COMMON SYMBOLS/

1 82

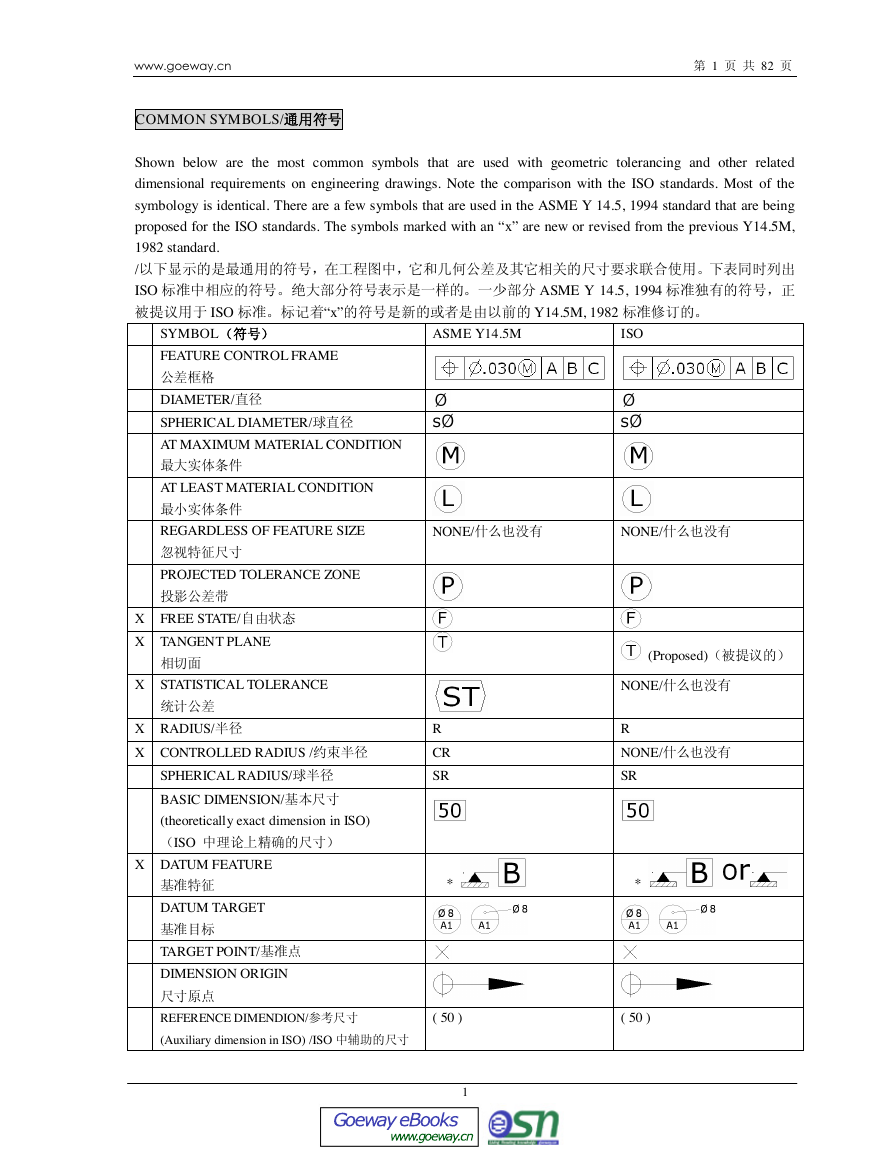

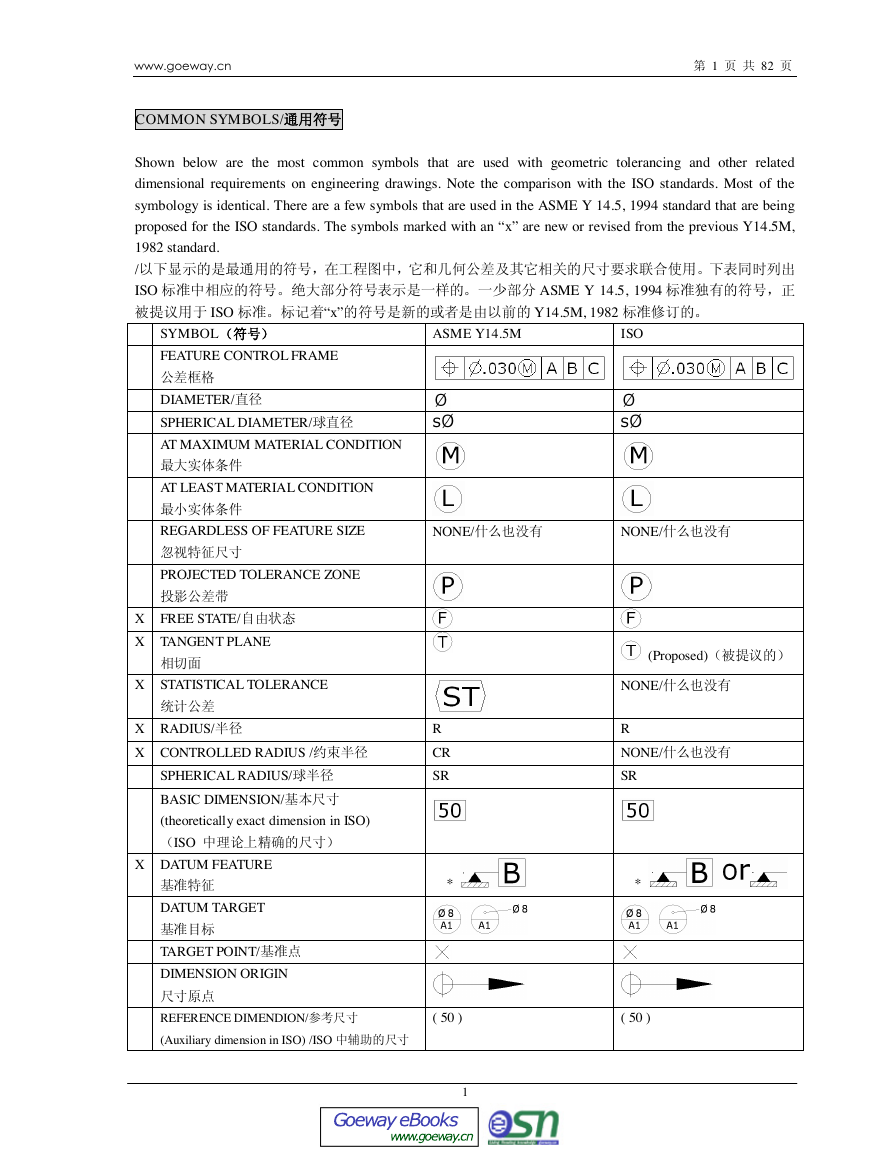

Shown below are the most common symbols that are used with geometric tolerancing and other related

dimensional requirements on engineering drawings. Note the comparison with the ISO standards. Most of the

symbology is identical. There are a few symbols that are used in the ASME Y 14.5, 1994 standard that are being

proposed for the ISO standards. The symbols marked with an “x” are new or revised from the previous Y14.5M,

1982 standard.

/

ISO ASME Y 14.5, 1994

ISO “x” Y14.5M, 1982

ASME Y14.5M

ISO

SYMBOL

FEATURE CONTROL FRAME

DIAMETER/

SPHERICAL DIAMETER/

AT MAXIMUM MATERIAL CONDITION

AT LEAST MATERIAL CONDITION

REGARDLESS OF FEATURE SIZE

PROJECTED TOLERANCE ZONE

NONE/

NONE/

X FREE STATE/

X TANGENT PLANE

X STATISTICAL TOLERANCE

X RADIUS/

X CONTROLLED RADIUS /

SPHERICAL RADIUS/

BASIC DIMENSION/

(theoretically exact dimension in ISO)

ISO

X DATUM FEATURE

DATUM TARGET

TARGET POINT/

DIMENSION ORIGIN

REFERENCE DIMENDION/

(Auxiliary dimension in ISO) /ISO

R

CR

SR

*

( 50 )

1

(Proposed)

NONE/

R

NONE/

SR

*

( 50 )

www.goeway.cnGoeway eBookswww.goeway.cn�

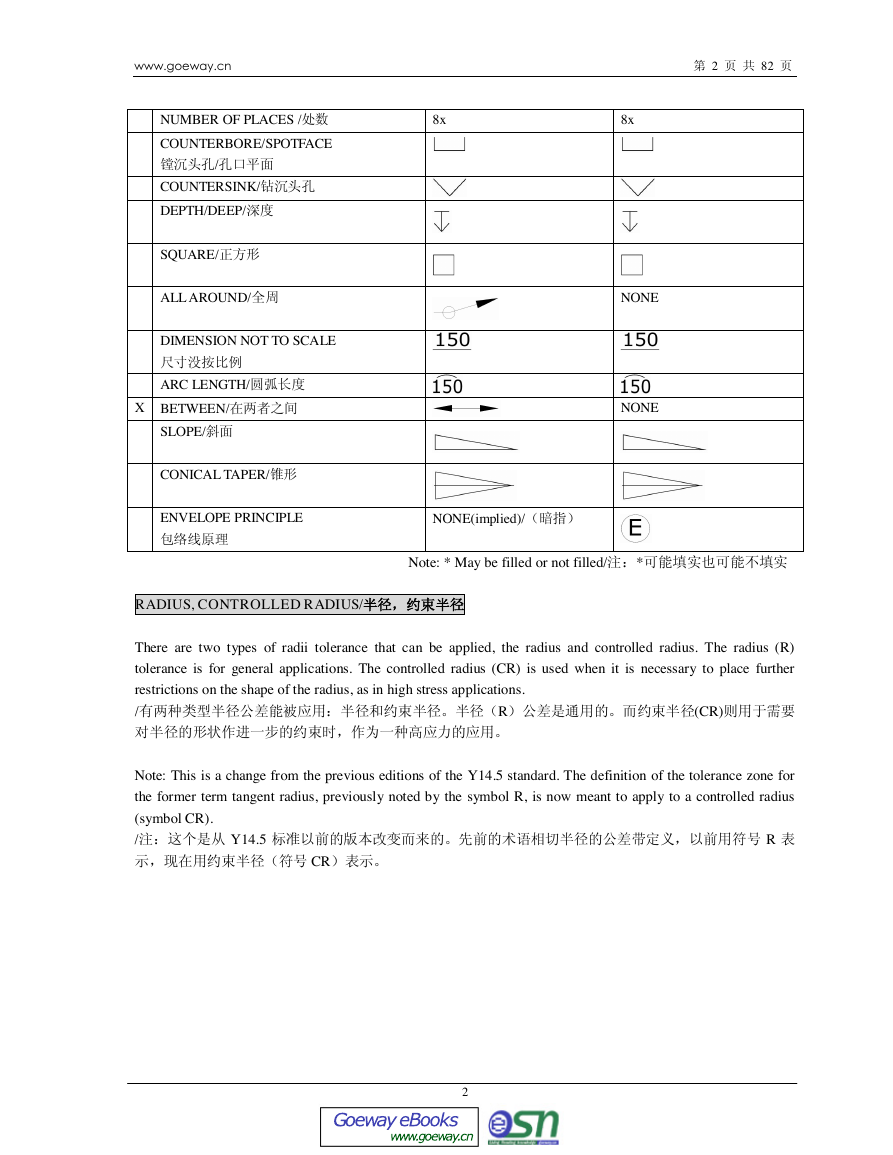

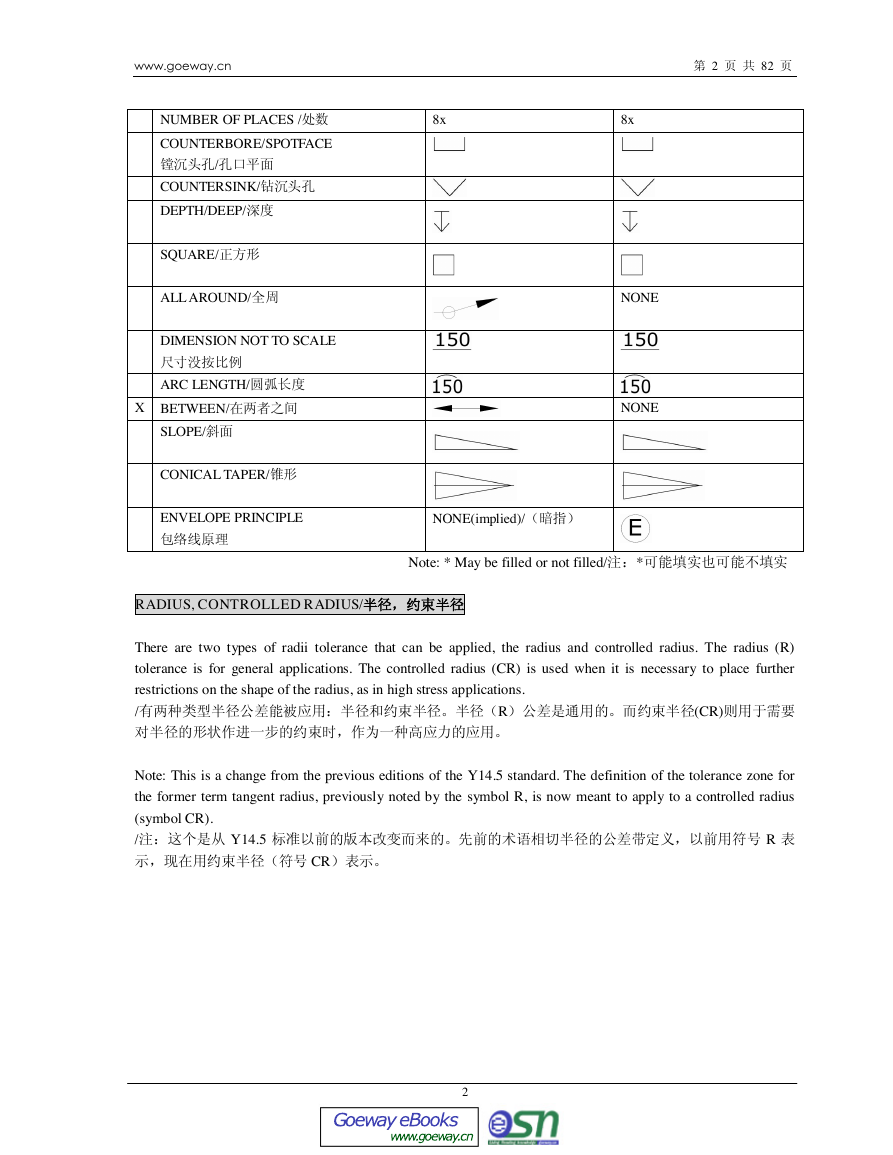

NUMBER OF PLACES /

COUNTERBORE/SPOTFACE

/

COUNTERSINK/

DEPTH/DEEP/

SQUARE/

ALL AROUND/

DIMENSION NOT TO SCALE

ARC LENGTH/

X BETWEEN/

SLOPE/

2 82

8x

8x

NONE

NONE

CONICAL TAPER/

ENVELOPE PRINCIPLE

NONE(implied)/

Note: * May be filled or not filled/*

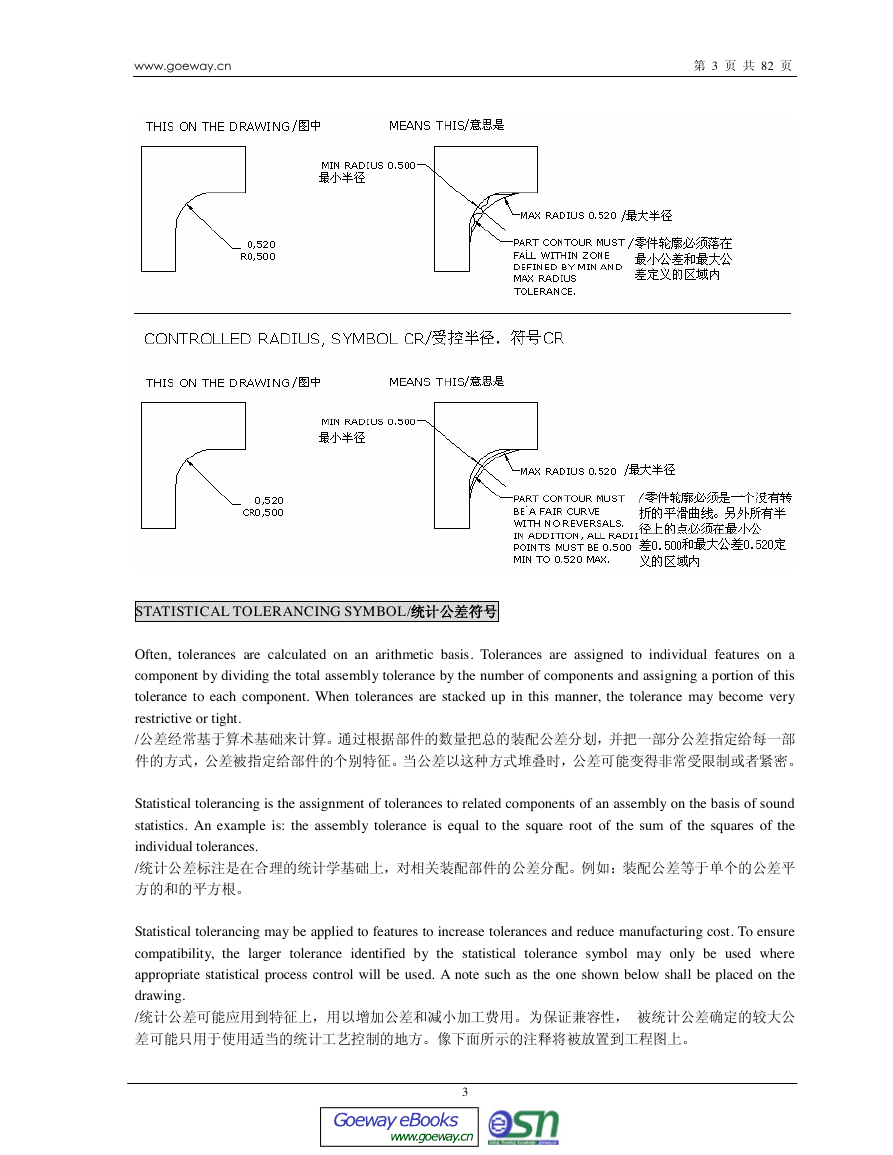

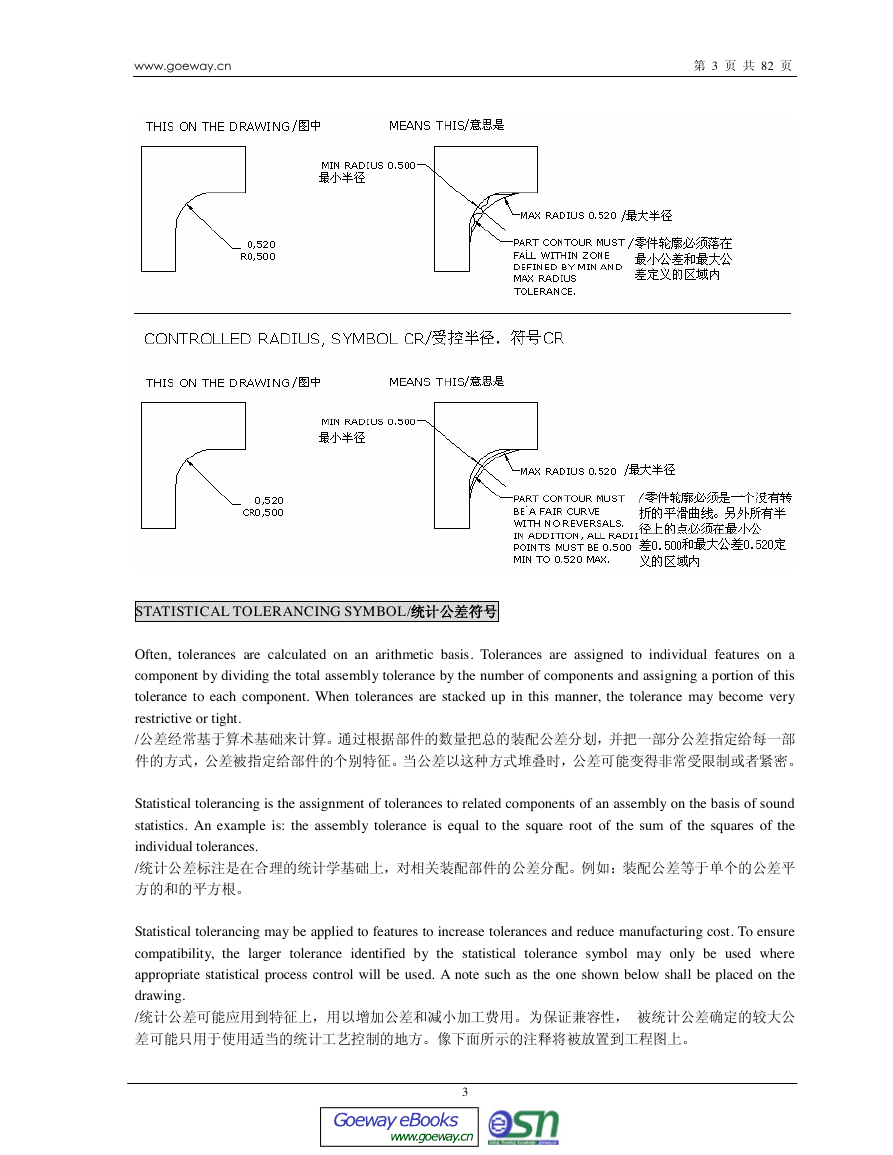

RADIUS, CONTROLLED RADIUS/

There are two types of radii tolerance that can be applied, the radius and controlled radius. The radius (R)

tolerance is for general applications. The controlled radius (CR) is used when it is necessary to place further

restrictions on the shape of the radius, as in high stress applications.

/R(CR)

Note: This is a change from the previous editions of the Y14.5 standard. The definition of the tolerance zone for

the former term tangent radius, previously noted by the symbol R, is now meant to apply to a controlled radius

(symbol CR).

/ Y14.5 R

CR

2

www.goeway.cnGoeway eBookswww.goeway.cn�

3 82

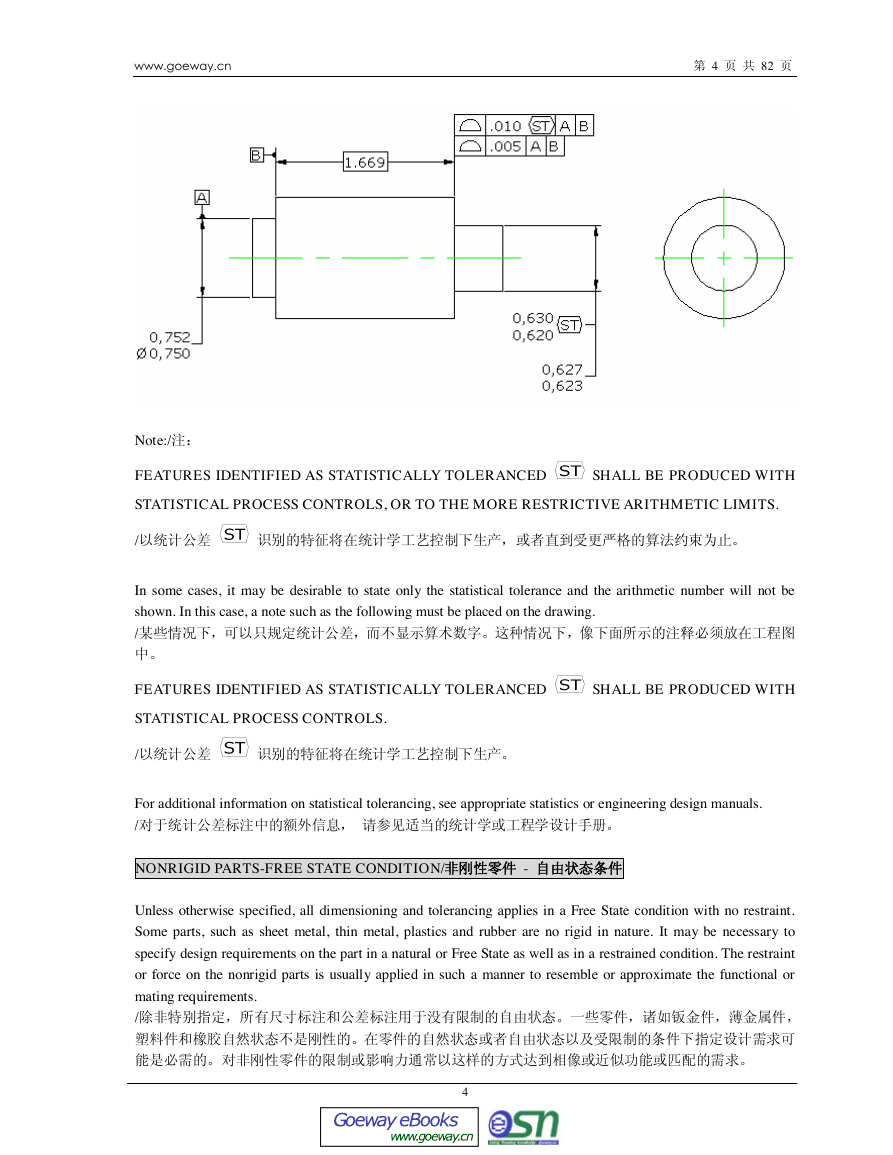

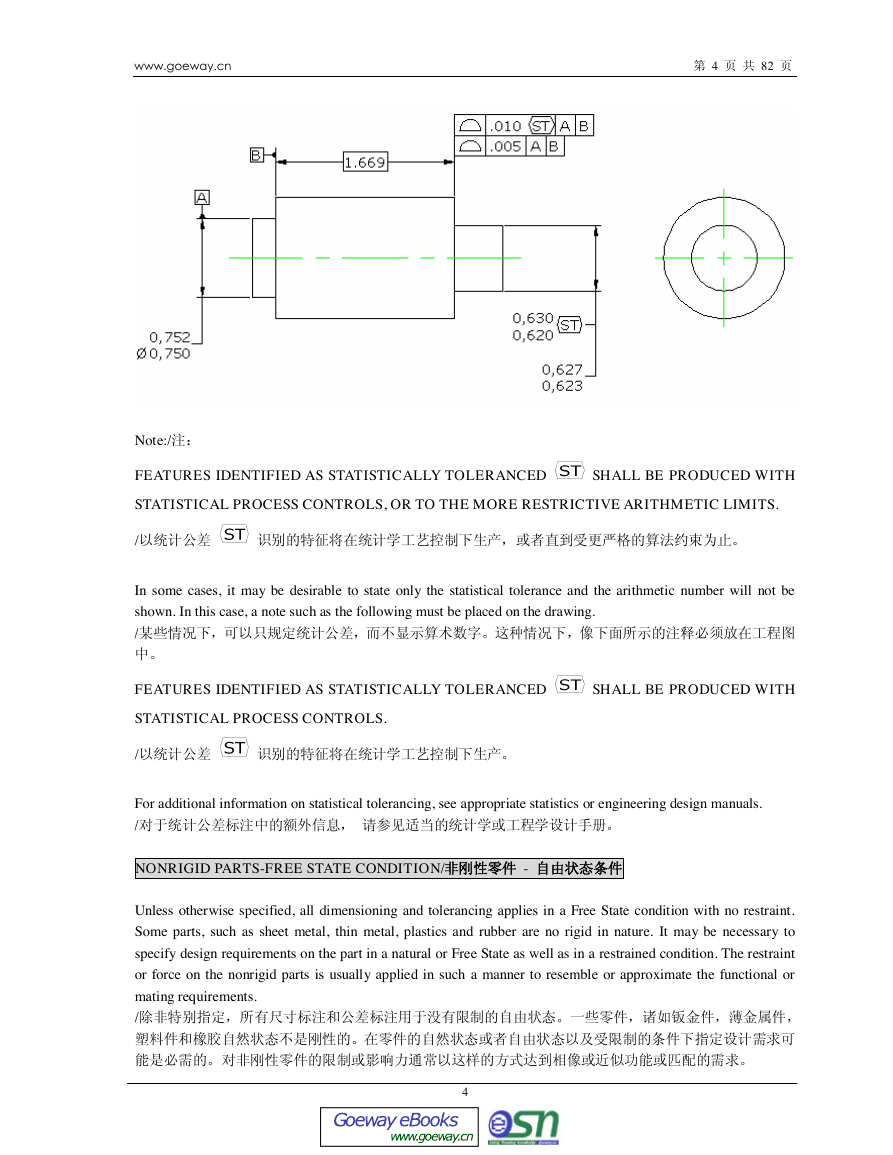

STATISTICAL TOLERANCING SYMBOL/

Often, tolerances are calculated on an arithmetic basis. Tolerances are assigned to individual features on a

component by dividing the total assembly tolerance by the number of components and assigning a portion of this

tolerance to each component. When tolerances are stacked up in this manner, the tolerance may become very

restrictive or tight.

/

Statistical tolerancing is the assignment of tolerances to related components of an assembly on the basis of sound

statistics. An example is: the assembly tolerance is equal to the square root of the sum of the squares of the

individual tolerances.

/

Statistical tolerancing may be applied to features to increase tolerances and reduce manufacturing cost. To ensure

compatibility, the larger tolerance identified by the statistical tolerance symbol may only be used where

appropriate statistical process control will be used. A note such as the one shown below shall be placed on the

drawing.

/

3

www.goeway.cnGoeway eBookswww.goeway.cn�

4 82

Note:/

FEATURES IDENTIFIED AS STATISTICALLY TOLERANCED

STATISTICAL PROCESS CONTROLS, OR TO THE MORE RESTRICTIVE ARITHMETIC LIMITS.

SHALL BE PRODUCED WITH

/

In some cases, it may be desirable to state only the statistical tolerance and the arithmetic number will not be

shown. In this case, a note such as the following must be placed on the drawing.

/

FEATURES IDENTIFIED AS STATISTICALLY TOLERANCED

STATISTICAL PROCESS CONTROLS.

/

SHALL BE PRODUCED WITH

For additional information on statistical tolerancing, see appropriate statistics or engineering design manuals.

/

NONRIGID PARTS-FREE STATE CONDITION/ -

Unless otherwise specified, all dimensioning and tolerancing applies in a Free State condition with no restraint.

Some parts, such as sheet metal, thin metal, plastics and rubber are no rigid in nature. It may be necessary to

specify design requirements on the part in a natural or Free State as well as in a restrained condition. The restraint

or force on the nonrigid parts is usually applied in such a manner to resemble or approximate the functional or

mating requirements.

/

4

www.goeway.cnGoeway eBookswww.goeway.cn�

5 82

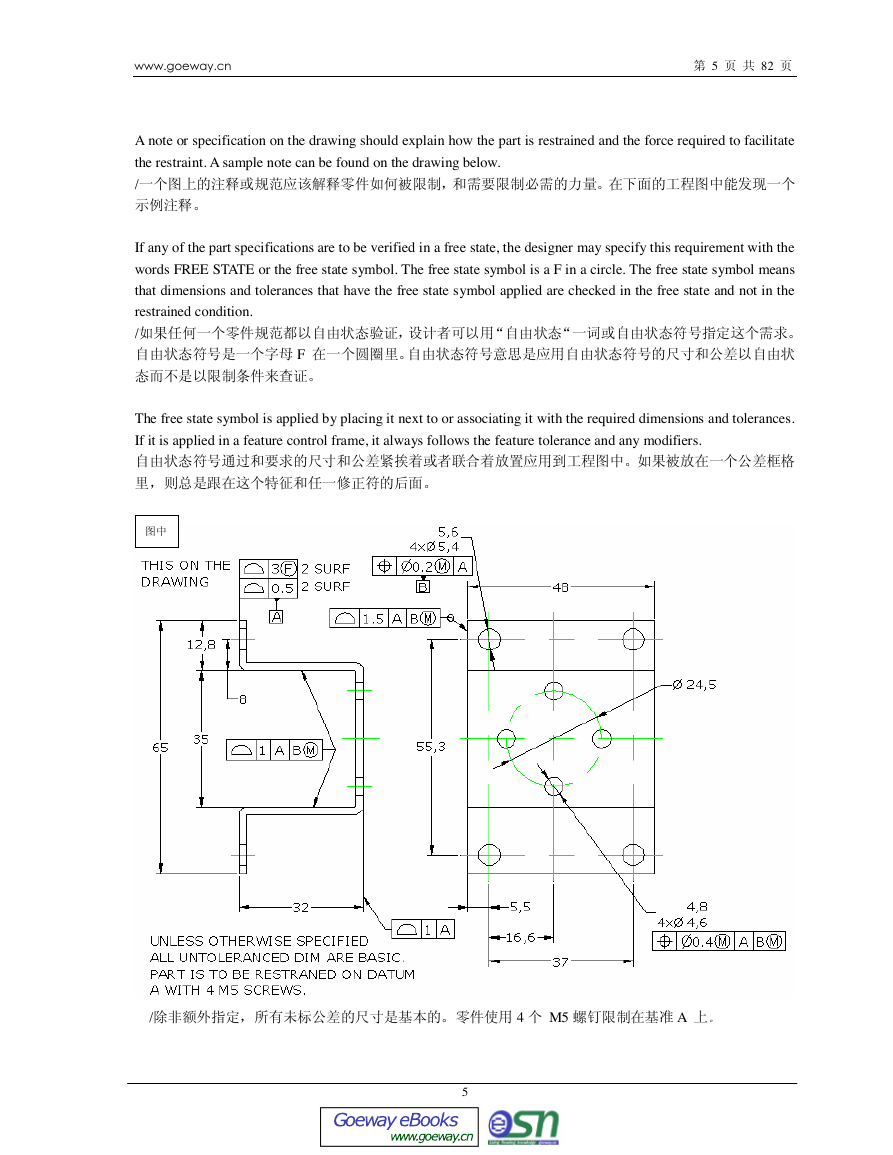

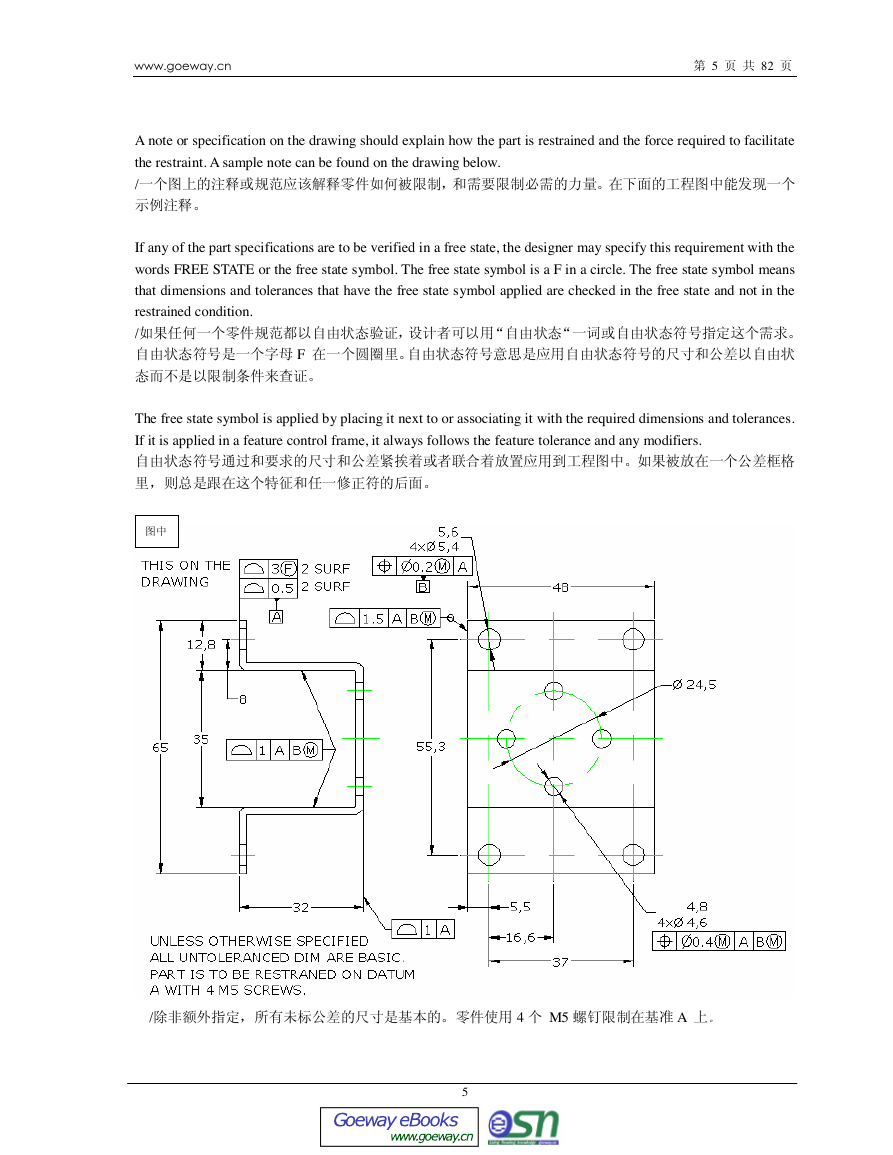

A note or specification on the drawing should explain how the part is restrained and the force required to facilitate

the restraint. A sample note can be found on the drawing below.

/

If any of the part specifications are to be verified in a free state, the designer may specify this requirement with the

words FREE STATE or the free state symbol. The free state symbol is a F in a circle. The free state symbol means

that dimensions and tolerances that have the free state symbol applied are checked in the free state and not in the

restrained condition.

/

F

The free state symbol is applied by placing it next to or associating it with the required dimensions and tolerances.

If it is applied in a feature control frame, it always follows the feature tolerance and any modifiers.

/ 4 M5 A

5

www.goeway.cnGoeway eBookswww.goeway.cn�

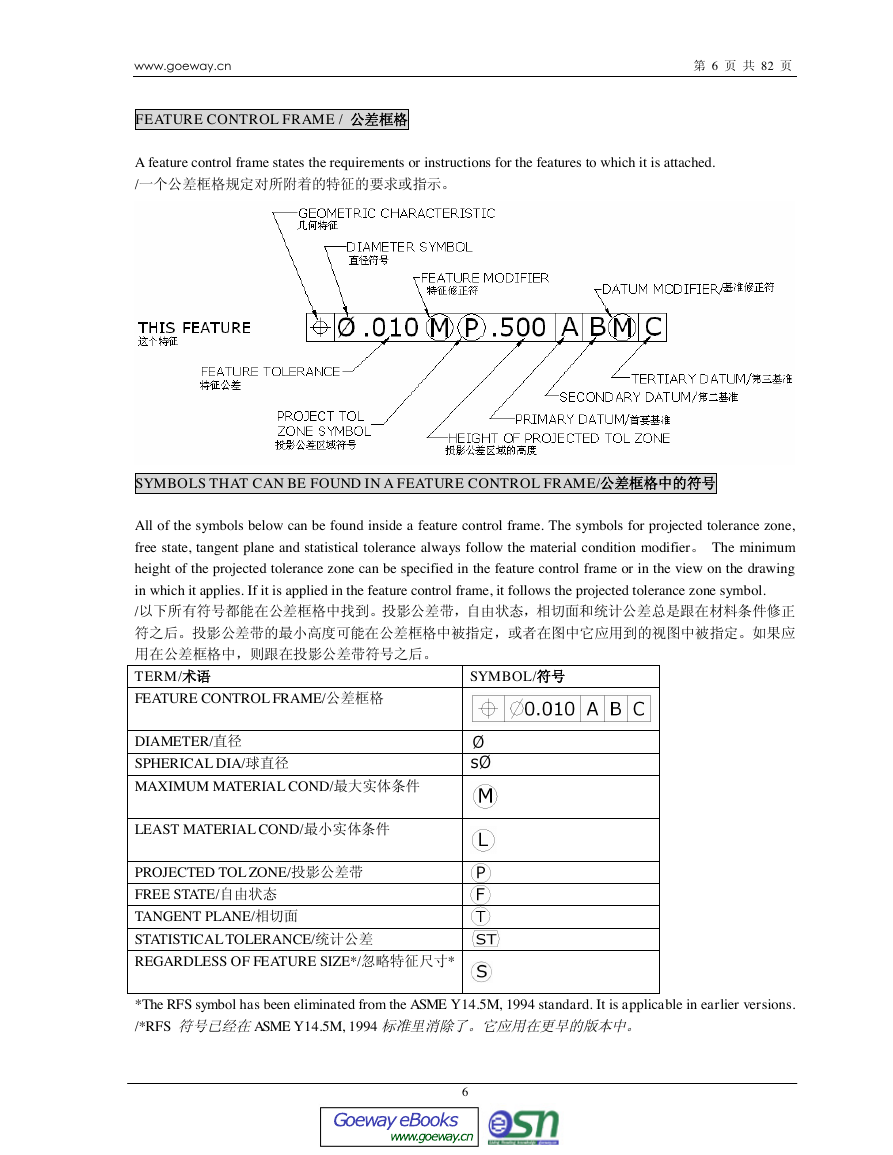

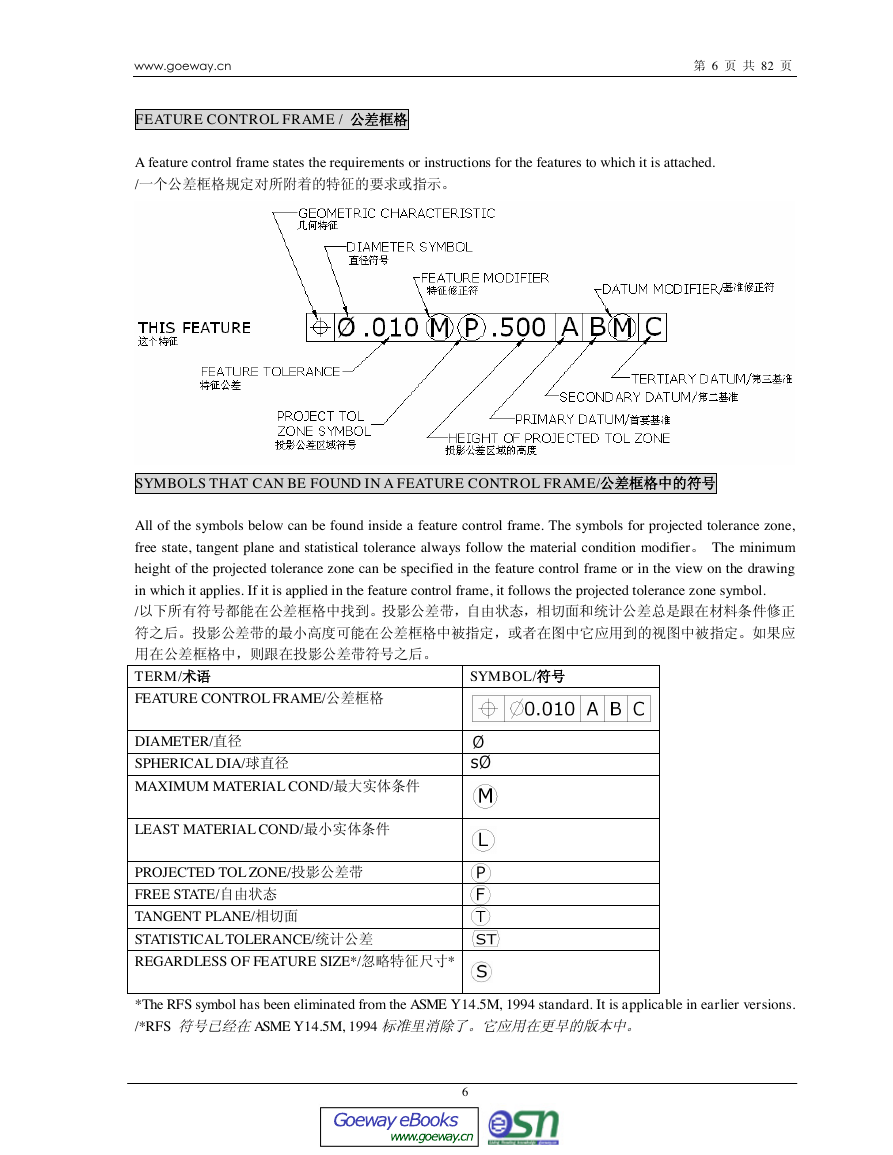

FEATURE CONTROL FRAME /

A feature control frame states the requirements or instructions for the features to which it is attached.

/

6 82

SYMBOLS THAT CAN BE FOUND IN A FEATURE CONTROL FRAME/

All of the symbols below can be found inside a feature control frame. The symbols for projected tolerance zone,

free state, tangent plane and statistical tolerance always follow the material condition modifier The minimum

height of the projected tolerance zone can be specified in the feature control frame or in the view on the drawing

in which it applies. If it is applied in the feature control frame, it follows the projected tolerance zone symbol.

/

TERM/

FEATURE CONTROL FRAME/

SYMBOL/

DIAMETER/

SPHERICAL DIA/

MAXIMUM MATERIAL COND/

LEAST MATERIAL COND/

PROJECTED TOL ZONE/

FREE STATE/

TANGENT PLANE/

STATISTICAL TOLERANCE/

REGARDLESS OF FEATURE SIZE*/*

*The RFS symbol has been eliminated from the ASME Y 14.5M, 1994 standard. It is applicable in earlier versions.

/*RFS ASME Y 14.5M, 1994

6

www.goeway.cnGoeway eBookswww.goeway.cn�

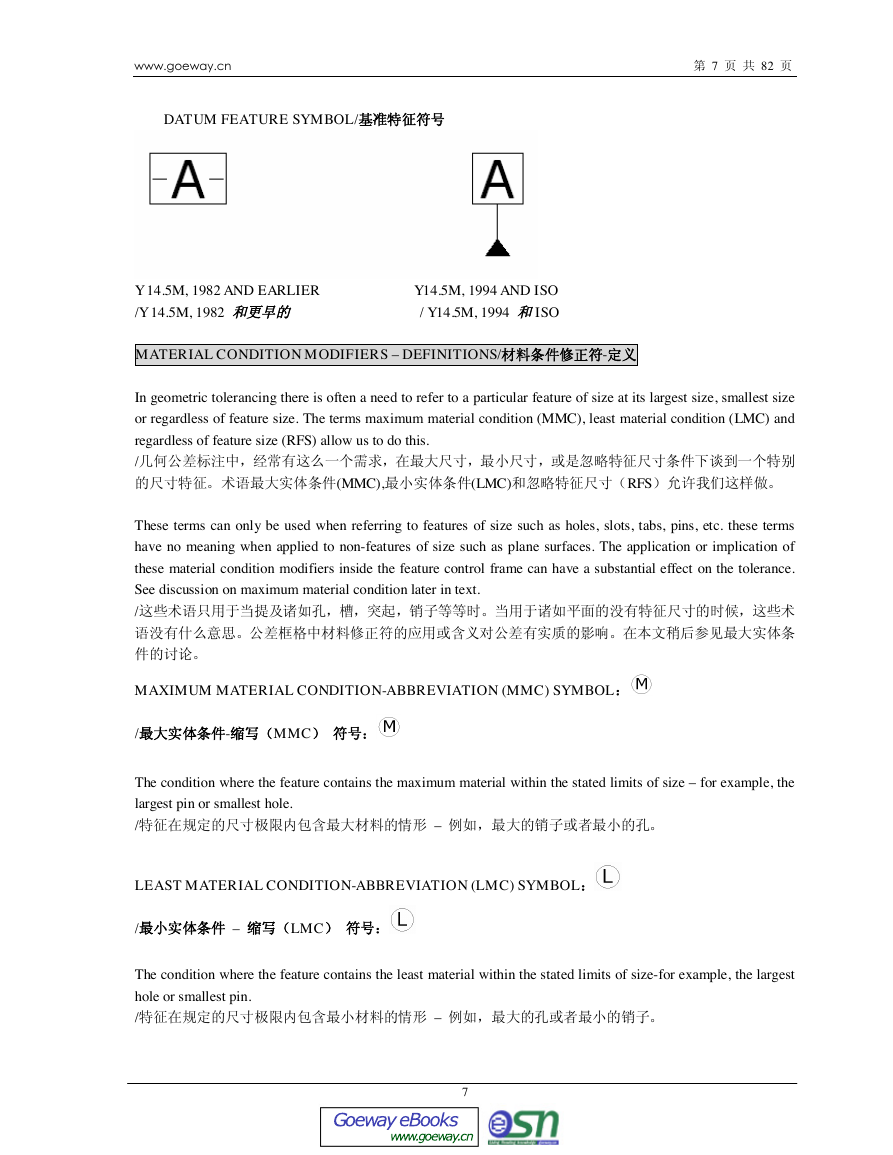

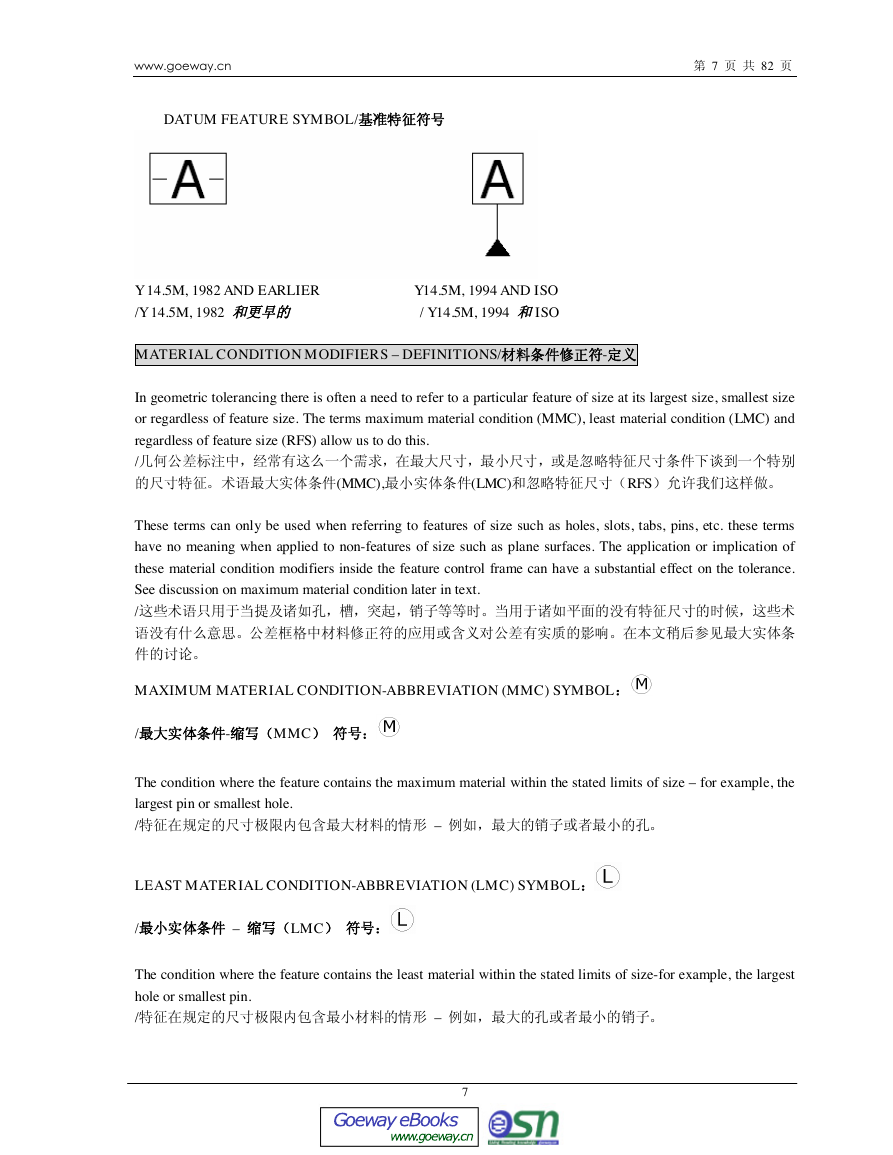

DATUM FEATURE SYMBOL/

7 82

Y 14.5M, 1982 AND EARLIER

/Y 14.5M, 1982

Y14.5M, 1994 AND ISO

/ Y14.5M, 1994 ISO

MATERIAL CONDITION MODIFIERS – DEFINITIONS/-

In geometric tolerancing there is often a need to refer to a particular feature of size at its largest size, smallest size

or regardless of feature size. The terms maximum material condition (MMC), least material condition (LMC) and

regardless of feature size (RFS) allow us to do this.

/

(MMC),(LMC)RFS

These terms can only be used when referring to features of size such as holes, slots, tabs, pins, etc. these terms

have no meaning when applied to non-features of size such as plane surfaces. The application or implication of

these material condition modifiers inside the feature control frame can have a substantial effect on the tolerance.

See discussion on maximum material condition later in text.

/

MAXIMUM MATERIAL CONDITION-ABBREVIATION (MMC) SYMBOL

/-MMC

The condition where the feature contains the maximum material within the stated limits of size – for example, the

largest pin or smallest hole.

/ –

LEAST MATERIAL CONDITION-ABBREVIATION (LMC) SYMBOL

/ – LMC

The condition where the feature contains the least material within the stated limits of size-for example, the largest

hole or smallest pin.

/ –

7

www.goeway.cnGoeway eBookswww.goeway.cn�

8 82

REGARDLESS OF FEATURE SIZE-ABBREVIATION (RFS)/ – RFS

The term used to indicate that a geometric tolerance applies at any increment of size of the feature within its size

limits. /

In the current ASME Y 14.5M, 1994 standard there is no symbol for RFS. (Unless otherwise specified all

geometric tolerances are implied RFS. See rule 2.) In previous editions of the Y14.5 standard the

was used for RFS.

/ ASME Y 14.5M, 1994 RFS RFS

symbol

2 Y14.5 RFS

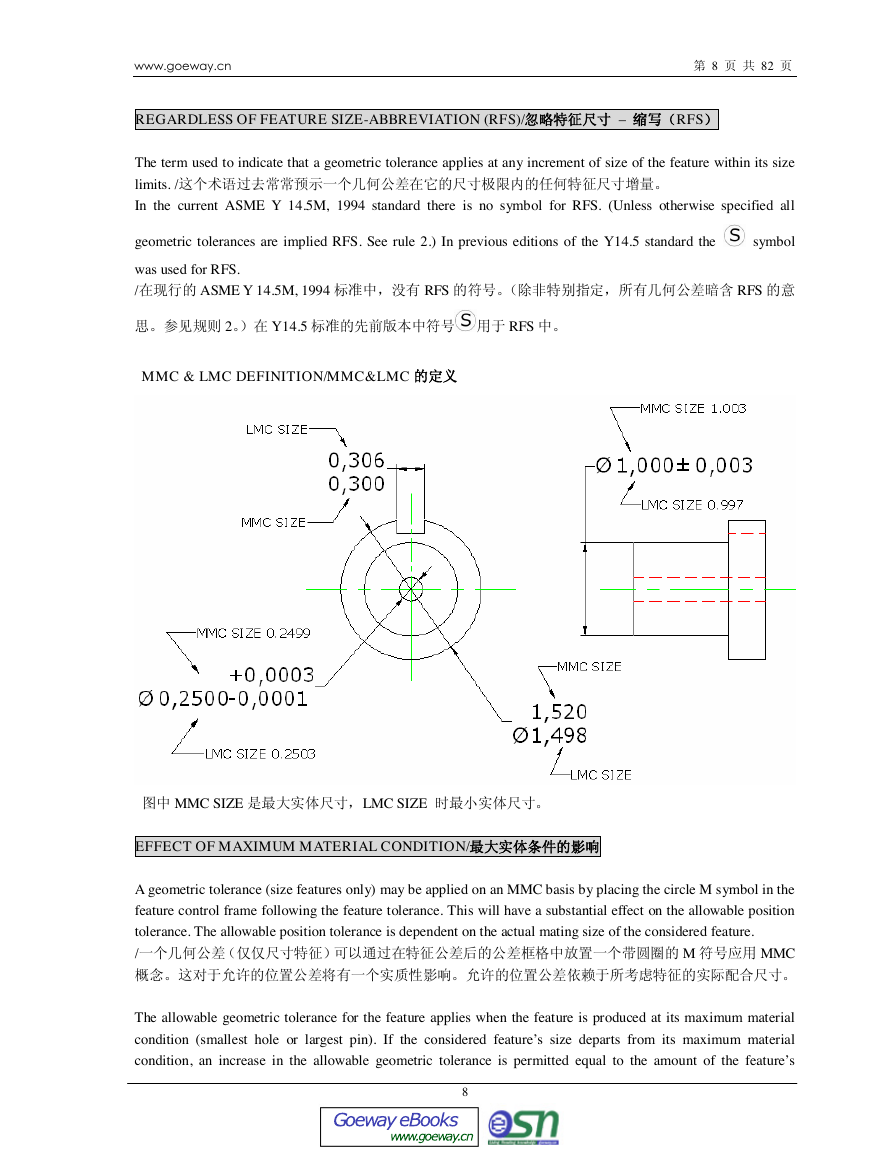

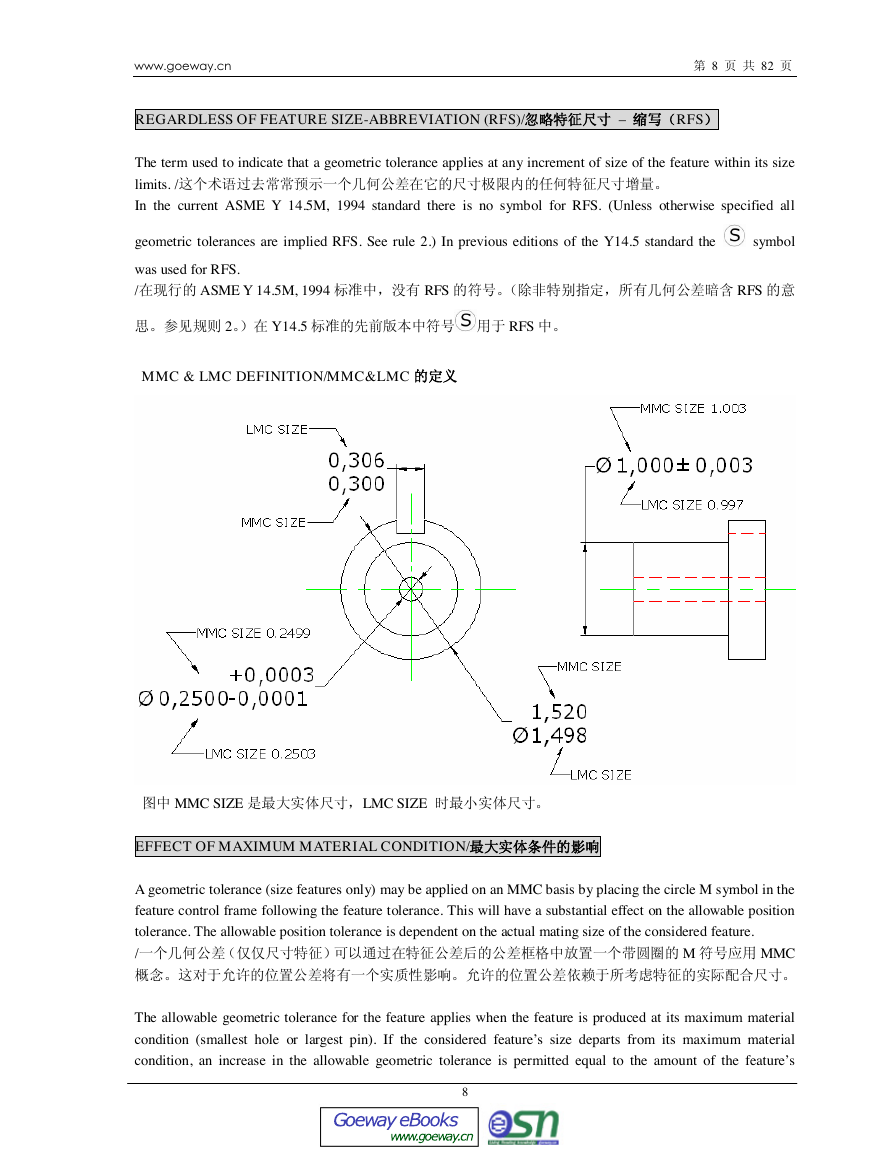

MMC & LMC DEFINITION/MMC&LMC

MMC SIZE LMC SIZE

EFFECT OF MAXIMUM MATERIAL CONDITION/

A geometric tolerance (size features only) may be applied on an MMC basis by placing the circle M symbol in the

feature control frame following the feature tolerance. This will have a substantial effect on the allowable position

tolerance. The allowable position tolerance is dependent on the actual mating size of the considered feature.

/ M MMC

The allowable geometric tolerance for the feature applies when the feature is produced at its maximum material

condition (smallest hole or largest pin). If the considered feature’s size departs from its maximum material

condition, an increase in the allowable geometric tolerance is permitted equal to the amount of the feature’s

8

www.goeway.cnGoeway eBookswww.goeway.cn�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc