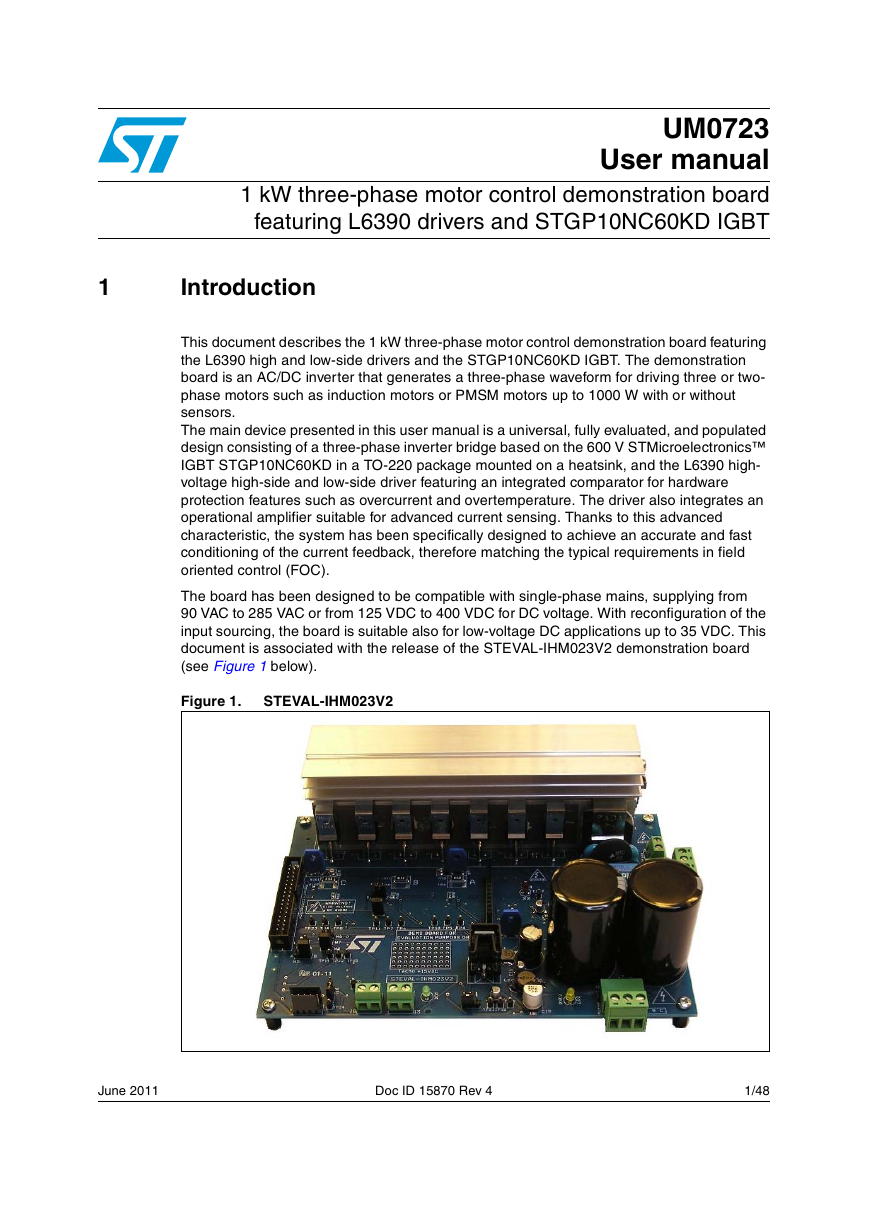

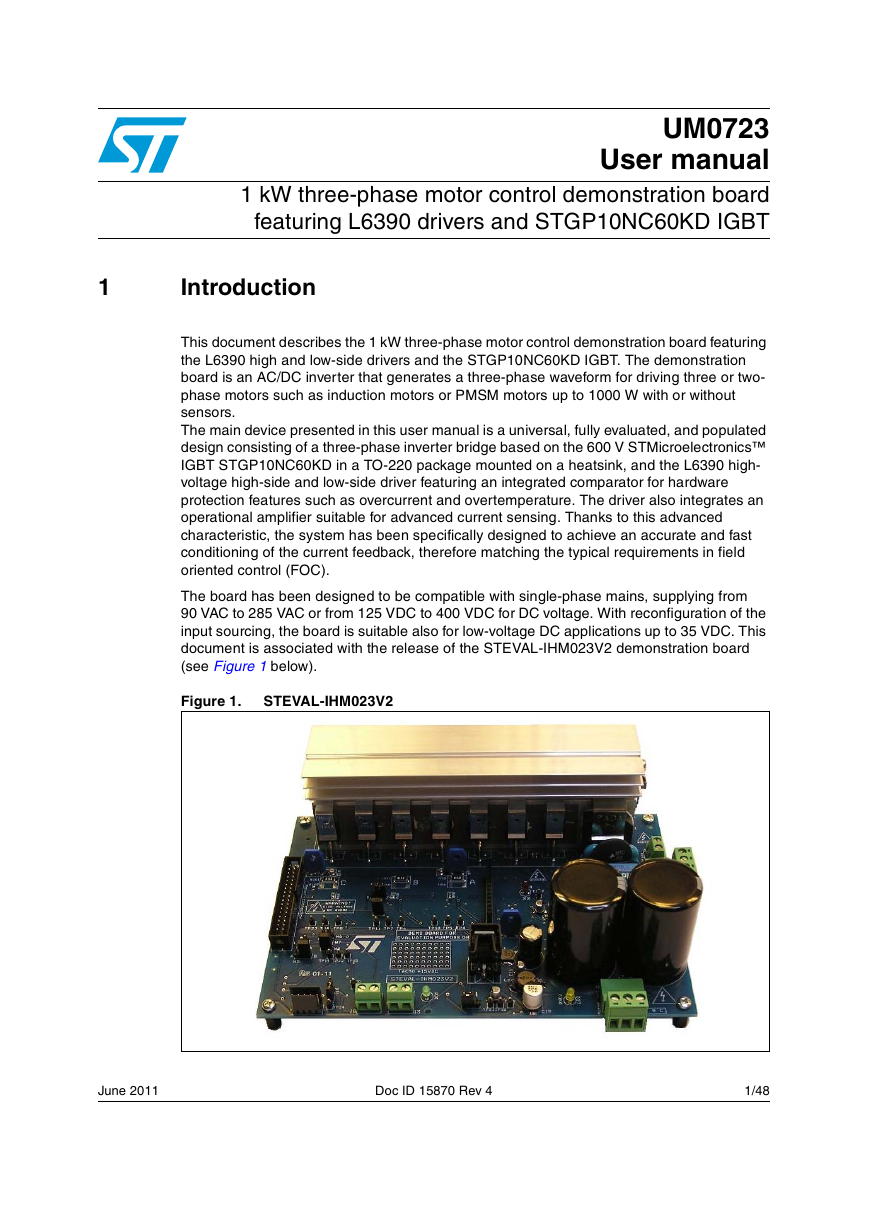

1 Introduction

Figure 1. STEVAL-IHM023V2

2 System introduction

2.1 Main characteristics

2.2 Target applications

2.3 Safety and operating instructions

2.3.1 General terms

2.3.2 Demonstration board intended use

2.3.3 Demonstration board installation

2.3.4 Electrical connections

2.3.5 Demonstration board operation

3 Board description

3.1 System architecture

Figure 2. Motor control system architecture

3.2 The board schematic

Figure 3. STEVAL- IHM023V2 schematic - part 1

Figure 4. STEVAL- IHM023V2 schematic - part 2

Figure 5. STEVAL- IHM023V2 schematic - part 3

Figure 6. STEVAL- IHM023V2 schematic - part 4

Figure 7. STEVAL- IHM023V2 schematic - part 5

Figure 8. STEVAL- IHM023V2 schematic - part 6

3.3 Circuit description

3.3.1 Power supply

Figure 9. Power supply block diagram

3.3.2 Inrush limitation

3.3.3 Brake function

3.3.4 Gate driving circuit

Figure 10. Gate driving network

3.3.5 Overcurrent protection

Figure 11. Overcurrent protection

3.3.6 Current sensing amplifying network

Figure 12. Three-shunt configuration

Figure 13. Six-step current sensing configuration

Table 1. Current reading configuration

3.3.7 The tachometer and Hall/encoder inputs

3.3.8 Temperature feedback and overtemperature protection

Figure 14. NTC placement on the heatsink

4 Hardware setting of the STEVAL-IHM023V2

4.1 Hardware settings for six-step (block commutation) control of BLDC motors

Table 2. Jumper settings for high-voltage BLDC motor in six-step control (continued)

Table 3. Jumper settings for low-voltage BLDC motor in six-step control

4.2 Hardware settings for “Field Oriented Control” (FOC) in single-shunt topology current reading configuration

Table 4. Jumper settings for high-voltage PMAC or generic AC motor in single- shunt FOC control

Table 5. Jumper settings for low-voltage BLDC motor in single-shunt FOC control

4.3 Hardware settings for FOC in three-shunt configuration

Table 6. Jumper settings for FOC of HV PMSM, BLDC, or AC IM in three-shunt configuration for current reading

Table 7. Jumper settings for FOC of LV PMSM or BLDC in three-shunt configuration for current reading

5 Description of jumpers, test pins, and connectors

Table 8. Jumpers description

Table 9. Connector pinout description (continued)

Table 10. Testing pins description (continued)

6 Connector placement

Figure 15. STEVAL-IHM023V2 connectors placement

7 Bill of material

Table 11. Bill of material (continued)

8 PCB layout

Figure 16. Silk screen - top side

Figure 17. Silk screen - bottom side

Figure 18. Copper tracks - top side

Figure 19. Copper tracks - bottom side

9 Ordering information

10 Using STEVAL-IHM023V2 with STM32 PMSM FOC firmware library v3.0

10.1 Environmental considerations

10.2 Hardware requirements

10.3 Software requirements

10.4 STM32 FOC firmware library v3.0 customization

Table 12. STEVAL-IHM023V2 motor control workbench parameters

11 Conclusion

12 References

13 Revision history

Table 13. Document revision history

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc