thus, calculation of the function

f k(.) will, in many cases, require the solution of a

family of separate optimization problems, parameter-

ized by the flow rate uk. This is illustrated by three

examples.

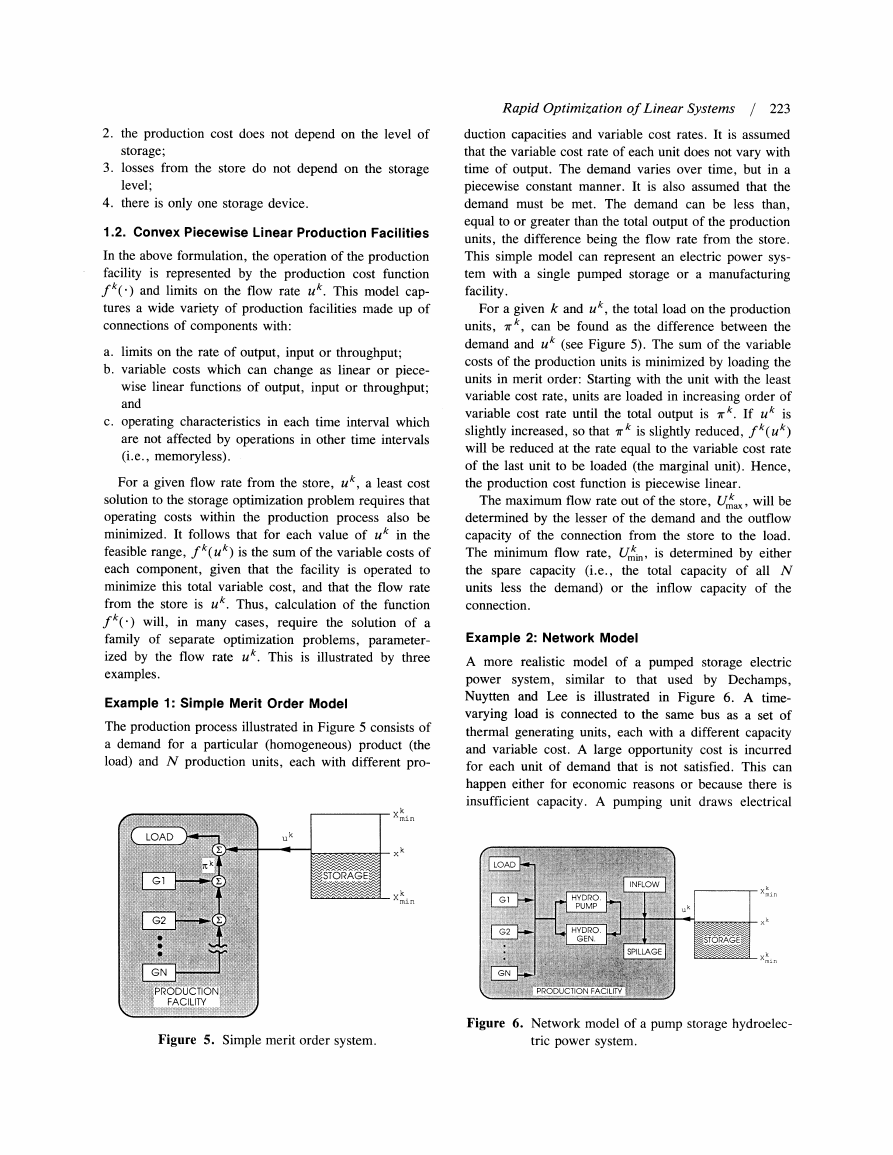

Example 1: Simple Merit Order Model

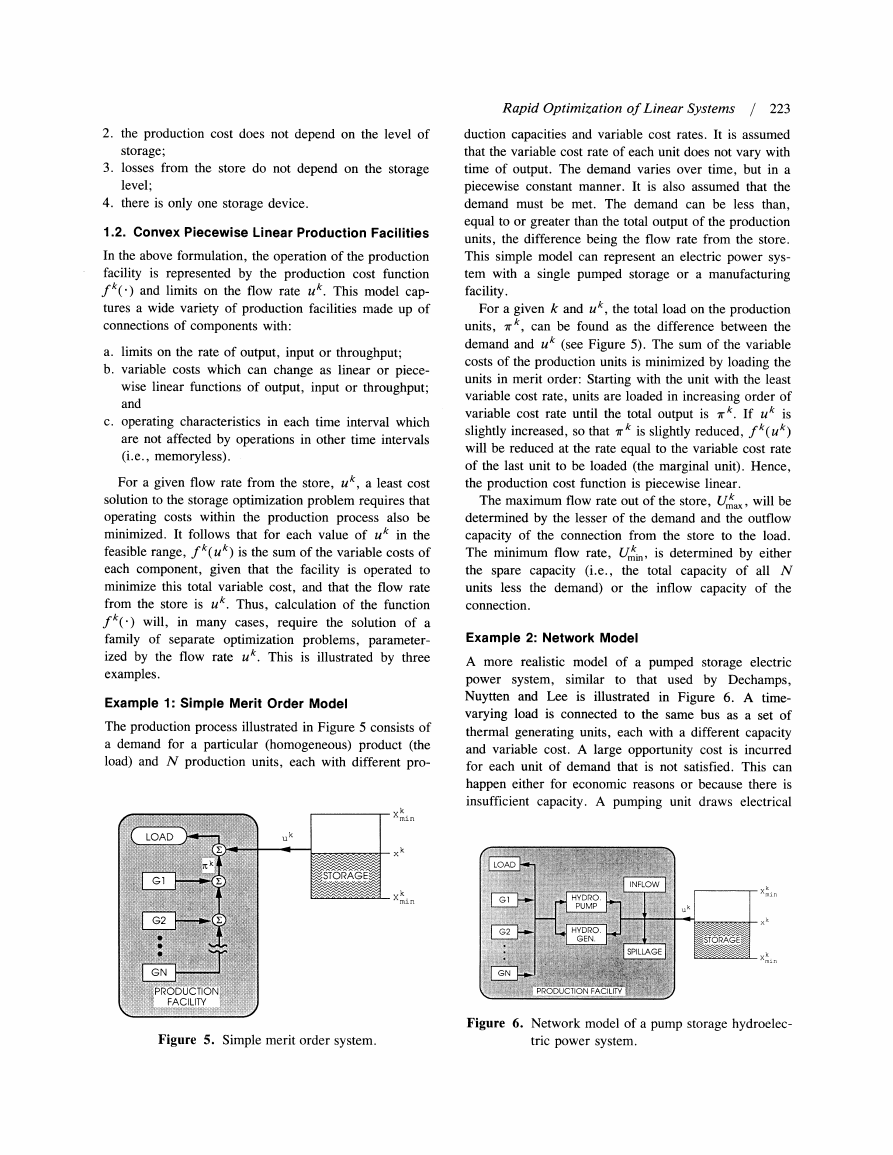

The production process illustrated in Figure 5 consists of

a demand for a particular (homogeneous) product (the

load) and N production units, each with different pro-

LOAD

..

>;t~~~~~o?

UkXk~~~~in

U

k

Rapid Optimization of Linear Systems

/ 223

duction capacities and variable cost rates. It is assumed

that the variable cost rate of each unit does not vary with

time of output. The demand varies over time, but in a

piecewise constant manner. It is also assumed that the

demand must be met. The demand can be less than,

equal to or greater than the total output of the production

units, the difference being the flow rate from the store.

This simple model can represent an electric power sys-

tem with a single pumped storage or a manufacturing

facility.

For a given k and uk, the total load on the production

units, r k, can be found as the difference between the

demand and u k (see Figure 5). The sum of the variable

costs of the production units is minimized by loading the

units in merit order: Starting with the unit with the least

variable cost rate, units are loaded in increasing order of

variable cost rate until the total output is

k. If U k is

slightly increased, so that 7rk is slightly reduced, f k(Uk)

will be reduced at the rate equal to the variable cost rate

of the last unit to be loaded (the marginal unit). Hence,

the production cost function is piecewise linear.

The maximum flow rate out of the store, Uk

, will be

determined by the lesser of the demand and the outflow

capacity of the connection from the store to the load.

The minimum flow rate, Uk. , is determined by either

the spare capacity (i.e.,

the total capacity of all N

units less the demand) or the inflow capacity of the

connection.

Example 2: Network Model

A more realistic model of a pumped storage electric

power system, similar to that used by Dechamps,

Nuytten and Lee is illustrated in Figure 6. A time-

varying load is connected to the same bus as a set of

thermal generating units, each with a different capacity

and variable cost. A large opportunity cost is incurred

for each unit of demand that is not satisfied. This can

happen either for economic reasons or because there is

insufficient capacity. A pumping unit draws electrical

Gi

~~~~~~STORAG

ll1

0

1

1

-

X

k~~~~~~~~~in

GN

PRODUCTION

~~~~~~~~~~~~~~.s..

e

S. .... ......

FACIL .

o

s

INFLOW

k

HmDR

PUM

l

k

HYDRO

GEN.SORG

~~~~~~~~~~~~~~~~Xk

Figure 5. Simple merit order system.

Figure 6. Network model of a pump storage hydroelec-

tric power system.

�

224

/ BANNISTER AND KAYE

energy from the bus and converts it to stored potential

energy with an efficiency that is less than unity. A

hydrogenerating unit, also with an efficiency that is less

than unity, can deliver electrical energy to the bus. In

addition, there is a known natural water inflow pattern,

and water spillage will occur if the upper storage limit is

exceeded. By connecting the natural inflow and the

spillage to the common storage input/output point as

shown, a boundary can be drawn to separate the produc-

tion facility from the storage.

The production facility has a linear network structure,

with each device shown being an arc with:

a. upper and lower bounds on throughput,

b. a cost rate, and

c. a gain on the flow within it.

A more elaborate linear network model could be con-

structed including, for example, lossy transmission lines,

thermal generating units with multiple incremental cost

blocks and restrictions on a common fuel supply to a

subset of generators.

Modern efficient network programming solution pro-

cedures can be adapted to solve for the complete produc-

tion cost function f k(*) using parametric techniques

(Heesterman 1983, 284-288). The result can be shown

to be piecewise linear and convex. The computational

effort involved is not much greater than solving a single

network flow problem of the same size.

Example 3: General Linear Model

There are many production processes with time-varying

parameters which do not have a network structure. For

example, if several different commodity streams are

joined in a fixed ratio, then the process cannot be

described by a network model, although it can still be

described by a set of linear relations.

For fixed uk, calculation of fk(Uk)

for models de-

scribed by linear relations involves solving a linear

program. There are efficient procedures for charac-

terizing each solution of a linear program as a model

parameter (which, in this case, is uk) that is varied

(Heesterman, 284-288). Furthermore, the optimal value

of the objective function will be a piecewise linear and

convex function of the parameter.

2. LINEAR PROGRAMMING FORMULATION

tk-1

(i.e.,

Suppose at some time

for some ke

{1, ... , K }) that the storage level is Xk- 1. The goal is

to choose a sequence uk, Uk+1,

..., uK of flow rates

which minimizes the total operating costs up to the time

horizon t K. The terminating cost function v K(.)

is

given. The problem can be expressed as a mathematical

program as

vk-l(Xk-i)

K

= min{ E

m =k

(fm(um) Atm) + vK(xK):

for m =k

...

, K:

.m

=Xml_

UmAtm

XmM. < M < XmaX}.

(16)

Using (10) and (13) to express um and fm(um)

in

terms of 6uT for je

,.

., jm} is given by

Vk-

k

( X

)

= minm { 1

K

m=k L

im

- E CJ6ul Attm + VK(XK)

j=

I

for = k, ... I K:

0 <' 6U

3. DYNAMIC PROGRAMMING FORMULATION

In the dynamic programming approach (Bellman 1957),

the principle of optimality is used to develop, for arbi-

trary k = 1, . . . , K, a relationship for the total cost

function v k- 1( * ) defined in (17) in terms of the total cost

for the next time interval. Starting with

function v k(.)

the terminating total cost function vK(. ), this relation-

ship can be used recursively to find v k(.)

1,...

uo, ...

stage.

,1,0. The optimizing sequence of flow rates

, uK can then be found using a simple forward

for k = K -

The recursive relation between v k-i (xk- ) and

V k(Xk)

is

k-1(Xk-1)

min

f

f gk1

k

E Cj6U1

j=l

tk+vk(Xk)

0 < 6u

gj

for j = 1,

Jk

XmiIn

/ BANNISTER AND KAYE

226

The convexity of this function implies that d4 decreases

with i. Thus, without loss of generality, it is assumed

that for E-

k_

1,

1'.

.

di > d+1.

Proposition 2. For each ke { 1,...

, K}, necessary

and sufficient conditions for the solution of the

single-stage dynamic programming problem in (19)

are that there exists

(28)

pka uforje{1

,Jk} and

< forie{1,

...Ik}

such that these three conditions hold:

I. Forj= 1,...,

jk

0

if Ck < pk then W u

if c _=pk thenO?u>,g

pk then 6

g

{I.

..Ik}

and Pk

such that

-_ci Atk' +pkAtk+ ykz=O

j= 1

jk

dik+ pk+Gk=O

i= 1, ...

Itk

xt+? E a-X_Xk-

i~~~~l~

IkrJkl

+ Iuok+Z

j=l

I kAtk=o

(33)

(34)

(35)

with complementary slackness conditions for j

1,.,,

j ok

and for

i1, .. .>I

(29)

ok

' 40 if ax> =O

=o

o

if O<6x

if xk =hk

H

(37)

II. For i = 1, ...,Ik

if di < pk then Wx -?

if d _=pk then O <

if dc > pk then x = h

h Ci[fu

J

l

jo

jk Atk+ Vk

0

6u<

gj

for j= 1,

i= 1

d x k1

-

Jk

Zi O

yok

6X ai=

I

Xk-1

0

Uok+

6Uk

1:

- 1

A

t

0 < bx < h

for i= 1,...Ik

(32)

where the last line expresses the constraint on the storage

level xk. Note that the parameter x k-1 appears only in

the storage continuity equality constraint.

The Kuhn-Tucker conditions are that there exists

,

for ie

8uk, G

for je{1

..,

J'} and

Noting that A t k> 0, it can easily be shown that

(29)-(31) are equivalent to (33)-(37).

The proof of the next result follows directly from the

previous proof.

Proposition. Fork=1,...,K

dvk1(xkl)

k

almost everywhere.

(38)

Thus, the marginal value of an additional increment of

is given by the storage

storage contents at time tkil

continuity multiplier pk. Furthermore, it can be shown

(Kaye 1987) that the values of this multiplier, calculated

for a sequence of single-stage problems in (19) are the

same as those calculated for the large-scale problem

in (17).

From the Kuhn-Tucker conditions for (16) it can be

shown that ji' only changes when the storage trajectory

hits a limit, so that

if xkI=X

a

ek+e

then pk+1 pk

(39)

The sensitivities of the total costs to the parameters Xtax

and Xmm can be calculated from the value of pk

Sensitivities to the parameters of the production cost

function can also be calculated. Further details can be

found in Bannister (1989).

�4. THE SOLUTION ALGORITHM

The results of the previous section are used to derive a

simple, exact and efficient algorithm which generates the

total cost function vk-i (), given a total cost function

Vk( ) and a production cost function f k(. ), both of

which are convex and piecewise linear. This procedure

can be applied recursively for k = K, K - 1, ... , 1 so

that each vk( ) function is characterized. The optimal

flow rates and storage levels can then be found using a

simple forward stage, similar to that used in a standard

dynamic programming approach.

For each feasible value of xk-1

there exists a p k

that satisfies the conditions of Proposition 2. For each

possible value of pk define

k(

P

k)=

x

k-i. p satisfies theconditions

of Proposition 2for x

i kI

,

)

40)

The set 92 k( pk) will consist of either a single point or an

interval. The algorithm proceeds by identifying this set

for each possible value of pk.

There are four possible cases.

Case 1

pko ? C,

dik: i = I, ..ik

j

I

j

k}

Case 2

pk =C *

for some j*=1,

Jk

and

pk

{d

IC:

l

Ik}

Case 3

p =di* for somei*=1,...,I

and

pk

{ck:j =

, ...,Jk}.

Case 4

pk =Cj/* for some j* =1.Jk

and

for some i* = 1,. . .,. I.

p =di*

Each case will be examined.

Case 1

c,

dik:i = II . ..

pko ?

From (14), there exists j*e{1,

k

c1 > P > c1* +, so that

Iik;

j=

k

k

I

jk}

. . .,

jk}

such that

Rapid Optimization of Linear Systems / 227

and

C1 < p

k

k

1

for j =j* + 1,

.

j

Jk

(41)

It follows from (29) that

bUk = gj

for j = 1,

j*

and

bu = O forj=j*+1,...,

jk

so that

uk= Ukj*.

Similarly, from (28), there exists i* E{ 1,..

that di >pk>

xk=X

Thus, by (31)

so that

d*+,

.

Xk1

= Xk*+

Uj Atk.

(42)

(43)

, I'k} such

(44)

(45)

There is thus only one value of x k-i corresponding

to values of pk in the range

max cj*+1,c4+1}

di*+ 1

From (28) there exists i*e{1,

di* >

so that from (30) and (27)

xk =X.

. .,

I'} such that

(48)

(49)

(50)

It follows from (31) that such values of pk correspond

X

TufA tk.

to values of x k-1 in the range

+

X/k+ U)k Atk xkl?

(51)

This range can be constructed on a t - x plane as the

wedge shaped region enclosed between the two rays of

slope -

and - U'T, both emanating from the point

(tk, X/*), as shown in Figure 8. Within this region, by

(38):

a Vk_ __

j1

1

)

(

k

- p

_ k

-c1*.

x

(52)

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc