< > !

R-30+A/R-30+A Mate/R-30iB CONTROLLER

CC-Link Interface (Slave)

OPERATOR'S MANUAL

B-82654EN/04

�

• Original Instructions

Before using the Robot, be sure to read the "FANUC Robot Safety Manual (B-80687EN)" and

understand the content.

• No part of this manual may be reproduced in any form.

• All specifications and designs are subject to change without notice.

The products in this manual are controlled based on Japan’s “Foreign Exchange and

Foreign Trade Law”. The export from Japan may be subject to an export license by the

government of Japan.

Further, re-export to another country may be subject to the license of the government of

the country from where the product is re-exported. Furthermore, the product may also be

controlled by re-export regulations of the United States government.

Should you wish to export or re-export these products, please contact FANUC for advice.

In this manual we have tried as much as possible to describe all the various matters.

However, we cannot describe all the matters which must not be done, or which cannot be

done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in this manual should be

regarded as ”impossible”.

�

B-82654EN/04

SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

Thank you for purchasing FANUC Robot.

This chapter describes the precautions which must be observed to ensure the safe use of the robot.

Before attempting to use the robot, be sure to read this chapter thoroughly.

Before using the functions related to robot operation, read the relevant operator's manual to become

familiar with those functions.

If any description in this chapter differs from that in the other part of this manual, the description given in

this chapter shall take precedence.

For the safety of the operator and the system, follow all safety precautions when operating a robot and its

peripheral devices installed in a work cell.

In addition, refer to the “FANUC Robot SAFETY HANDBOOK (B-80687EN)”.

WORKING PERSON

The personnel can be classified as follows.

Operator:

• Turns robot controller power ON/OFF

• Starts robot program from operator’s panel

Programmer or teaching operator:

• Operates the robot

• Teaches robot inside the safety fence

Maintenance engineer:

• Operates the robot

• Teaches robot inside the safety fence

• Maintenance (adjustment, replacement)

1

-

-

An operator cannot work inside the safety fence.

A programmer, teaching operator, and maintenance engineer can work inside the safety fence. The

working activities inside the safety fence include lifting, setting, teaching, adjusting, maintenance,

etc.

To work inside the fence, the person must be trained on proper robot operation.

-

During the operation, programming, and maintenance of your robotic system, the programmer, teaching

operator, and maintenance engineer should take additional care of their safety by using the following

safety precautions.

-

- Wear safety shoes

-

Use adequate clothing or uniforms during system operation

Use helmet

s-1

�

2

SAFETY PRECAUTIONS

B-82654EN/04

DEFINITION OF WARNING, CAUTION AND

NOTE

To ensure the safety of user and prevent damage to the machine, this manual indicates each precaution on

safety with "Warning" or "Caution" according to its severity. Supplementary information is indicated by

"Note". Read the contents of each "Warning", "Caution" and "Note" before attempting to use the

oscillator.

WARNING

Applied when there is a danger of the user being injured or when there is a

danger of both the user being injured and the equipment being damaged if the

approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment being damaged, if the

approved procedure is not observed.

NOTE

Notes are used to indicate supplementary information other than Warnings and

Cautions.

•

3

Read this manual carefully, and store it in a sales place.

WORKING PERSON SAFETY

Working person safety is the primary safety consideration. Because it is very dangerous to enter the

operating space of the robot during automatic operation, adequate safety precautions must be observed.

The following lists the general safety precautions. Careful consideration must be made to ensure

working person safety.

(1) Have the robot system working persons attend the training courses held by FANUC.

FANUC provides various training courses. Contact our sales office for details.

(2) Even when the robot is stationary, it is possible that the robot is still in a ready to move state, and is

waiting for a signal. In this state, the robot is regarded as still in motion. To ensure working

person safety, provide the system with an alarm to indicate visually or aurally that the robot is in

motion.

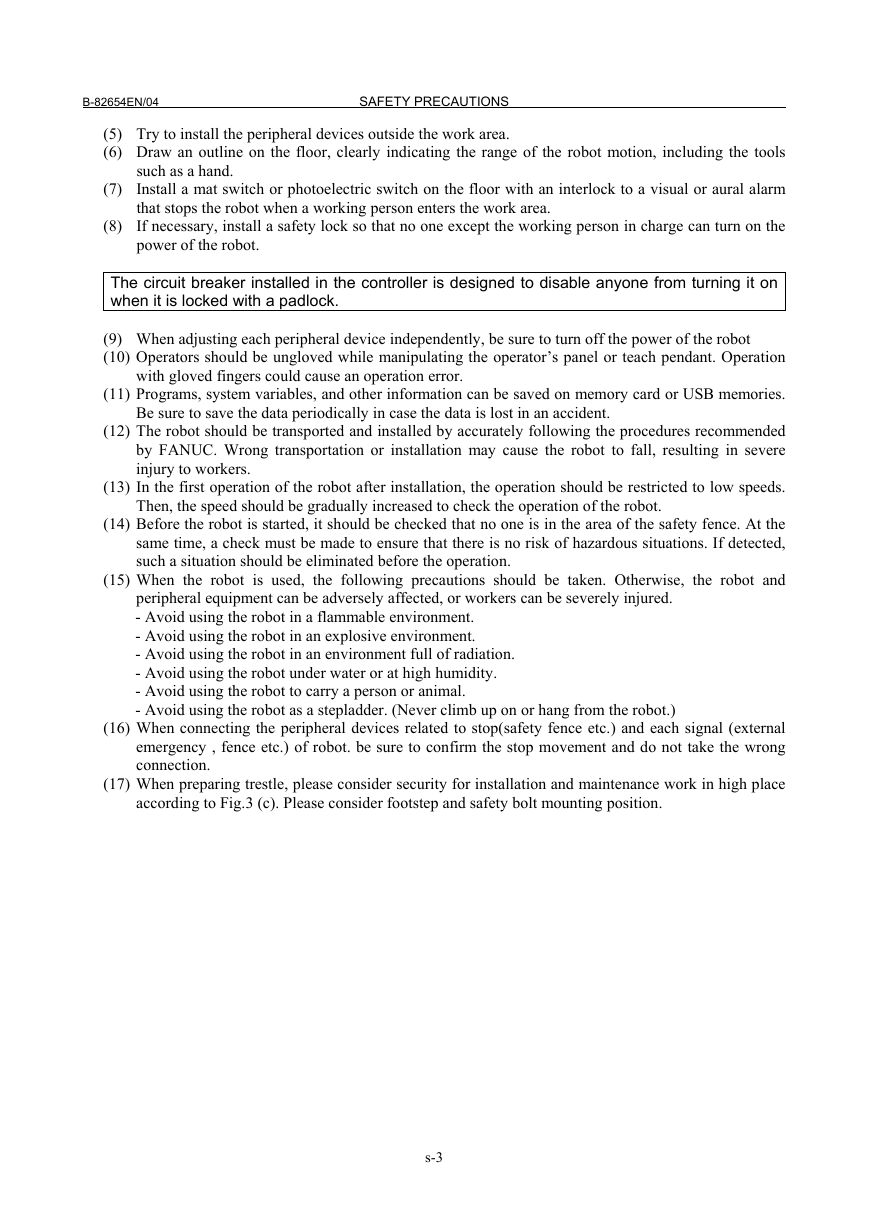

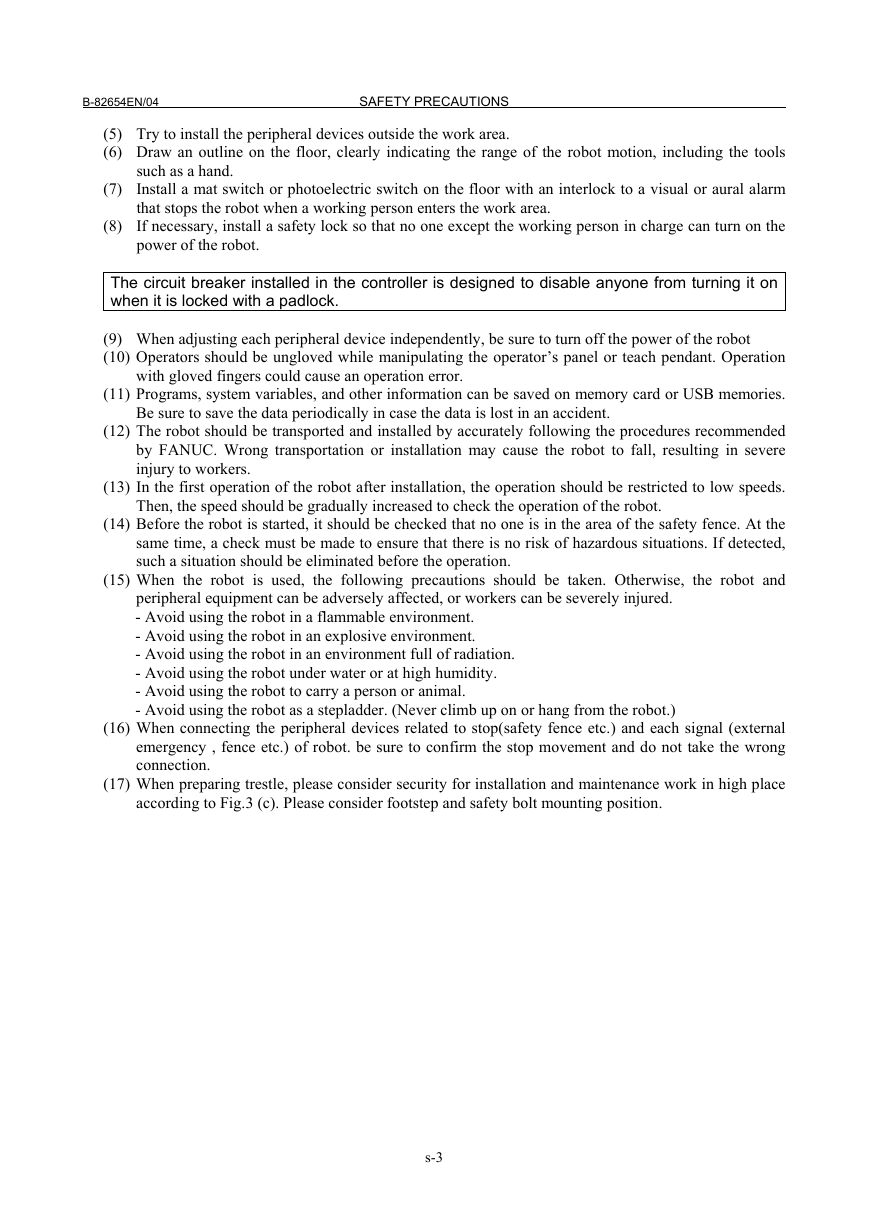

(3) Install a safety fence with a gate so that no working person can enter the work area without passing

through the gate. Install an interlocking device, a safety plug, and so forth in the safety gate so that

the robot is stopped as the safety gate is opened.

The controller is designed to receive this interlocking signal of the door switch. When the gate

is opened and this signal received, the controller stops the robot (Please refer to "STOP

TYPE OF ROBOT" in SAFETY PRECAUTIONS for detail of stop type). For connection, see

Fig.3 (a) and Fig.3 (b).

(4) Provide the peripheral devices with appropriate grounding (Class A, Class B, Class C, and Class D).

s-2

�

B-82654EN/04

SAFETY PRECAUTIONS

(5) Try to install the peripheral devices outside the work area.

(6) Draw an outline on the floor, clearly indicating the range of the robot motion, including the tools

(7) Install a mat switch or photoelectric switch on the floor with an interlock to a visual or aural alarm

that stops the robot when a working person enters the work area.

(8) If necessary, install a safety lock so that no one except the working person in charge can turn on the

such as a hand.

power of the robot.

The circuit breaker installed in the controller is designed to disable anyone from turning it on

when it is locked with a padlock.

(9) When adjusting each peripheral device independently, be sure to turn off the power of the robot

(10) Operators should be ungloved while manipulating the operator’s panel or teach pendant. Operation

with gloved fingers could cause an operation error.

(11) Programs, system variables, and other information can be saved on memory card or USB memories.

Be sure to save the data periodically in case the data is lost in an accident.

(12) The robot should be transported and installed by accurately following the procedures recommended

by FANUC. Wrong transportation or installation may cause the robot to fall, resulting in severe

injury to workers.

(13) In the first operation of the robot after installation, the operation should be restricted to low speeds.

Then, the speed should be gradually increased to check the operation of the robot.

(14) Before the robot is started, it should be checked that no one is in the area of the safety fence. At the

same time, a check must be made to ensure that there is no risk of hazardous situations. If detected,

such a situation should be eliminated before the operation.

(15) When the robot is used, the following precautions should be taken. Otherwise, the robot and

peripheral equipment can be adversely affected, or workers can be severely injured.

- Avoid using the robot in a flammable environment.

- Avoid using the robot in an explosive environment.

- Avoid using the robot in an environment full of radiation.

- Avoid using the robot under water or at high humidity.

- Avoid using the robot to carry a person or animal.

- Avoid using the robot as a stepladder. (Never climb up on or hang from the robot.)

(16) When connecting the peripheral devices related to stop(safety fence etc.) and each signal (external

emergency , fence etc.) of robot. be sure to confirm the stop movement and do not take the wrong

connection.

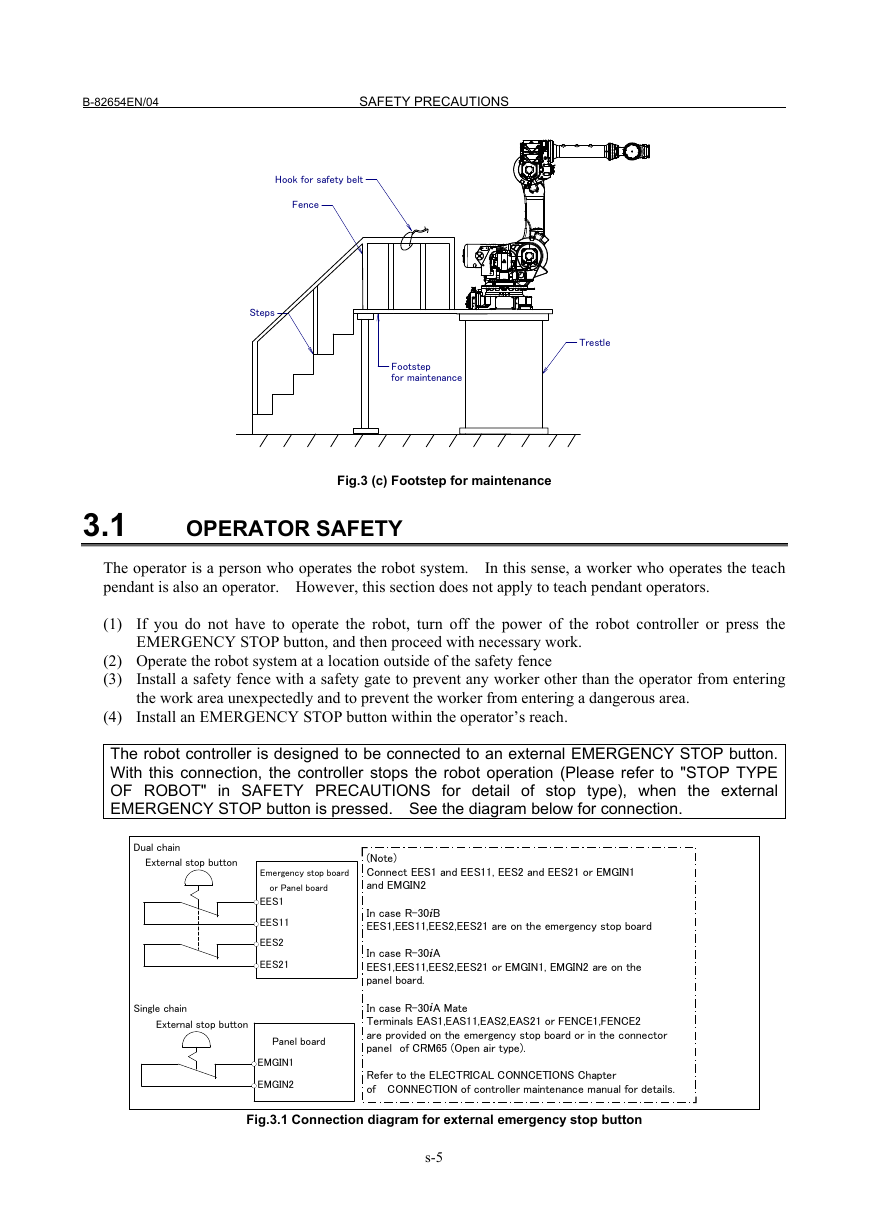

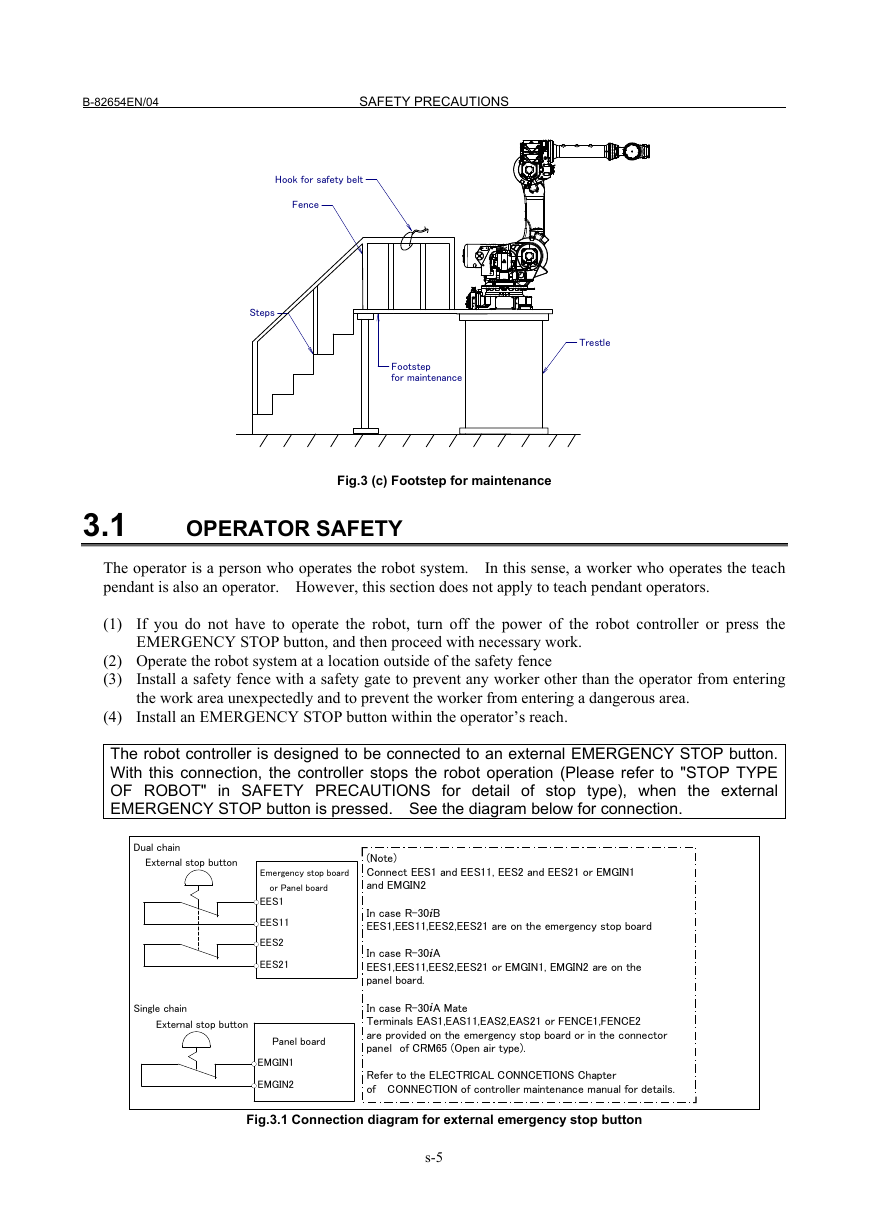

(17) When preparing trestle, please consider security for installation and maintenance work in high place

according to Fig.3 (c). Please consider footstep and safety bolt mounting position.

s-3

�

SAFETY PRECAUTIONS

B-82654EN/04

RP1

Pulsecoder

RI/RO,XHBK,XROT

RM1

Motor power/brake

EARTH

Safety fence

Interlocking device and safety plug that are activated if the

gate is opened.

Fig. 3 (a) Safety fence and safety gate

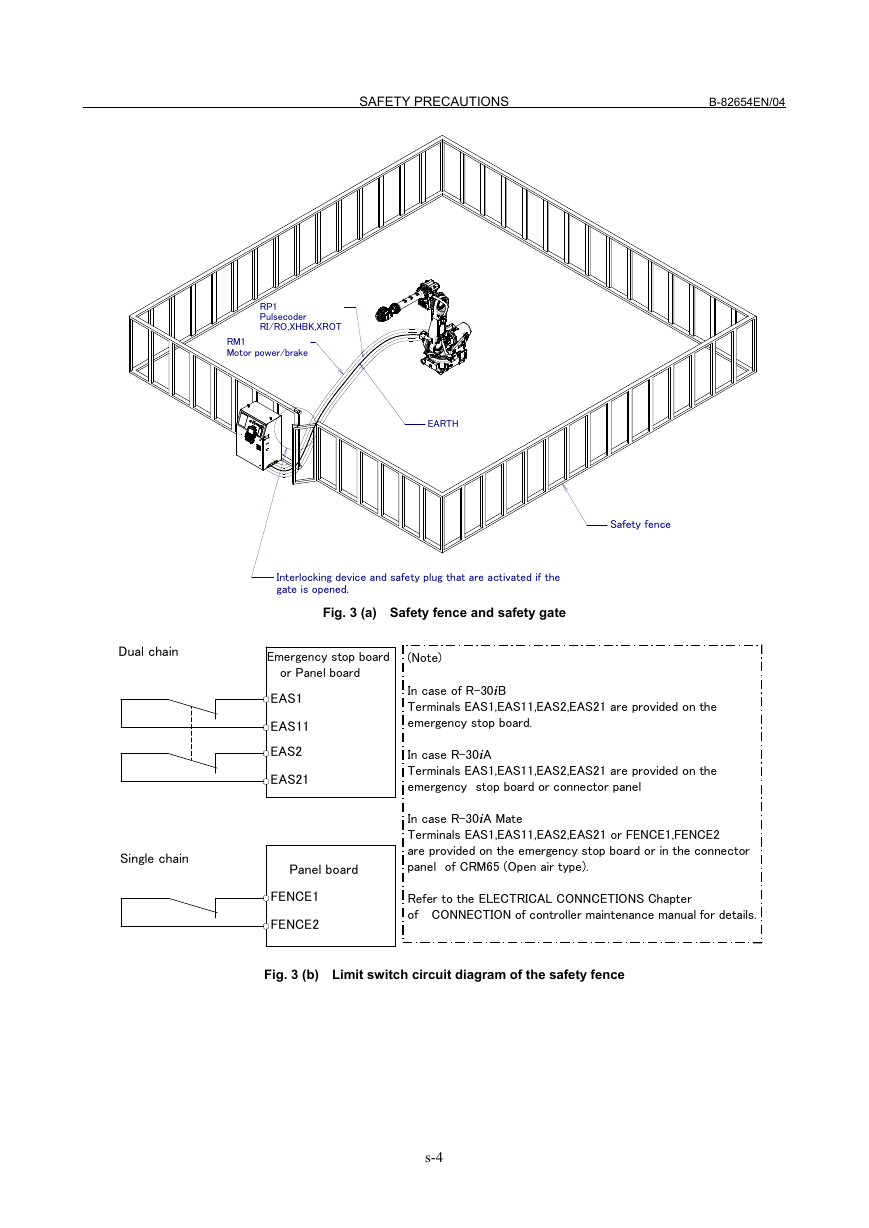

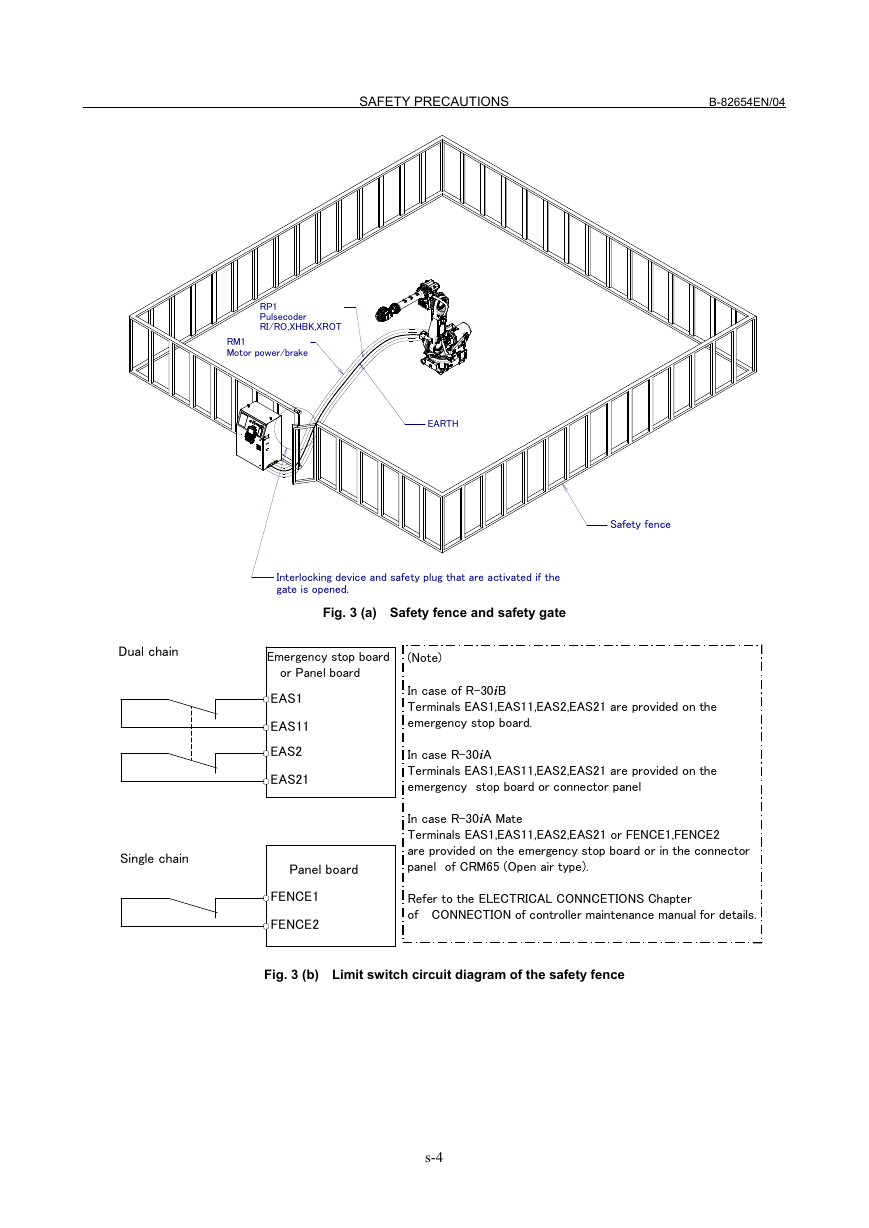

Dual chain

Emergency stop board

Panel board

or Panel board

EAS1

EAS11

EAS2

EAS21

Panel board

FENCE1

FENCE2

Single chain

(Note)

(Note)

In case of R-30iB

In case of R-30iA

Terminals EAS1,EAS11,EAS2,EAS21 are provided on the

Terminals EAS1,EAS11,EAS2,EAS21 or FENCE1,FENCE2

emergency stop board.

are provided on the operation box or on the terminal block

of the printed circuit board.

In case R-30iA

In case of R-30iA Mate

Terminals EAS1,EAS11,EAS2,EAS21 are provided on the

Terminals EAS1,EAS11,EAS2,EAS21 are provided

emergency stop board or connector panel

on the emergency stop board or connector panel.

(in case of Open air type)

In case R-30iA Mate

Terminals EAS1,EAS11,EAS2,EAS21 or FENCE1,FENCE2

Termianls FENCE1,FENCE2 are provided

on the emergency stop board.

are provided on the emergency stop board or in the connector

panel of CRM65 (Open air type).

Refer to the ELECTRICAL CONNCETIONS Chapter

of CONNECTION of controller maintenance manual for details.

Refer to controller maintenance manual for details.

Fig. 3 (b) Limit switch circuit diagram of the safety fence

s-4

�

B-82654EN/04

SAFETY PRECAUTIONS

Hook for safety belt

Fence

Steps

Footstep

for maintenance

Trestle

Fig.3 (c) Footstep for maintenance

OPERATOR SAFETY

3.1

The operator is a person who operates the robot system. In this sense, a worker who operates the teach

pendant is also an operator. However, this section does not apply to teach pendant operators.

(1) If you do not have to operate the robot, turn off the power of the robot controller or press the

EMERGENCY STOP button, and then proceed with necessary work.

(2) Operate the robot system at a location outside of the safety fence

(3) Install a safety fence with a safety gate to prevent any worker other than the operator from entering

the work area unexpectedly and to prevent the worker from entering a dangerous area.

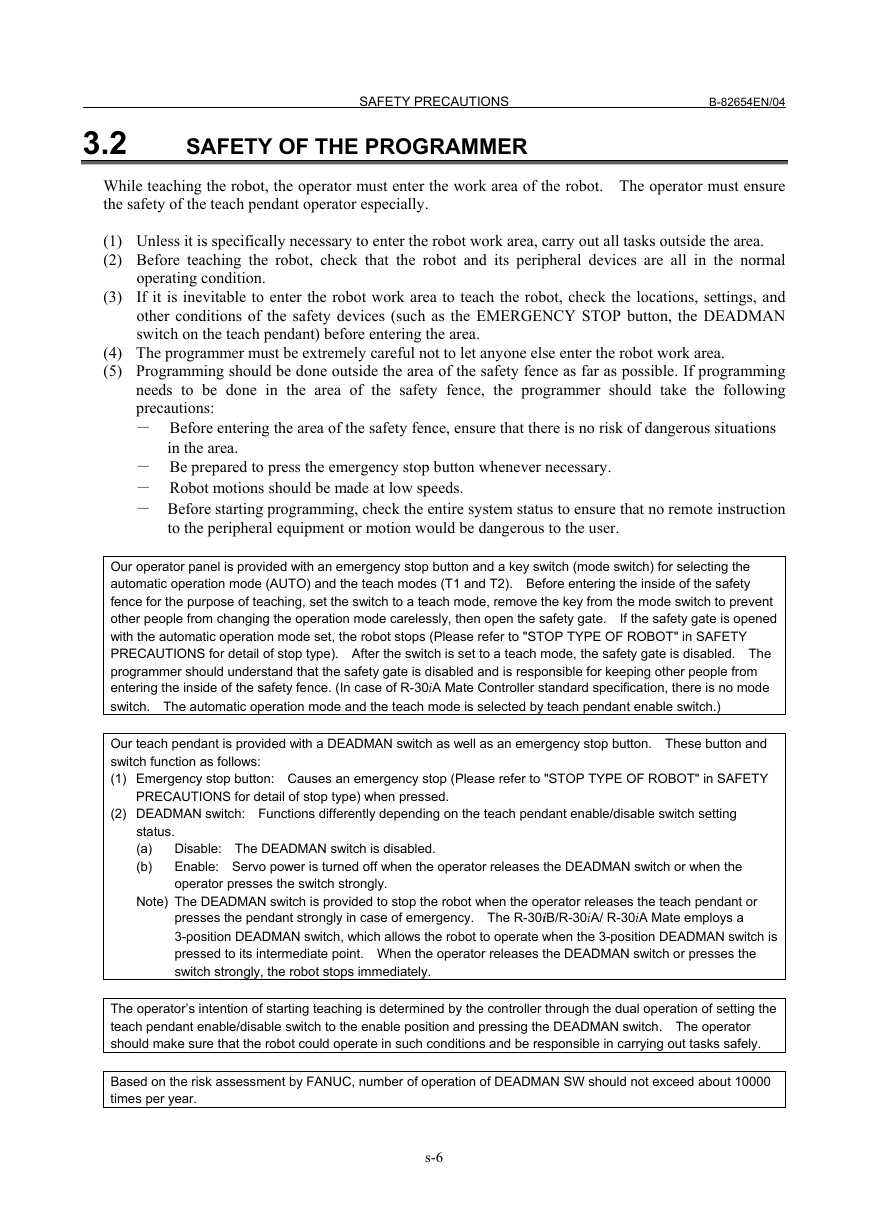

(4) Install an EMERGENCY STOP button within the operator’s reach.

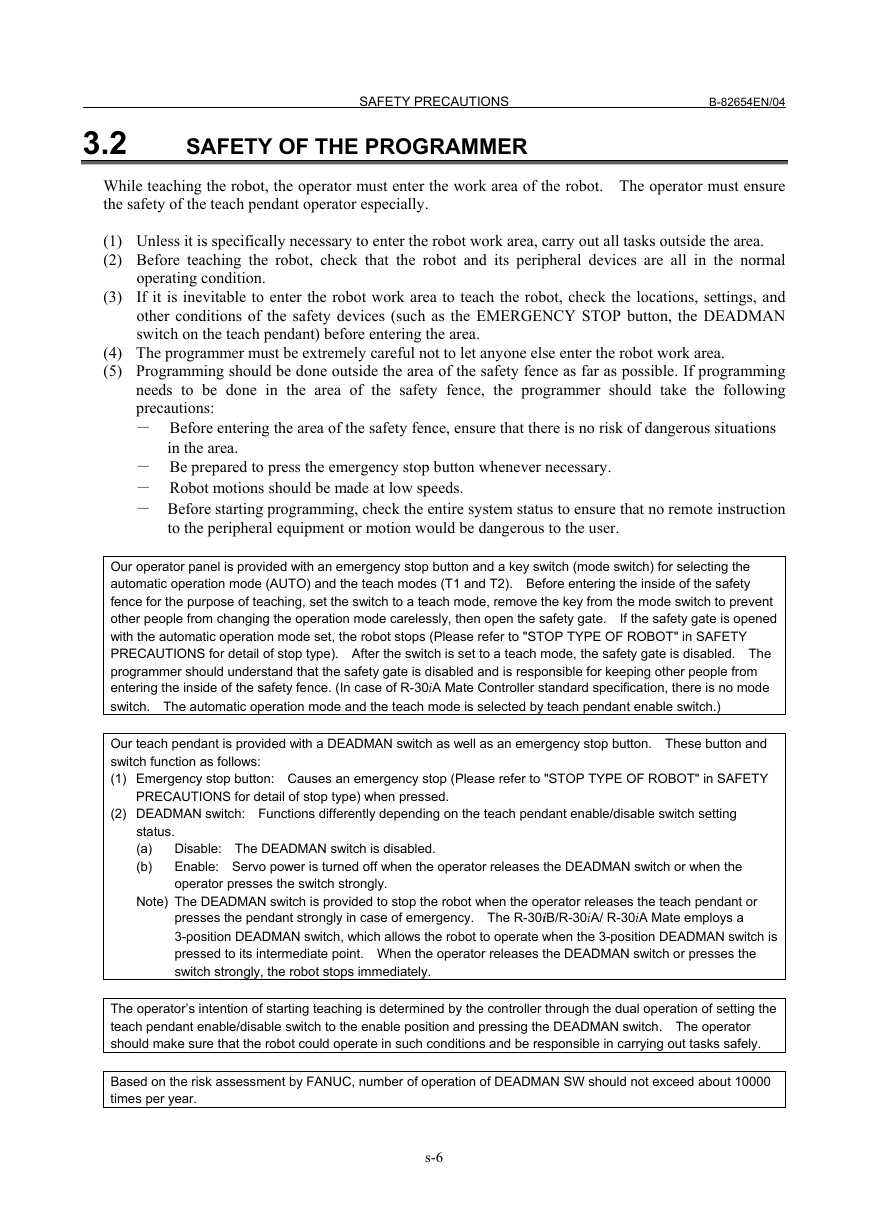

The robot controller is designed to be connected to an external EMERGENCY STOP button.

With this connection, the controller stops the robot operation (Please refer to "STOP TYPE

OF ROBOT" in SAFETY PRECAUTIONS for detail of stop type), when the external

EMERGENCY STOP button is pressed. See the diagram below for connection.

Dual chain

External stop button

Single chain

External stop button

Emergency stop board

Panel board

or Panel board

EES1

EES11

EES2

EES21

Panel board

EMGIN1

EMGIN2

(Note)

Connect EES1 and EES11, EES2 and EES21 or EMGIN1

and EMGIN2

(Note)

In case R-30iB

Connect EES1and EES11,EES2 and EES21or EMGIN1and EMGIN2.

EES1,EES11,EES2,EES21 are on the emergency stop board

In case of R-30iA

In case R-30iA

EES1,EES11,EES2,EES21 or EMGIN1,EMGIN2 are on the panel board.

EES1,EES11,EES2,EES21 or EMGIN1, EMGIN2 are on the

In case of R-30iA Mate

panel board.

EES1,EES11,EES2,EES21 are on the emergency stop board

or connector panel (in case of Open air type).

In case R-30iA Mate

EMGIN1,EMGIN2 are on the emergency stop board.

Terminals EAS1,EAS11,EAS2,EAS21 or FENCE1,FENCE2

Refer to the maintenance manual of the controller for details.

are provided on the emergency stop board or in the connector

panel of CRM65 (Open air type).

Refer to the ELECTRICAL CONNCETIONS Chapter

of CONNECTION of controller maintenance manual for details.

Fig.3.1 Connection diagram for external emergency stop button

s-5

�

3.2

SAFETY PRECAUTIONS

B-82654EN/04

SAFETY OF THE PROGRAMMER

While teaching the robot, the operator must enter the work area of the robot. The operator must ensure

the safety of the teach pendant operator especially.

(1) Unless it is specifically necessary to enter the robot work area, carry out all tasks outside the area.

(2) Before teaching the robot, check that the robot and its peripheral devices are all in the normal

operating condition.

(3) If it is inevitable to enter the robot work area to teach the robot, check the locations, settings, and

other conditions of the safety devices (such as the EMERGENCY STOP button, the DEADMAN

switch on the teach pendant) before entering the area.

(4) The programmer must be extremely careful not to let anyone else enter the robot work area.

(5) Programming should be done outside the area of the safety fence as far as possible. If programming

needs to be done in the area of the safety fence, the programmer should take the following

precautions:

- Before entering the area of the safety fence, ensure that there is no risk of dangerous situations

in the area.

- Be prepared to press the emergency stop button whenever necessary.

- Robot motions should be made at low speeds.

- Before starting programming, check the entire system status to ensure that no remote instruction

to the peripheral equipment or motion would be dangerous to the user.

Our operator panel is provided with an emergency stop button and a key switch (mode switch) for selecting the

automatic operation mode (AUTO) and the teach modes (T1 and T2). Before entering the inside of the safety

fence for the purpose of teaching, set the switch to a teach mode, remove the key from the mode switch to prevent

other people from changing the operation mode carelessly, then open the safety gate. If the safety gate is opened

with the automatic operation mode set, the robot stops (Please refer to "STOP TYPE OF ROBOT" in SAFETY

PRECAUTIONS for detail of stop type). After the switch is set to a teach mode, the safety gate is disabled. The

programmer should understand that the safety gate is disabled and is responsible for keeping other people from

entering the inside of the safety fence. (In case of R-30iA Mate Controller standard specification, there is no mode

switch. The automatic operation mode and the teach mode is selected by teach pendant enable switch.)

Our teach pendant is provided with a DEADMAN switch as well as an emergency stop button. These button and

switch function as follows:

(1) Emergency stop button: Causes an emergency stop (Please refer to "STOP TYPE OF ROBOT" in SAFETY

PRECAUTIONS for detail of stop type) when pressed.

(2) DEADMAN switch: Functions differently depending on the teach pendant enable/disable switch setting

status.

(a) Disable: The DEADMAN switch is disabled.

(b)

Enable: Servo power is turned off when the operator releases the DEADMAN switch or when the

operator presses the switch strongly.

Note) The DEADMAN switch is provided to stop the robot when the operator releases the teach pendant or

presses the pendant strongly in case of emergency. The R-30iB/R-30iA/ R-30iA Mate employs a

3-position DEADMAN switch, which allows the robot to operate when the 3-position DEADMAN switch is

pressed to its intermediate point. When the operator releases the DEADMAN switch or presses the

switch strongly, the robot stops immediately.

The operator’s intention of starting teaching is determined by the controller through the dual operation of setting the

teach pendant enable/disable switch to the enable position and pressing the DEADMAN switch. The operator

should make sure that the robot could operate in such conditions and be responsible in carrying out tasks safely.

Based on the risk assessment by FANUC, number of operation of DEADMAN SW should not exceed about 10000

times per year.

s-6

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc