Chapter 1. Features and Capabilities

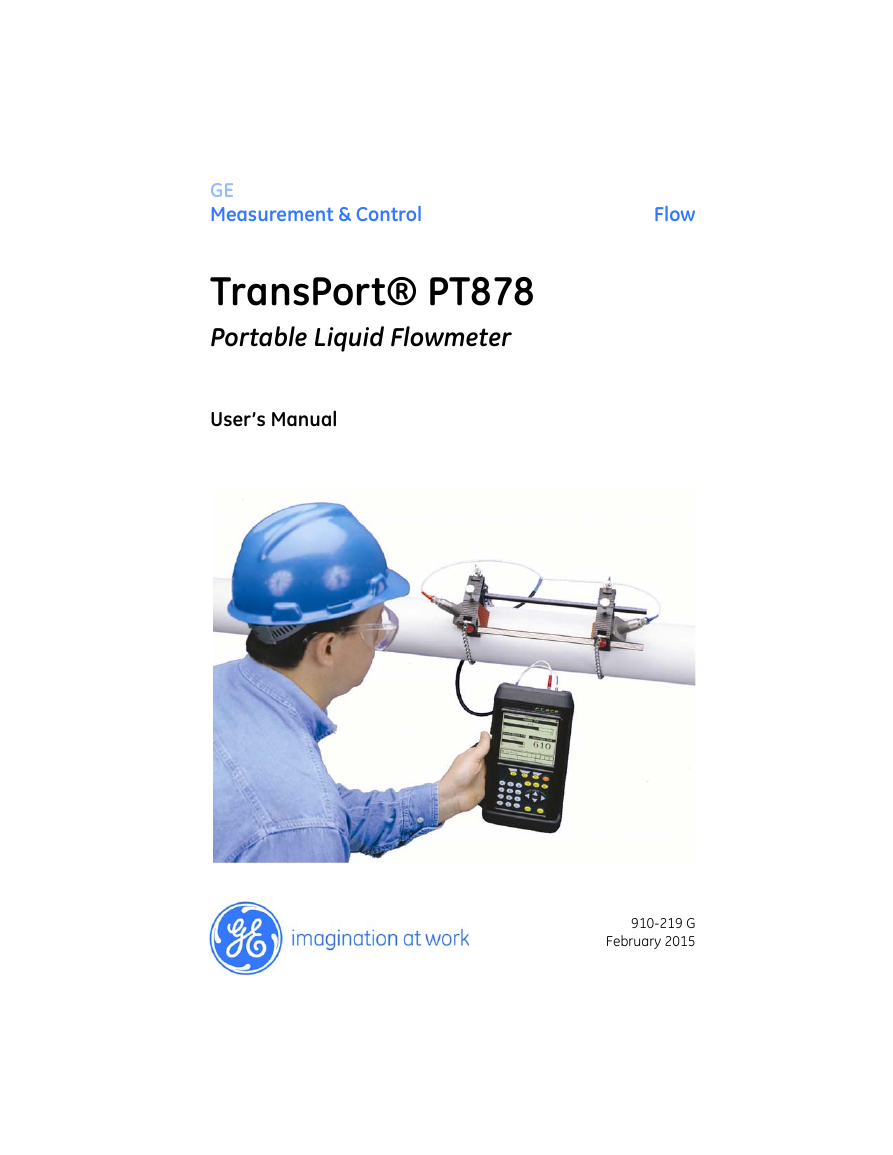

1.1 Overview

1.2 System Description

1.2.1 The Flowcell

1.2.2 Electronics Package

1.3 Theory of Operation

Chapter 2. Initial Setup

2.1 Making Electrical Connections

2.1.1 Power Connections

2.1.2 Transducer Connections

2.1.3 Input/Output Connections

2.1.4 The USB Port

2.2 Caring for the PT878 Batteries

2.2.1 Charging and Storing the Batteries

2.2.2 Replacing the Batteries

2.2.3 Disposing of Batteries

2.3 Powering ON and OFF

2.4 Using the Screen and Keypad

2.4.1 Screen

2.4.2 Keypad

2.5 Obtaining On-Line Help

Chapter 3. Programming Site Data

3.1 Entering the Program Menu

3.2 Entering Transducer Parameters

3.2.1 Parameters for Special Transducers

3.2.2 Confirming Entries

3.3 Entering Pipe Parameters

3.4 Entering Pipe Lining Parameters

3.5 Entering Fluid Types and Speeds

3.6 Entering the Signal Path Parameters

3.6.1 Path Parameters for Clamp-On Transducers

3.6.2 Path Parameters for Wetted Transducers

3.7 Entering the Energy Option Parameters

3.7.1 Entering Inputs in the Energy Option

3.7.2 Entering Custom Cp Data in the Energy Option

3.8 Entering Analog Inputs

3.8.1 Entering General-Purpose Analog Inputs

3.8.2 Entering Analog Inputs in the Energy Option

3.9 Entering the Analog Output

3.10 Entering the Digital Output

3.11 Entering User Functions

3.11.1 Entering Correction Factors

3.11.2 Entering Reynolds Correction

3.11.3 Entering a Calibration Factor

Chapter 4. Creating and Managing Sites

4.1 The Site Manager

4.1.1 Creating a New Site

4.1.2 Opening an Existing Site

4.1.3 Saving a Site

4.1.4 Saving a Site with a Different Name

4.1.5 Refreshing a Site

4.1.6 Renaming a Site

4.1.7 Deleting a Site

4.1.8 Creating a Site Message

4.1.9 Transfer Files Between the PT878 and a PC

4.1.10 Listing Files by Name

4.1.11 Listing Files in Chronological Order

Chapter 5. Displaying and Configuring Data

5.1 The Format Option

5.2 The View Option

5.3 The Limits Option

5.4 The Measurement Option

5.5 Customizing the Display Screen

5.5.1 Specifying the Number of Displayed Parameters

5.5.2 Customizing Softkeys

5.6 Managing Files — The Drive Manager

5.6.1 Transferring a File to a PC

5.6.2 Transferring a File from a PC to the PT878

5.6.3 Refreshing a File

5.6.4 Deleting a File

5.6.5 Listing Files by Name

5.6.6 Listing Files in Chronological Order

5.7 Accessing Meter Data —The About Option

Chapter 6. Programming Meter Settings

6.1 Entering the Meter Menu

6.2 Selecting Measurement Units

6.3 The Battery Charger

6.4 Entering Date and Time

6.5 Changing Date and Time Appearance

6.6 Adjusting the Contrast

6.7 Setting Backlight Timeout

6.8 Changing the Display Language

6.9 Changing Communications Settings

6.10 Resetting Forward and Reverse Totals

6.11 Setting Up User Tables

6.12 Taking a Bitmap Capture of a Current Screen

Chapter 7. Logging Data

7.1 Entering the Logging Menu

7.2 The Log Manager

7.3 The File Menu

7.3.1 Setting up a New Log

7.3.2 Copying (Cloning) a Selected Log

7.3.3 Renaming a Log

7.3.4 Deleting a Log

7.3.5 Deleting All Logs

7.3.6 Refreshing the Log Manager Screen

7.3.7 Transferring a Log to a PC

7.4 The Log Menu

7.4.1 Stopping (Pausing) a Log

7.4.2 Restarting a Log

7.4.3 Ending a Log

7.4.4 Stopping All Logs

7.4.5 Restarting All Logs

7.4.6 Ending All Logs

7.4.7 View All Sites

7.5 The View Menu

7.5.1 Displaying Log Details

7.5.2 Displaying Log Data in Graphical Form

7.5.3 Displaying Log Data in Spreadsheet Form

7.6 The Sort Menu

7.6.1 Listing Logs by Name

7.6.2 Listing Logs in Chronological Order

Chapter 8. Servicing the PT878

8.1 Entering the Service Menu

8.2 Transferring Reports

8.3 Setting up the Thickness Gauge

8.4 Measuring Pipe Wall Thickness

8.4.1 Entering the Material and Soundspeed

8.4.2 Measuring Thickness in Numeric Format

8.4.3 Displaying the Receive Signal in Graphical Format

8.4.4 Calibrating the Thickness Gauge Transducer

8.4.5 Calculating Velocity (Pipe Material Soundspeed)

8.5 Programming the Thickness Gauge

8.6 Displaying Diagnostic Parameters

8.7 Calibrating the Analog Output and Inputs

8.7.1 Calibrating the Analog Output

8.7.2 Calibrating Inputs

8.8 Setting up Signal Parameters

8.8.1 Setting up Signal Parameters

8.8.2 Setting up Peak Detection

8.8.3 Selecting the Transmit Code

8.9 Setting Error Limits

8.10 The Test Option

8.10.1 Testing the Screen

8.10.2 Testing the Keys

8.10.3 Testing the Watchdog Timer Circuit

8.10.4 Setting Impulse Response

8.10.5 Taking Wave Samples for Diagnosis

8.10.6 Transferring a Wave Snapshot

8.10.7 Testing the Battery

8.11 Resetting to Factory Default Parameters

8.12 Updating PT878 Firmware

Chapter 9. Diagnostics and Troubleshooting

9.1 Error Code Messages

9.2 Displaying Diagnostic Parameters

9.3 Flowcell Problems

9.3.1 Fluid Problems

9.3.2 Pipe Problems

9.4 Transducer Problems

9.4.1 Wetted Transducer Problems

9.4.2 Clamp-on Transducer Problems

9.4.3 Relocating Transducers

Chapter 10. Specifications

10.1 Overall

10.1.1 Hardware Configuration

10.1.2 Size/Weight

10.1.3 Enclosure

10.1.4 Flow Accuracy (Velocity, % of reading):

10.2 Electrical

10.3 Operational Specifications

10.4 Transducer

10.4.1 Clamp-On Ultrasonic Flow Transducers

10.4.2 Temperature Transducers

10.5 Pipe Size and Material

10.5.1 Clamp-On Transducers:

10.6 Available Options

Appendix A. Menu Maps

Figure 138: Site Menu

Figure 139: Program Menu with Pipe Option

Figure 140: Meter Menu

Figure 141: Logging Menu

Figure 142: Service Menu

Appendix B. Measuring P and L Dimensions

Appendix C. Temperature Transmitter Installation

C.1 Guidelines for RTD Installation

C.2 Mounting RTDs on the Pipe

C.2.1 Assembling the Clamping Fixture

C.2.2 Mounting the RTD to the Pipe

C.3 Making Electrical Connections

C.3.1 Connecting the RTD to the 4 to 20-mA Transmitter

C.3.2 Connecting the Transmitter to the PT878

Appendix D. Ultrasonic Thickness Gauge Theory of Operation

D.1 Factors Affecting Performance and Accuracy

D.1.1 Transducer Positioning/Alignment

D.1.2 Calibration

D.1.3 Taper or Eccentricity

D.1.4 Acoustic Properties of the Material

Appendix E. Material Safety Data Sheet for Couplant

E.1 Product Identification

E.2 Hazardous Ingredients

E.3 Physical Data (nominal)

E.4 Fire and Explosion Hazard Data

E.5 Reactivity Data

E.6 Health Hazard and First Aid Data

E.7 Storage and Handling Information

E.8 Control Measures

Appendix F. Glossary

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc