design

ideas

The best of

design ideas

8 Check it out at:

www.edn.com

Edited by Bill Travis

Steve Woodward, Chapel Hill, NC

Combine two 8-bit outputs to make one 16-bit DAC

Inexpensive, 16-bit, monolithic DACs

Combine two 8-bit outputs

to make one 16-bit DAC ..................................85

can serve almost all applications.

However, some applications require

unconventional approaches. This Design

Idea design concerns circuitry I recently

designed for a tunable-diode laser spec-

trometer for a Mars-exploration applica-

tion. The control circuitry included two

16-bit DACs that interface to the radia-

tion-hardened, 8051-variant 69RH051A

microcontroller. Because of the intend-

ed space-flight-qualified specification,

everything in the design had to consist

solely of components from the NPSL

(NASA parts-selection list). This restric-

tion posed a challenge, because, at design

finalization, the NPSL included no ap-

propriate, flight-qualified, 16-bit DACs,

and the budget included no funds for cer-

tification of new devices. I escaped from

this impasse by exploiting two fortuitous

facts: The update rate of the two DACs

was only tens of hertz, and the 69RH-

051A had a number of uncommitted, 8-

bit, 14.5-kHz PWM outputs. These out-

puts made one 16-bit DAC; a second pair

of PWM bits and an identical circuit

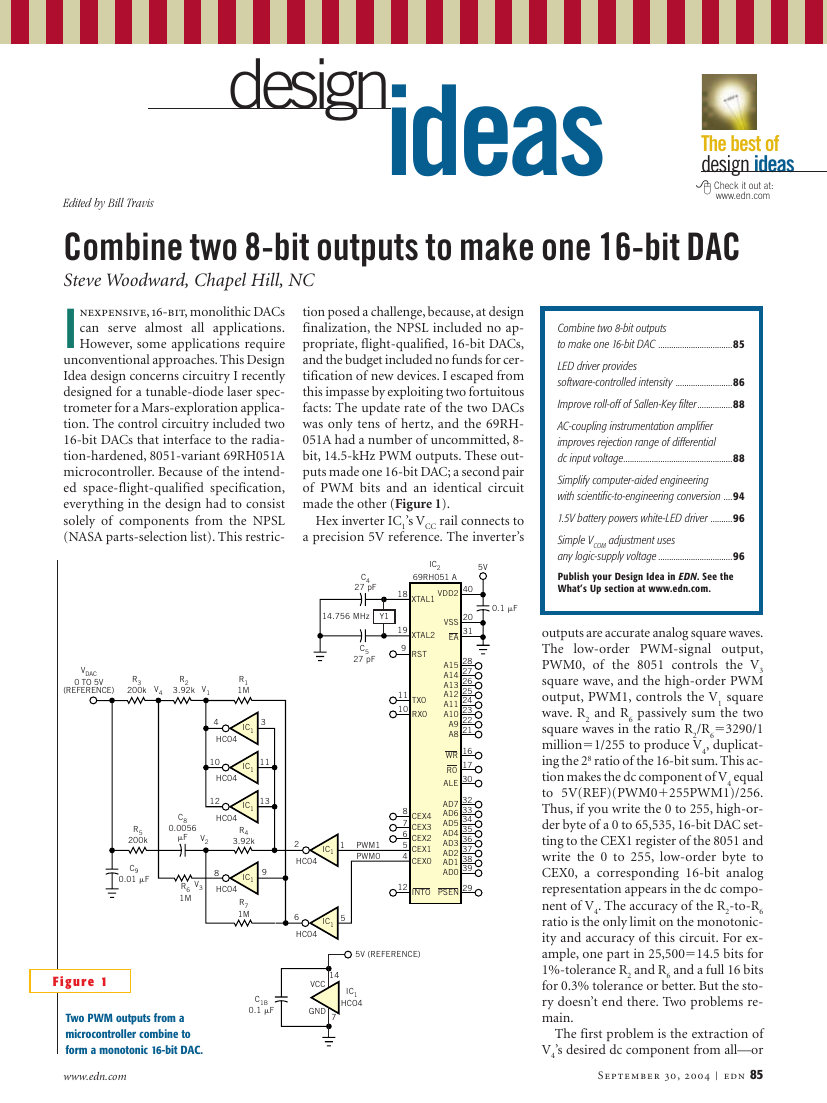

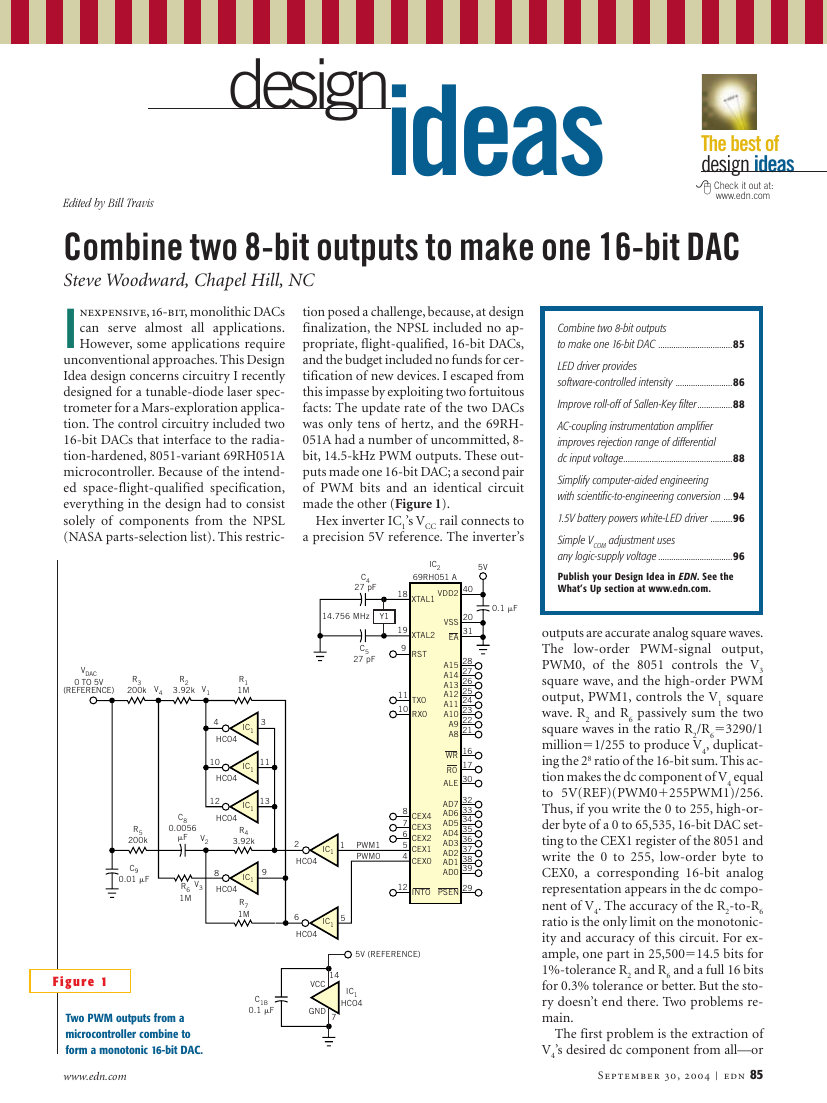

made the other (Figure 1).

Hex inverter IC1’s VCC rail connects to

a precision 5V reference. The inverter’s

LED driver provides

software-controlled intensity ..........................86

Improve roll-off of Sallen-Key filter ................88

AC-coupling instrumentation amplifier

improves rejection range of differential

dc input voltage..................................................88

Simplify computer-aided engineering

with scientific-to-engineering conversion ....94

1.5V battery powers white-LED driver ..........96

Simple VCOM adjustment uses

any logic-supply voltage ..................................96

Publish your Design Idea in EDN. See the

What’s Up section at www.edn.com.

outputs are accurate analog square waves.

The low-order PWM-signal output,

PWM0, of the 8051 controls the V3

square wave, and the high-order PWM

output, PWM1, controls the V1 square

wave. R2 and R6 passively sum the two

⫽3290/1

square waves in the ratio R2/R6

million⫽1/255 to produce V4, duplicat-

ing the 28 ratio of the 16-bit sum. This ac-

tion makes the dc component of V4 equal

to 5V(REF)(PWM0⫹255PWM1)/256.

Thus, if you write the 0 to 255, high-or-

der byte of a 0 to 65,535, 16-bit DAC set-

ting to the CEX1 register of the 8051 and

write the 0 to 255, low-order byte to

CEX0, a corresponding 16-bit analog

representation appears in the dc compo-

nent of V4. The accuracy of the R2-to-R6

ratio is the only limit on the monotonic-

ity and accuracy of this circuit. For ex-

ample, one part in 25,500⫽14.5 bits for

1%-tolerance R2 and R6 and a full 16 bits

for 0.3% tolerance or better. But the sto-

ry doesn’t end there. Two problems re-

main.

The first problem is the extraction of

V4’s desired dc component from all—or

September 30, 2004 | edn 85

VDAC

0 TO 5V

(REFERENCE)

R3

200k

V4

R2

3.92k

V1

R1

1M

3

IC1

4

HC04

10

HC04

11

IC1

12

HC04

13

IC1

V2

R4

3.92k

2

HC04

1

IC1

PWM1

PWM0

0.0056

C8

F

V3

R6

1M

9

IC1

8

HC04

R7

1M

R5

200k

C9

0.01 F

IC2

69RH051 A

5V

18

XTAL1

VDD2

C4

27 pF

14.756 MHz

Y1

19

9

XTAL2

RST

C5

27 pF

0.1 F

40

20

31

28

27

26

25

24

23

22

21

16

17

30

32

33

34

35

36

37

38

39

29

VSS

EA

A15

A14

A13

A12

A11

A10

A9

A8

WR

R0

ALE

AD7

AD6

AD5

AD4

AD3

AD2

AD1

AD0

11

10

TX0

RX0

8

7

6

5

4

CEX4

CEX3

CEX2

CEX1

CEX0

12

INTO PSEN

5

IC1

6

HC04

5V (REFERENCE)

Figure 1

Two PWM outputs from a

microcontroller combine to

form a monotonic 16-bit DAC.

www.edn.com

C1B

0.1 F

14

VCC

GND

7

IC1

HCO4

�

design

ideas

at least 15 or 16 bits⫽99.995%—of the

undesired square-wave ac ripple. The R3-

C9 lowpass filter does some of this work.

If you make C9 large enough, in princi-

ple, the filter could do the whole job. The

reason this simple approach wouldn’t

work is that, to get such a large ripple at-

tenuation of approximately 90 dB with a

single-stage RC filter would require an

approximately 300-msec time constant

and a resultant 3-sec, 16-bit settling time.

This glacial response time would be too

slow even for this undemanding applica-

tion. To speed things, the R4, R5, R7, C8

network synthesizes and then sums V2: an

inverse-polarity duplicate of V4’s 14.5-

kHz ac component. This summation ac-

tively nulls out approximately 99% of the

ripple. This nullifying action leaves such

a small residue that an approximately 2-

msec and, therefore, approximately 25-

msec-settling-time R3C9 product easily

erases it.

The other problem is compensation for

the low, but still nonzero, on-resistance of

the HC14 internal CMOS switches, so

that the resistance doesn’t perturb the

critical R2-to-R6 ratio. This issue is of no

particular concern for R6, because the R6-

to-on-resistance ratio is greater than

10,000-to-1, making any associated error

negligible. This situation is not the case

for R2, however, in which, despite the

triple-parallel gates, the R2-to-on-resist-

ance ratio is approximately 300-to-1,

which is small enough to merit attention.

Load-cancellation resistor R1 provides

such attention. R1 sums a current into the

R2 driving node that, because it is equal in

magnitude but opposite in phase to the

current through R6, effectively cancels the

load on the R2 drivers. This process makes

the combined on-resistance approxi-

mately 100 times less important than it

otherwise would be. The result is a sim-

ple, highly linear and accurate voltage-

output DAC with a respectable, if not

blazingly fast, settling time of approxi-

mately 25 msec. And the most important

result, in this case, was a parts list with an

impeccable NPSL-compliant pedigree.왏

Neda Shahi and Bjorn Starmark, Maxim Integrated Products, Sunnyvale, CA

LED driver provides software-controlled intensity

Recent advances in

CMSH1-100

D1 SMB

R1

51

VIN

C1

L1

1

2

22 H

ELL6RH

3.3 F

1206

10V

11

VIN

GATE

10

12

1

2

3

4

5

6

7

8

9

CA⫹

CS⫺

IC1

CS

SCLK

DIN

CL

DACOUT

FB

COMP

GND

MAX1932

12QFN

Q1

IRLL110

SOT223

R6

12k

C5

0.33 F

R2

16k

C3

0.1 F

1206

100V

C2

0.47 F

1210

100V

VIN

R3

56k

Q2

MMBT5551

SOT23

Q3

MMBT3906

SOT23

R4

10k

R5

510k

R7

10k

LED1

LED2

LED(N-1)

LED(N)

C4

0.1 F

CONTROLLER

TO

VCC

GND

operating efficiency

have expanded the use

of LEDs from one of mere

indicators

to becoming

driving forces in electronic

lighting. Increased reliabili-

ty and ruggedness (versus

other lighting technologies)

gives the LED a bright fu-

ture indeed. Vendors in re-

cent years have introduced

many ICs for driving LEDs,

but the problem of driving

serial chains of LEDs has re-

ceived less attention. One

approach to that problem

adapts a bias-supply IC

for APDs (avalanche

photodiodes) to provide

adjustable-current,

soft-

ware shutdown, and logic

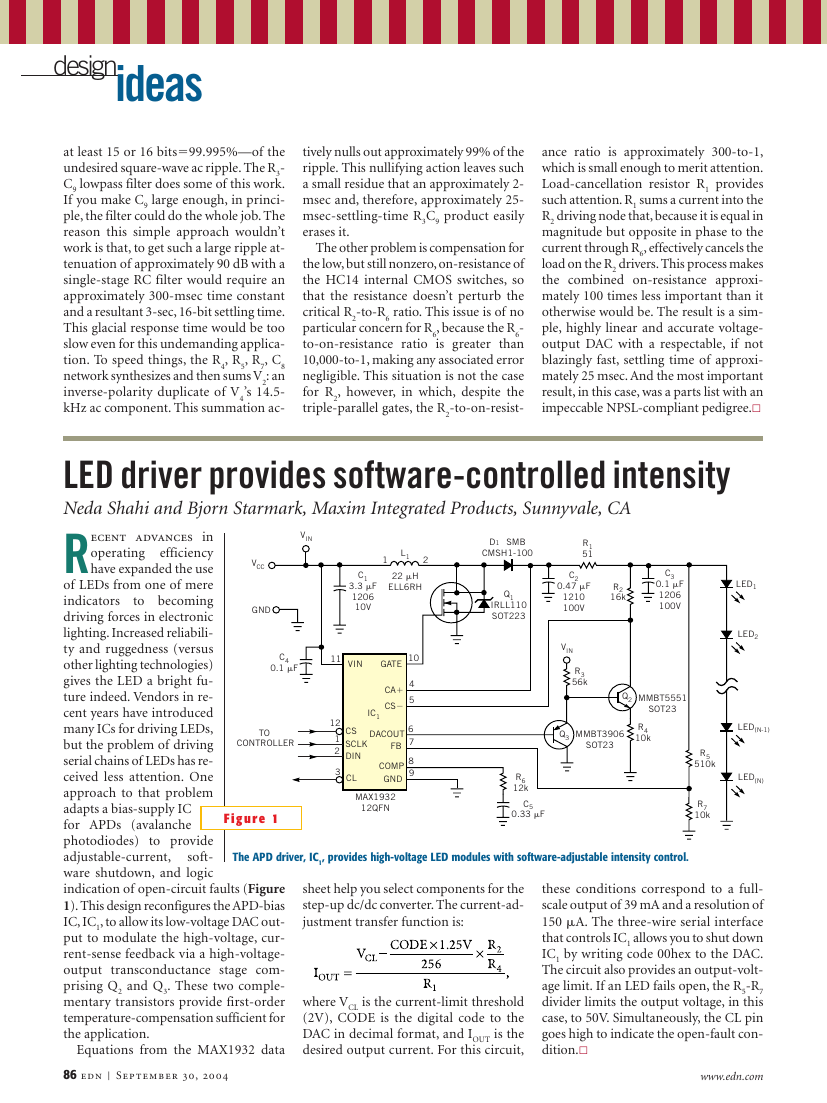

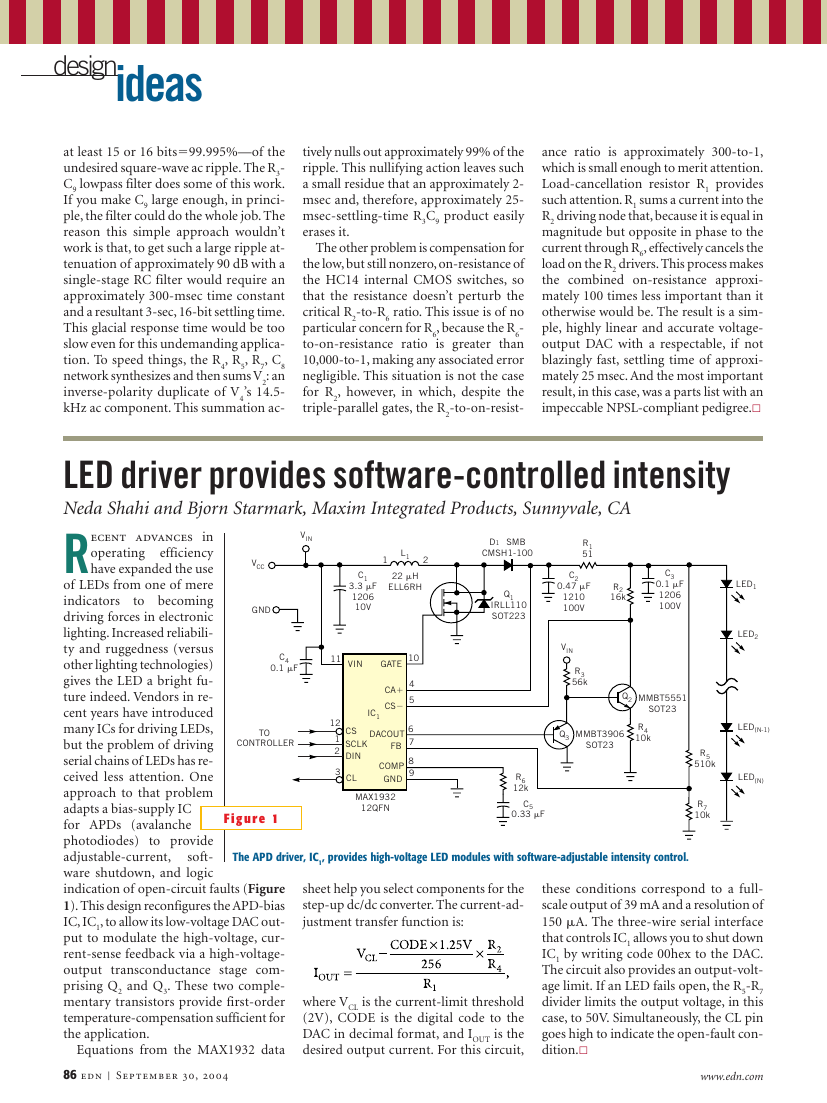

indication of open-circuit faults (Figure

1). This design reconfigures the APD-bias

IC, IC1, to allow its low-voltage DAC out-

put to modulate the high-voltage, cur-

rent-sense feedback via a high-voltage-

output transconductance stage com-

prising Q2 and Q3. These two comple-

mentary transistors provide first-order

temperature-compensation sufficient for

the application.

Figure 1

Equations from the MAX1932 data

86 edn | September 30, 2004

The APD driver, IC1, provides high-voltage LED modules with software-adjustable intensity control.

sheet help you select components for the

step-up dc/dc converter. The current-ad-

justment transfer function is:

where VCL is the current-limit threshold

(2V), CODE is the digital code to the

DAC in decimal format, and IOUT is the

desired output current. For this circuit,

these conditions correspond to a full-

scale output of 39 mA and a resolution of

150 A. The three-wire serial interface

that controls IC1 allows you to shut down

IC1 by writing code 00hex to the DAC.

The circuit also provides an output-volt-

age limit. If an LED fails open, the R5-R7

divider limits the output voltage, in this

case, to 50V. Simultaneously, the CL pin

goes high to indicate the open-fault con-

dition.왏

www.edn.com

�

design

ideas

Doug Glenn, Teledyne, Lewisburg, TN

Improve roll-off of Sallen-Key filter

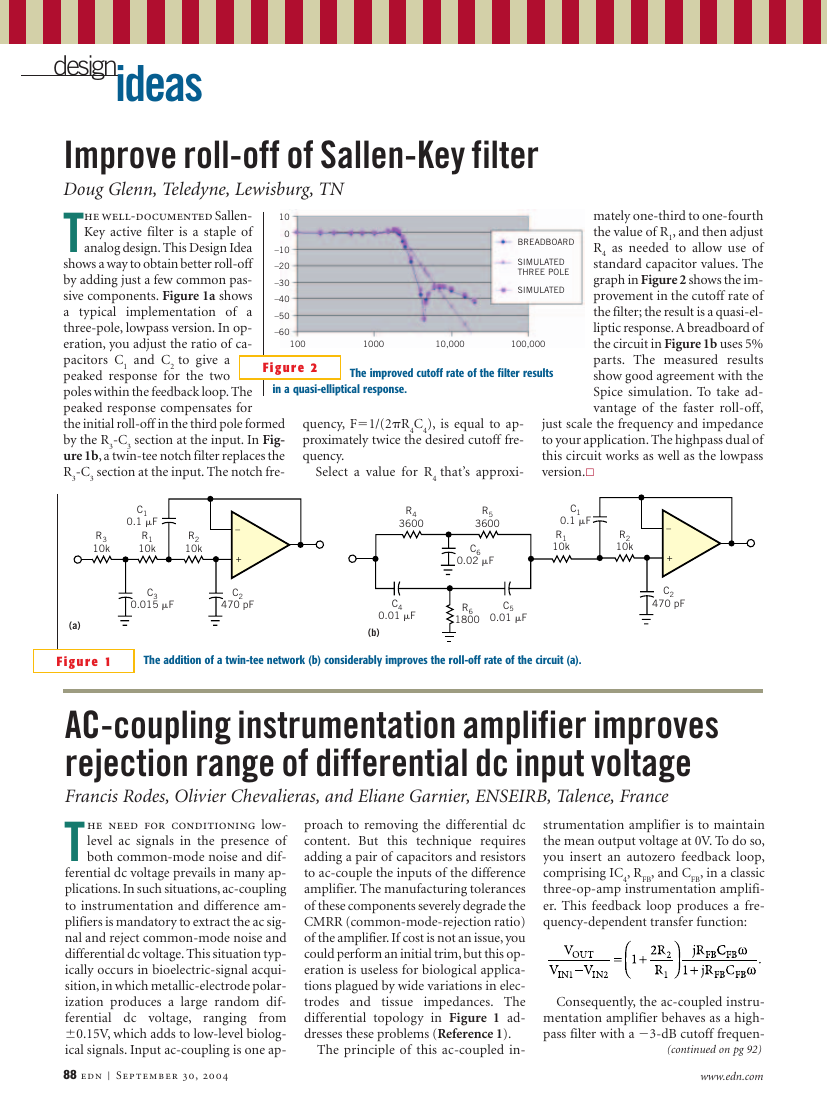

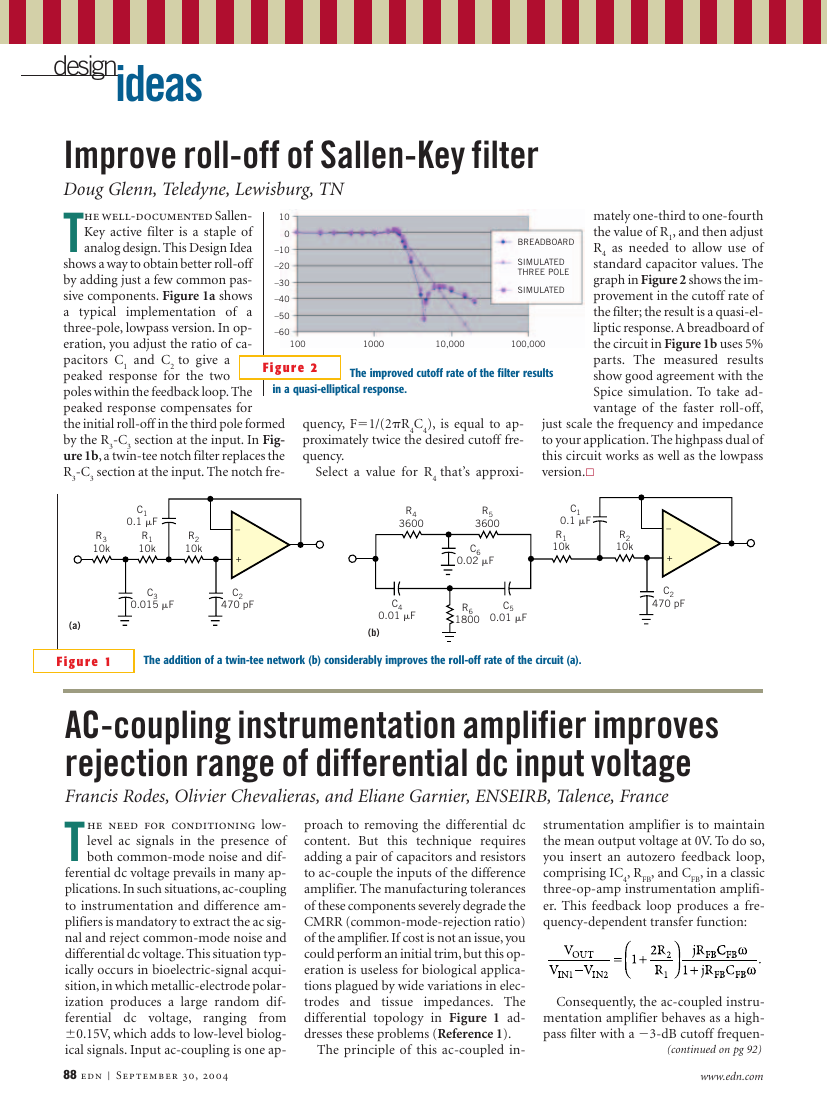

The well-documented Sallen-

–10

10

0

–20

–30

–40

–50

–60

Key active filter is a staple of

analog design. This Design Idea

shows a way to obtain better roll-off

by adding just a few common pas-

sive components. Figure 1a shows

a typical implementation of a

three-pole, lowpass version. In op-

eration, you adjust the ratio of ca-

pacitors C1 and C2 to give a

peaked response for the two

poles within the feedback loop. The

peaked response compensates for

the initial roll-off in the third pole formed

by the R3-C3 section at the input. In Fig-

ure 1b, a twin-tee notch filter replaces the

R3-C3 section at the input. The notch fre-

100

1000

10,000

100,000

Figure 2

The improved cutoff rate of the filter results

in a quasi-elliptical response.

quency, F⫽1/(2R4C4), is equal to ap-

proximately twice the desired cutoff fre-

quency.

Select a value for R4 that’s approxi-

BREADBOARD

SIMULATED

THREE POLE

SIMULATED

mately one-third to one-fourth

the value of R1, and then adjust

R4 as needed to allow use of

standard capacitor values. The

graph in Figure 2 shows the im-

provement in the cutoff rate of

the filter; the result is a quasi-el-

liptic response. A breadboard of

the circuit in Figure 1b uses 5%

parts. The measured results

show good agreement with the

Spice simulation. To take ad-

vantage of the faster roll-off,

just scale the frequency and impedance

to your application. The highpass dual of

this circuit works as well as the lowpass

version.왏

C1

0.1 F

R1

10k

R3

10k

R2

10k

_

+

C3

0.015 F

C2

470 pF

(a)

R4

3600

R5

3600

C6

0.02 F

C1

0.1 F

R1

10k

R2

10k

C4

0.01 F

(b)

R6

1800

C5

0.01 F

_

+

C2

470 pF

Figure 1

The addition of a twin-tee network (b) considerably improves the roll-off rate of the circuit (a).

AC-coupling instrumentation amplifier improves

rejection range of differential dc input voltage

The need for conditioning low-

Francis Rodes, Olivier Chevalieras, and Eliane Garnier, ENSEIRB, Talence, France

level ac signals in the presence of

both common-mode noise and dif-

ferential dc voltage prevails in many ap-

plications. In such situations, ac-coupling

to instrumentation and difference am-

plifiers is mandatory to extract the ac sig-

nal and reject common-mode noise and

differential dc voltage. This situation typ-

ically occurs in bioelectric-signal acqui-

sition, in which metallic-electrode polar-

ization produces a large random dif-

ferential dc voltage,

from

⫾0.15V, which adds to low-level biolog-

ical signals. Input ac-coupling is one ap-

88 edn | September 30, 2004

ranging

proach to removing the differential dc

content. But this technique requires

adding a pair of capacitors and resistors

to ac-couple the inputs of the difference

amplifier. The manufacturing tolerances

of these components severely degrade the

CMRR (common-mode-rejection ratio)

of the amplifier. If cost is not an issue, you

could perform an initial trim, but this op-

eration is useless for biological applica-

tions plagued by wide variations in elec-

trodes and tissue impedances. The

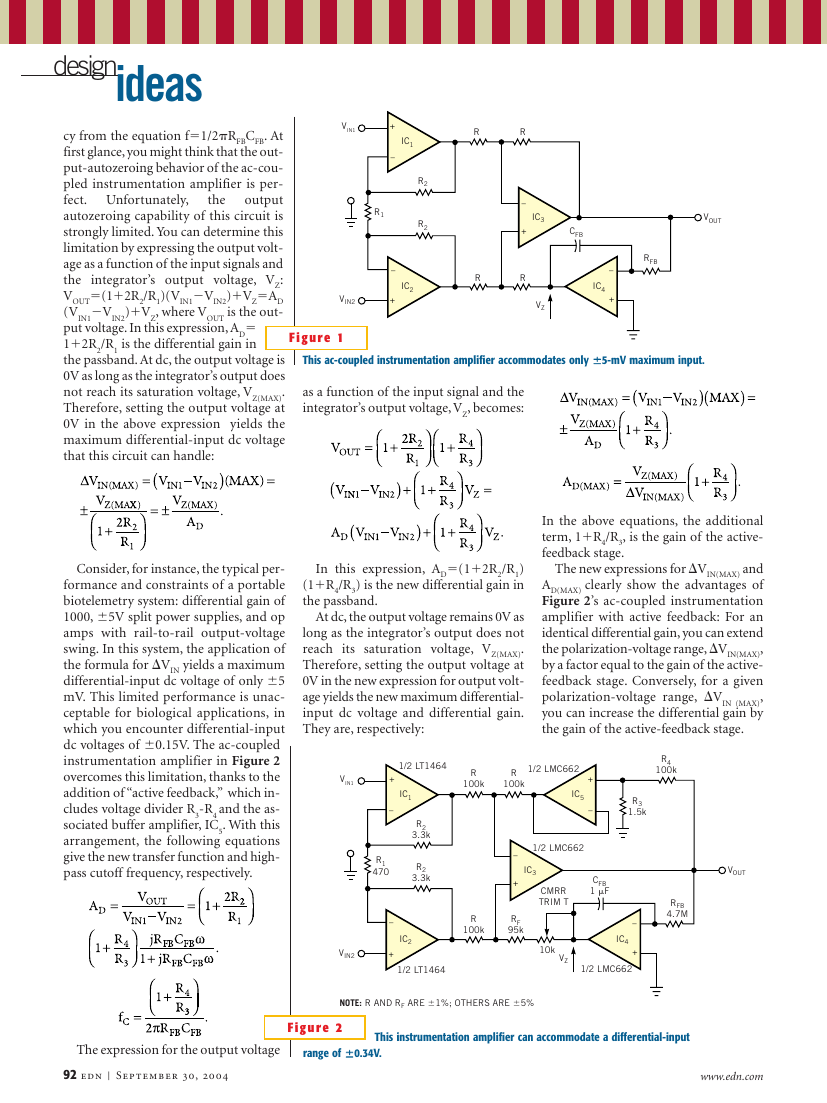

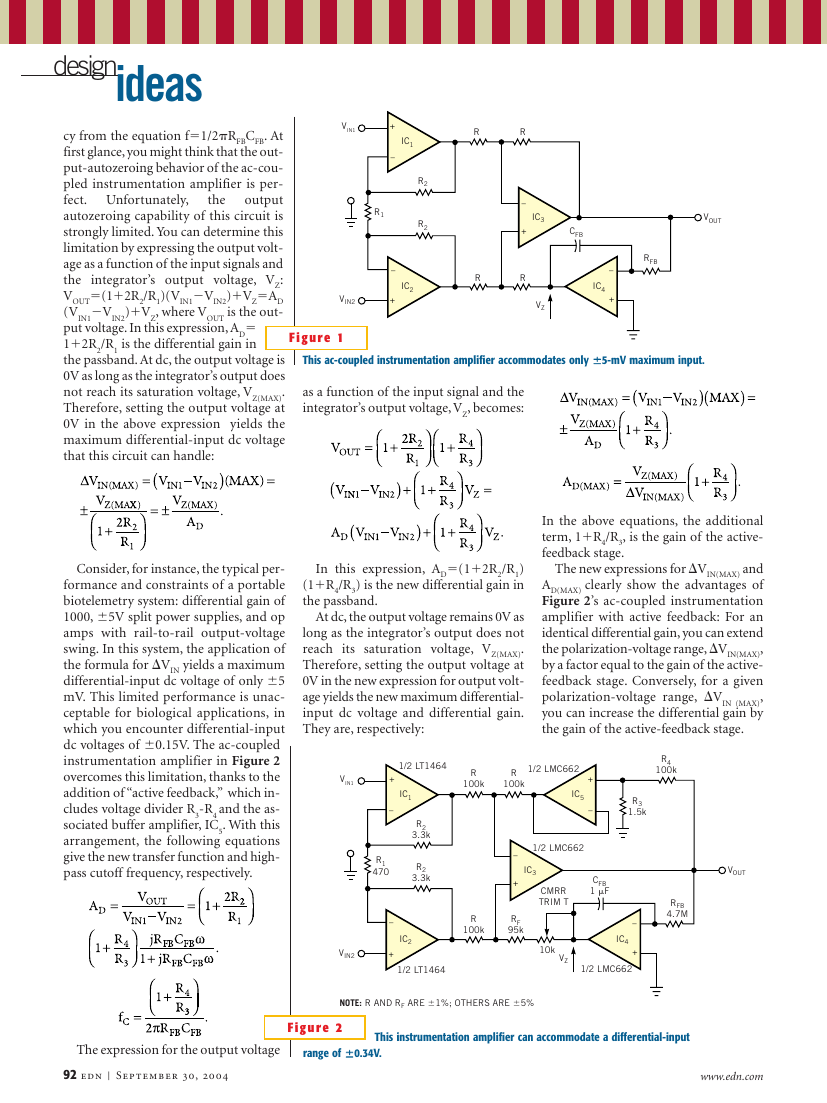

differential topology in Figure 1 ad-

dresses these problems (Reference 1).

The principle of this ac-coupled in-

strumentation amplifier is to maintain

the mean output voltage at 0V. To do so,

you insert an autozero feedback loop,

comprising IC4, RFB, and CFB, in a classic

three-op-amp instrumentation amplifi-

er. This feedback loop produces a fre-

quency-dependent transfer function:

Consequently, the ac-coupled instru-

mentation amplifier behaves as a high-

pass filter with a ⫺3-dB cutoff frequen-

(continued on pg 92)

www.edn.com

�

design

ideas

the

cy from the equation f⫽1/2RFBCFB. At

first glance, you might think that the out-

put-autozeroing behavior of the ac-cou-

pled instrumentation amplifier is per-

fect. Unfortunately,

output

autozeroing capability of this circuit is

strongly limited. You can determine this

limitation by expressing the output volt-

age as a function of the input signals and

the integrator’s output voltage, VZ:

⫽(1⫹2R2/R1)(VIN1

⫽AD

VOUT

⫺VIN2)⫹VZ, where VOUT is the out-

(VIN1

⫽

put voltage. In this expression, AD

1⫹2R2/R1 is the differential gain in

the passband. At dc, the output voltage is

0V as long as the integrator’s output does

not reach its saturation voltage, VZ(MAX).

Therefore, setting the output voltage at

0V in the above expression yields the

maximum differential-input dc voltage

that this circuit can handle:

⫺VIN2)⫹VZ

VIN1

+

_

IC1

R2

R2

R1

_

+

IC2

VIN2

R

R

R

_

+

R

IC3

VZ

VOUT

CFB

RFB

_

+

IC4

Figure 1

This ac-coupled instrumentation amplifier accommodates only ⫾⫾5-mV maximum input.

as a function of the input signal and the

integrator’s output voltage, VZ, becomes:

Consider, for instance, the typical per-

formance and constraints of a portable

biotelemetry system: differential gain of

1000, ⫾5V split power supplies, and op

amps with rail-to-rail output-voltage

swing. In this system, the application of

the formula for ⌬VIN yields a maximum

differential-input dc voltage of only ⫾5

mV. This limited performance is unac-

ceptable for biological applications, in

which you encounter differential-input

dc voltages of ⫾0.15V. The ac-coupled

instrumentation amplifier in Figure 2

overcomes this limitation, thanks to the

addition of “active feedback,” which in-

cludes voltage divider R3-R4 and the as-

sociated buffer amplifier, IC5. With this

arrangement, the following equations

give the new transfer function and high-

pass cutoff frequency, respectively.

In this expression, AD

⫽(1⫹2R2/R1)

(1⫹R4/R3) is the new differential gain in

the passband.

At dc, the output voltage remains 0V as

long as the integrator’s output does not

reach its saturation voltage, VZ(MAX).

Therefore, setting the output voltage at

0V in the new expression for output volt-

age yields the new maximum differential-

input dc voltage and differential gain.

They are, respectively:

In the above equations, the additional

term, 1⫹R4/R3, is the gain of the active-

feedback stage.

The new expressions for ⌬VIN(MAX) and

AD(MAX) clearly show the advantages of

Figure 2’s ac-coupled instrumentation

amplifier with active feedback: For an

identical differential gain, you can extend

the polarization-voltage range, ⌬VIN(MAX),

by a factor equal to the gain of the active-

feedback stage. Conversely, for a given

polarization-voltage range, ⌬VIN (MAX),

you can increase the differential gain by

the gain of the active-feedback stage.

VIN1

1/2 LT1464

+

_

IC1

R

100k

R

100k

1/2 LMC662

IC5

+

_

R4

100k

R3

1.5k

R2

3.3k

R2

3.3k

R1

470

_

+

1/2 LMC662

IC3

CMRR

TRIM T

CFB

1 F

_

+

IC2

1/2 LT1464

VIN2

R

100k

RF

95k

_

+

IC4

1/2 LMC662

10k

VZ

VOUT

RFB

4.7M

The expression for the output voltage

92 edn | September 30, 2004

NOTE: R AND RF ARE ⫾1%; OTHERS ARE ⫾5%

Figure 2

This instrumentation amplifier can accommodate a differential-input

range of ⫾⫾0.34V.

www.edn.com

�

design

ideas

The only drawback of this topology is

apparent in the expression for fC, the

highpass cutoff frequency.You multiply

this frequency by the gain of the active-

feedback stage. Therefore, to maintain a

given cutoff frequency, you must multi-

ply the time constant by a factor equal to

the active-feedback stage gain. This fac-

tor can be an issue in processing signals

whose spectrum includes low-frequency

components. In such applications, RFB

and CFB can reach prohibitive values.

Consequently, you must make a trade-off

between the time constant and the active-

feedback stage gain. The component val-

ues in Figure 2 are a typical example of

such a trade-off: The values are for an

EEG (electroencephalogram) amplifier

with ⫾5V split power supplies. The am-

plifier has a differential gain of 1000 and

a highpass cutoff frequency of 2.3 Hz,

and it can handle a differential-input dc-

voltage range of ⫾0.34V.

To obtain this performance, you set the

active-feedback stage gain and the differ-

ential-amplifier gain, respectively, to 67.6

and 15. With these gain values, the noise

performance of the ac-coupled instru-

mentation amplifier of Figure 2 is simi-

lar to that of a classic instrumentation

amplifier. This situation occurs because

the autozeroing and active-feedback

stages, IC4 and IC5, are after the input dif-

ferential stage, IC1 and IC2. Consequent-

ly, the gain of the differential stage rough-

ly divides their respective noise con-

tributions, which are therefore negligible.

You can use several low-noise op-amps

for IC1 and IC2. For portable bioteleme-

try applications, the LT1464 is a good

compromise for input-noise density,

noise-corner frequency, input-bias cur-

rent and current drain. (Respectively:

⫽0.4

VNOISE

pA, and ICC

⫽26 nV/公Hz, fC

⫽230 A.)

⫽9 Hz, IBIAS

A theoretical analysis using the LT

1464’s noise parameters shows that un-

der worst-case conditions, the input-

noise voltage should not exceed 11 V

rms. Tests on prototypes confirm this

prediction; the tests effectively measure

input-noise voltages of 3 to 6 V rms. To

sum up, an ac-coupled instrumentation

amplifier with active feedback is well-

suited for applications requiring high dif-

ferential gain, a capability for handling

large differential-input dc voltages, and

low-noise performance.왏

Reference

1. Stitt, Mark, “AC-Coupled Instru-

mentation and Difference Amplifier,”

Burr-Brown, AB-008, May 1990.

Simplify computer-aided engineering

with scientific-to-engineering conversion

The simple yet useful

Alexander Bell, Infosoft International, Rego Park, NY

formula in this Design

Idea enables conver-

sion from scientific format

(for example, 2.2⫺9), which

is typical for CAE (com-

puter-aided-engineering),

double-precision output

values,

“human-

friendly” engineering for-

mat (for example, 2.2 nF).

The engineering format is

more suitable for bills of

material and other electri-

cal and electronic-engi-

neering

and specifications.

documents

into

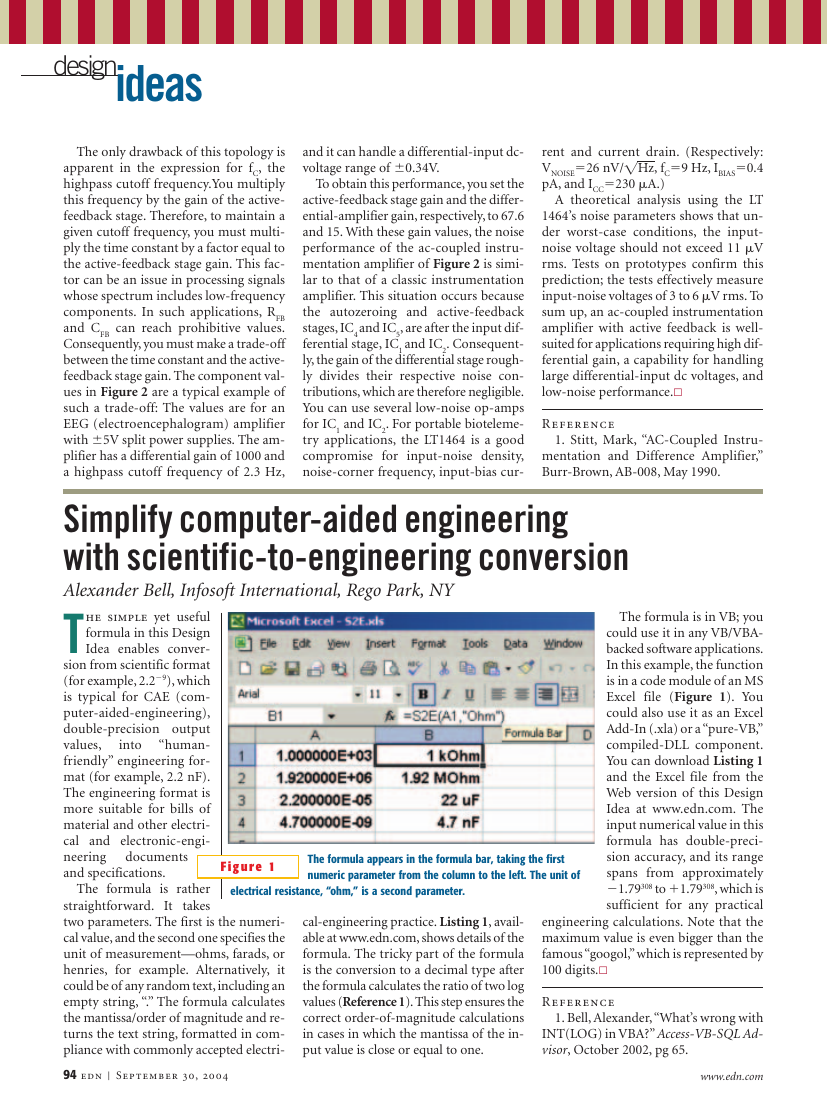

The formula is in VB; you

could use it in any VB/VBA-

backed software applications.

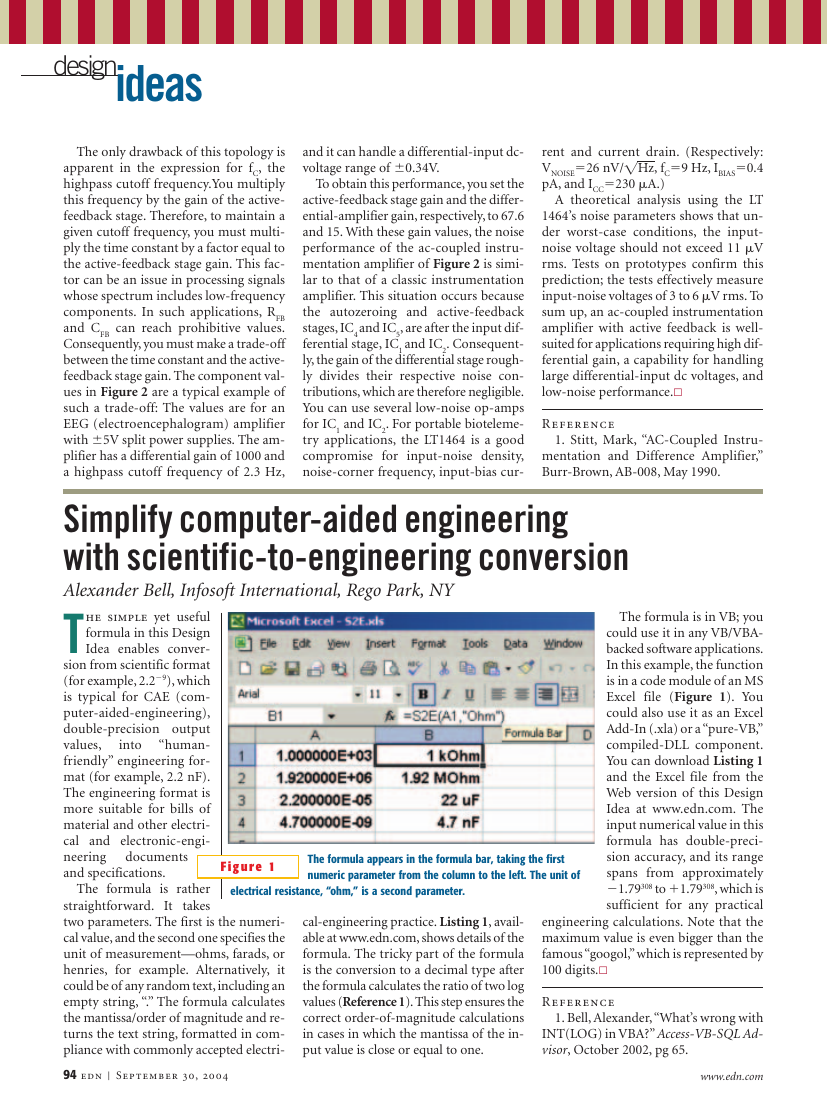

In this example, the function

is in a code module of an MS

Excel file (Figure 1). You

could also use it as an Excel

Add-In (.xla) or a “pure-VB,”

compiled-DLL component.

You can download Listing 1

and the Excel file from the

Web version of this Design

Idea at www.edn.com. The

input numerical value in this

formula has double-preci-

sion accuracy, and its range

spans from approximately

⫺1.79308 to ⫹1.79308, which is

sufficient for any practical

engineering calculations. Note that the

maximum value is even bigger than the

famous “googol,” which is represented by

100 digits.왏

Reference

1. Bell, Alexander, “What’s wrong with

INT(LOG) in VBA?” Access-VB-SQL Ad-

visor, October 2002, pg 65.

www.edn.com

Figure 1

The formula appears in the formula bar, taking the first

numeric parameter from the column to the left. The unit of

electrical resistance, “ohm,” is a second parameter.

The formula is rather

It takes

straightforward.

two parameters. The first is the numeri-

cal value, and the second one specifies the

unit of measurement—ohms, farads, or

henries, for example. Alternatively, it

could be of any random text, including an

empty string, “.” The formula calculates

the mantissa/order of magnitude and re-

turns the text string, formatted in com-

pliance with commonly accepted electri-

94 edn | September 30, 2004

cal-engineering practice. Listing 1, avail-

able at www.edn.com, shows details of the

formula. The tricky part of the formula

is the conversion to a decimal type after

the formula calculates the ratio of two log

values (Reference 1). This step ensures the

correct order-of-magnitude calculations

in cases in which the mantissa of the in-

put value is close or equal to one.

�

design

ideas

Steve Caldwell, Maxim Integrated Products, Chandler, AZ

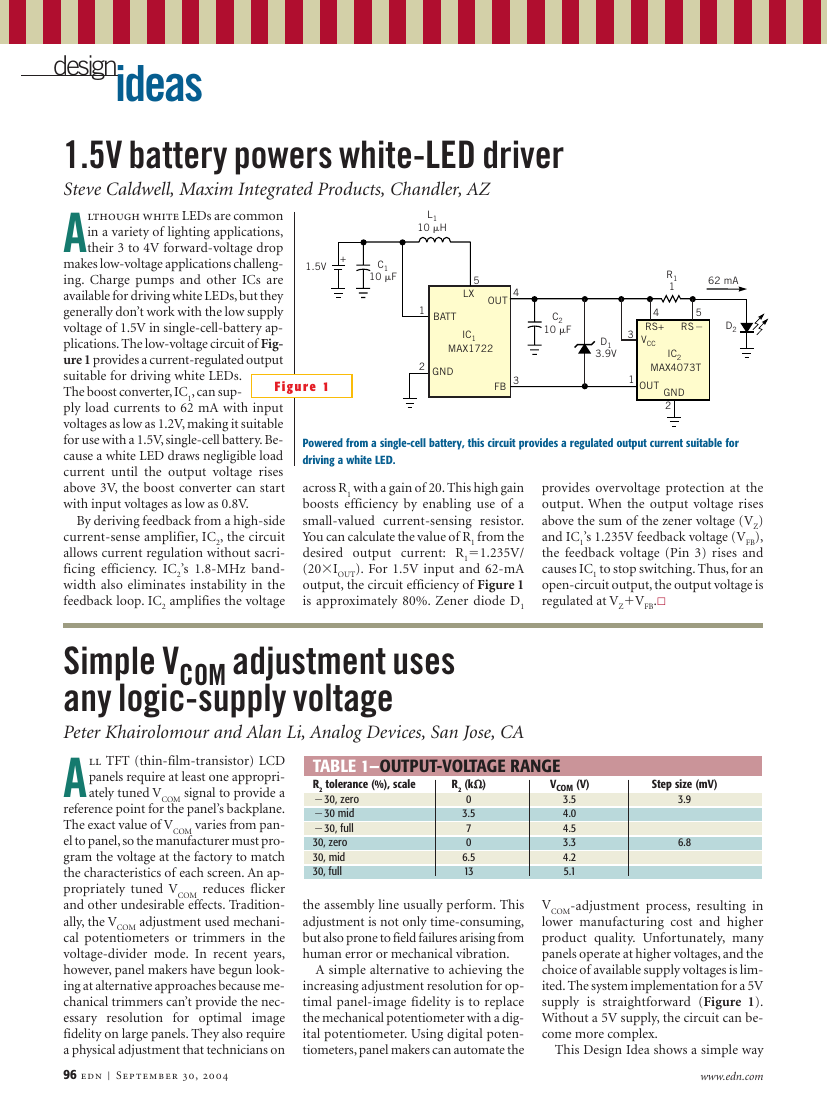

1.5V battery powers white-LED driver

Although white LEDs are common

10 H

L1

+

1.5V

C1

10 F

in a variety of lighting applications,

their 3 to 4V forward-voltage drop

makes low-voltage applications challeng-

ing. Charge pumps and other ICs are

available for driving white LEDs, but they

generally don’t work with the low supply

voltage of 1.5V in single-cell-battery ap-

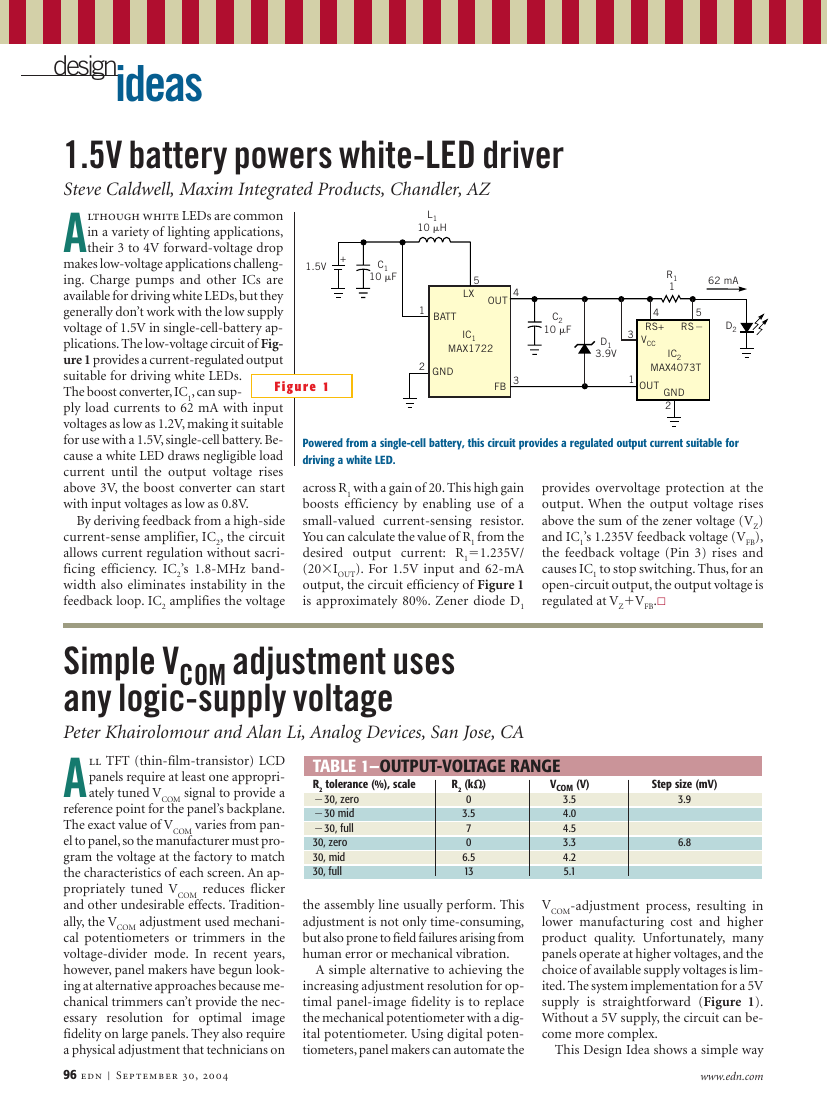

plications. The low-voltage circuit of Fig-

ure 1 provides a current-regulated output

suitable for driving white LEDs.

The boost converter, IC1, can sup-

ply load currents to 62 mA with input

voltages as low as 1.2V, making it suitable

for use with a 1.5V, single-cell battery. Be-

cause a white LED draws negligible load

current until the output voltage rises

above 3V, the boost converter can start

with input voltages as low as 0.8V.

By deriving feedback from a high-side

current-sense amplifier, IC2, the circuit

allows current regulation without sacri-

ficing efficiency. IC2’s 1.8-MHz band-

width also eliminates instability in the

feedback loop. IC2 amplifies the voltage

Figure 1

5

LX

4

OUT

1

BATT

IC1

MAX1722

2

GND

3

FB

C2

10 F

D1

3.9V

3

1

R1

1

62 mA

5

RSⳮ

D2

4

RS+

VCC

IC2

MAX4073T

OUT

GND

2

Powered from a single-cell battery, this circuit provides a regulated output current suitable for

driving a white LED.

across R1 with a gain of 20. This high gain

boosts efficiency by enabling use of a

small-valued current-sensing resistor.

You can calculate the value of R1 from the

⫽1.235V/

desired output current: R1

(20⫻IOUT). For 1.5V input and 62-mA

output, the circuit efficiency of Figure 1

is approximately 80%. Zener diode D1

provides overvoltage protection at the

output. When the output voltage rises

above the sum of the zener voltage (VZ)

and IC1’s 1.235V feedback voltage (VFB),

the feedback voltage (Pin 3) rises and

causes IC1 to stop switching. Thus, for an

open-circuit output, the output voltage is

regulated at VZ

⫹VFB.왏

Simple VCOM adjustment uses

any logic-supply voltage

All TFT (thin-film-transistor) LCD

Peter Khairolomour and Alan Li, Analog Devices, San Jose, CA

panels require at least one appropri-

ately tuned VCOM signal to provide a

reference point for the panel’s backplane.

The exact value of VCOM varies from pan-

el to panel, so the manufacturer must pro-

gram the voltage at the factory to match

the characteristics of each screen. An ap-

propriately tuned VCOM reduces flicker

and other undesirable effects. Tradition-

ally, the VCOM adjustment used mechani-

cal potentiometers or trimmers in the

voltage-divider mode. In recent years,

however, panel makers have begun look-

ing at alternative approaches because me-

chanical trimmers can’t provide the nec-

essary resolution for optimal image

fidelity on large panels. They also require

a physical adjustment that technicians on

96 edn | September 30, 2004

R2 (k⍀⍀)

TABLE 1—OUTPUT-VOLTAGE RANGE

R2 tolerance (%), scale

ⳮ30, zero

ⳮ30 mid

ⳮ30, full

30, zero

30, mid

30, full

0

3.5

7

0

6.5

13

3.5

4.0

4.5

3.3

4.2

5.1

VCOM (V)

Step size (mV)

3.9

6.8

the assembly line usually perform. This

adjustment is not only time-consuming,

but also prone to field failures arising from

human error or mechanical vibration.

A simple alternative to achieving the

increasing adjustment resolution for op-

timal panel-image fidelity is to replace

the mechanical potentiometer with a dig-

ital potentiometer. Using digital poten-

tiometers, panel makers can automate the

VCOM-adjustment process, resulting in

lower manufacturing cost and higher

product quality. Unfortunately, many

panels operate at higher voltages, and the

choice of available supply voltages is lim-

ited. The system implementation for a 5V

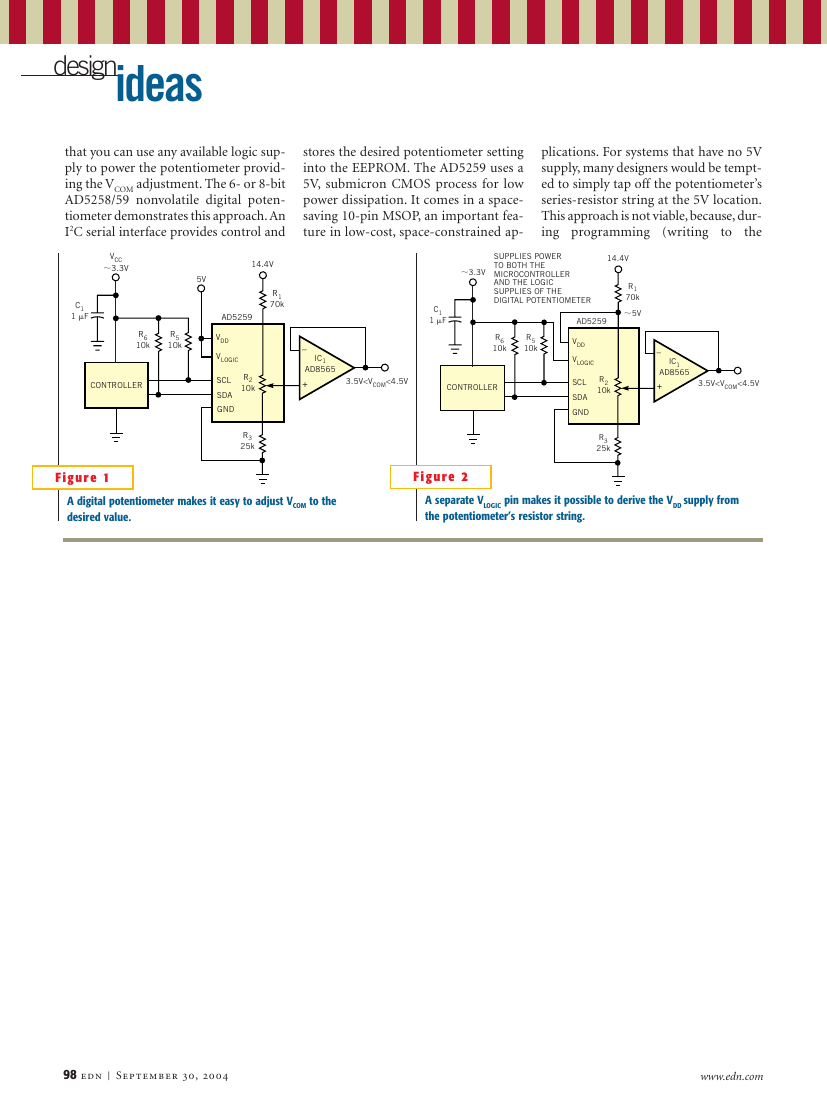

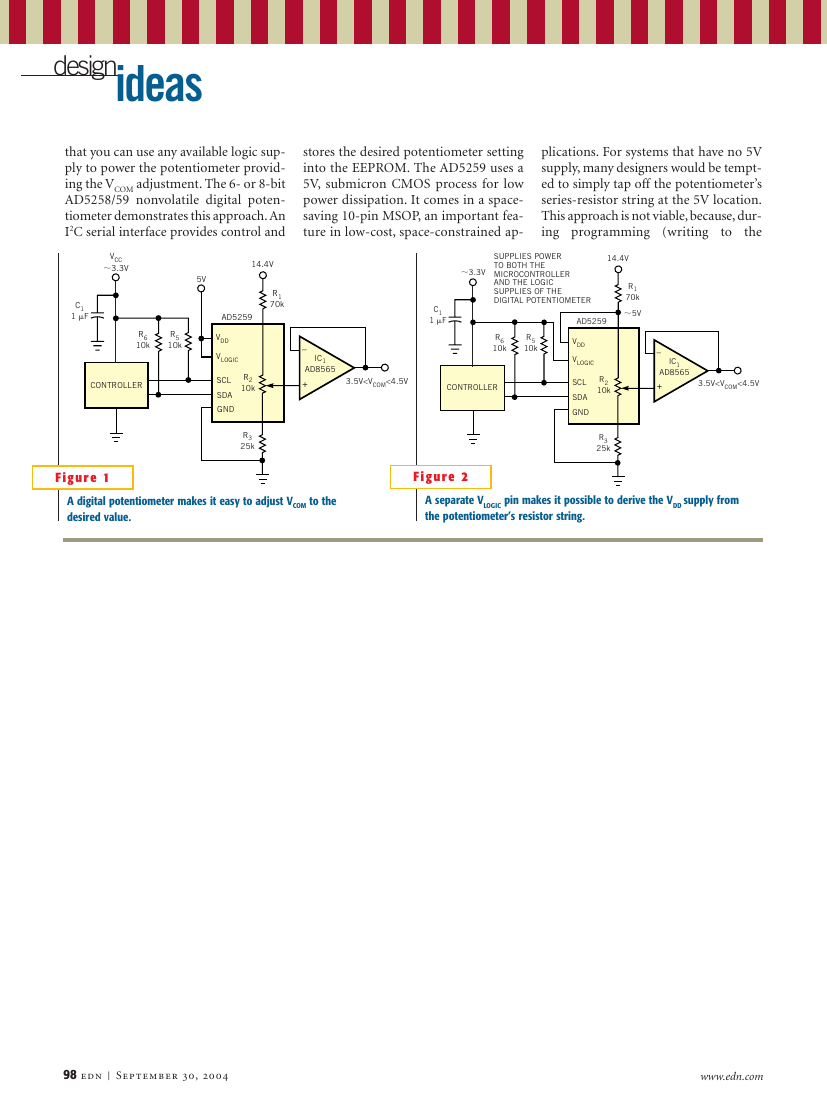

supply is straightforward (Figure 1).

Without a 5V supply, the circuit can be-

come more complex.

This Design Idea shows a simple way

www.edn.com

�

design

ideas

that you can use any available logic sup-

ply to power the potentiometer provid-

ing the VCOM adjustment. The 6- or 8-bit

AD5258/59 nonvolatile digital poten-

tiometer demonstrates this approach. An

I2C serial interface provides control and

stores the desired potentiometer setting

into the EEPROM. The AD5259 uses a

5V, submicron CMOS process for low

power dissipation. It comes in a space-

saving 10-pin MSOP, an important fea-

ture in low-cost, space-constrained ap-

plications. For systems that have no 5V

supply, many designers would be tempt-

ed to simply tap off the potentiometer’s

series-resistor string at the 5V location.

This approach is not viable, because, dur-

the

ing programming (writing

to

VCC

⬃3.3V

C1

1 F

R6

10k

R5

10k

CONTROLLER

5V

14.4V

R1

70k

AD5259

VDD

VLOGIC

SCL

SDA

GND

R2

10k

R3

25k

⬃3.3V

SUPPLIES POWER

TO BOTH THE

MICROCONTROLLER

AND THE LOGIC

SUPPLIES OF THE

DIGITAL POTENTIOMETER

AD5259

14.4V

R1

70k

⬃5V

C1

1 F

_

IC1

AD8565

+

R6

10k

R5

10k

3.5V

design

ideas

EEPROM), the AD5259’s VLOGIC pin typ-

ically draws 35 mA. It cannot draw this

current level through R1 because the volt-

age drop would be too large. For this rea-

son, the AD5259 has a separate VLOGIC pin

that can connect to any available logic

supply. In Figure 2, VLOGIC uses the sup-

ply voltage from the microcontroller that

is controlling the digital potentiometer.

Now, VLOGIC draws the 35-mA program-

ming current, and VDD draws only mi-

croamps of supply current to bias the in-

ternal switches in the digital potentio-

meter’s internal resistor string. If the pan-

el requires a higher VCOM voltage, you can

add two resistors to place the op amp in

a noninverting gain configuration.

The digital potentiometer has ⫾30%

end-to-end resistance tolerance. Assum-

ing that the tolerances of R1, R3, and VDD

are negligible compared with those of the

potentiometer, you can achieve the range

of output values that Table 1 shows. As-

sume that the desired value of VCOM is

VDD

VLOGIC

DGND

SCL

SDA

AD0

AD1

RDAC EEPROM

RDAC1

REGISTER

RDAC1

A1

W1

B1

DATA

8

8

CONTROL

COMMAND-DECODE LOGIC

ADDRESS-DECODE LOGIC

CONTROL LOGIC

I2C

SERIAL

INTERFACE

POWER-

ON

RESET

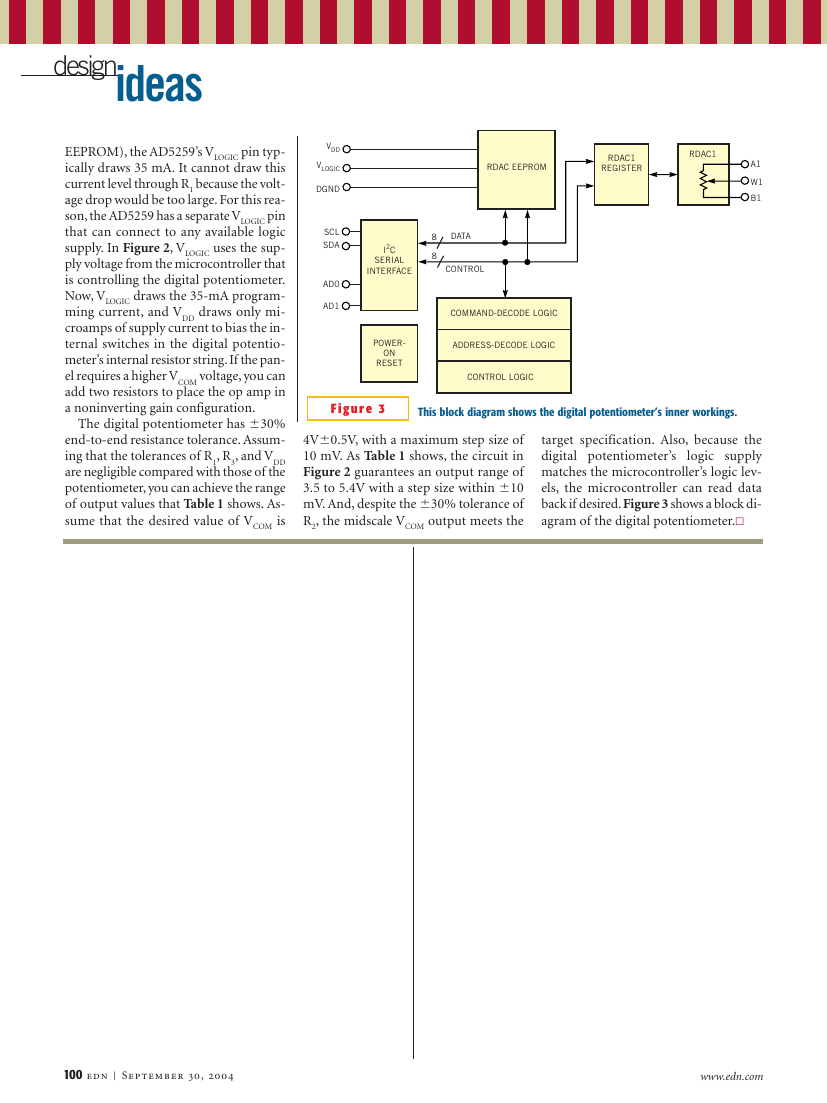

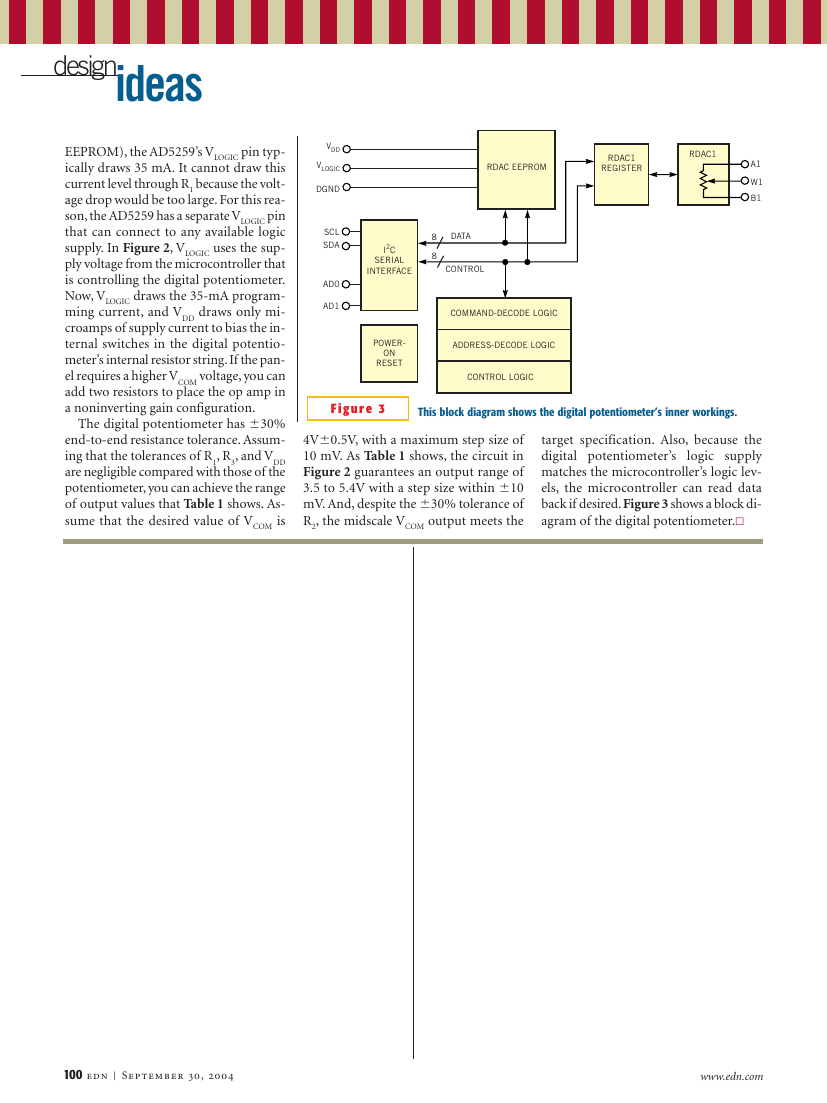

Figure 3

This block diagram shows the digital potentiometer’s inner workings.

4V⫾0.5V, with a maximum step size of

10 mV. As Table 1 shows, the circuit in

Figure 2 guarantees an output range of

3.5 to 5.4V with a step size within ⫾10

mV. And, despite the ⫾30% tolerance of

R2, the midscale VCOM output meets the

target specification. Also, because the

digital potentiometer’s

logic supply

matches the microcontroller’s logic lev-

els, the microcontroller can read data

back if desired. Figure 3 shows a block di-

agram of the digital potentiometer.왏

100 edn | September 30, 2004

www.edn.com

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc