Warranty Information

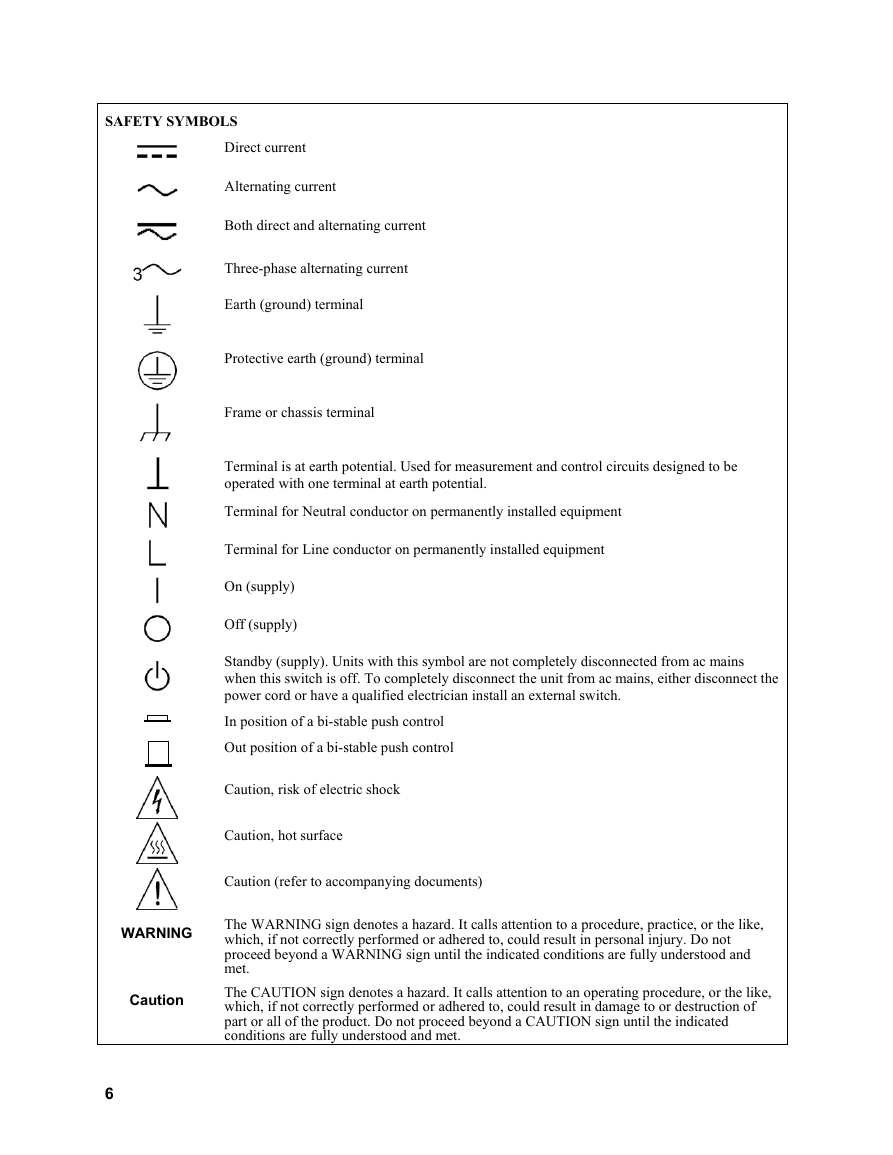

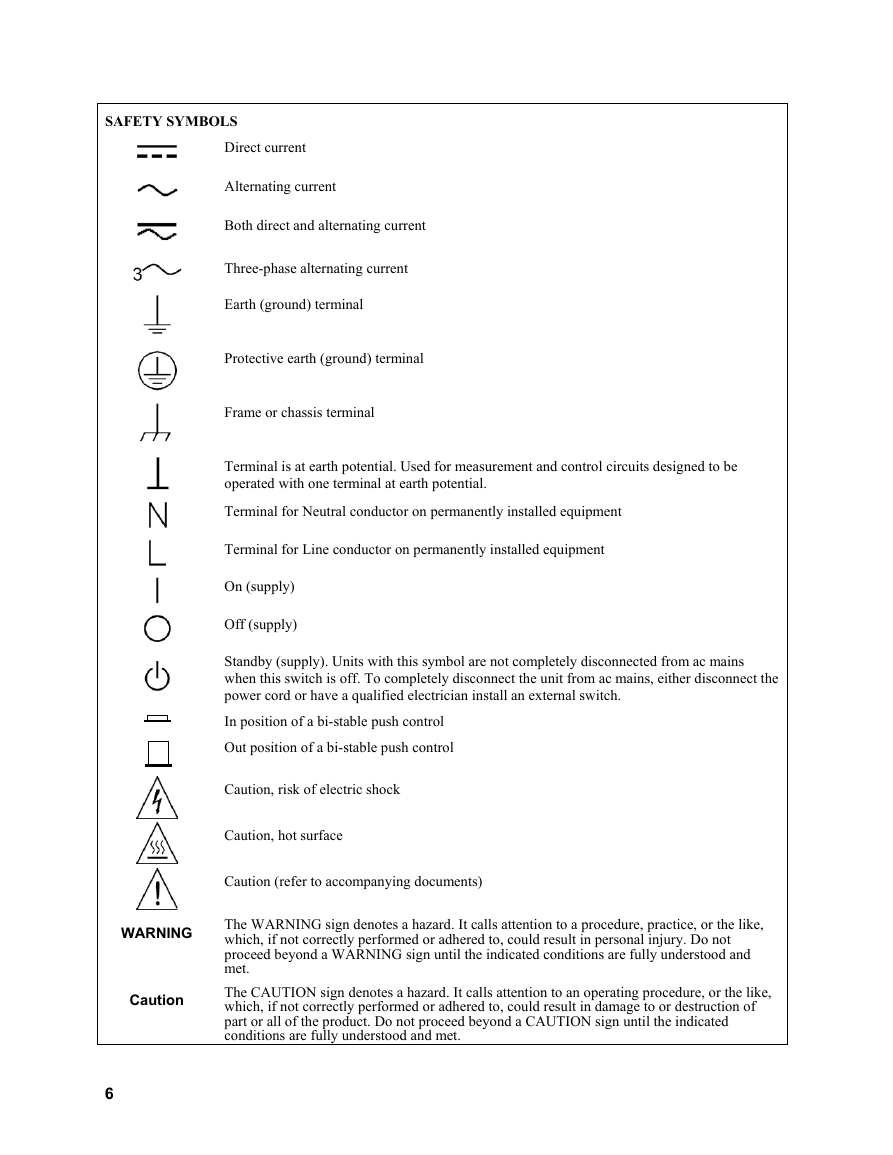

Safety Summary

Declaration of Conformity

Acoustic Noise Information

Printing History

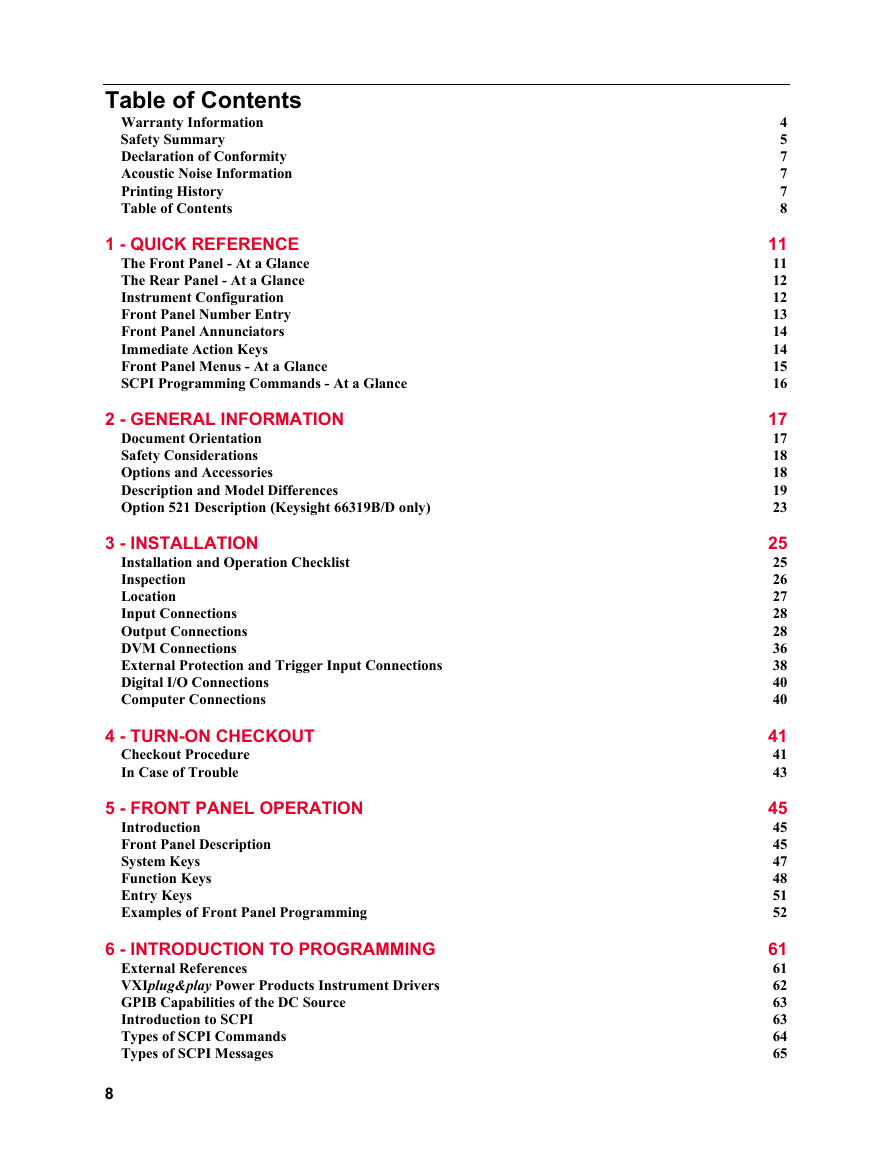

Table of Contents

1

Quick Reference

The Front Panel - At a Glance

The Rear Panel - At a Glance

Instrument Configuration

Use the front panel Address key to configure the interface

Front Panel Number Entry

Use the arrow keys and knob to change voltage or current settings

Use the Function keys and knob to change the displayed settings

Use the arrow keys to edit individual digits in the displayed setting

Use the Function keys and Entry keys to enter a new value

Front Panel Annunciators

Immediate Action Keys

Front Panel Menus - At a Glance

SCPI Programming Commands - At a Glance

1 CURR 2.0002 CURR 1.000

2

General Information

Document Orientation

Safety Considerations

Options and Accessories

Description and Model Differences

Keysight 66321B

Keysight 66319B

Keysight 66321D and 66319D

Common Features

Front Panel Controls

Remote Programming

Output 1 Characteristic

Programmable Output Resistance

Output 2 Characteristic

Option 521 Description (Keysight 66319B/D only)

Table 2-5. Option 521 Relay Modes

Table 2-6. Option 521 Factory Settings

3

Installation

Installation and Operation Checklist

Inspection

Damage

Packaging Material

Items Supplied

Cleaning

Location

Bench Operation

Rack Mounting

Input Connections

Connect the Power Cord

Output Connections

Output 1

Output 2

Current Ratings

Voltage Drops and Lead Resistance

Remote Sense Connections

Load Regulation and Voltage Drop in the Remote Sense Leads

Maintaining Stability while Remote Sensing

Open Sense Lead Protection

Local Sensing

Output Compensation

OVP Considerations

Programmable Voltage Protection

DVM Connections

Measuring Circuits that are Not Powered by the Main Output

Measuring Circuits that are Floating with Respect to the Main Output

External Protection and Trigger Input Connections

Table 3-3. 4-Pin Connector Configurations

Digital I/O Connections

Computer Connections

GPIB Interface

4

Turn-On Checkout

Checkout Procedure

In Case of Trouble

Selftest Error Messages

Runtime Error Messages

Line Fuse

5

Front Panel Operation

Introduction

Front Panel Description

System Keys

Function Keys

Immediate Action Keys

Scrolling Keys

Metering Keys

Output Control Keys

Entry Keys

Examples of Front Panel Programming

1 - Using the Front Panel Display

Independently Control Output 1 and Output 2 on Keysight 66319B/D units

2 - Setting the Output Voltage, Current, Resistance, Compensation, and Relay Mode

Setting the relay mode (Keysight 66319B/66319D with Option 521 only)

3 - Setting the Output 2 Voltage and Current (Keysight 66319B/66319D only)

4 - Querying and Clearing Output Protection and Errors

5 – Making Basic Front Panel Measurements

6 – Making Enhanced Front Panel Measurements

7 – Making DVM Measurements (Keysight 66321D/66319D only)

8 - Programming Output Port Functions

9 - Setting the GPIB Address

10 - Storing and Recalling Instrument States

Command Function

Command Function

6

Introduction to Programming

External References

GPIB References

SCPI References

VXIplug&play Power Products Instrument Drivers

Supported Applications

System Requirements

Downloading and Installing the Driver

Accessing Online Help

GPIB Capabilities of the DC Source

GPIB Address

Introduction to SCPI

Conventions Used in This Guide

Types of SCPI Commands

Multiple Commands in a Message

Moving Among Subsystems

Including Common Commands

Using Queries

Types of SCPI Messages

The Message Unit

Headers

Query Indicator

Message Unit Separator

Root Specifier

Message Terminator

SCPI Data Formats

Numerical Data Formats

Suffixes and Multipliers

Response Data Types

SCPI Command Completion

Using Device Clear

SCPI Conformance Information

SCPI Conformed Commands

Non-SCPI Commands

7

Programming the DC Source

Introduction

Programming the Output

Power-on Initialization

Enabling the Output

Output Voltage

Maximum Voltage

Overvoltage Protection

Output Current

Maximum Current

Overcurrent Protection

Output Resistance

Triggering Output Changes

SCPI Triggering Nomenclature

Output Trigger Model

Setting the Voltage, Current, or Resistance Transient Levels

Enabling the Output Trigger System

Selecting the Output Trigger Source

Generating Triggers

Single Trigger

Multiple Triggers

Making Basic Measurements

Average Measurements

Controlling Measurement Samples

Window Functions

Measuring Output 2 Voltage and Current (Keysight 66319B/66319D only)

Making Enhanced Measurements

Current Ranges and Measurement Detector

RMS Measurements

Pulse Measurements

Minimum and Maximum Measurements

High/Low Measurements

Returning All Measurement Data From the Data Buffer

Making DVM Measurements

Average Measurements

RMS Measurements

Triggered Measurements

SCPI Triggering Nomenclature

Measurement Trigger Model

Enabling the Measurement Trigger System

Selecting the Measurement Trigger Source

Selecting the Sensing Function

Generating Measurement Triggers

Single Triggers

Multiple Triggers

Pre-trigger and Post-trigger Data Acquisition

Programming the Status Registers

Power-On Conditions

Operation Status Group

Questionable Status Group

Standard Event Status Group

The PON (Power On) Bit

Status Byte Register

The MSS Bit

The RQS Bit

The MAV Bit and Output Queue

Determining the Cause of a Service Interrupt

Servicing Operation Status and Questionable Status Events

Monitoring Both Phases of a Status Transition

Inhibit/Fault Indicator

Remote Inhibit (RI)

Discrete Fault Indicator (DFI)

Using the Inhibit/Fault Port as a Digital I/O

8

Language Dictionary

Introduction

Subsystem Commands

Common Commands

Programming Parameters

Calibration Commands

CALibrate:CURRent

CALibrate:CURRent2

CALibrate:CURRent:MEASure:R3

CALibrate:CURRent:MEASure:LOWRange

CALibrate:CURRent:MEASure:AC

CALibrate:DATA

CALibrate:DATE

CALibrate:DVM

CALibrate:LEVel

CALibrate:PASSword

CALibrate:RESistance

CALibrate:SAVE

CALibrate:STATe

CALibrate:VOLTage

CALibrate:VOLTage2

Display Commands

DISPlay

DISPlay:CHANnel

DISPlay:MODE

DISPlay:TEXT

Measurement Commands

FORMat

FORMat:BORDer

MEASure:ARRay:CURRent? FETCh:ARRay:CURRent?

MEASure:ARRay:VOLTage? FETCh:ARRay:VOLTage?

MEASure:CURRent? [MAX | MIN | ] FETCh:CURRent?

MEASure:CURRent2?

MEASure:CURRent:ACDC? FETCh:CURRent:ACDC?

MEASure:CURRent:HIGH? FETCh:CURRent:HIGH?

MEASure:CURRent:LOW? FETCh:CURRent:LOW?

MEASure:CURRent:MAXimum? FETCh:CURRent: MAXimum?

MEASure:CURRent:MINimum? FETCh:CURRent:MINimum?

MEASure:DVM? FETCh:DVM?

MEASure:DVM:ACDC? FETCh:DVM:ACDC?

MEASure:VOLTage? FETCh:VOLTage?

MEASure:VOLTage2

MEASure:VOLTage:ACDC? FETCh:VOLTage:ACDC?

MEASure:VOLTage:HIGH? FETCh:VOLTage:HIGH?

MEASure:VOLTage:LOW? FETCh:VOLTage:LOW?

MEASure:VOLTage:MAXimum? FETCh:VOLTage:MAXimum?

MEASure:VOLTage:MINimum? FETCh:VOLTage:MINimum?

SENSe:CURRent:DETector

SENSe:CURRent:RANGe

SENSe:LEAD:STATus?

SENSe:FUNCtion

SENSe:PROTection:STATe

SENSe:SWEep:OFFSet:POINts

SENSe:SWEep:POINts

SENSe:SWEep:TINTerval

SENSe:WINDow

Output Commands

INSTrument:COUPle:OUTPut:STATe

OUTPut[1 | 2]

OUTPut[1 | 2]:RELay:MODE

OUTPut:COMPensation:MODE

OUTPut:DFI

OUTPut:DFI:SOURce

OUTPut:PON:STATe

OUTPut:PROTection:CLEar

OUTPut:PROTection:DELay

OUTPut:RI:MODE

[SOURce:]CURRent

[SOURce:]CURRent

[SOURce:]CURRent2

[SOURce:]CURRent:PROTection:STATe

[SOURce:]CURRent:TRIGger

[SOURce:]CURRent2:TRIGger

[SOURce:]DIGital:DATA

[SOURce:]DIGital:FUNCtion

[SOURce:]RESistance

[SOURce:]RESistance:TRIGger

[SOURce:]VOLTage

[SOURce:]VOLTage2

[SOURce:]VOLTage:PROTection

[SOURce:]VOLTage:PROTection:STATe

[SOURce:]VOLTage:TRIGger

[SOURce:]VOLTage2:TRIGger

Status Commands

STATus:PRESet

STATus:OPERation?

STATus:OPERation:CONDition?

STATus:OPERation:ENABle

STATus:OPERation:NTR STATus:OPERation:PTR

STATus:QUEStionable?

STATus:QUEStionable:CONDition?

STATus:QUEStionable:ENABle

STATus:QUEStionable:NTR STATus:QUEStionable:PTR

System Commands

SYSTem:ERRor?

SYSTem:LANGuage

SYSTem:VERSion?

Trigger Commands

ABORt

INITiate:SEQuence INITiate:NAME

INITiate:CONTinuous:SEQuence1 INITiate:CONTinuous:NAME TRANsient

TRIGger

TRIGger:SOURce

TRIGger:SEQuence2 TRIGger:ACQuire

TRIGger:SEQuence2:COUNt:CURRent TRIGger:ACQuire:COUNt:CURRent

TRIGger:SEQuence2:COUNt:DVM TRIGger:ACQuire:COUNt:DVM

TRIGger:SEQuence2:COUNt:VOLTage TRIGger:ACQuire:COUNt:VOLTage

TRIGger:SEQuence2:HYSTeresis:CURRent TRIGger:ACQuire:HYSTeresis:CURRent

TRIGger:SEQuence2:HYSTeresis:DVM TRIGger:ACQuire:HYSTeresis:DVM

TRIGger:SEQuence2:HYSTeresis:VOLTage TRIGger:ACQuire:HYSTeresis:VOLTage

TRIGger:SEQuence2:LEVel:CURRent TRIGger:ACQuire:LEVel:CURRent

TRIGger:SEQuence2:LEVel:DVM TRIGger:ACQuire:LEVel:DVM

TRIGger:SEQuence2:LEVel:VOLTage TRIGger:ACQuire:LEVel:VOLTage

TRIGger:SEQuence2:SLOPe:CURRent TRIGger:ACQuire:SLOPe:CURRent

TRIGger:SEQuence2:SLOPe:DVM TRIGger:ACQuire:SLOPe:DVM

TRIGger:SEQuence2:SLOPe:VOLTage TRIGger:ACQuire:SLOPe:VOLTage

TRIGger:SEQuence2:SOURce TRIGger:ACQuire:SOURce

TRIGger:SEQuence1:DEFine TRIGger:SEQuence2:DEFine

Common Commands

*CLS

*ESE

*ESR?

*IDN?

*OPC

*OPT?

*PSC

*RCL

*RST

*SAV

*SRE

*STB?

*TRG

*TST?

*WAI

Syntax Forms

DC Common Mode Rejection Ratio

Action

A

Specifications

Specifications

Supplemental Characteristics

B

Performance, Calibration, and Configuration

Introduction

Equipment Required

Measurement Techniques

Test Setup

Electronic Load

Current-Monitoring Resistor

Performance Tests

Programming

Constant Voltage (CV) Tests

CV Setup

Voltage Programming and Readback Accuracy (performance, calibration)

CV Load Effect (performance)

CV Source Effect (performance)

CV Noise (performance)

Transient Recovery Time (performance)

Constant Current (CC) Tests

CC Setup

Current Programming and Readback Accuracy (performance, calibration)

1A Range Current Readback Accuracy (performance, calibration)

0.02A Range Current Readback Accuracy (performance, calibration)

- 0.02A Range Current Sink Operation (performance, calibration)

- 3A Range Current Sink Operation (performance, calibration)

CC Load and Line Regulation (performance)

CC Load Effect (performance)

CC Source Effect (performance)

CC Noise (performance)

Resistance Tests

Resistance Programming (performance, calibration)

DVM Tests

DVM Measurement Accuracy (calibration)

Performance Test Equipment Form

Performance Test Record Form

Performing the Calibration Procedure

Front Panel Calibration Menu

Front Panel Calibration Procedure

Resistance Calibration

Calibration Error Messages

Changing the Calibration Password

Calibration Over the GPIB

Performing the Configuration Procedure

C

Error Messages

Error Number List

D

Example Programs

Pulse Measurements

Current Pulse Measurement Using BASIC

Voltage Pulse Measurement Using VISA Library Calls

E

Line Voltage Conversion

Open the Unit

Configure the Power Transformer

Install the Correct Line Fuse

Close the Unit

Index

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc