User Guide

FXMP25

Field Controller

Part Number: 0476-0009-02

Issue: 2

www.controltechniques.com

�

General Information

The manufacturer accepts no liability for any consequences resulting from inappropriate, negligent or

incorrect installation or adjustment of the optional operating parameters of the equipment or from

mismatching the field controller with the motor.

The contents of this guide are believed to be correct at the time of printing. In the interests of a commitment

to a policy of continuous development and improvement, the manufacturer reserves the right to change the

specification of the product or its performance, or the contents of the guide, without notice.

All rights reserved. No parts of this guide may be reproduced or transmitted in any form or by any means,

electrical or mechanical including photocopying, recording or by an information storage or retrieval system,

without permission in writing from the publisher.

Field Controller software version

This product is supplied with the latest software version. If this drive is to be connected to an existing system

or machine, all drive software versions should be verified to confirm the same functionality as drives of the

same model already present. This may also apply to drives returned from a Control Techniques Service

Centre or Repair Centre. If there is any doubt please contact the supplier of the product. The software

versions of the drive can be checked by looking at Pr 97 and Pr 99.

When used in conjunction with a Mentor MP the Mentor MP software must be V01.05.01 or later.

Environmental statement

Control Techniques is committed to minimising the environmental impacts of its manufacturing operations

and of its products throughout their life cycle. To this end, we operate an Environmental Management

System (EMS) which is certified to the International Standard ISO 14001. Further information on the EMS,

our Environmental Policy and other relevant information is available on request, or can be found at

www.greendrives.com.

The electronic variable-speed drives manufactured by Control Techniques have the potential to save

energy and (through increased machine/process efficiency) reduce raw material consumption and scrap

throughout their long working lifetime. In typical applications, these positive environmental effects far

outweigh the negative impacts of product manufacture and end-of-life disposal.

Nevertheless, when the products eventually reach the end of their useful life, they must not be discarded

but should instead be recycled by a specialist recycler of electronic equipment. Recyclers will find the

products easy to dismantle into their major component parts for efficient recycling. Many parts snap

together and can be separated without the use of tools, while other parts are secured with conventional

fasteners. Virtually all parts of the product are suitable for recycling.

Product packaging is of good quality and can be re-used. Large products are packed in wooden crates,

while smaller products come in strong cardboard cartons which themselves have a high recycled fibre

content. If not re-used, these containers can be recycled. Polythene, used on the protective film and bags

for wrapping product, can be recycled in the same way. Control Techniques' packaging strategy prefers

easily-recyclable materials of low environmental impact, and regular reviews identify opportunities for

improvement.

When preparing to recycle or dispose of any product or packaging, please observe local legislation and

best practice.

REACH legislation

EC Regulation 1907/2006 on the Registration, Evaluation, Authorisation and restriction of Chemicals

(REACH) requires the supplier of an article to inform the recipient if it contains more than a specified

proportion of any substance which is considered by the European Chemicals Agency (ECHA) to be a

Substance of Very High Concern (SVHC) and is therefore listed by them as a candidate for compulsory

authorisation.

For current information on how this requirement applies in relation to specific Control Techniques products,

please approach your usual contact in the first instance. Control Techniques position statement can be

viewed at:

http://www.controltechniques.com/REACH

Copyright

Issue Number: 2

© October 2010 Control Techniques Ltd.

�

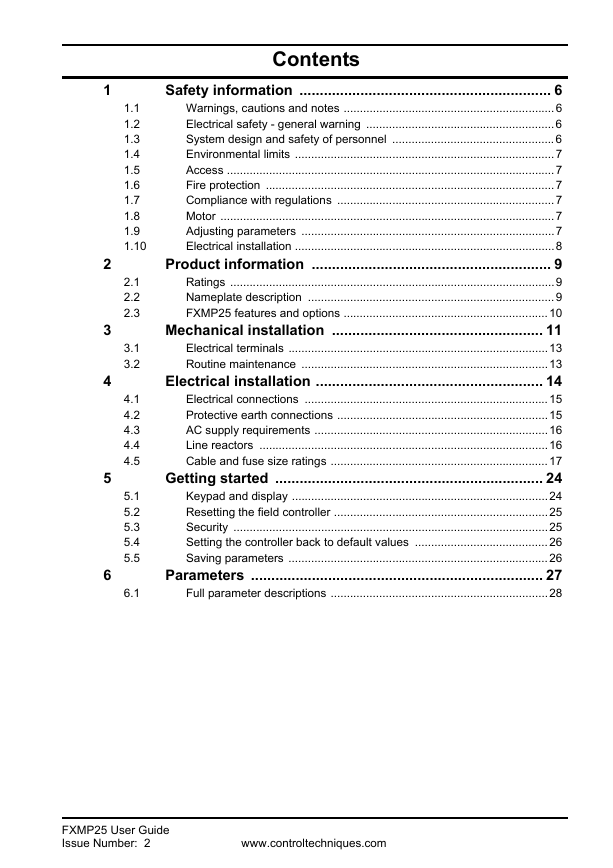

Contents

1

2

3

4

5

6

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

1.10

2.1

2.2

2.3

3.1

3.2

4.1

4.2

4.3

4.4

4.5

5.1

5.2

5.3

5.4

5.5

6.1

Safety information .............................................................. 6

Warnings, cautions and notes .................................................................6

Electrical safety - general warning ..........................................................6

System design and safety of personnel ..................................................6

Environmental limits ................................................................................7

Access .....................................................................................................7

Fire protection .........................................................................................7

Compliance with regulations ...................................................................7

Motor .......................................................................................................7

Adjusting parameters ..............................................................................7

Electrical installation ................................................................................8

Product information ........................................................... 9

Ratings ....................................................................................................9

Nameplate description ............................................................................9

FXMP25 features and options ...............................................................10

Mechanical installation .................................................... 11

Electrical terminals ................................................................................13

Routine maintenance ............................................................................13

Electrical installation ........................................................ 14

Electrical connections ...........................................................................15

Protective earth connections .................................................................15

AC supply requirements ........................................................................16

Line reactors .........................................................................................16

Cable and fuse size ratings ...................................................................17

Getting started .................................................................. 24

Keypad and display ...............................................................................24

Resetting the field controller ..................................................................25

Security .................................................................................................25

Setting the controller back to default values .........................................26

Saving parameters ................................................................................26

Parameters ........................................................................ 27

Full parameter descriptions ...................................................................28

FXMP25 User Guide

Issue Number: 2

www.controltechniques.com

�

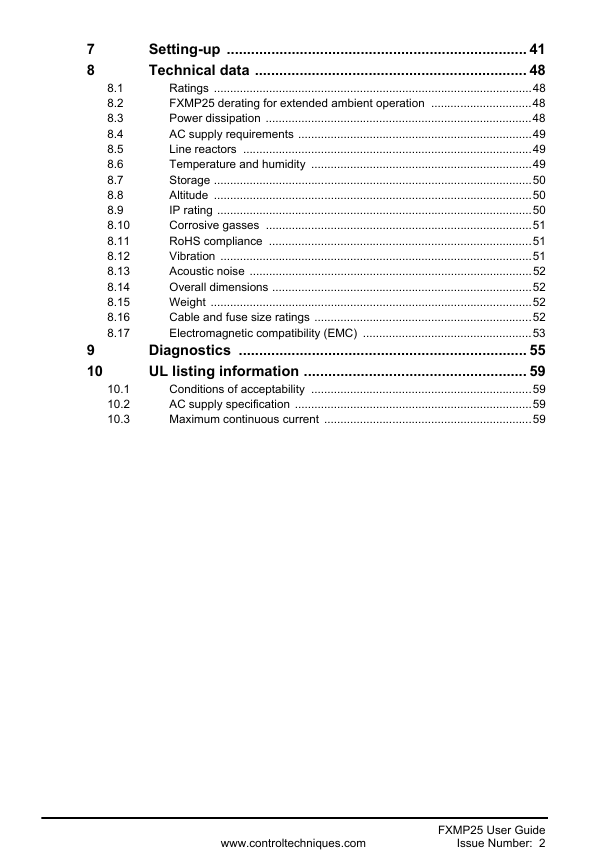

7

8

8.1

8.2

8.3

8.4

8.5

8.6

8.7

8.8

8.9

8.10

8.11

8.12

8.13

8.14

8.15

8.16

8.17

9

10

10.1

10.2

10.3

Setting-up .......................................................................... 41

Technical data ................................................................... 48

Ratings ..................................................................................................48

FXMP25 derating for extended ambient operation ...............................48

Power dissipation ..................................................................................48

AC supply requirements ........................................................................49

Line reactors .........................................................................................49

Temperature and humidity ....................................................................49

Storage ..................................................................................................50

Altitude ..................................................................................................50

IP rating .................................................................................................50

Corrosive gasses ..................................................................................51

RoHS compliance .................................................................................51

Vibration ................................................................................................51

Acoustic noise .......................................................................................52

Overall dimensions ................................................................................52

Weight ...................................................................................................52

Cable and fuse size ratings ...................................................................52

Electromagnetic compatibility (EMC) ....................................................53

Diagnostics ....................................................................... 55

UL listing information ....................................................... 59

Conditions of acceptability ....................................................................59

AC supply specification .........................................................................59

Maximum continuous current ................................................................59

www.controltechniques.com

FXMP25 User Guide

Issue Number: 2

�

Declaration of Conformity

Control Techniques Ltd, The Gro, Newtown, Powys UK. SY16 3BE

FXMP25 Field Controller

The field controller product listed above has been designed and manufactured in

accordance with the following European harmonized standards:

EN 61800-5-1:2007

Adjustable speed electrical power drive systems - safety

requirements - electrical, thermal and energy

EN 61800-3:2004

Adjustable speed electrical power drive systems. EMC

product standard including specific test methods

EN 61000-6-2:2005

Electromagnetic compatibility (EMC). Generic standards.

Immunity standard for industrial environments

EN 61000-6-4:2007

Electromagnetic compatibility (EMC). Generic standards.

Emission standard for industrial environments

The corresponding international standards are:

IEC 61800-5-1:2007

IEC 61800-3:2004

IEC 61000-6-2:2005

IEC 61000-6-4:2006

These products comply with the Low Voltage Directive 2006/95/EC and the

Electromagnetic Compatibility (EMC) Directive 2004/108/EC.

T. Alexander

VP Technology

Newtown

Date: 8th July 2010

This electronic field controller product is intended to be used with appropriate

motors, controllers, electrical protection components and other equipment to

form complete end products or systems. Compliance with safety and EMC

regulations depends upon installing and configuring drives correctly, including

using the specified input filters. The drives must be installed only by professional

assemblers who are familiar with requirements for safety and EMC. The

assembler is responsible for ensuring that the end product or system complies

with all the relevant laws in the country where it is to be used. Refer to the User

Guide. An EMC Data Sheet is also available giving detailed EMC information.

FXMP25 User Guide

Issue Number: 2

www.controltechniques.com

5

�

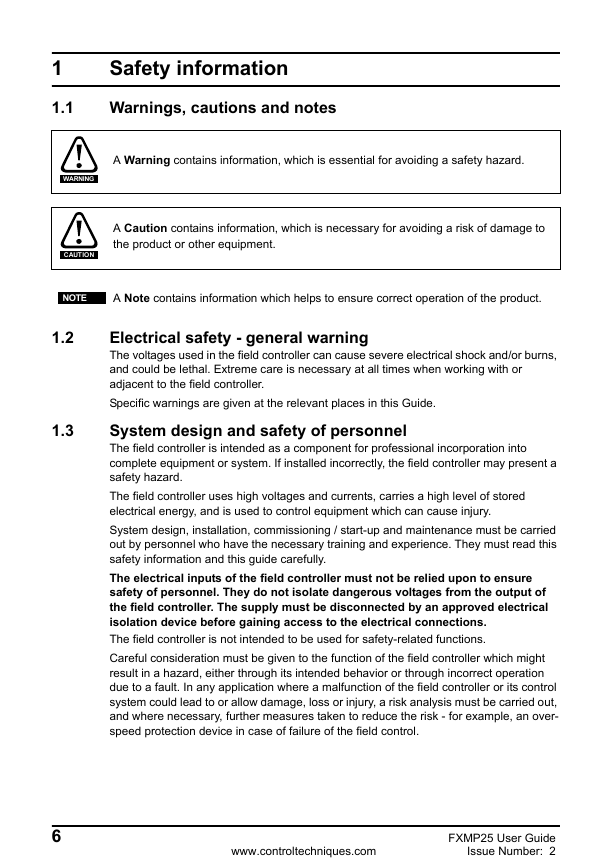

1

1.1

WARNING

CAUTION

Safety information

Warnings, cautions and notes

A Warning contains information, which is essential for avoiding a safety hazard.

A Caution contains information, which is necessary for avoiding a risk of damage to

the product or other equipment.

NOTE

A Note contains information which helps to ensure correct operation of the product.

1.2

1.3

Electrical safety - general warning

The voltages used in the field controller can cause severe electrical shock and/or burns,

and could be lethal. Extreme care is necessary at all times when working with or

adjacent to the field controller.

Specific warnings are given at the relevant places in this Guide.

System design and safety of personnel

The field controller is intended as a component for professional incorporation into

complete equipment or system. If installed incorrectly, the field controller may present a

safety hazard.

The field controller uses high voltages and currents, carries a high level of stored

electrical energy, and is used to control equipment which can cause injury.

System design, installation, commissioning / start-up and maintenance must be carried

out by personnel who have the necessary training and experience. They must read this

safety information and this guide carefully.

The electrical inputs of the field controller must not be relied upon to ensure

safety of personnel. They do not isolate dangerous voltages from the output of

the field controller. The supply must be disconnected by an approved electrical

isolation device before gaining access to the electrical connections.

The field controller is not intended to be used for safety-related functions.

Careful consideration must be given to the function of the field controller which might

result in a hazard, either through its intended behavior or through incorrect operation

due to a fault. In any application where a malfunction of the field controller or its control

system could lead to or allow damage, loss or injury, a risk analysis must be carried out,

and where necessary, further measures taken to reduce the risk - for example, an over-

speed protection device in case of failure of the field control.

6

www.controltechniques.com

FXMP25 User Guide

Issue Number: 2

�

1.4

1.5

1.6

1.7

1.8

1.9

Environmental limits

Instructions within the supplied data regarding transport, storage, installation and the

use of the field controller must be complied with, including the specified environmental

limits. Field controllers must not be subjected to excessive physical force.

Access

Access must be restricted to authorized personnel only. Safety regulations which apply

at the place of use must be complied with.

Fire protection

The field controller enclosure is not classified as a fire enclosure. A separate fire

enclosure must be provided.

Compliance with regulations

The installer is responsible for complying with all relevant regulations, such as national

wiring regulations, accident prevention regulations and electromagnetic compatibility

(EMC) regulations. Particular attention must be given to the cross-sectional areas of

conductors, the selection of fuses and other protection, and protective earth

connections.

The FXMP25 User Guide contains instructions for achieving compliance with specific

EMC standards.

Within the European Union, all machinery in which this product is used must comply

with the following directives:

2006/42/EC: Safety of machinery

2004/108/EC: Electromagnetic compatibility

Motor

Ensure the motor is installed in accordance with the manufacturer's recommendations.

Ensure the motor shaft is not exposed.

Low speeds may cause the motor to overheat because the cooling fan becomes less

effective. The motor should be installed with a protection thermistor. If necessary, an

electric forced ventilation fan should be used.

The values of the motor parameters set in the field controller affect the protection of the

motor. The default values in the field controller should not be relied upon.

Adjusting parameters

Some parameters have a profound effect on the operation of the field controller. They

must not be altered without careful consideration of the impact on the controlled system.

Measures must be taken to prevent unwanted changes due to error or tampering.

FXMP25 User Guide

Issue Number: 2

www.controltechniques.com

7

i

n

f

o

r

m

a

t

i

o

n

S

a

f

e

t

y

i

f

n

o

r

m

a

P

r

o

d

u

c

t

t

i

o

n

i

n

s

t

a

l

l

a

t

i

o

n

M

e

c

h

a

n

c

a

i

l

i

n

s

t

a

l

l

a

t

i

o

n

l

E

e

c

t

r

i

c

a

l

G

e

t

t

i

n

g

s

t

a

r

t

e

d

P

a

r

a

m

e

e

r

s

t

S

e

t

t

i

n

g

-

u

p

T

e

c

h

n

c

a

i

l

d

a

a

t

i

D

a

g

n

o

s

t

i

c

s

U

L

l

i

s

t

i

n

g

i

f

n

o

r

m

a

t

i

o

n

�

1.10

Electrical installation

1.10.1 Electric shock risk

AC supply cables and connections

The voltages present in the following locations can cause severe electric shock and may

be lethal:

•

• Output cables and connections

• Many internal parts of the field controller

Unless otherwise indicated, control terminals are single insulated and must not be

touched.

1.10.2 Stored charge

The field controller contains capacitors that remain charged to a potentially lethal

voltage after the AC supply has been disconnected. If the field controller has been

energized, the AC supply must be isolated at least five minutes before work may

continue.

8

www.controltechniques.com

FXMP25 User Guide

Issue Number: 2

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc