Zhang et al. Robot. Biomim. (2018) 5:3

https://doi.org/10.1186/s40638-018-0085-7

RESEARCH

A 6-DOF robot-time optimal trajectory

planning based on an improved genetic

algorithm

Jiayan Zhang, Qingxi Meng*

, Xugang Feng and Hao Shen

Open Access

Abstract

By using quintic polynomial function to interpolate several given points of each joint of the robot, the mathematical

expressions of each joint variable of the robot with time are established. In addition, to improve the search algo-

rithm performance crossover operator and mutation operator of the genetic algorithm are improved in cosine form.

Furthermore, the improved adaptive genetic algorithm is applied to optimize the time interval of interpolation points

of each joint, so as to realize time optimal trajectory planning. Moreover, MATLAB simulation is carried out, and the

results show that the method proposed in this paper reduces the running time of the robot tasks. Meanwhile, the

curves of angle position, velocity and acceleration of each joint are smooth enough, which ensure accomplish its

tasks in a stable and efficient way.

Keywords: Industrial robot, Trajectory planning, Adaptive genetic algorithm (AGA), Time optimal

Background

Robot trajectory planning usually refers to track points

given several expectations and target pose, and timely

adjust the rotation angle of each joint of the robot to the

end effector at a prescribed trajectory followed by each

point to eventually reach the target point. The trajectory

planning in joint space is simpler and convenient than

that of Cartesian space. Therefore, several fixed points

which located at the end of several robotic arms are usu-

ally given. Then, these track points for the robot are com-

puted by using the inverse kinematics so as to convert it

from Cartesian space to joint coordinate space. Next, the

track points are used to carry out interpolation opera-

tion using various spline functions, polynomial functions

or other forms of curves, and the expressions about the

time of each joint variable for the robot are obtained. In

addition, in light of the mechanical characteristics of the

robot, the speed and acceleration of each joint should be

limited to the allowable range. Therefore, it is necessary

to optimize the speed and acceleration of each joint arm,

*Correspondence: mqx3021@qq.com

College of Electrical Engineering and Information, Anhui University

of Technology, Ma’anshan 243002, China

not only to ensure the smooth operation of the joint arm

but also to reduce the wear and impact to prolong the

working life of the robot.

The method of optimal trajectory planning generally

includes time optimal trajectory planning [1–3], energy

minimum trajectory planning [3, 4] and impact mini-

mum trajectory planning [5], or multi-objective trajec-

tory optimization combining these estimation schemes.

Among them, the optimal trajectory planning with the

robot running time as main consideration is favored by

many scholars. In recent years, many researchers have

made some achievements in the field of robot trajectory

planning. Tohfeh and Fakharian [6] constructed a func-

tion expression for the omnidirectional robot’s energy

dissipation by combining obstacle avoidance perfor-

mance, and the optimization problem was transformed

into a parameter minimization problem by the poly-

nomial interpolation method, which provided a more

effective way for the study of robot obstacle avoidance.

However, due to the complexity of this method, there is a

certain degree of difficulty in practice. Bende [7] studied

a method of modeling underwater robot based on bond

graph theory and optimized the model parameters with

the genetic algorithm to obtain the optimized trajectory

© The Author(s) 2018. This article is distributed under the terms of the Creative Commons Attribution 4.0 International License

(http://creat iveco mmons .org/licen ses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium,

provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license,

and indicate if changes were made.

�

Zhang et al. Robot. Biomim. (2018) 5:3

Page 2 of 7

of the robot. Experiments were carried to show the sig-

nificance of this method. Zhu and Liu [8] applied the

seventh-order B-spline curve for the interpolation opera-

tion of robot’s articulation arm trajectory and applied

the sequential quadratic programming for the trajectory

planning, which achieved the optimal planning goal and

the angular displacement, velocity and acceleration curve

of each joint of the robot are smoother.

In this paper, from the point of view of robot run-

ning time, the trajectory of robot joint is planned by the

quintic polynomial interpolation under the premise of

smooth operation of the manipulator, and the time inter-

val of trajectory interpolation point is optimized by the

improved adaptive genetic algorithm, so that the robot

accomplishes task time as short as possible.

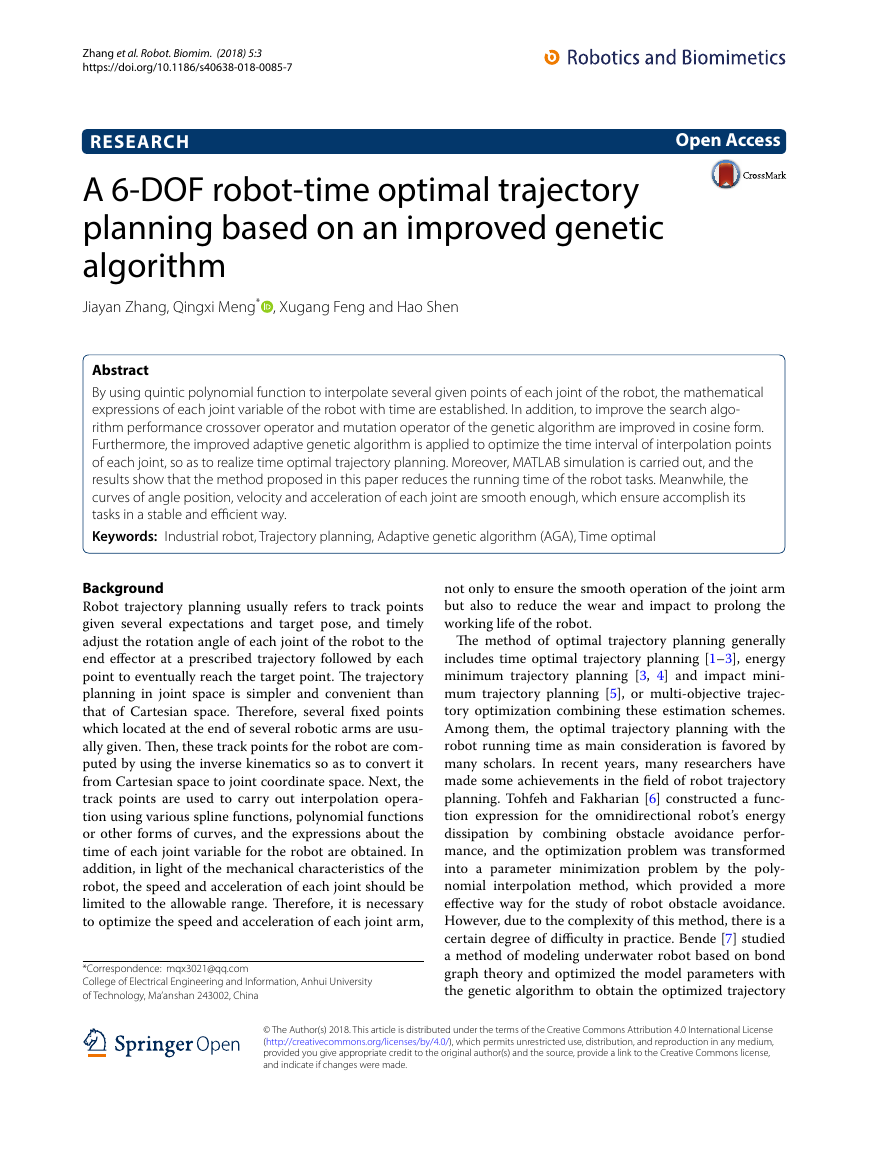

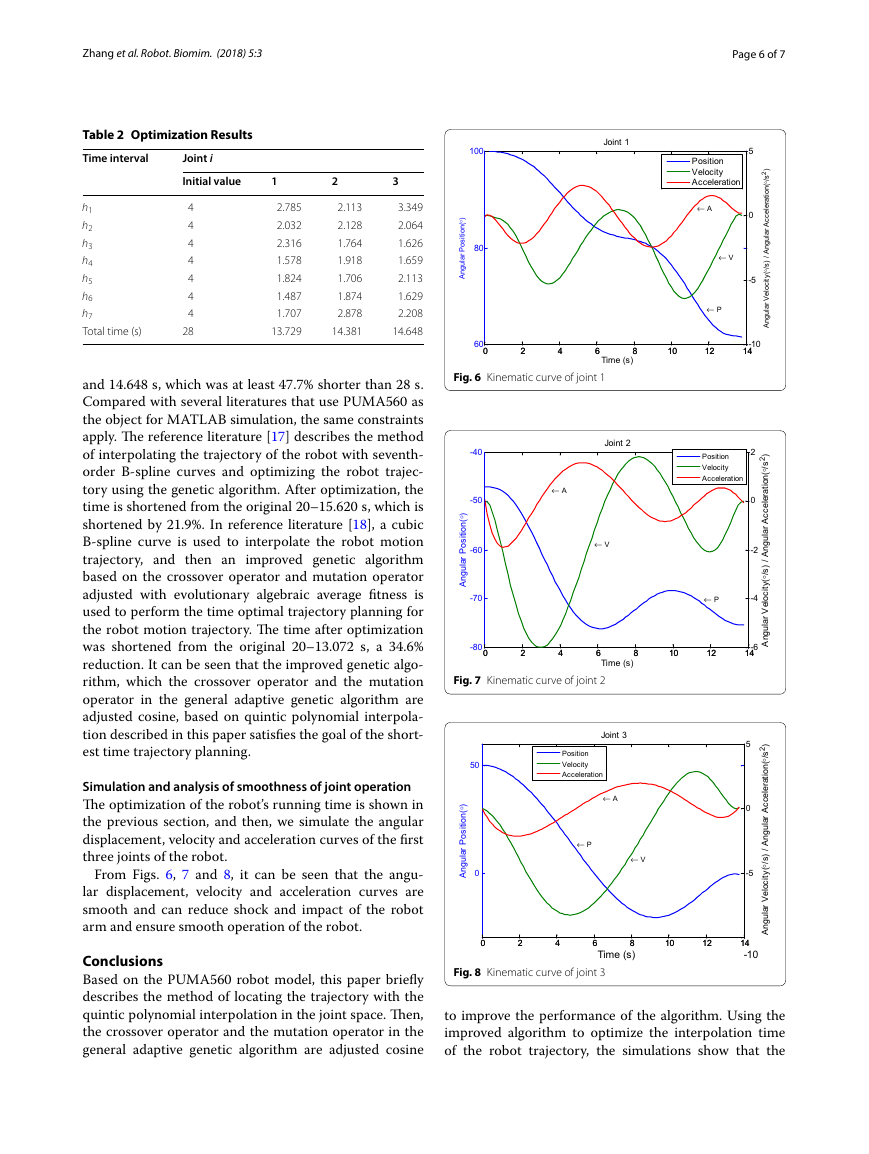

Model

In this paper, we consider PUMA560 robot as the

research object, which belongs to a conventional six-

arm-type robot. Its first three joints are used to deter-

mine the position of the robot end effector, and the latter

three joints are used to determine its attitude. In order

to make it easier to analyze the motion of articulation

arm of the robot, it is necessary to establish the kinematic

equation of the robot. The link pole coordinate system is

established by D-H method, and through the translation,

rotation and other coordinate transformation to establish

the relationship between the coordinate system. The link

pole coordinate system is shown in Fig. 1.

0T1 =

2T3 =

4T5 =

1T2 =

3T4 =

5T6 =

cθ4 −sθ4 0 a3

1 d4

0

−sθ4 −cθ4 0 0

0 1

cθ2 −sθ2 0 0

1 d2

0

−sθ2 −cθ1 0 0

0 1

cθ6 −sθ6 0 0

0

1 0

−sθ6 −cθ6 0 0

0 1

cθ5 −sθ5 0 0

0 −1 0

0

sθ5

cθ5

0 0

0

0

0 1

cθ3 −sθ3 0 a2

cθ3 0 0

sθ3

1 0

0

0

0

0

0 1

cθ1 −sθ1 0 0

cθ1 0 0

sθ1

1 0

0

0

0

0

0 1

0

0

0

0

0

0

0

0

0

(1)

z0 (z1)

�1

x0

d2

z2

a2

x3

�2

x2

a3

y0 (x1)

6

6

0

.

4

�3

�4

d4

z3

x4 (x5)(x6)

z5

�5

z4 (z6)

o(y)

56.25

�6

n(x)

a(z)

Fig. 1 The link pole coordinate system of PUMA560 robot according

to the link pole coordinate system of Fig. 1, the transformation matrix

of each link can be obtained as follows

nx ox ax

ny oy ay

nz oz az

the posture of the end effector relative to the base system

where the third-order sub-matrix

represents

represents its position relative to the base

{0}, and

px

py

pz

system {0}.

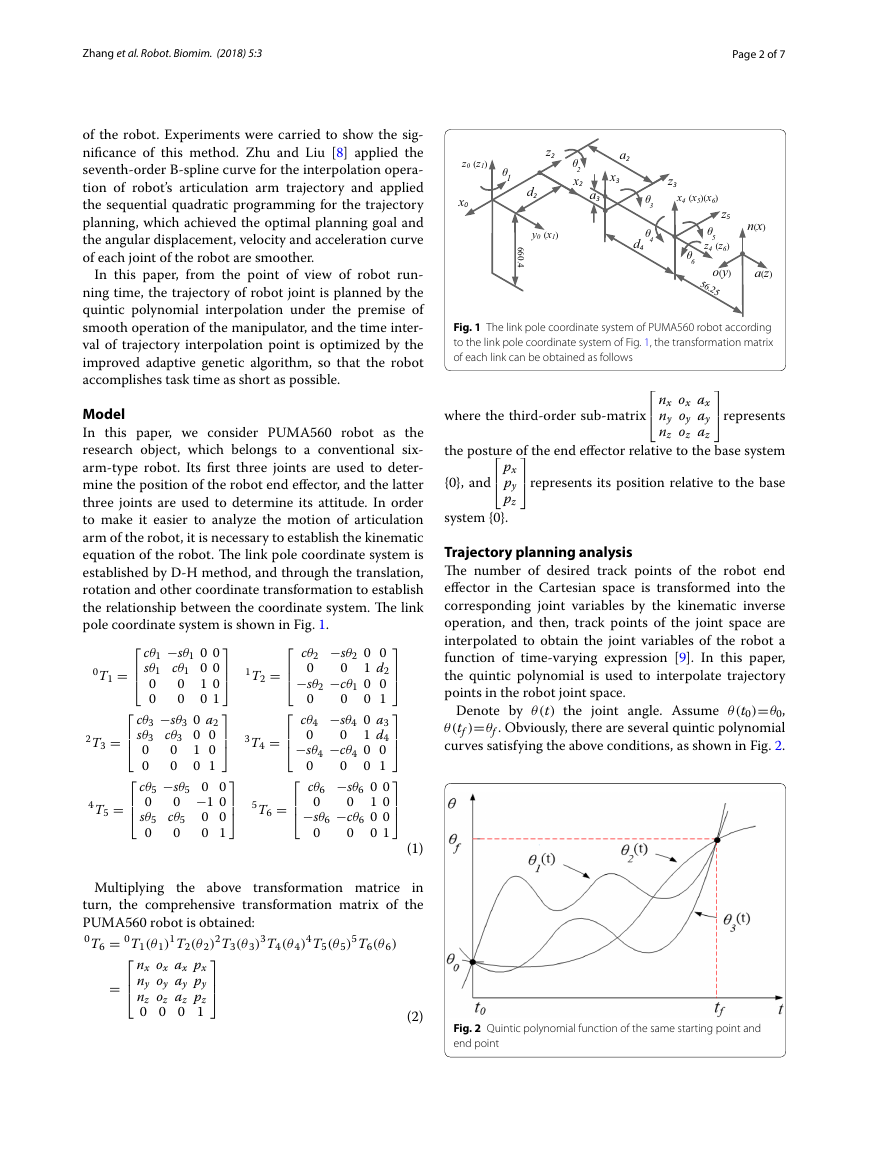

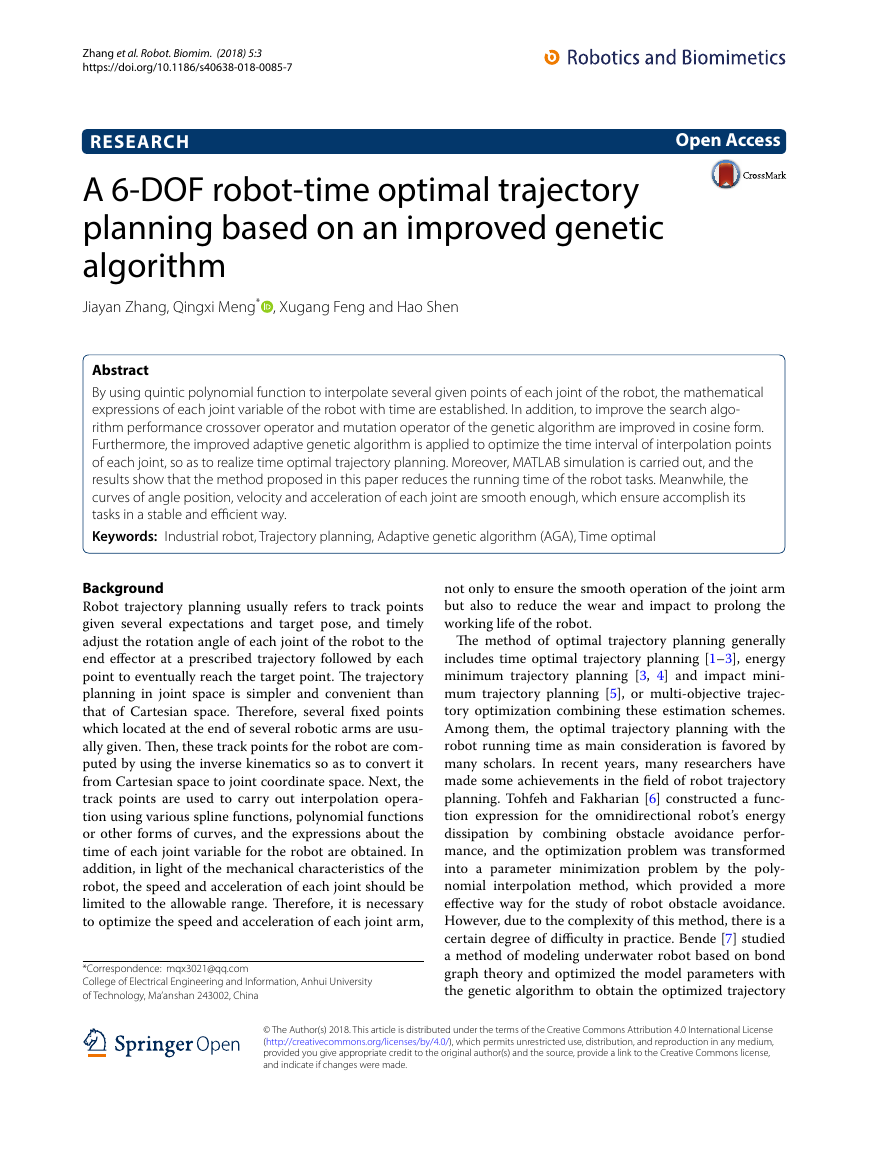

Trajectory planning analysis

The number of desired track points of the robot end

effector in the Cartesian space is transformed into the

corresponding joint variables by the kinematic inverse

operation, and then, track points of the joint space are

interpolated to obtain the joint variables of the robot a

function of time-varying expression [9]. In this paper,

the quintic polynomial is used to interpolate trajectory

points in the robot joint space.

Denote by θ (t) the joint angle. Assume θ (t0) = θ0 ,

θ (tf ) = θf . Obviously, there are several quintic polynomial

curves satisfying the above conditions, as shown in Fig. 2.

Multiplying the above transformation matrice

in

turn, the comprehensive transformation matrix of the

PUMA560 robot is obtained:

0T6 = 0T1(θ 1)1T2(θ 2)2T3(θ 3)3T4(θ 4)4T5(θ 5)5T6(θ 6)

nx ox ax px

ny oy ay py

nz oz az pz

0 0 0 1

=

(2)

Fig. 2 Quintic polynomial function of the same starting point and

end point

�

Zhang et al. Robot. Biomim. (2018) 5:3

Page 3 of 7

It is now necessary to find a smooth curve with starting

point θ0 and ending point θf . In addition, the expression

of the quintic polynomial is:

θ (t) = a0 + a1t + a2t2 + a3t3 + a4t4 + a5t5

(3)

At the start and the end points, the displacement con-

straint, speed constraint and acceleration constraint are

expressed in (4)–(6), respectively:

θ (tf ) = θf

θ (0) = θ0

θ ′(0) = θ ′

θ ′′(0) = θ ′′

0

θ ′(tf ) = θ ′

f

0

θ ′′(tf ) = θ ′′

f

(4)

(5)

(6)

Deriving Eq. (3), the velocity expression of the robot’s

trajectory is obtained as:

θ ′(t) = a1 + 2a2t + 3a3t2 + 4a4t3 + 5a5t4

(7)

Similarly, by means of the second derivative of t in

formula Eq. (6), we can get the acceleration function as

follows:

θ ′′(t) = 2a2 + 6a3t + 12a4t2 + 20a5t3

(8)

Combining Eqs. (4), (5) and (6), we obtain the coeffi-

cients of the quintic polynomial as follows:

a0 = θ0

a1 = θ ′

0

θ ′′

0

a2 =

2

20θf −20θ0−(12θ ′

a3 =

a4 =

a5 =

)tf −(3θ ′′

0 −θ ′′

f

)t2

f

0+8θ ′

f

2t3

f

0+14θ ′

f

30θf −30θ0+(16θ ′

)tf +(3θ ′′

0 −2θ ′′

f

)t2

f

12θf −12θ0−(6θ ′

)tf −(θ ′′

0 −θ ′′

f

)t2

f

2t4

f

0+6θ ′

f

2t5

f

(9)

Introducing the above factors into Eq. (3), the robot

trajectory equation of the quintic polynomial can be

derived.

Improvement in genetic algorithm

The basic knowledge of the kinematics of the robot and

the basic principle of the interpolation of the trajec-

tory points of the joint space by the quintic polynomial

have been introduced in the preceding narrative. On

this basis, it is necessary to optimize the time interval

of the interpolation point of the track point by using the

genetic algorithm to realize the optimal planning of the

robot time and further make the angular displacement,

velocity and acceleration curve of each joint movement

smoother.

The genetic algorithm, which is an artificial intelligence

optimization algorithm for simulating the genetic and

evolutionary processes in nature [10–12], owns the char-

acteristics of simplicity and robustness, and starts from

the parallel solution of the problem (rather than a single

solution). Therefore, it not only has excellent global opti-

mization but also is used in the optimization process of

practical problems [13].

However, the crossover operator and mutation opera-

tor of a simple genetic algorithm are invariant in the pro-

cess of algorithm implementation and do not satisfy the

dynamic requirement of biological evolution. To this end,

Ren and San [14] proposed an adaptive genetic algorithm

according to the individual fitness of different dynamic

adjustment of crossover probability and mutation prob-

ability. The adjustment of the crossover and mutation

probabilities is shown in Eqs. (10) and (11), respectively:

pc = pc1 −

pc1,

(pc1−pc2)(f ′−favg)

fmax −favg

, f ′ ≥ favg

f ′ < favg

pm = pm1 −

pm1,

(pm1−pm2)(f ′−favg)

fmax −favg

, f ≥ favg

f ′ < favg

(10)

(11)

where pc1 = 0.9 , pc2 = 0.6 , pm1 = 0.1 , pm2 = 0.01 f ′ is

the parent of the larger fitness value; favg is the average

fitness value in the population; fmax is the fitness value of

the largest individual in the current population.

Equation (10) shows that a larger fixed crossover prob-

ability is given when the fitness value of the cross parent

is small. And the greater the fitness of the two chro-

mosomes, the smaller the crossover probability is. The

adjustment of the mutation probability in Eq. (11) is con-

sistent with the crossover probability.

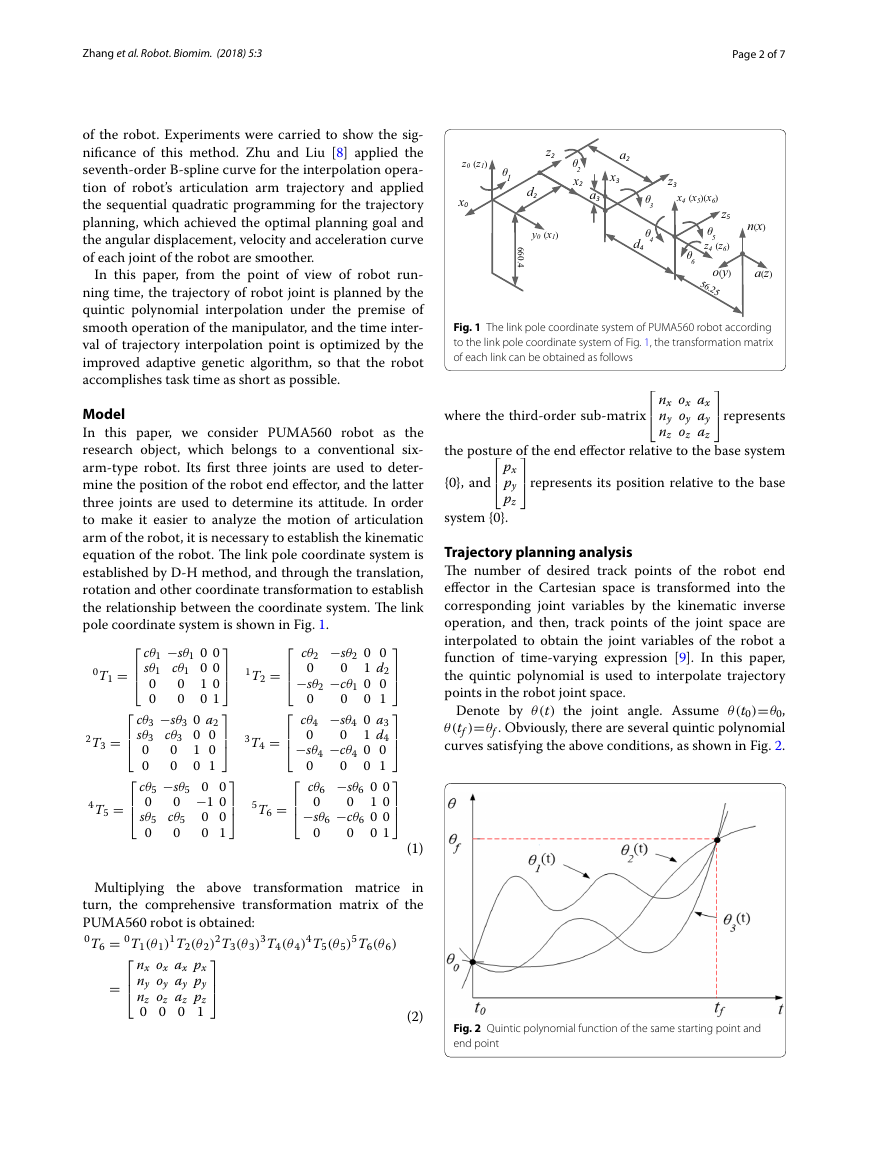

It is noted that the above method has two drawbacks.

Firstly, the crossover probability and the mutation prob-

ability are fixed for the parent chromosomes whose fit-

ness is lower than the average fitness of the population.

Secondly, the adjustment of crossover and mutation

probability is linear, and it can not meet the objective of

population evolution. To overcome the two drawbacks,

this paper presents an adaptive genetic algorithm that

uses a cosine function to adjust crossover probability

and mutation probability. Adjusting Eqs. (10) and (11) as

follows:

pc0+pc min

2

pc0+pc max

2

pc =

+ pc0−pc min

+ pc0−pc max

2

2

fmax −favg

π�, f ≥ favg

cos� f −favg

cos� favg−f

π�,

f < favg

favg

(12)

�

Zhang et al. Robot. Biomim. (2018) 5:3

Page 4 of 7

Fig. 4 Mutation probability adjustment curve of IAGA

T = T1 + T2 + · · · +T i−1 =

Pcmax

Pc0

Pcmin

Fmin

F0

Fmax

Fig. 3 Crossover probability adjustment curve of IAGA

Pmmax

Pm0

Pmmin

Fmin

F0

Fmax

pm =

pm0+pm min

2

pm0+pm max

2

+ pm0−pm min

2

+ pm0−pm max

2

fmax −favg

cos� f ′−favg

π�, f ′ ≥ favg

cos� favg−f ′

π�,

f ′ < favg

favg

(13)

where pc min and Pc max are the minimum and the maxi-

mum probability, respectively. pc min ≤ pc0 ≤ pc max is

a crossover probability; pm min and pm max denote the

smallest and largest mutation probabilities, respectively,

and pc min ≤ pm0 ≤ pc max is a mutation probabilities;

fmax is the fitness of the best individual in the population

and favg is the average fitness; f is the greater fitness of

crossed parent; f ′ is the fitness of the individual perform-

ing the mutation.

For the crossover probability adjustment method in

Eq. (12), pc0 represents a crossover probability for the

average fitness of the population, and the size of pc0 can

be determined based on the required problem and the

algorithm optimization process. If pc0 is larger, it means

raising the crossover probability of the individual in the

population and promoting the change in the individual

gene pattern from a wide range. If x is small, the oppo-

site is true. Therefore, in order to improve the optimiza-

tion performance of the algorithm, we need to adjust the

value of pc0 to balance the global optimization ability and

local optimization ability of the algorithm.

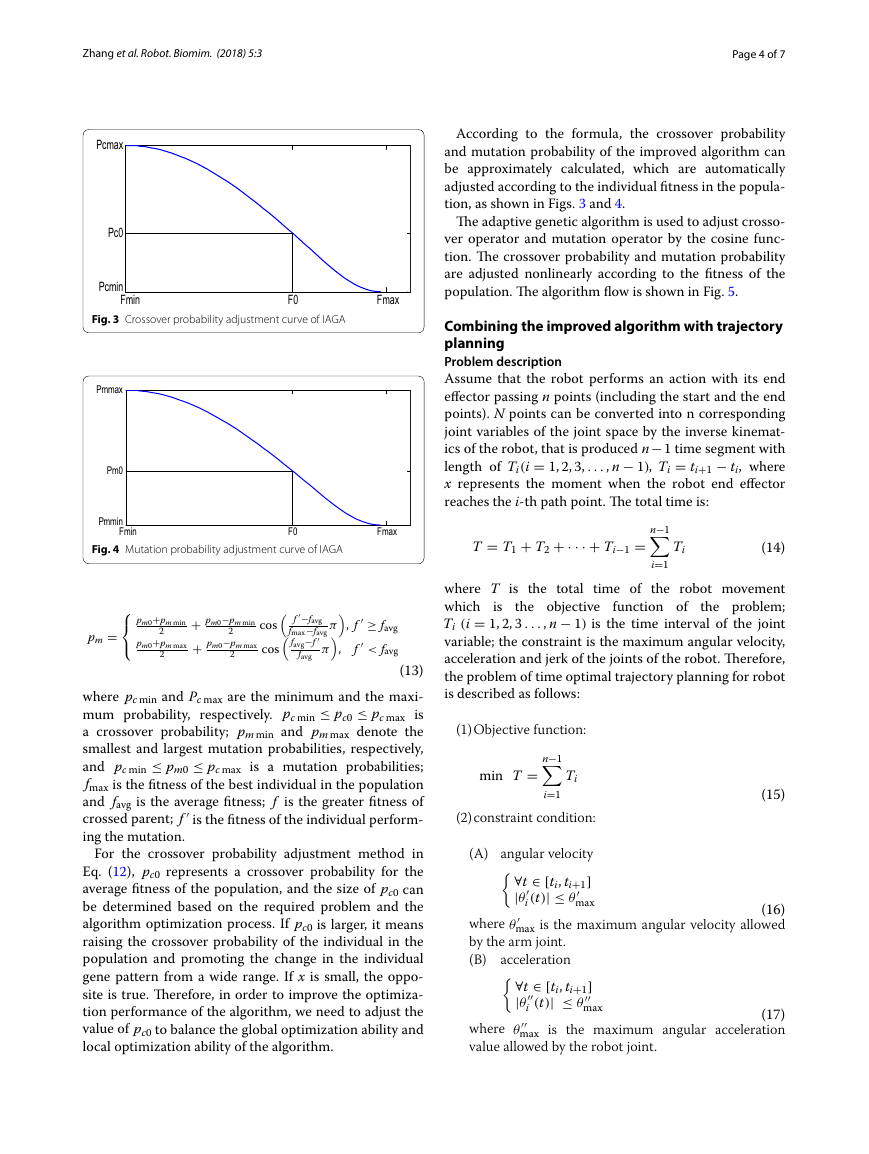

According to the formula, the crossover probability

and mutation probability of the improved algorithm can

be approximately calculated, which are automatically

adjusted according to the individual fitness in the popula-

tion, as shown in Figs. 3 and 4.

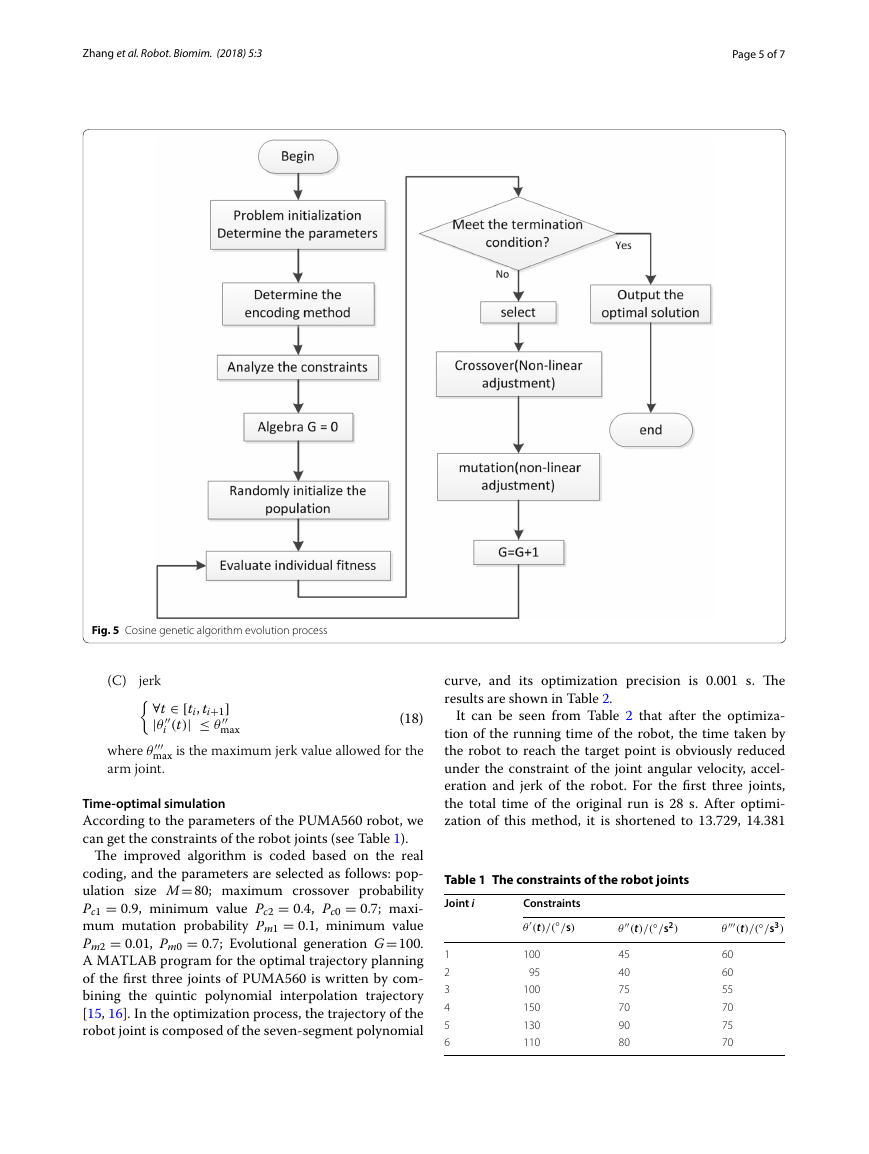

The adaptive genetic algorithm is used to adjust crosso-

ver operator and mutation operator by the cosine func-

tion. The crossover probability and mutation probability

are adjusted nonlinearly according to the fitness of the

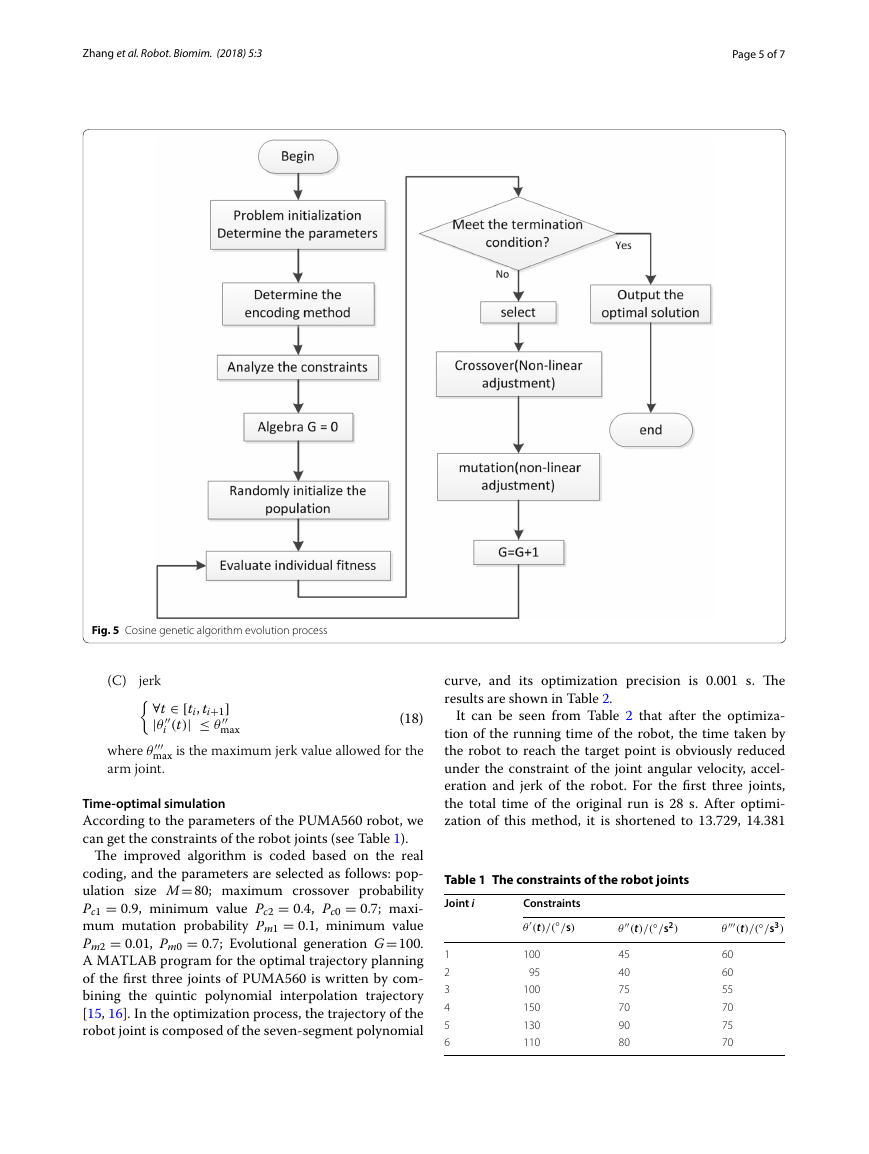

population. The algorithm flow is shown in Fig. 5.

Combining the improved algorithm with trajectory

planning

Problem description

Assume that the robot performs an action with its end

effector passing n points (including the start and the end

points). N points can be converted into n corresponding

joint variables of the joint space by the inverse kinemat-

ics of the robot, that is produced n − 1 time segment with

length of Ti(i = 1, 2, 3, . . . , n − 1) , Ti = ti+1 − ti , where

x represents the moment when the robot end effector

reaches the i-th path point. The total time is:

Ti

n−1

i=1

(14)

is the objective

where T is the total time of the robot movement

which

function of the problem;

Ti (i = 1, 2, 3 . . . , n − 1) is the time interval of the joint

variable; the constraint is the maximum angular velocity,

acceleration and jerk of the joints of the robot. Therefore,

the problem of time optimal trajectory planning for robot

is described as follows:

(1) Objective function:

min T =

n−1

i=1

(2) constraint condition:

Ti

(15)

(A) angular velocity

∀t ∈ [ti, ti+1]

|θ ′

where θ ′

by the arm joint.

(B) acceleration

i (t)| ≤ θ ′

(16)

max is the maximum angular velocity allowed

max

∀t ∈ [ti, ti+1]

|θ ′′

i (t)| ≤ θ ′′

(17)

max is the maximum angular acceleration

max

where θ ′′

value allowed by the robot joint.

�

Zhang et al. Robot. Biomim. (2018) 5:3

Page 5 of 7

Fig. 5 Cosine genetic algorithm evolution process

(C)

jerk

∀t ∈ [ti, ti+1]

|θ ′′

where θ ′′′

arm joint.

i (t)| ≤ θ ′′

max is the maximum jerk value allowed for the

max

(18)

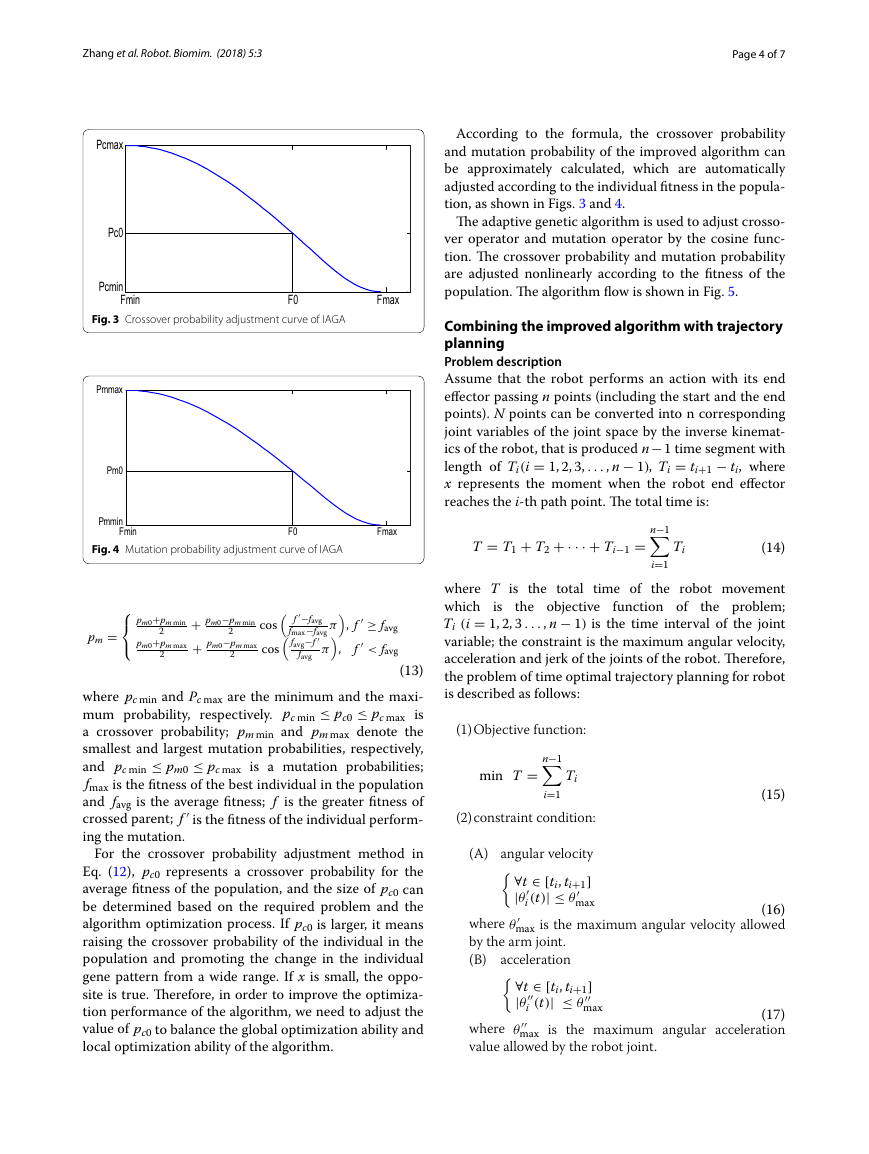

Time‑optimal simulation

According to the parameters of the PUMA560 robot, we

can get the constraints of the robot joints (see Table 1).

The improved algorithm is coded based on the real

coding, and the parameters are selected as follows: pop-

ulation size M = 80; maximum crossover probability

Pc1 = 0.9 , minimum value Pc2 = 0.4 , Pc0 = 0.7 ; maxi-

mum mutation probability Pm1 = 0.1 , minimum value

Pm2 = 0.01 , Pm0 = 0.7 ; Evolutional generation G = 100.

A MATLAB program for the optimal trajectory planning

of the first three joints of PUMA560 is written by com-

bining the quintic polynomial interpolation trajectory

[15, 16]. In the optimization process, the trajectory of the

robot joint is composed of the seven-segment polynomial

curve, and its optimization precision is 0.001 s. The

results are shown in Table 2.

It can be seen from Table 2 that after the optimiza-

tion of the running time of the robot, the time taken by

the robot to reach the target point is obviously reduced

under the constraint of the joint angular velocity, accel-

eration and jerk of the robot. For the first three joints,

the total time of the original run is 28 s. After optimi-

zation of this method, it is shortened to 13.729, 14.381

Table 1 The constraints of the robot joints

Joint i

Constraints

θ ′(t)/(◦/s)

θ ′′(t)/(◦/s2)

θ ′′′(t)/(◦/s3)

1

2

3

4

5

6

100

95

100

150

130

110

45

40

75

70

90

80

60

60

55

70

75

70

�

Zhang et al. Robot. Biomim. (2018) 5:3

Page 6 of 7

Table 2 Optimization Results

Time interval

Joint i

Initial value

1

h1

h2

h3

h4

h5

h6

h7

Total time (s)

4

4

4

4

4

4

4

28

2.785

2.032

2.316

1.578

1.824

1.487

1.707

13.729

100

)

°

(

n

o

i

t

i

s

o

P

l

r

a

u

g

n

A

80

2

2.113

2.128

1.764

1.918

1.706

1.874

2.878

14.381

3

3.349

2.064

1.626

1.659

2.113

1.629

2.208

14.648

Joint 1

5

0

-5

Position

Velocity

Acceleration

← A

← V

← P

)

2

s

/

°

(

n

o

i

t

l

a

r

e

e

c

c

A

l

r

a

u

g

n

A

/

)

s

/

°

(

y

t

i

l

c

o

e

V

l

r

a

u

g

n

A

60

0

0

2

2

4

4

6

6

8

8

Time (s)

10

10

12

12

-10

14

14

Fig. 6 Kinematic curve of joint 1

and 14.648 s, which was at least 47.7% shorter than 28 s.

Compared with several literatures that use PUMA560 as

the object for MATLAB simulation, the same constraints

apply. The reference literature [17] describes the method

of interpolating the trajectory of the robot with seventh-

order B-spline curves and optimizing the robot trajec-

tory using the genetic algorithm. After optimization, the

time is shortened from the original 20–15.620 s, which is

shortened by 21.9%. In reference literature [18], a cubic

B-spline curve is used to interpolate the robot motion

trajectory, and then an improved genetic algorithm

based on the crossover operator and mutation operator

adjusted with evolutionary algebraic average fitness is

used to perform the time optimal trajectory planning for

the robot motion trajectory. The time after optimization

was shortened from the original 20–13.072 s, a 34.6%

reduction. It can be seen that the improved genetic algo-

rithm, which the crossover operator and the mutation

operator in the general adaptive genetic algorithm are

adjusted cosine, based on quintic polynomial interpola-

tion described in this paper satisfies the goal of the short-

est time trajectory planning.

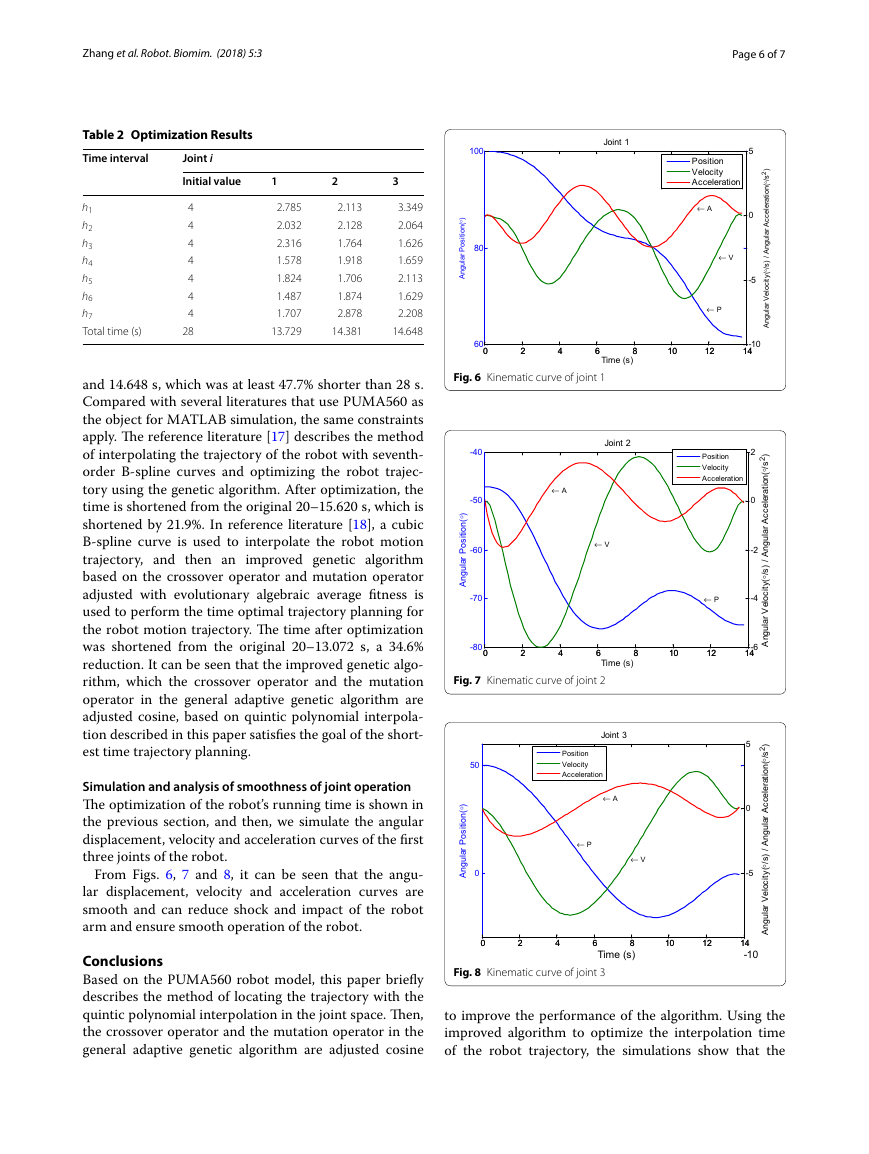

Simulation and analysis of smoothness of joint operation

The optimization of the robot’s running time is shown in

the previous section, and then, we simulate the angular

displacement, velocity and acceleration curves of the first

three joints of the robot.

From Figs. 6, 7 and 8, it can be seen that the angu-

lar displacement, velocity and acceleration curves are

smooth and can reduce shock and impact of the robot

arm and ensure smooth operation of the robot.

Conclusions

Based on the PUMA560 robot model, this paper briefly

describes the method of locating the trajectory with the

quintic polynomial interpolation in the joint space. Then,

the crossover operator and the mutation operator in the

general adaptive genetic algorithm are adjusted cosine

Joint 2

← A

← V

-40

-50

-60

-70

)

°

(

n

o

i

t

i

s

o

P

l

r

a

u

g

n

A

Joint 3

Position

Velocity

Acceleration

← A

← P

← V

50

)

°

(

n

o

i

t

i

s

o

P

l

r

a

u

g

n

A

0

Position

Velocity

Acceleration

2

0

)

2

s

/

°

(

n

o

i

t

a

r

e

e

c

c

A

l

-2

-4

← P

l

r

a

u

g

n

A

/

)

s

/

°

(

y

t

i

l

c

o

e

V

l

r

a

u

g

n

A

5

0

-5

)

2

s

/

°

(

n

o

i

t

a

r

e

e

c

c

A

l

l

r

a

u

g

n

A

/

)

s

/

°

(

y

t

i

l

c

o

e

V

l

r

a

u

g

n

A

-80

0

0

2

2

4

4

6

6

8

8

Time (s)

10

10

12

12

-6

14

14

Fig. 7 Kinematic curve of joint 2

0

0

2

2

4

4

6

6

8

8

Time (s)

10

10

12

12

14

14

-10

Fig. 8 Kinematic curve of joint 3

to improve the performance of the algorithm. Using the

improved algorithm to optimize the interpolation time

of the robot trajectory, the simulations show that the

�

Zhang et al. Robot. Biomim. (2018) 5:3

Page 7 of 7

running time of each joint of the robot has been greatly

reduced. The angular displacement, velocity and acceler-

ation curve of the joint operation shows that the smooth-

ness of the robot is better and the oscillations and shocks

of the manipulator can be reduced. In conclusion, the

method of this paper realizes the optimal trajectory plan-

ning target for robot time.

Authors’ contributions

JYZ completed the system modeling and the main algorithm improvement.

QXM worked on algorithm optimization and simulation. XGF and HS studied

the improved method of adaptive genetic algorithm, analyzed the simula-

tions and revised the manuscript. All authors read and approved the final

manuscript.

Acknowledgements

This research study was supported financially by the National Natural Science

Foundation of China under Grant No. 61473171 and the Natural Science

Foundation of Anhui Province (KJ2015A058).

Competing interests

The authors declare that they have no competing interests.

Ethics approval and consent to participate

Not applicable.

Funding

This research has been funded by the National Natural Science Foundation of

China under Grant No. 61473171 and the Natural Science Foundation of Anhui

Province (KJ2015A058).

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in pub-

lished maps and institutional affiliations.

Received: 8 November 2017 Accepted: 14 May 2018

References

1. Kim KB, Kim BK. Minimum-time trajectory for three-wheeled omnidi-

rectional mobile robots following a bounded-curvature path with a

referenced heading profile. IEEE Trans Rob. 2011;27(4):800–8. https ://doi.

org/10.1109/tro.2011.21384 90.

2. Chen H, Fang Y, Sun N, Qian Y (2015) Pseudospectral method based time

optimal trajectory planning for double pendulum cranes. In: Control con-

ference. IEEE; p. 4302–4307. https ://doi.org/10.1109/chicc .2015.72603 05.

3. Haili XU. Global time-energy optimal planning of industrial robot trajec-

4.

tories. J Mech Eng. 2010;46(9):19–25.

Liu H, Lai X, Wu W. Time-optimal and jerk-continuous trajectory planning

for robot manipulators with kinematic constraints. Rob Comput Integr

Manuf. 2013;29(2):309–17. https ://doi.org/10.1016/j.rcim.2012.08.002.

5. Yang JT, Jiang WG, Lin YC. Jerk-optimal trajectory planning algorithm of

industry robot. Sci Technol Eng. 2014;28:64–9. https ://doi.org/10.3969/j.

issn.1671-1815.2014.28.013.

Tohfeh F, Fakharian A (2015) Polynomial based optimal trajectory plan-

ning and obstacle avoidance for an omni-directional robot. In: Ai and

robotics, vol. 2010. IEEE; p. 1–6. https ://doi.org/10.1109/rios.2015.72707

31.

6.

7. Bende V, Pathak PM, Dixit KS, Harsha SP. Energy optimal trajectory

planning of an underwater robot using a genetic algorithm. Proc Inst

Mech Eng Part I J Syst Control Eng. 2012;226(8):1077–87. https ://doi.

org/10.1177/09596 51812 44723 2.

8. Zhu S, Wang. Time-optimal and jerk-continuous trajectory planning

algorithm for manipulators. J Mech Eng. 2010;46(3):456–62. https ://doi.

org/10.3901/jme.20.

9. Guan-zheng Tan, Sheng-yuan HU. Real-time accurate hand path tracking

and joint trajectory planning for industrial robots (I). J Cent South Univ

Technol. 2002;9(4):273–8. https ://doi.org/10.1007/s1177 1-002-0041-z.

10. Xu D, Liu M, Zhu L (2013) Single frequency GNSS integer ambiguity

resolution with adaptive genetic algorithm. In: International conference

on information science and technology. IEEE; p. 1049–1051. https ://doi.

org/10.1109/icist .2013.67477 16.

11. Ling Wang. Intelligent optimization algorithm and its application. Beijing:

Tsinghua University Press; 2001.

12. Liang Xu. Modern intelligent optimization hybrid algorithm and its appli-

cation. 2nd ed. Beijing: Publishing House of electronics industry, Beijing;

2014 (In Chinese).

13. Ying-Ying YU, Yan C, Tao-Ying LI. Improved genetic algorithm for solving

tsp. Control Decis. 2014;29(8):1483–8. https ://doi.org/10.13195 /j.kzyjc

.2013.0598.

14. Ren ZW, San Y. Improved adaptive genetic algorithm and its application

research in parameter identification. J Syst Simul. 2006;18(1):40–1. https ://

doi.org/10.16182 /j.cnki.joss.2006.01.011.

15. Yingjie L, Shanwen Z, Xuwu L et al (2005) MATLAB genetic algorithm

toolbox and its application. Xi’an Electronic and Science University press,

Xi’an (In Chinese).

16. Jinwu Zhuo. The application of MATLAB in mathematical modeling.

Beijing: Beijing Aerospace publishing house; 2011.

17. He J, Zhu L, Cheng L, Yin J (2015) Time-optimal trajectory planning of

6-dof robot based on genetic algorithm. J Mech Transm. https ://doi.

org/10.16578 /j.issn.1004.2539.2015.09.010.

18. Niu Y (2013) Time-optimal trajectory planning of 6DOF serial robot. Dis-

sertation, Changchun University of Technology, Changchun, Jilin, China.

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc