Operator`s Manual

Tamp Applicator

1300

�

2

Operator's Manual - Translation of the Original Version

for the following products

Description

Type

Part.-No.

5941000

5941001

5941100

5941131

Tamp Applicator

Tamp Applicator

Tamp Applicator

Tamp Applicator

1300L-220H

1300L-300H

1300R-220H

1300R-300H

2

Edition: 03/2010 - Part.-No. 9008170

Copyright

This documentation as well as translation hereof are property of cab Produkttechnik GmbH & Co. KG.

The replication, conversion, duplication or divulgement of the whole manual or parts of it for other intentions than its original

intended purpose demand the previous written authorization by cab.

Trademark

Centronics® is a registered trademark of the Data Computer Corporation.

Microsoft® is a registered trademark of the Microsoft Corporation.

Windows 2000®, 2003®, XP® are registered trademarks of the Microsoft Corporation.

TrueTypeTM is a registered trademark of Apple Computer, Inc.

Editor

Regarding questions or comments please contact cab Produkttechnik GmbH & Co. KG.

Topicality

Due to the constant further development of our products discrepancies between documentation and product can occur.

Please check www.cab.de for the latest update.

Terms and conditions

Deliveries and performances are effected under the General conditions of sale of cab.

Germany

cab Produkttechnik

GmbH & Co KG

Postfach 1904

D-76007 Karlsruhe

Wilhelm-Schickard-Str. 14

D-76131 Karlsruhe

Telefon +49 721 6626-0

Telefax +49 721 6626-249

www.cab.de

info@cab.de

France

cab technologies s.a.r.l.

F-67350 Niedermodern

Téléphone +33 388 722 501

www.cab.de

info@cab-technologies.fr

España

cab España S.L.

E-08304 Montaró (Barcelona)

Teléfono +34 937 414 605

www.cab.de

info@cabsl.com

USA

cab Technology Inc.

Tyngsboro MA, 01879

Phone +1 978 649 0293

www.cabtechn.com

info@cabtechn.com

South Afrika

cab Technology (Pty.) Ltd.

2125 Randburg

Phone +27 11-886-3580

www.cab.de

info@cabtechn.co.za

Representatives in other countries on request.

Asia

cab Technology Co, Ltd.

Junghe 23552, Taipei, Taiwan

Phone +886 2 8227 3966

www.cabasia.net

cabasia@cab.de

cab (Shanghai) Trading Co.,Ltd

2299 11C60

Phone +86 21 6236-3161

cabasia@cab.de

�

Table of Contents

3

1

1.1

1.2

1.3

1.4

1.5

2

2.1

2.2

Introduction ............................................................................................................................................ 4

Instructions ............................................................................................................................................... 4

Intended Use ............................................................................................................................................ 4

Safety Instructions .................................................................................................................................... 4

Safety Marking ......................................................................................................................................... 5

Environment ............................................................................................................................................. 5

Product Description ............................................................................................................................... 6

Function ................................................................................................................................................... 6

Device Overview ...................................................................................................................................... 7

3

Installation .............................................................................................................................................. 8

3.1

Delivery Of The Applicator ....................................................................................................................... 8

3.2 Mounting Applicator .................................................................................................................................. 8

3.2.1 Attach Applicator At Printer ...................................................................................................................... 8

3.2.2 Connections ............................................................................................................................................. 9

3.2.3 Mounting maintenance unit (Option) ........................................................................................................ 9

4

Adjustments ......................................................................................................................................... 10

4.1 Mechanical Adjustments ........................................................................................................................ 10

4.1.1 Adjustment - Pad Position ..................................................................................................................... 10

4.1.2 Adjustment the angle of the pad in the take over position ......................................................................11

4.1.3 Adjust the level of the cylinder assembly ................................................................................................11

4.1.4 Adjustment - Air Tube ............................................................................................................................. 12

4.2

Pneumatic Adjustments .......................................................................................................................... 12

4.2.1 Set Valves .............................................................................................................................................. 12

4.2.2 Slide Valve ............................................................................................................................................. 12

4.2.3 Throttle Valves At The Valve Block ......................................................................................................... 13

4.2.4 Throttle Valve At The Cylinder ................................................................................................................ 13

Operation .............................................................................................................................................. 14

5

5.1

Setting The Operating Mode And Delay Times ...................................................................................... 14

5.1.1 DIP-Switches .......................................................................................................................................... 14

5.1.2 Potentiometer ......................................................................................................................................... 14

5.1.3 Read Settings Of Potentiometers ........................................................................................................... 15

5.1.4 Operating Mode ..................................................................................................................................... 15

Pre-Dispense Key .................................................................................................................................. 16

5.2

Peel Position .......................................................................................................................................... 17

5.3

5.4

Normal Operation ................................................................................................................................... 17

6

6.1

6.2

6.3

7

7.1

7.2

8

9

9.1

9.2

10

PLC Interface ........................................................................................................................................ 18

Comments On The Signals .................................................................................................................... 18

Circuit Diagrams Of Inputs And Outputs ................................................................................................ 20

Examples For Circuits To Creating An External Start Signal .................................................................. 21

Error Messages .................................................................................................................................... 23

Printer Error Messages ......................................................................................................................... 23

Applicator Error Messages ..................................................................................................................... 23

Function Of The LED's On The PCB ................................................................................................... 24

Declaration ............................................................................................................................................ 25

EC Declaration of Incorporation ............................................................................................................. 25

EC Declaration of Conformity ................................................................................................................. 26

Index ...................................................................................................................................................... 27

�

4

1

Introduction

4

1.1

Instructions

Important information and instructions in this documentation are designated as follows:

Danger!

Draws your attention to an exceptionally grave, impending danger to your health or life.

!

!

i

Warning!

Indicates a hazardous situation that could lead to injuries or material damage.

Attention!

Draws attention to possible dangers, material damage or loss of quality.

Notice!

Gives you tips. They make a working sequence easier or draw attention to important working processes.

Environment!

Gives you tips on protecting the environment.

Handling instruction

Reference to section, position, illustration number or document.

Option (accessories, peripheral equipment, special fittings).

Zeit Information in the display.

1.2

Intended Use

• The device is manufactured in accordance with the current technological status and the recognized safety rules.

However, danger to the life and limb of the user or third parties and/or damage to the device and other tangible

assets can arise during use.

• The device may only be used for its intended purpose and if it is in perfect working order, and it must be used with

regard to safety and dangers as stated in the operating manual.

• The device is developed to work in a system with a Hermes A printer

• The device applicator is intended exclusively for labeling suitable materials that have been approved by the

manufacturer. Any other use or use going beyond this shall be regarded as improper use. The manufacturer/

supplier shall not be liable for damage resulting from unauthorized use; the user shall bear the risk alone.

• Usage for the intended purpose also includes complying with the operating manual, including the manufacturer‘s

maintenance recommendations and specifications.

i

Notice!

The complete documentation is currently in the Internet.

1.3

Safety Instructions

• Only connect the device to other devices which have a protective low voltage.

• Switch off all affected devices (computer, printer, accessories) before connecting or disconnecting.

• The device may only be used in a dry environment, do not expose it to moisture (sprays of water, mists, etc.).

!

!

Warning!

Make sure that the printer is disconnected from the power supply and the valve at the service unit as well

as the shutoff valve at the applicator are closed, while installing the delivered components.

Warning!

In operation, moving parts are easily accessible. Therefore, keep long hair, loose clothes and jewelry

distant. Before any manipulations in those areas, close the shutoff valve.

�

1

Introduction

5

!

Warning!

Do not try to manipulate or repair parts they are not described in the manuals of the tamp applicator or the

printer.

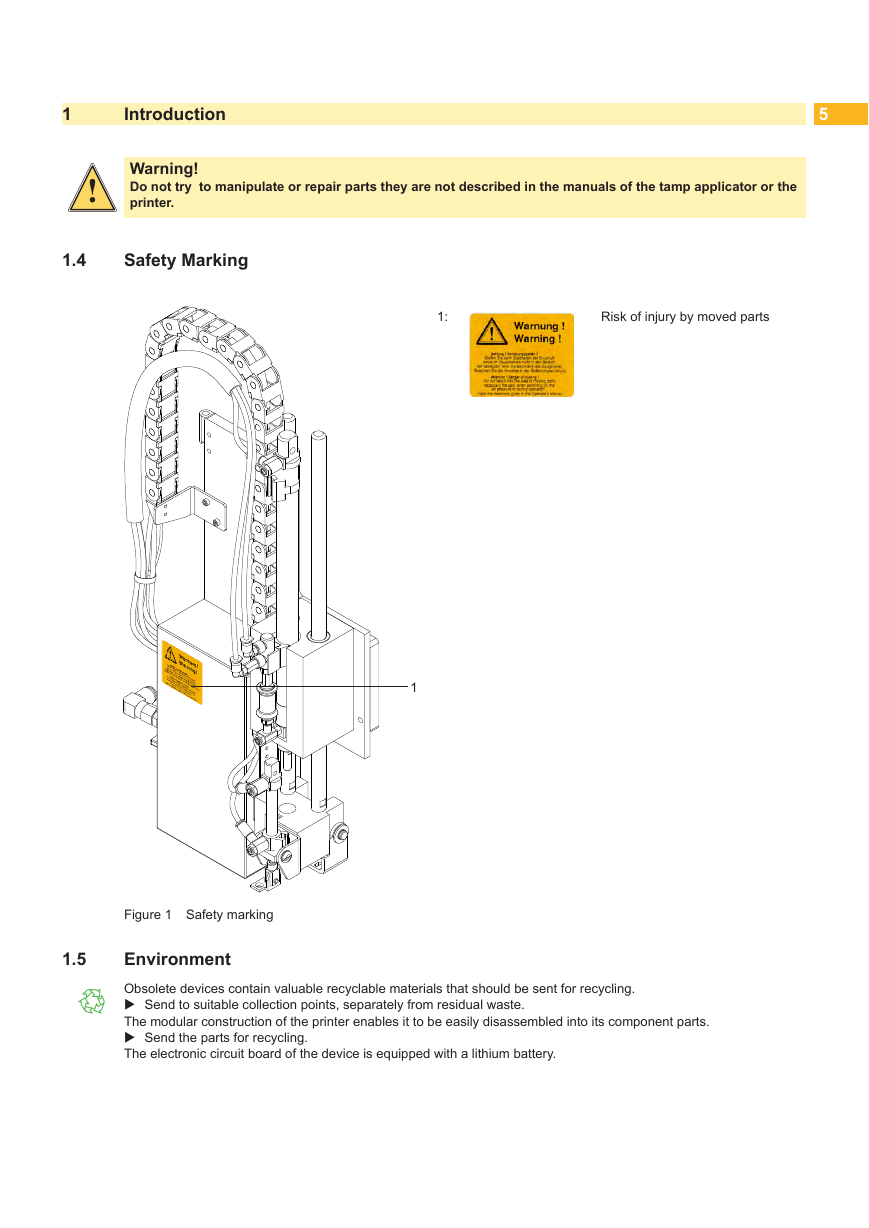

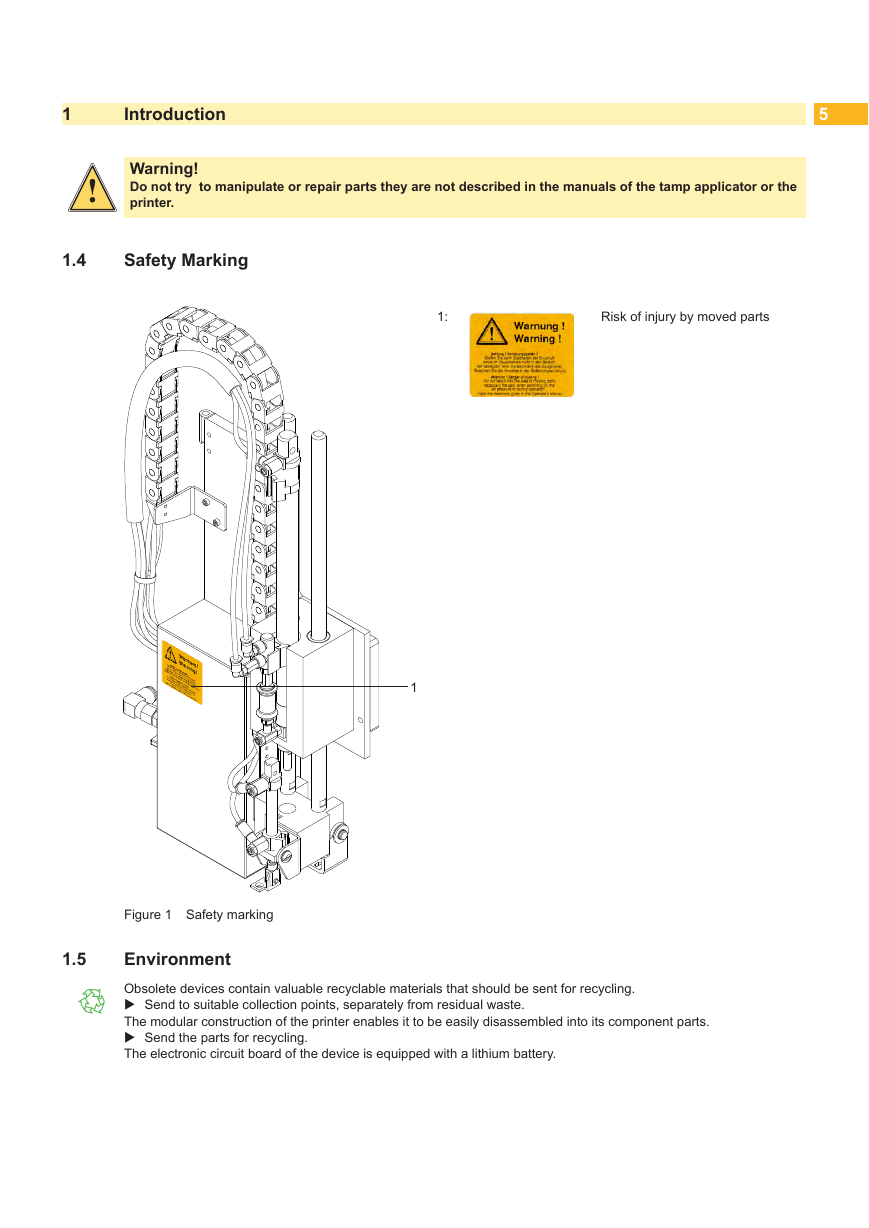

1.4

Safety Marking

1:

Risk of injury by moved parts

1

Figure 1 Safety marking

1.5

Environment

Obsolete devices contain valuable recyclable materials that should be sent for recycling.

Send to suitable collection points, separately from residual waste.

The modular construction of the printer enables it to be easily disassembled into its component parts.

Send the parts for recycling.

The electronic circuit board of the device is equipped with a lithium battery.

�

6

2

Product Description

2.1

Function

6

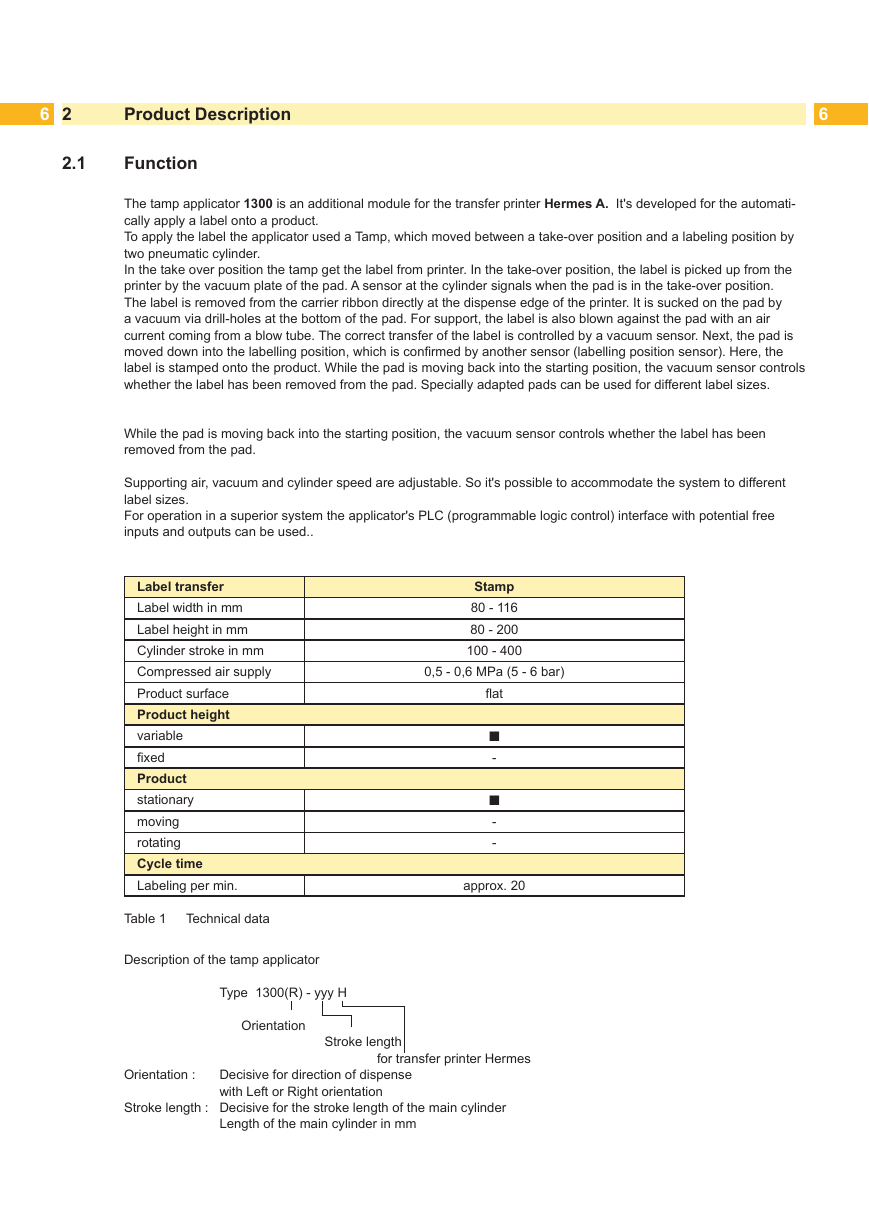

The tamp applicator 1300 is an additional module for the transfer printer Hermes A. It's developed for the automati-

cally apply a label onto a product.

To apply the label the applicator used a Tamp, which moved between a take-over position and a labeling position by

two pneumatic cylinder.

In the take over position the tamp get the label from printer. In the take-over position, the label is picked up from the

printer by the vacuum plate of the pad. A sensor at the cylinder signals when the pad is in the take-over position.

The label is removed from the carrier ribbon directly at the dispense edge of the printer. It is sucked on the pad by

a vacuum via drill-holes at the bottom of the pad. For support, the label is also blown against the pad with an air

current coming from a blow tube. The correct transfer of the label is controlled by a vacuum sensor. Next, the pad is

moved down into the labelling position, which is confirmed by another sensor (labelling position sensor). Here, the

label is stamped onto the product. While the pad is moving back into the starting position, the vacuum sensor controls

whether the label has been removed from the pad. Specially adapted pads can be used for different label sizes.

While the pad is moving back into the starting position, the vacuum sensor controls whether the label has been

removed from the pad.

Supporting air, vacuum and cylinder speed are adjustable. So it's possible to accommodate the system to different

label sizes.

For operation in a superior system the applicator's PLC (programmable logic control) interface with potential free

inputs and outputs can be used..

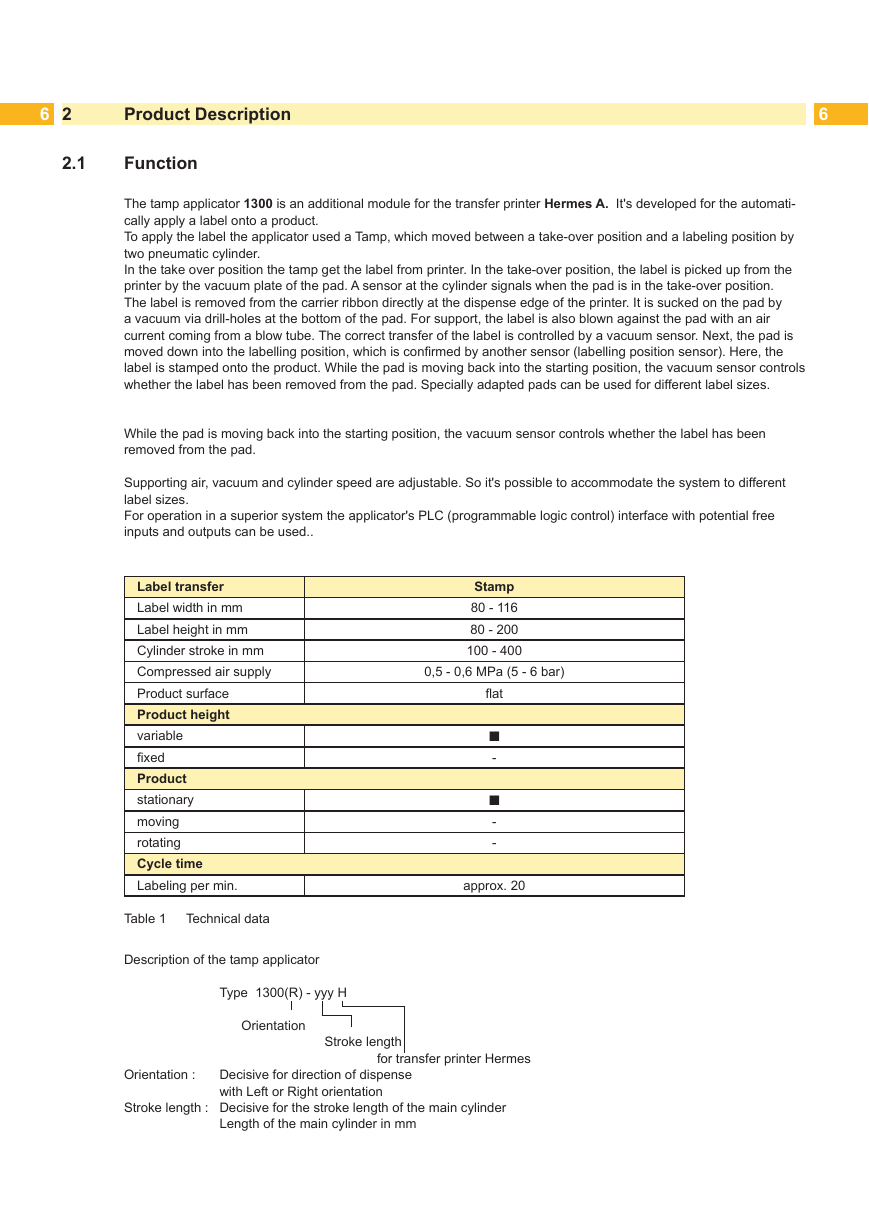

Label transfer

Label width in mm

Label height in mm

Cylinder stroke in mm

Compressed air supply

Product surface

Product height

variable

fixed

Product

stationary

moving

rotating

Cycle time

Labeling per min.

Table 1

Technical data

Description of the tamp applicator

Stamp

80 - 116

80 - 200

100 - 400

0,5 - 0,6 MPa (5 - 6 bar)

flat

¢

-

¢

-

-

approx. 20

Type 1300(R) - yyy H

Orientation

Orientation : Decisive for direction of dispense

Stroke length : Decisive for the stroke length of the main cylinder

Length of the main cylinder in mm

with Left or Right orientation

Stroke length

for transfer printer Hermes

�

2

Product Description

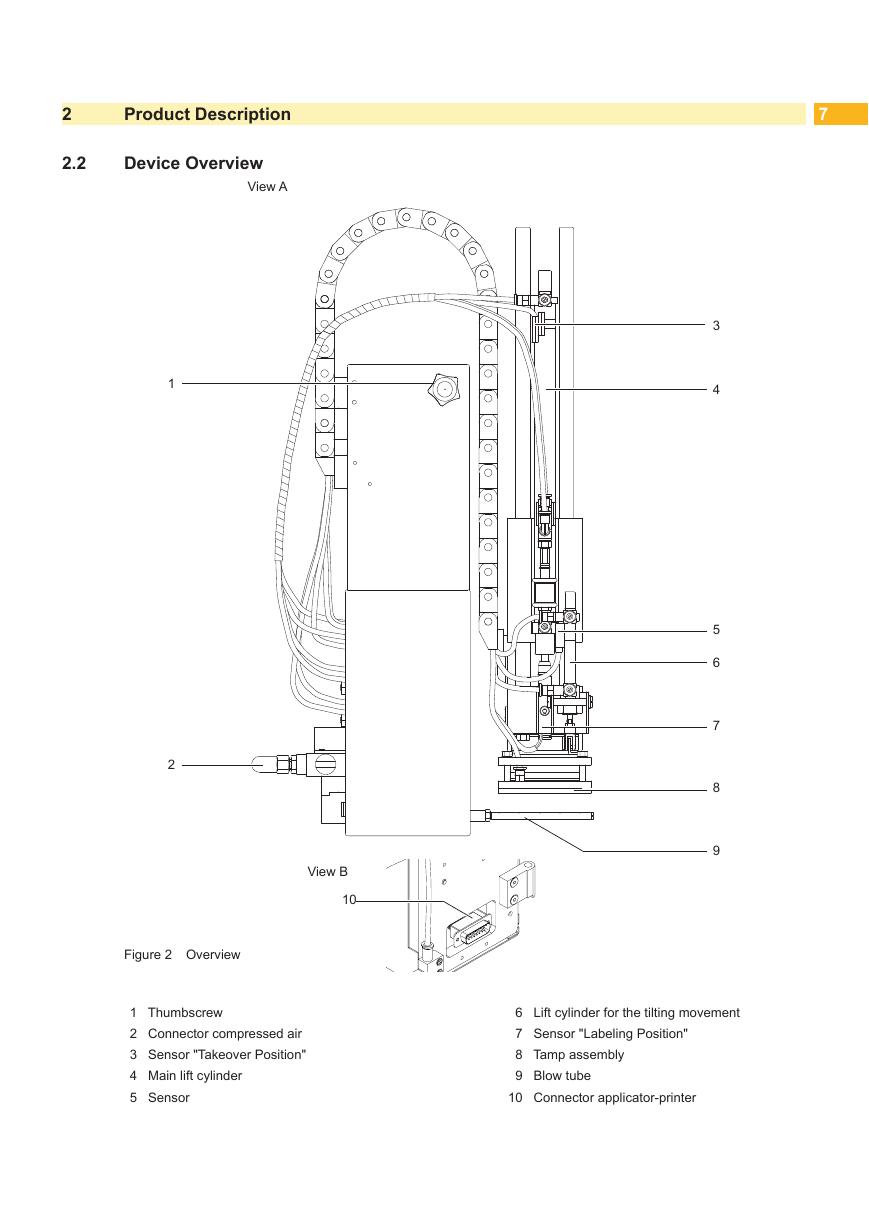

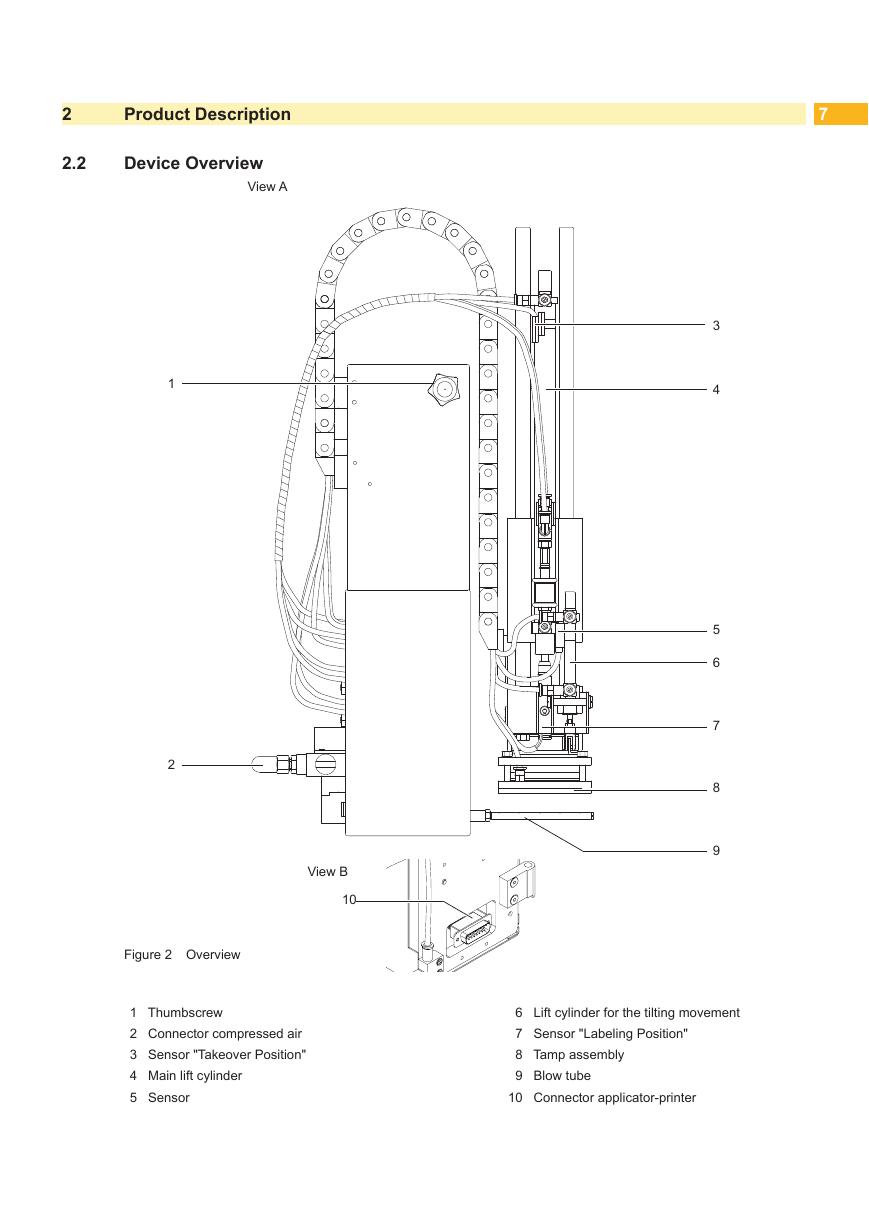

2.2

Device Overview

View A

7

1

2

3

4

5

6

7

8

9

View B

10

Figure 2 Overview

1 Thumbscrew

2 Connector compressed air

3 Sensor "Takeover Position"

4 Main lift cylinder

5 Sensor

6 Lift cylinder for the tilting movement

7 Sensor "Labeling Position"

8 Tamp assembly

9 Blow tube

10 Connector applicator-printer

�

8

3

Installation

8

3.1

Delivery Of The Applicator

Check the applicator at transport damage and totality.

Scope of delivery:

• Applicator

• Pad and blow tube (customized)

• Hinges and screws

• Maintenance unit (option)

• Documentation

i

Notice!

Please keep the original packaging in case the printer must be returned.

3.2

!

!

Mounting Applicator

Attention!

Mounting and installation the applicator only if the printer switched of.

Warning!

Risk of injury and damage in case of using the applicator not appropriate.

Use the applicator only secure mounted at a Hermes A - printer.

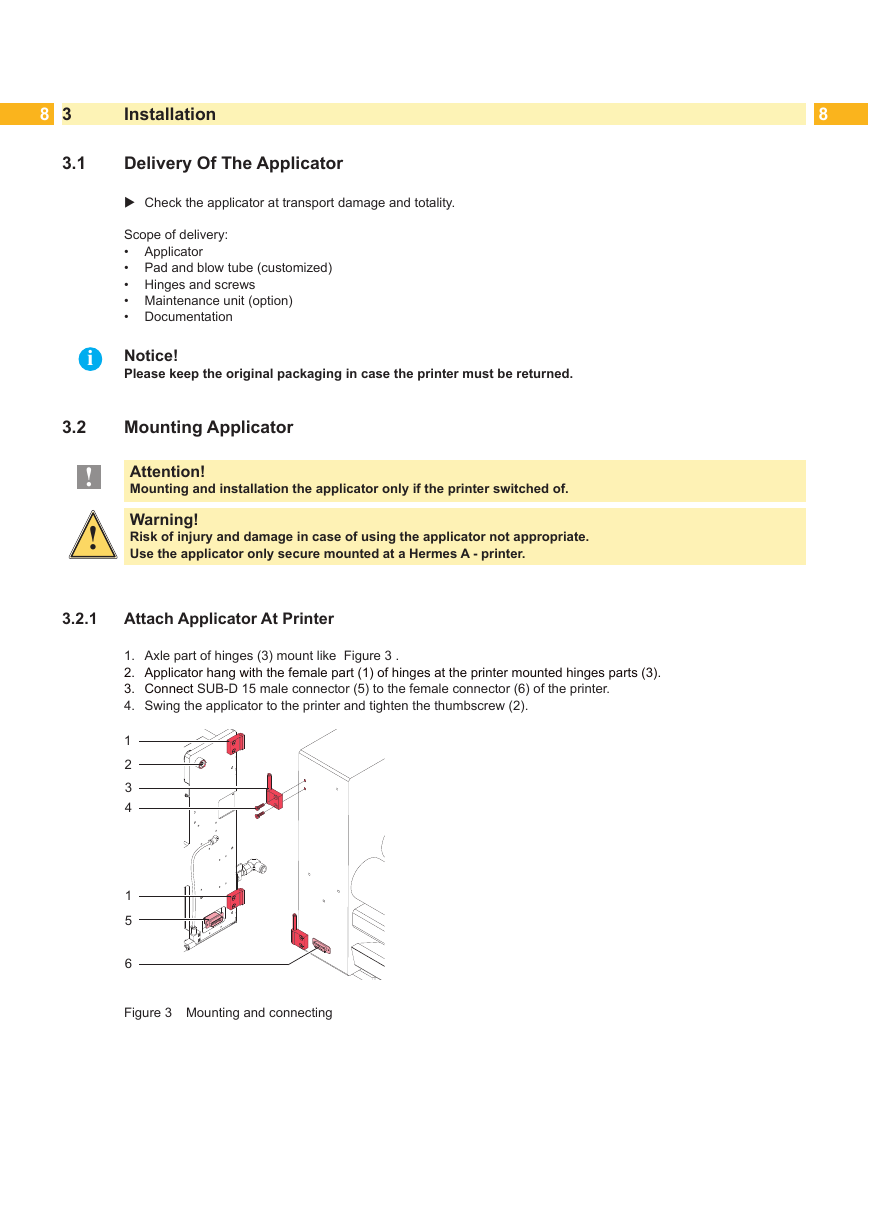

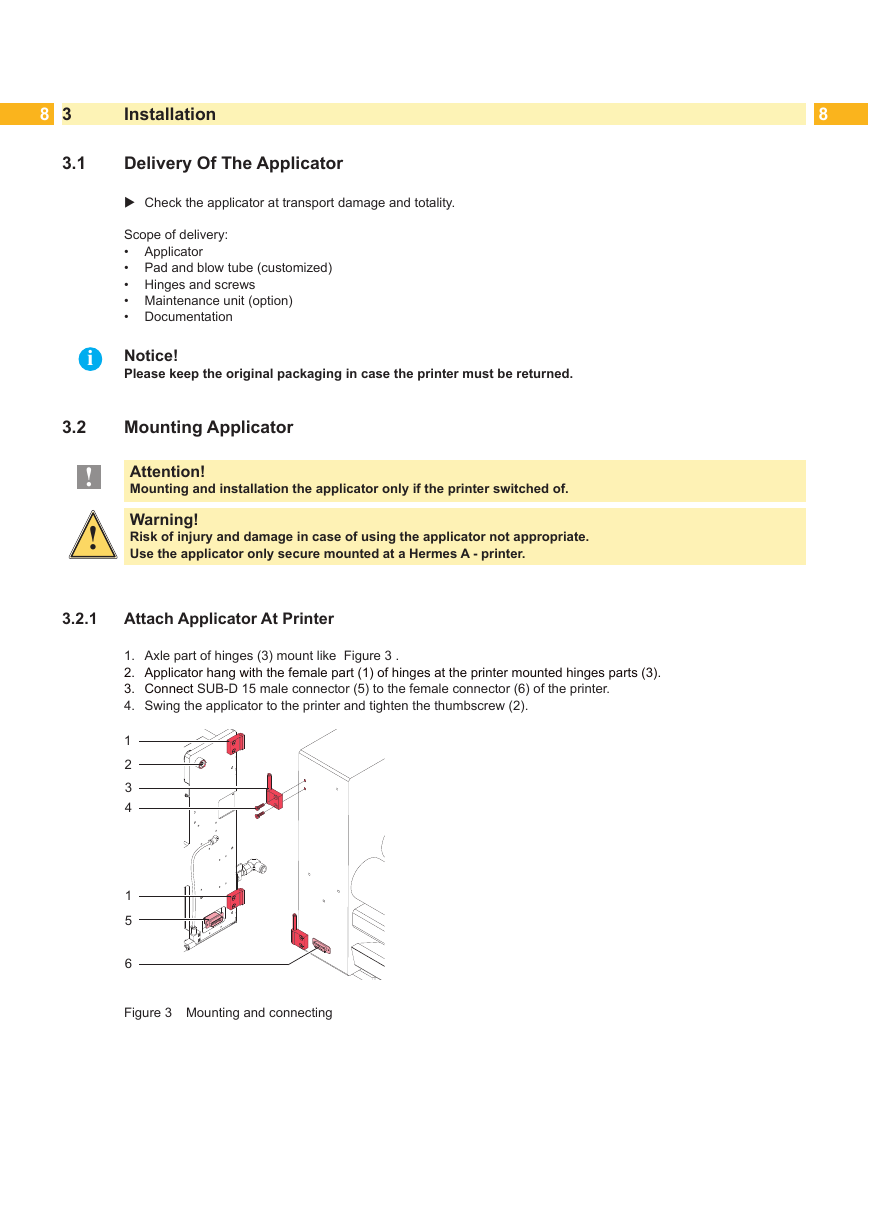

3.2.1 Attach Applicator At Printer

1. Axle part of hinges (3) mount like Figure 3 .

2. Applicator hang with the female part (1) of hinges at the printer mounted hinges parts (3).

3. Connect SUB-D 15 male connector (5) to the female connector (6) of the printer.

4. Swing the applicator to the printer and tighten the thumbscrew (2).

1

2

3

4

1

5

6

Figure 3 Mounting and connecting

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc