特别说明

此资料来自百度文库(http://wenku.baidu.com/)

您目前所看到的文档是使用的抱米花百度文库下载器所生成

此文档原地址来自

http://wenku.baidu.com/view/5a2c42f90242a8956bece407.html

感谢您的支持

抱米花

http://blog.sina.com.cn/lotusbaob

�

1

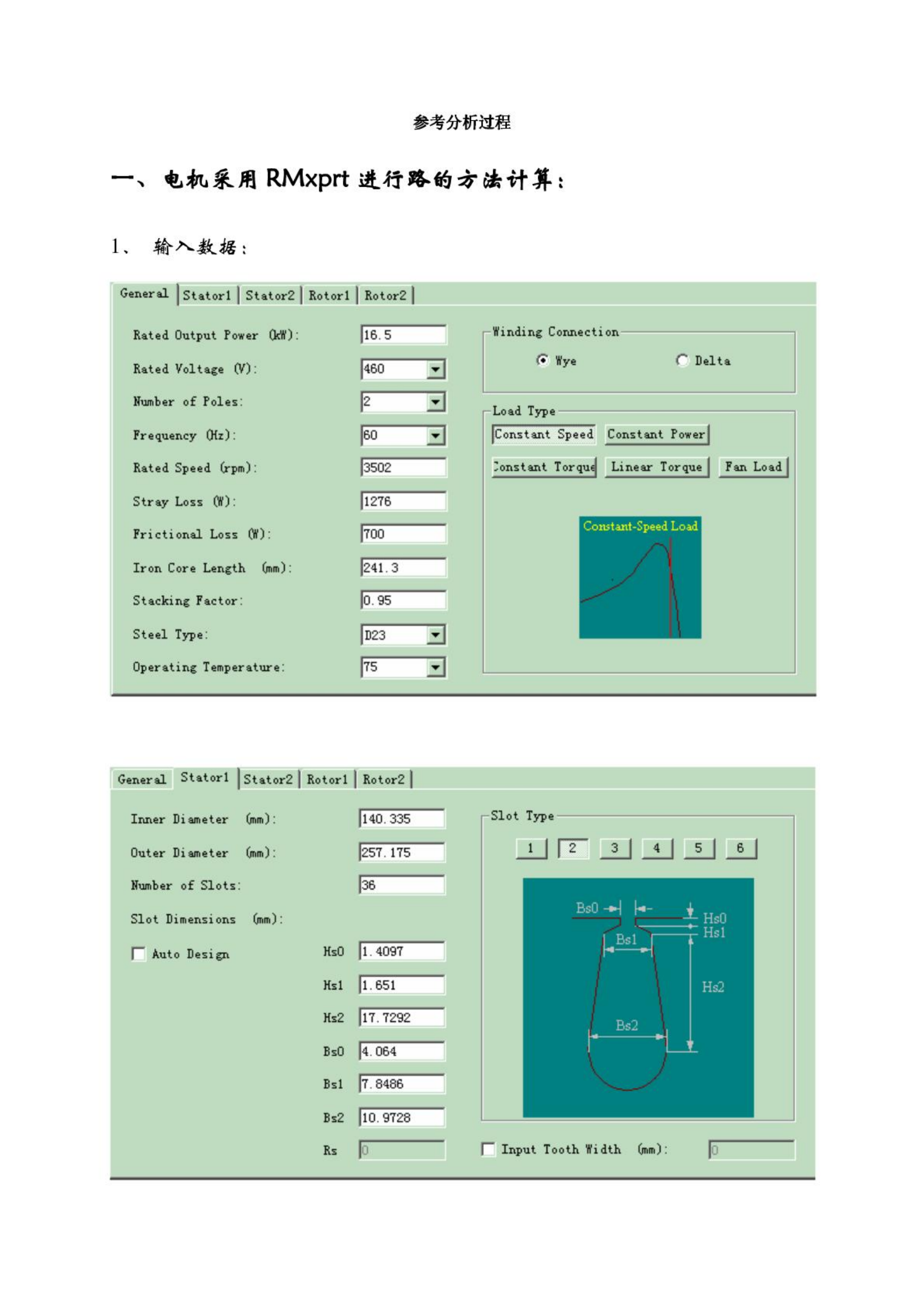

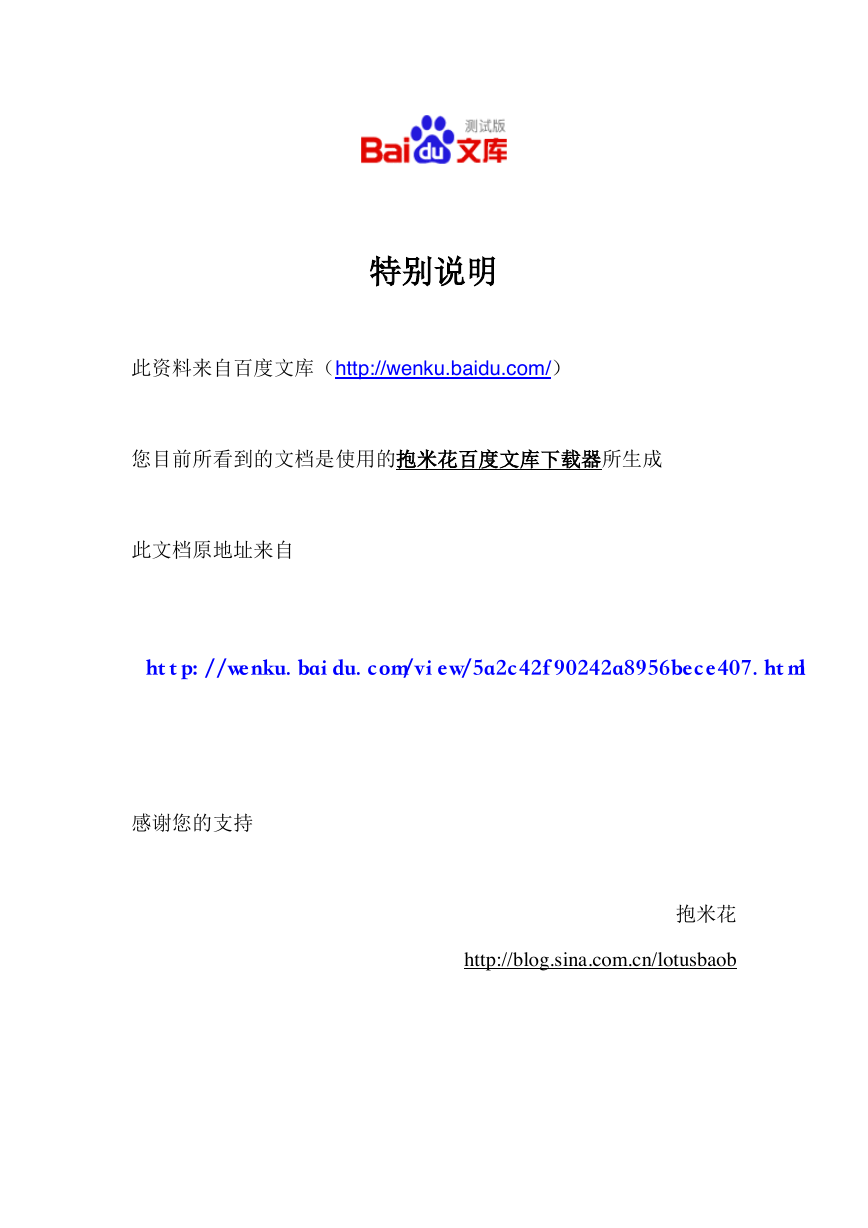

输入据:

、

�

�

二、算输出果-据部分

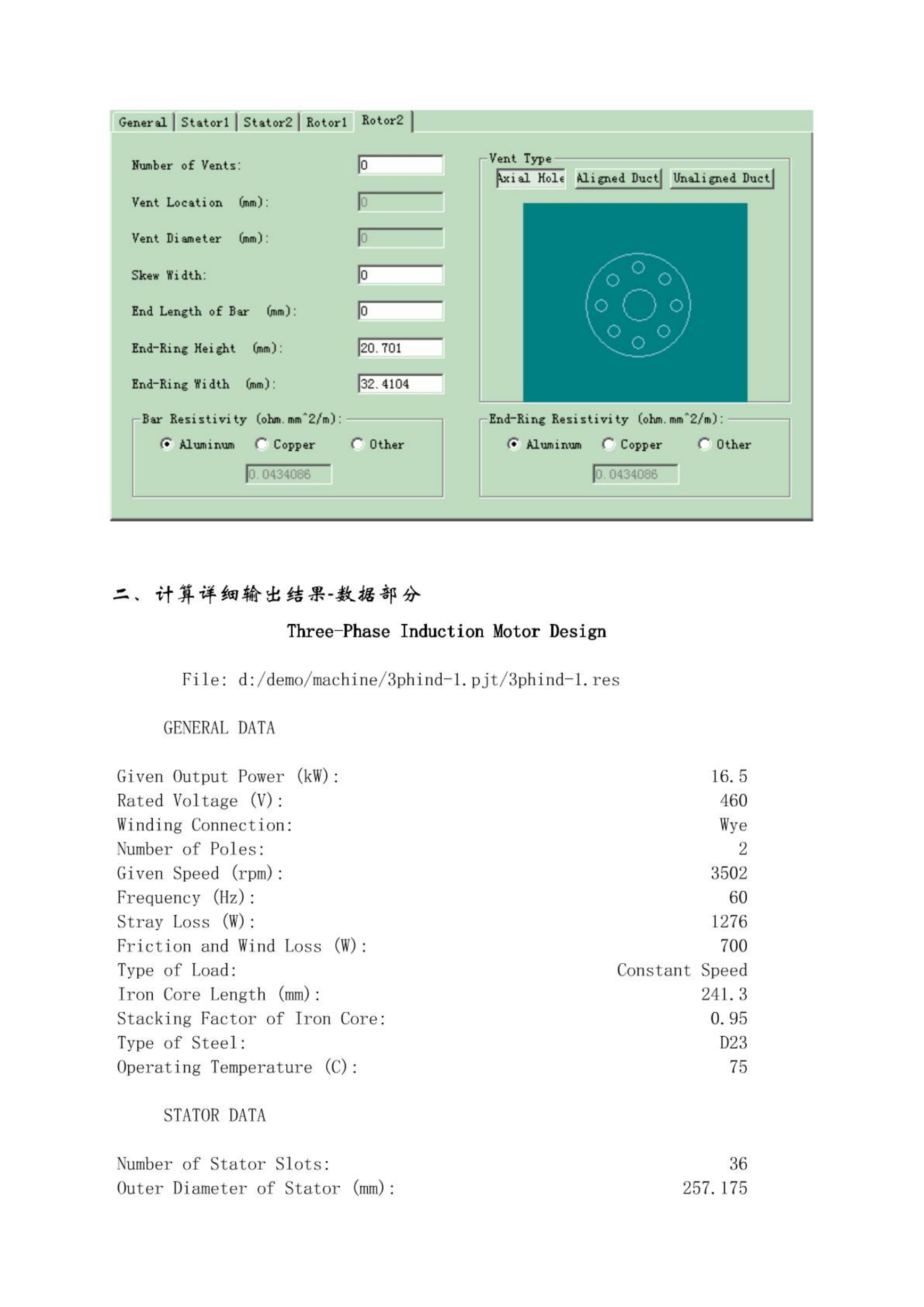

File: d:/demo/machine/3phind-1.pjt/3phind-1.res GENERAL DATA Given Output Power (kW): 16.5 Rated Voltage (V): 460 Winding Connection: Wye Number of Poles: 2 Given Speed (rpm): 3502 Frequency (Hz): 60 Stray Loss (W): 1276 Friction and Wind Loss (W): 700 Type of Load: Constant Speed Iron Core Length (mm): 241.3 Stacking Factor of Iron Core: 0.95 Type of Steel: D23 Operating Temperature (C): 75 STATOR DATA Number of Stator Slots: 36 Outer Diameter of Stator (mm): 257.175

�

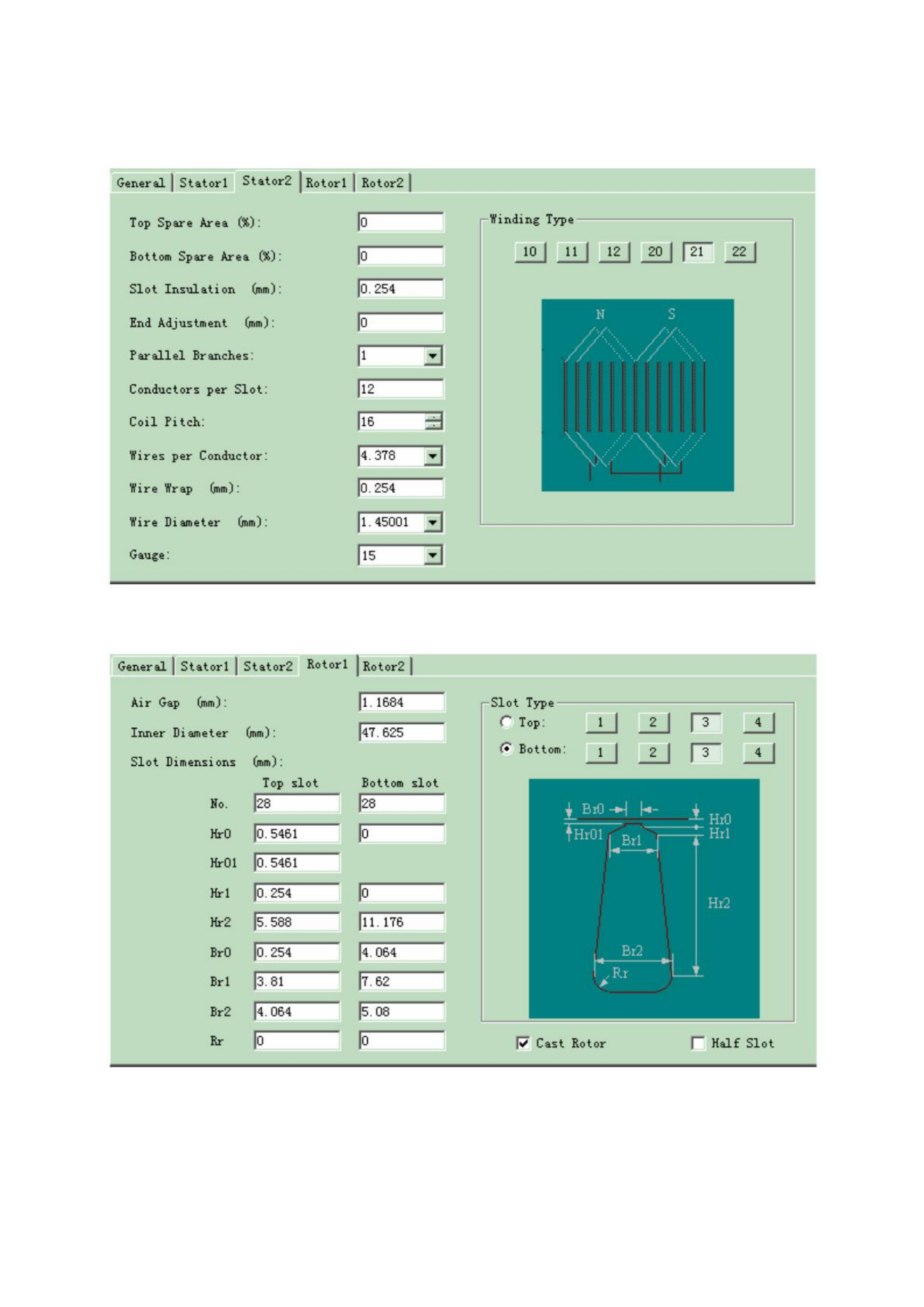

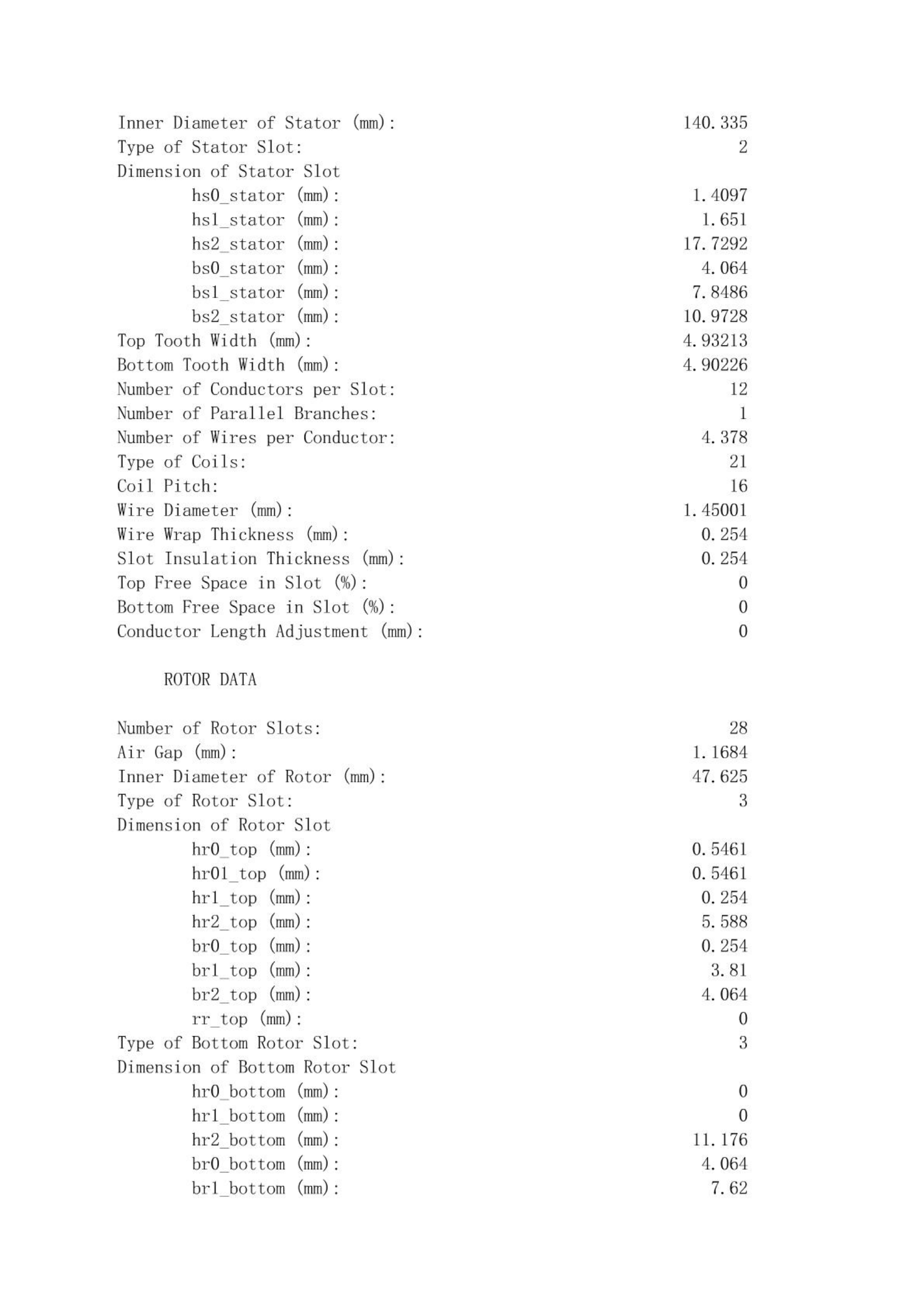

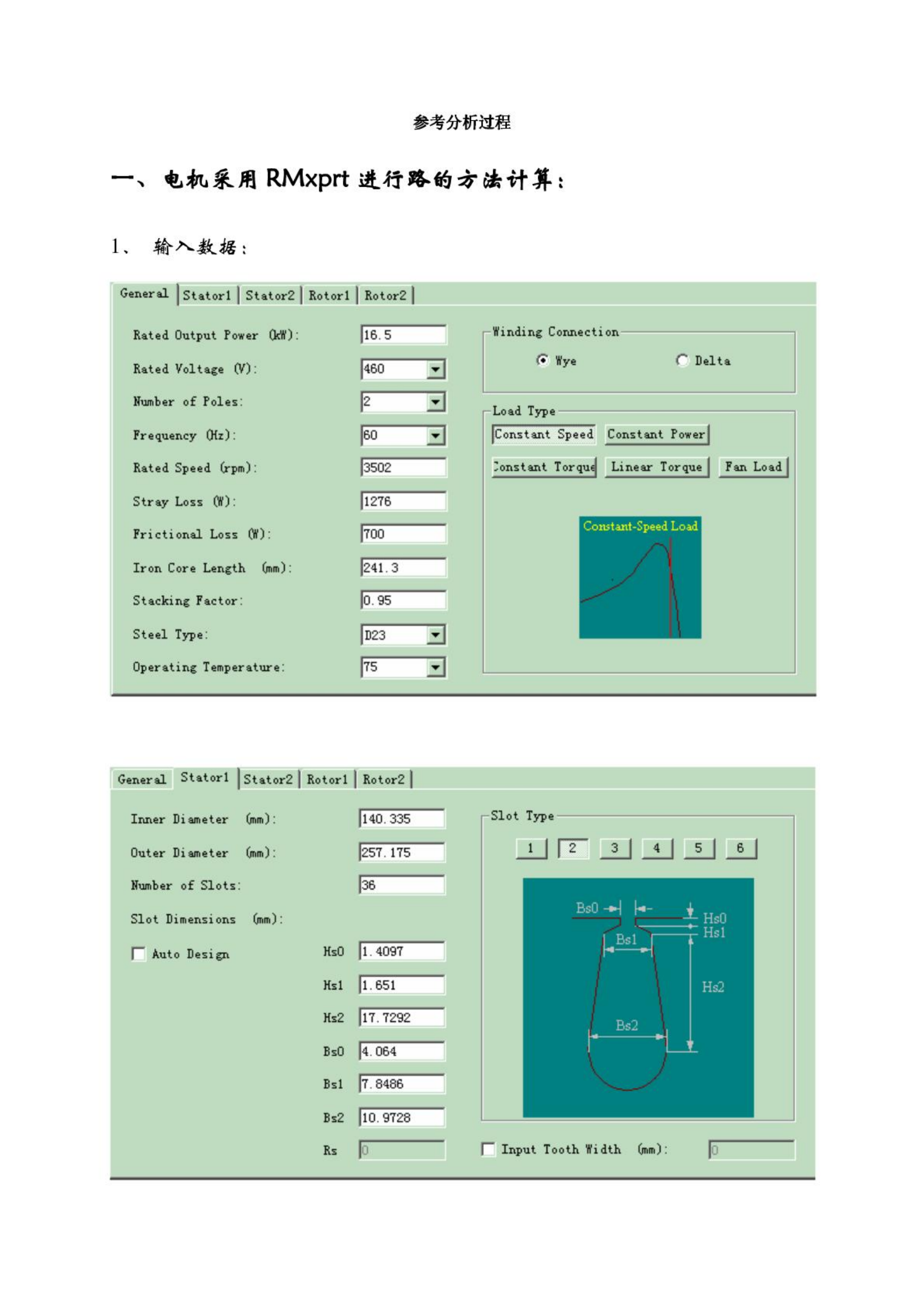

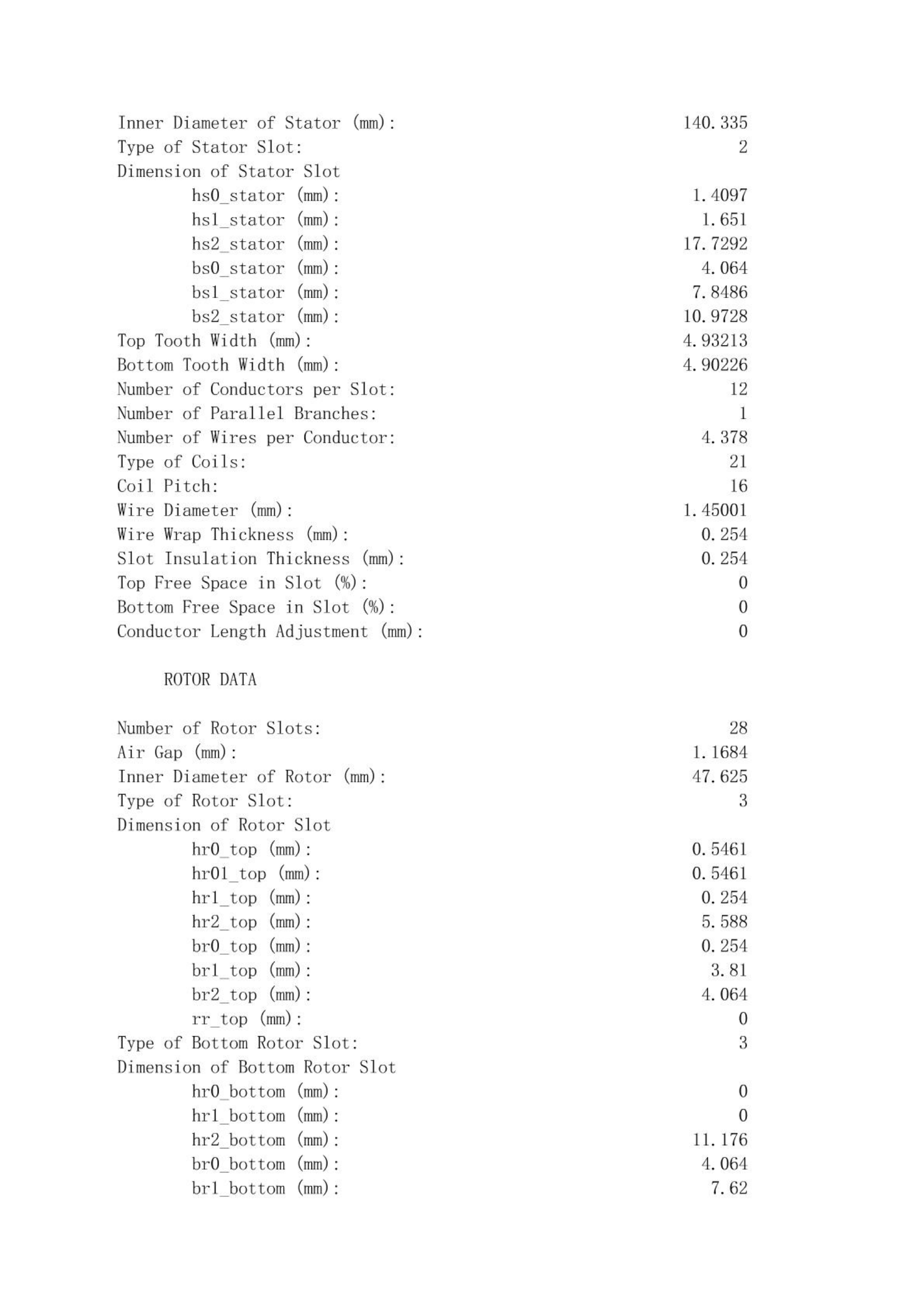

Inner Diameter of Stator (mm): 140.335 Type of Stator Slot: 2 Dimension of Stator Slot hs0_stator (mm): 1.4097 hs1_stator (mm): 1.651 hs2_stator (mm): 17.7292 bs0_stator (mm): 4.064 bs1_stator (mm): 7.8486 bs2_stator (mm): 10.9728 Top Tooth Width (mm): 4.93213 Bottom Tooth Width (mm): 4.90226 Number of Conductors per Slot: 12 Number of Parallel Branches: 1 Number of Wires per Conductor: 4.378 Type of Coils: 21 Coil Pitch: 16 Wire Diameter (mm): 1.45001 Wire Wrap Thickness (mm): 0.254 Slot Insulation Thickness (mm): 0.254 Top Free Space in Slot (%): 0 Bottom Free Space in Slot (%): 0 Conductor Length Adjustment (mm): 0 ROTOR DATA Number of Rotor Slots: 28 Air Gap (mm): 1.1684 Inner Diameter of Rotor (mm): 47.625 Type of Rotor Slot: 3 Dimension of Rotor Slot hr0_top (mm): 0.5461 hr01_top (mm): 0.5461 hr1_top (mm): 0.254 hr2_top (mm): 5.588 br0_top (mm): 0.254 br1_top (mm): 3.81 br2_top (mm): 4.064 rr_top (mm): 0 Type of Bottom Rotor Slot: 3 Dimension of Bottom Rotor Slot hr0_bottom (mm): 0 hr1_bottom (mm): 0 hr2_bottom (mm): 11.176 br0_bottom (mm): 4.064 br1_bottom (mm): 7.62

�

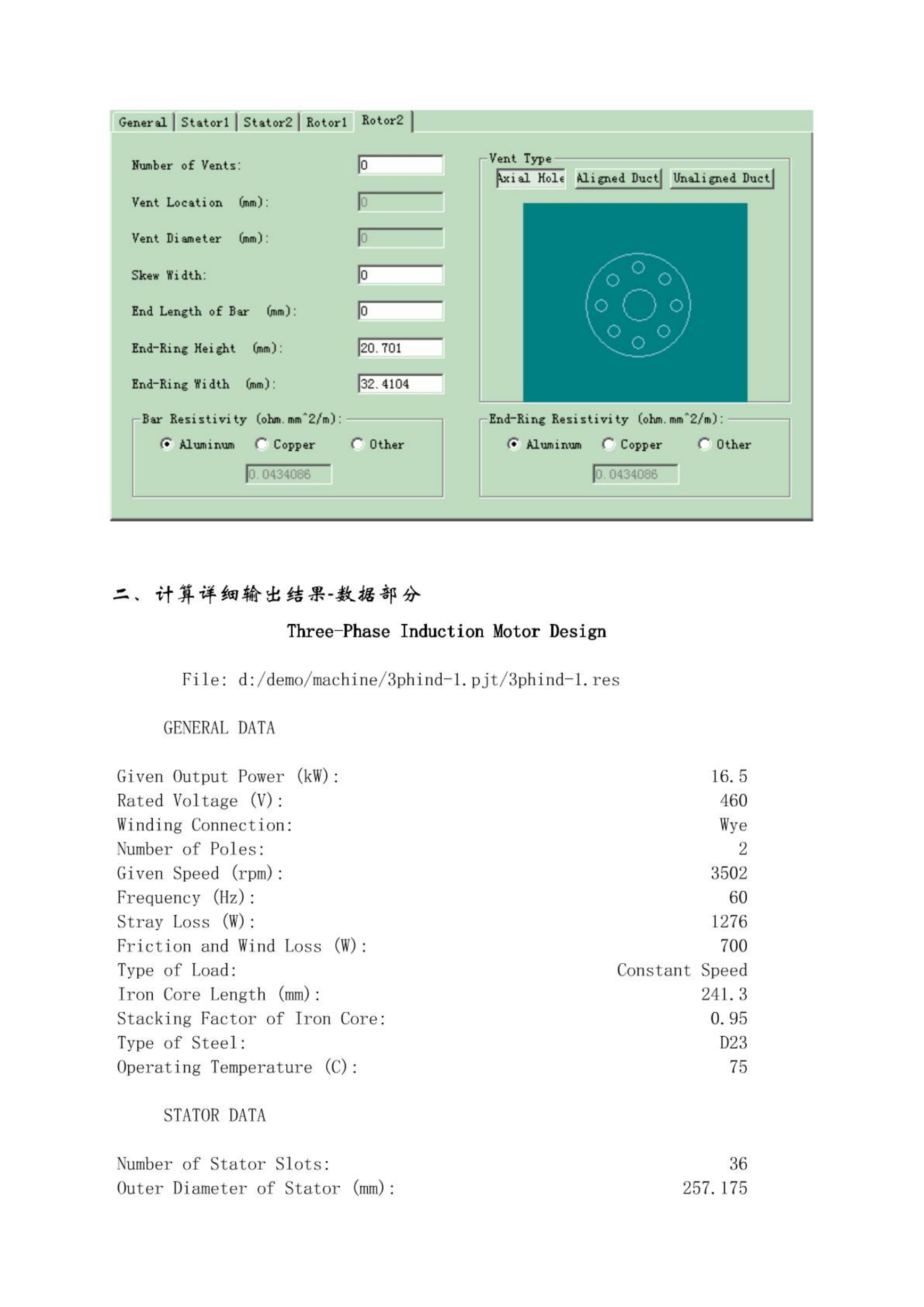

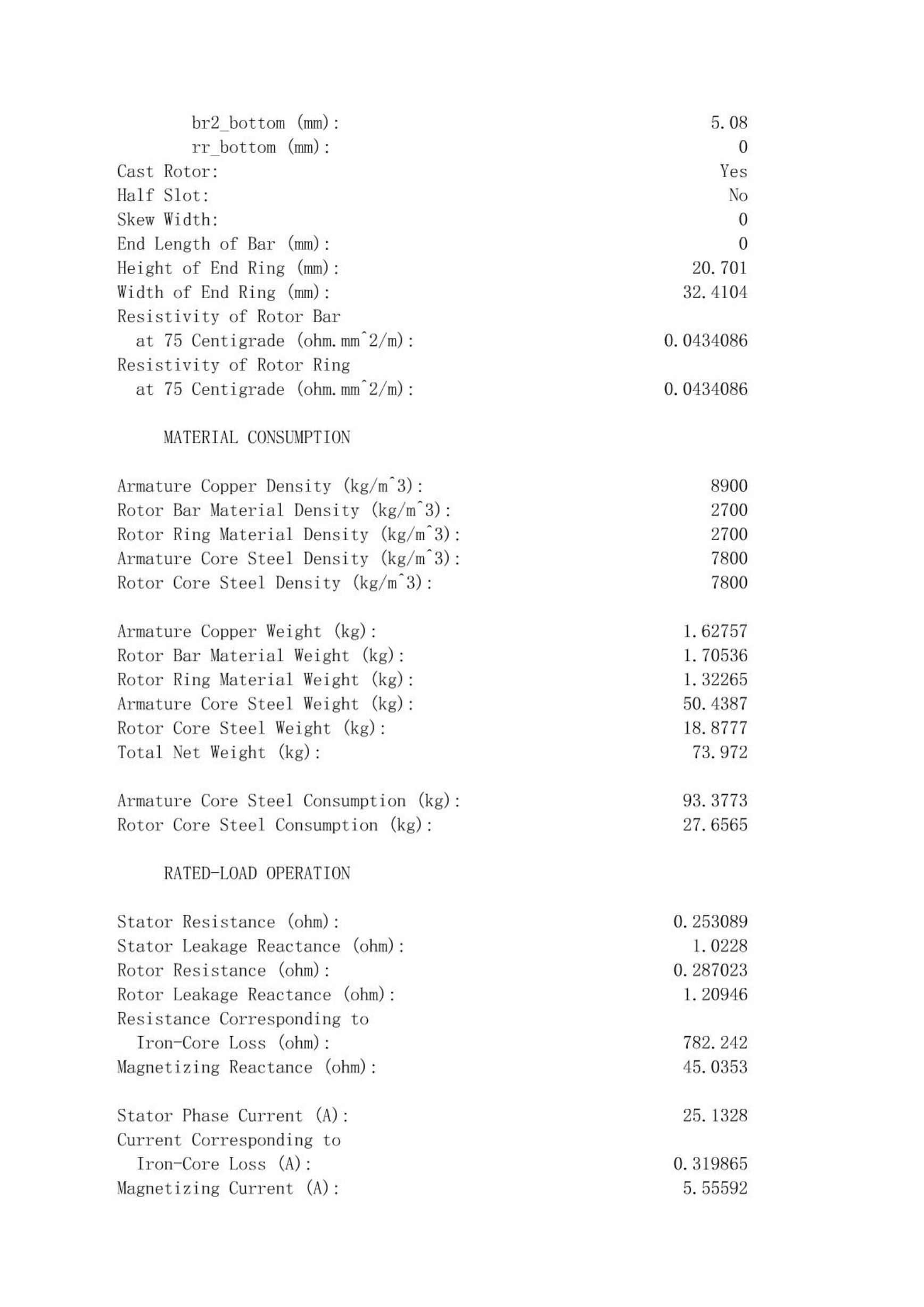

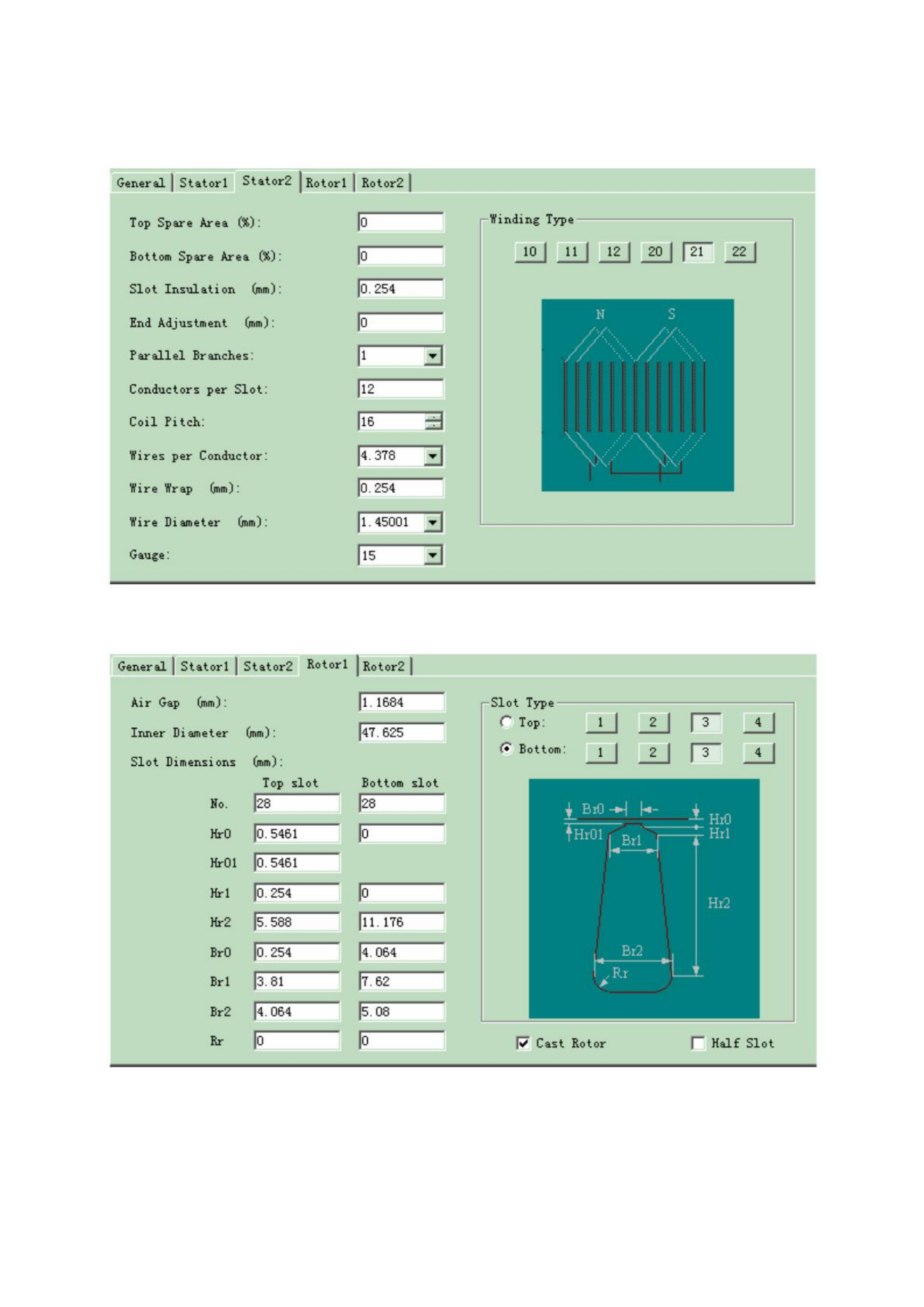

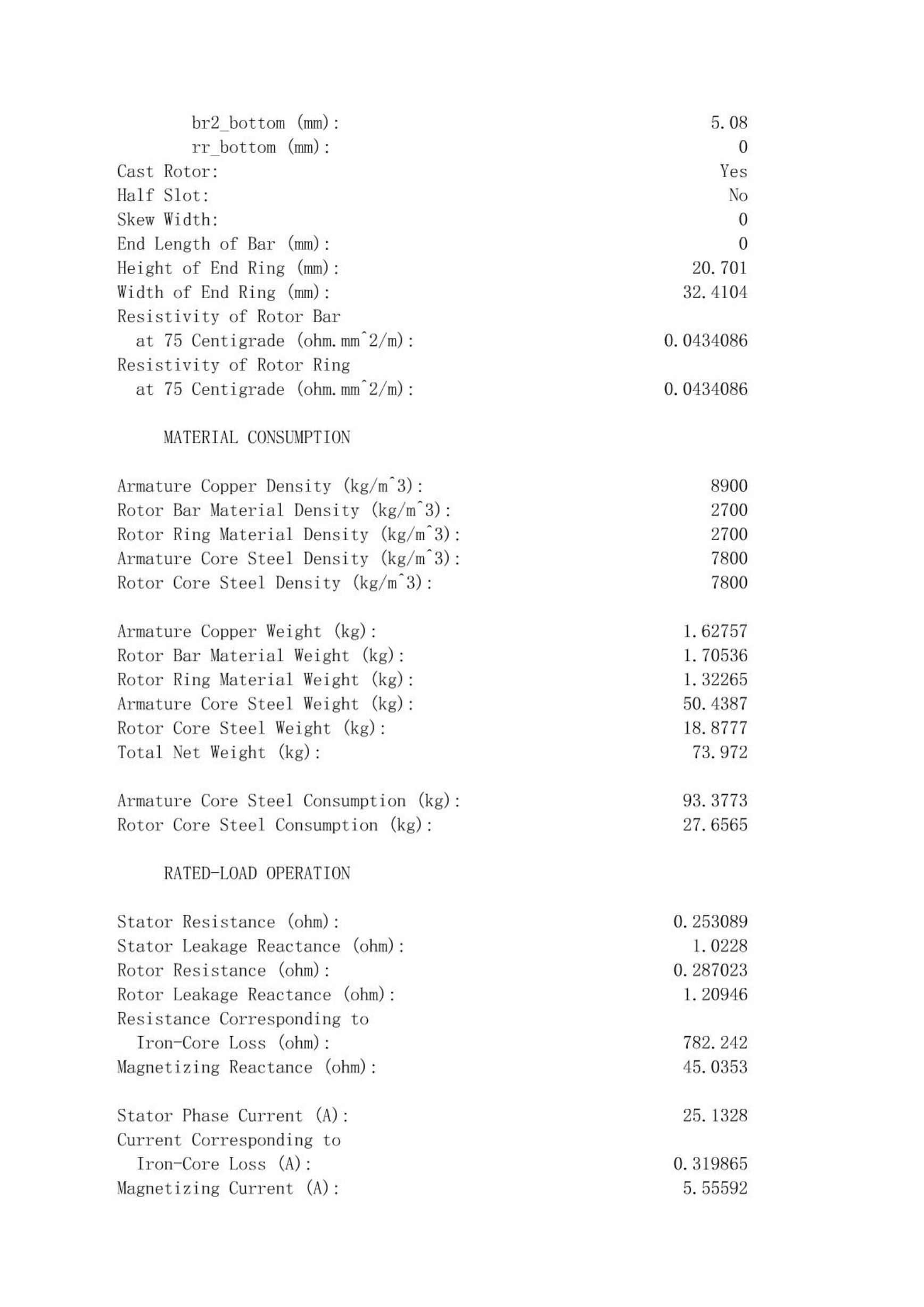

br2_bottom (mm): 5.08 rr_bottom (mm): 0 Cast Rotor: Yes Half Slot: No Skew Width: 0 End Length of Bar (mm): 0 Height of End Ring (mm): 20.701 Width of End Ring (mm): 32.4104 Resistivity of Rotor Bar at 75 Centigrade (ohm.mm^2/m): 0.0434086 Resistivity of Rotor Ring at 75 Centigrade (ohm.mm^2/m): 0.0434086 MATERIAL CONSUMPTION Armature Copper Density (kg/m^3): 8900 Rotor Bar Material Density (kg/m^3): 2700 Rotor Ring Material Density (kg/m^3): 2700 Armature Core Steel Density (kg/m^3): 7800 Rotor Core Steel Density (kg/m^3): 7800 Armature Copper Weight (kg): 1.62757 Rotor Bar Material Weight (kg): 1.70536 Rotor Ring Material Weight (kg): 1.32265 Armature Core Steel Weight (kg): 50.4387 Rotor Core Steel Weight (kg): 18.8777 Total Net Weight (kg): 73.972 Armature Core Steel Consumption (kg): 93.3773 Rotor Core Steel Consumption (kg): 27.6565 RATED-LOAD OPERATION Stator Resistance (ohm): 0.253089 Stator Leakage Reactance (ohm): 1.0228 Rotor Resistance (ohm): 0.287023 Rotor Leakage Reactance (ohm): 1.20946 Resistance Corresponding to Iron-Core Loss (ohm): 782.242 Magnetizing Reactance (ohm): 45.0353 Stator Phase Current (A): 25.1328 Current Corresponding to Iron-Core Loss (A): 0.319865 Magnetizing Current (A): 5.55592

�

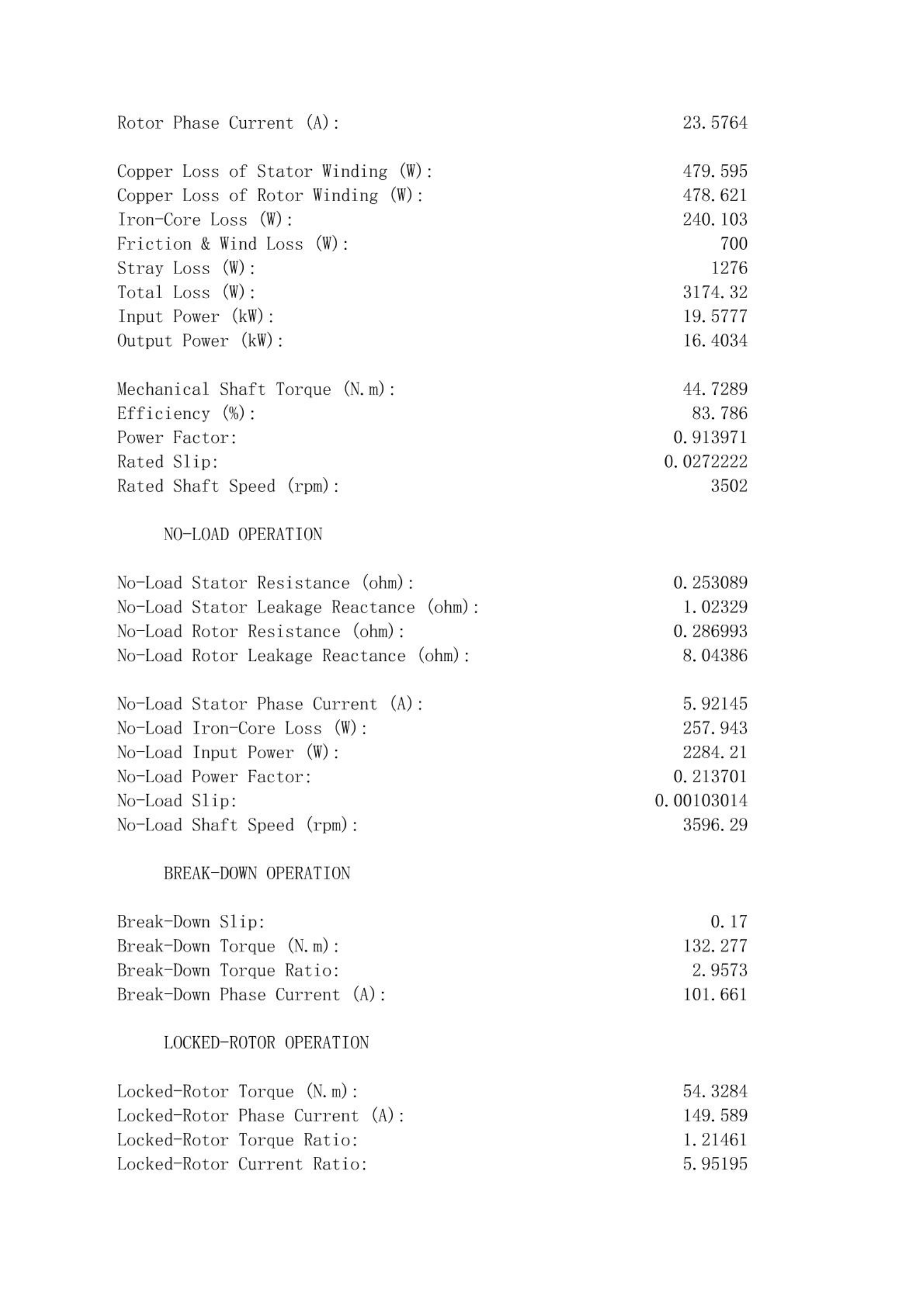

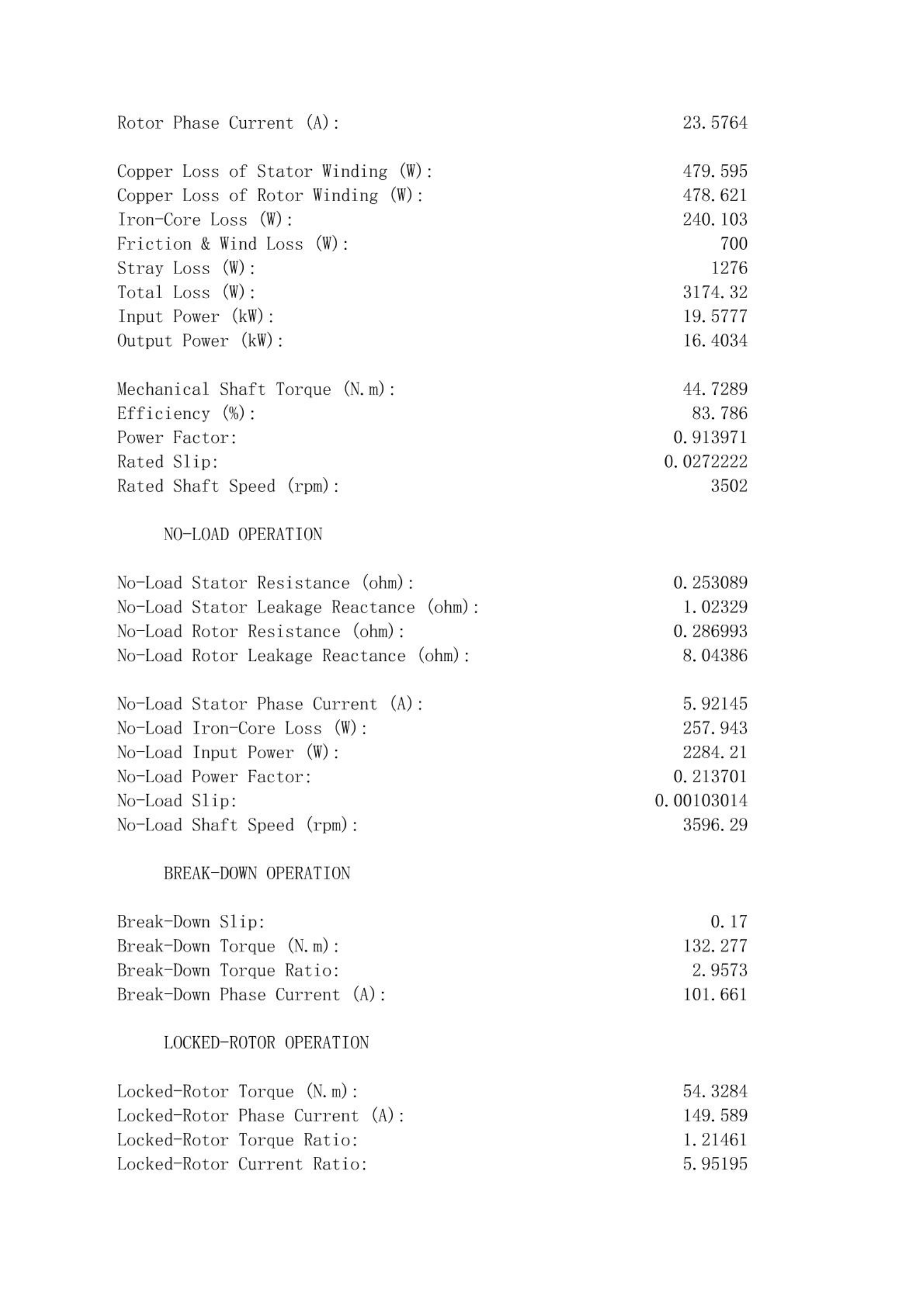

Rotor Phase Current (A): 23.5764 Copper Loss of Stator Winding (W): 479.595 Copper Loss of Rotor Winding (W): 478.621 Iron-Core Loss (W): 240.103 Friction & Wind Loss (W): 700 Stray Loss (W): 1276 Total Loss (W): 3174.32 Input Power (kW): 19.5777 Output Power (kW): 16.4034 Mechanical Shaft Torque (N.m): 44.7289 Efficiency (%): 83.786 Power Factor: 0.913971 Rated Slip: 0.0272222 Rated Shaft Speed (rpm): 3502 NO-LOAD OPERATION No-Load Stator Resistance (ohm): 0.253089 No-Load Stator Leakage Reactance (ohm): 1.02329 No-Load Rotor Resistance (ohm): 0.286993 No-Load Rotor Leakage Reactance (ohm): 8.04386 No-Load Stator Phase Current (A): 5.92145 No-Load Iron-Core Loss (W): 257.943 No-Load Input Power (W): 2284.21 No-Load Power Factor: 0.213701 No-Load Slip: 0.00103014 No-Load Shaft Speed (rpm): 3596.29 BREAK-DOWN OPERATION Break-Down Slip: 0.17 Break-Down Torque (N.m): 132.277 Break-Down Torque Ratio: 2.9573 Break-Down Phase Current (A): 101.661 LOCKED-ROTOR OPERATION Locked-Rotor Torque (N.m): 54.3284 Locked-Rotor Phase Current (A): 149.589 Locked-Rotor Torque Ratio: 1.21461 Locked-Rotor Current Ratio: 5.95195

�

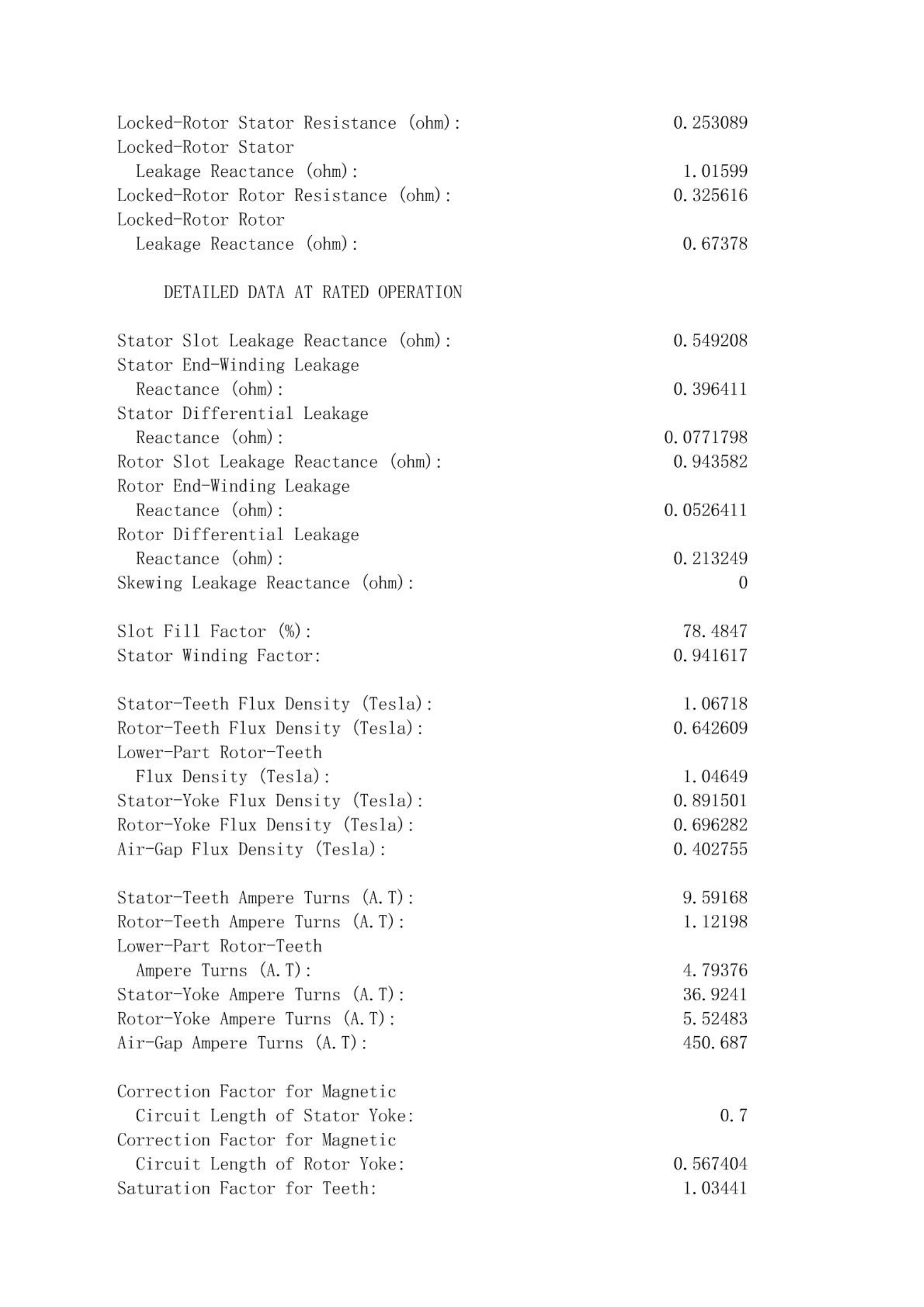

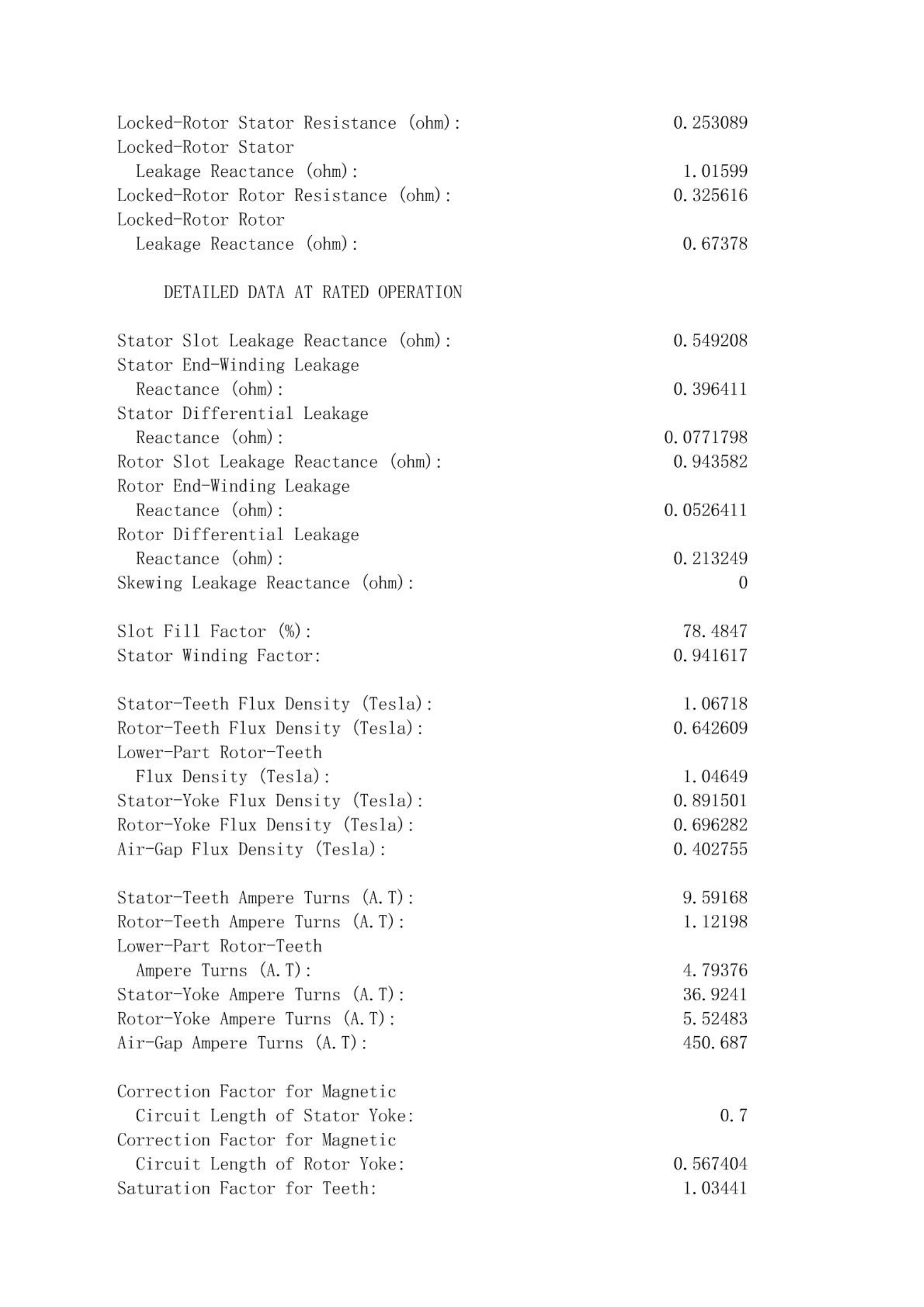

Locked-Rotor Stator Resistance (ohm): 0.253089 Locked-Rotor Stator Leakage Reactance (ohm): 1.01599 Locked-Rotor Rotor Resistance (ohm): 0.325616 Locked-Rotor Rotor Leakage Reactance (ohm): 0.67378 DETAILED DATA AT RATED OPERATION Stator Slot Leakage Reactance (ohm): 0.549208 Stator End-Winding Leakage Reactance (ohm): 0.396411 Stator Differential Leakage Reactance (ohm): 0.0771798 Rotor Slot Leakage Reactance (ohm): 0.943582 Rotor End-Winding Leakage Reactance (ohm): 0.0526411 Rotor Differential Leakage Reactance (ohm): 0.213249 Skewing Leakage Reactance (ohm): 0 Slot Fill Factor (%): 78.4847 Stator Winding Factor: 0.941617 Stator-Teeth Flux Density (Tesla): 1.06718 Rotor-Teeth Flux Density (Tesla): 0.642609 Lower-Part Rotor-Teeth Flux Density (Tesla): 1.04649 Stator-Yoke Flux Density (Tesla): 0.891501 Rotor-Yoke Flux Density (Tesla): 0.696282 Air-Gap Flux Density (Tesla): 0.402755 Stator-Teeth Ampere Turns (A.T): 9.59168 Rotor-Teeth Ampere Turns (A.T): 1.12198 Lower-Part Rotor-Teeth Ampere Turns (A.T): 4.79376 Stator-Yoke Ampere Turns (A.T): 36.9241 Rotor-Yoke Ampere Turns (A.T): 5.52483 Air-Gap Ampere Turns (A.T): 450.687 Correction Factor for Magnetic Circuit Length of Stator Yoke: 0.7 Correction Factor for Magnetic Circuit Length of Rotor Yoke: 0.567404 Saturation Factor for Teeth: 1.03441

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc