Bias Stability measurement

Bias Stability Measurement: Allan Variance

Dr. Walter Stockwell

Crossbow Technology, Inc.

http://www.xbow.com

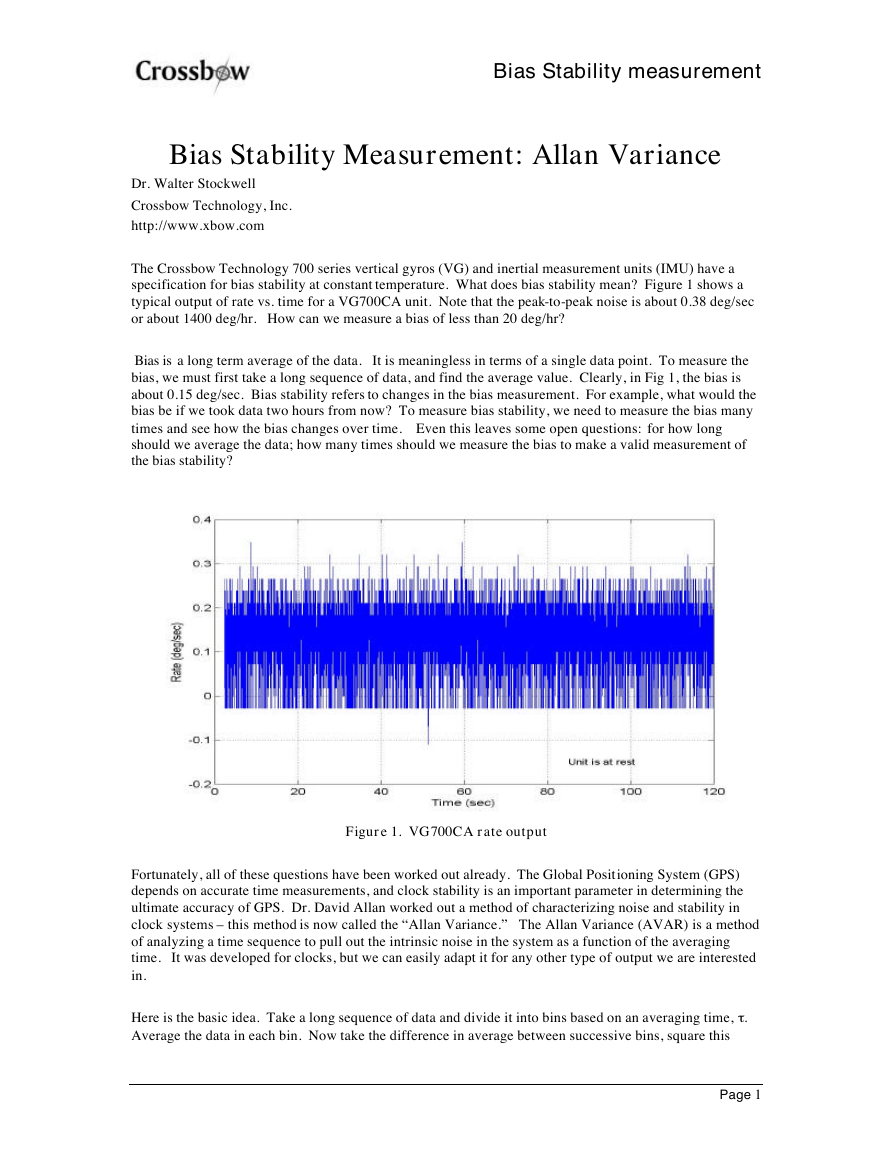

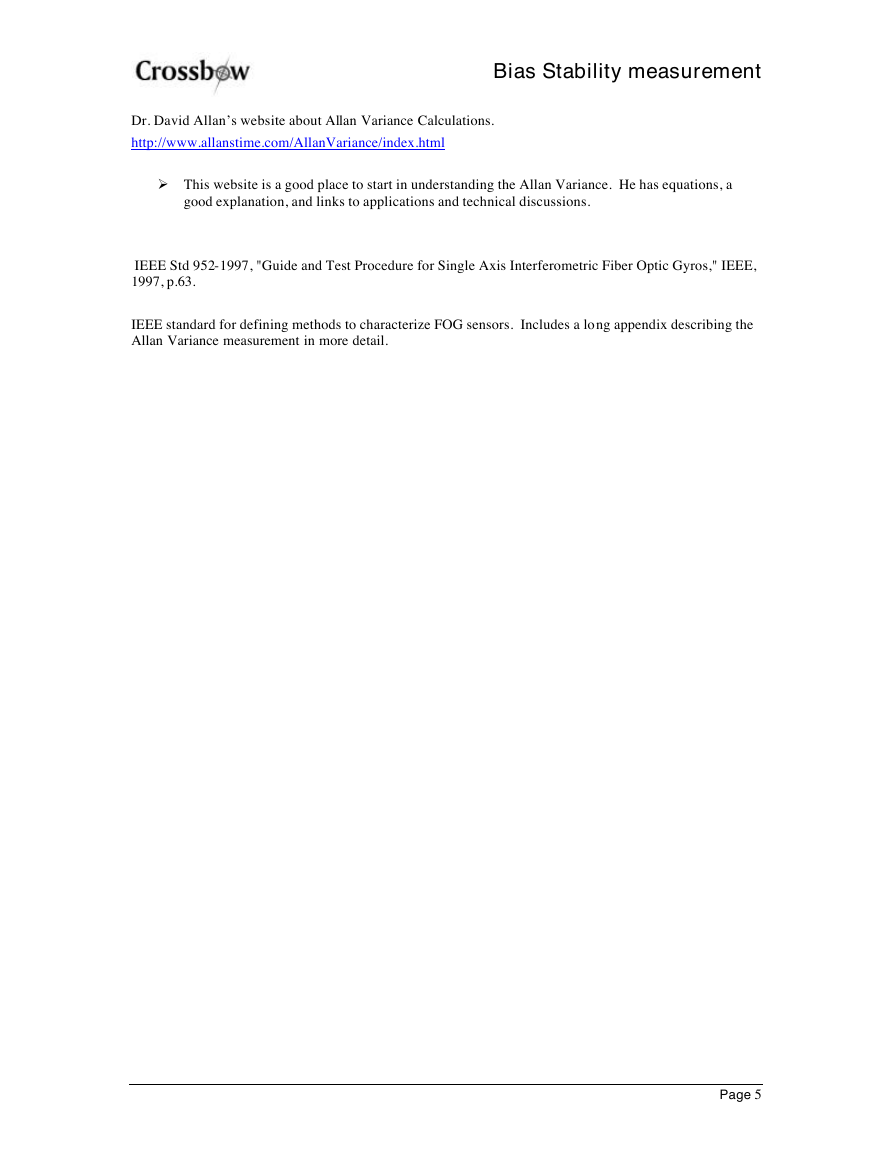

The Crossbow Technology 700 series vertical gyros (VG) and inertial measurement units (IMU) have a

specification for bias stability at constant temperature. What does bias stability mean? Figure 1 shows a

typical output of rate vs. time for a VG700CA unit. Note that the peak-to-peak noise is about 0.38 deg/sec

or about 1400 deg/hr. How can we measure a bias of less than 20 deg/hr?

Bias is a long term average of the data. It is meaningless in terms of a single data point. To measure the

bias, we must first take a long sequence of data, and find the average value. Clearly, in Fig 1, the bias is

about 0.15 deg/sec. Bias stability refers to changes in the bias measurement. For example, what would the

bias be if we took data two hours from now? To measure bias stability, we need to measure the bias many

times and see how the bias changes over time. Even this leaves some open questions: for how long

should we average the data; how many times should we measure the bias to make a valid measurement of

the bias stability?

Figure 1. VG700CA rate output

Fortunately, all of these questions have been worked out already. The Global Positioning System (GPS)

depends on accurate time measurements, and clock stability is an important parameter in determining the

ultimate accuracy of GPS. Dr. David Allan worked out a method of characterizing noise and stability in

clock systems – this method is now called the “Allan Variance.” The Allan Variance (AVAR) is a method

of analyzing a time sequence to pull out the intrinsic noise in the system as a function of the averaging

time. It was developed for clocks, but we can easily adapt it for any other type of output we are interested

in.

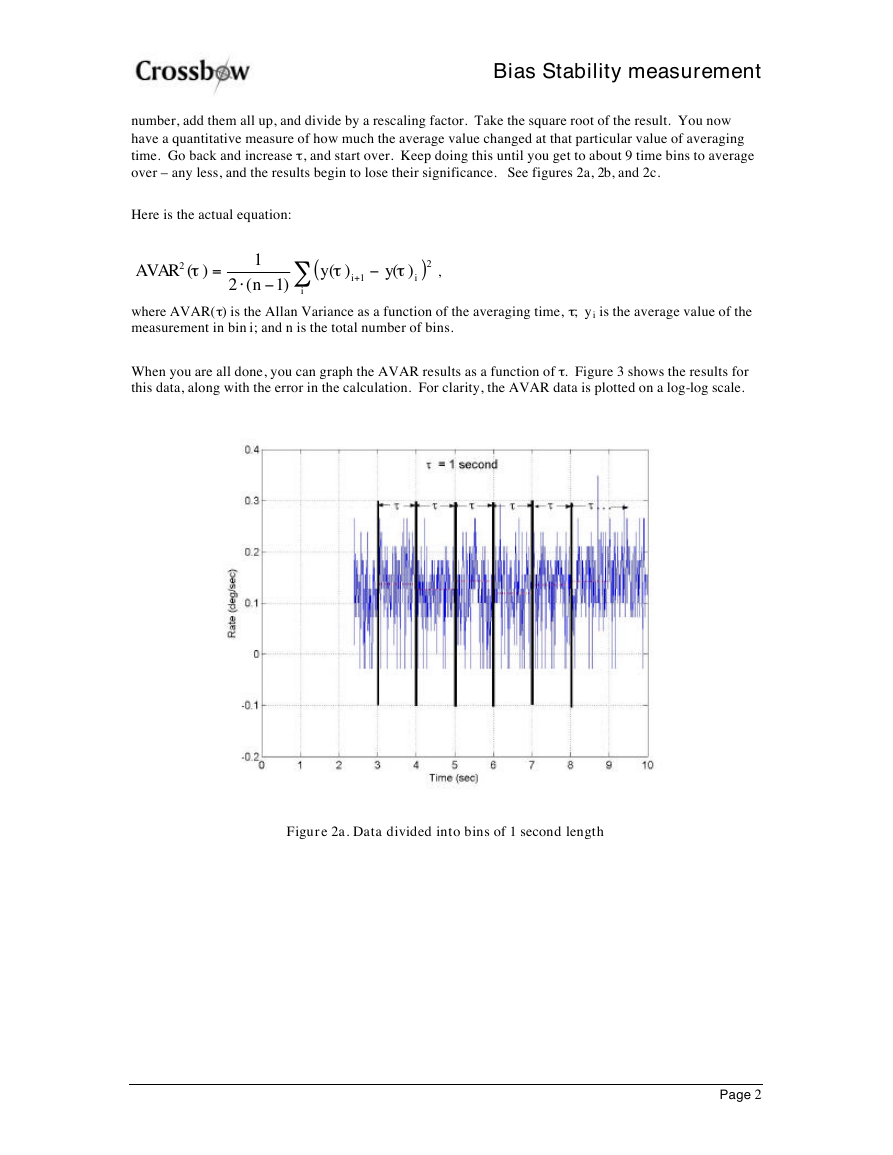

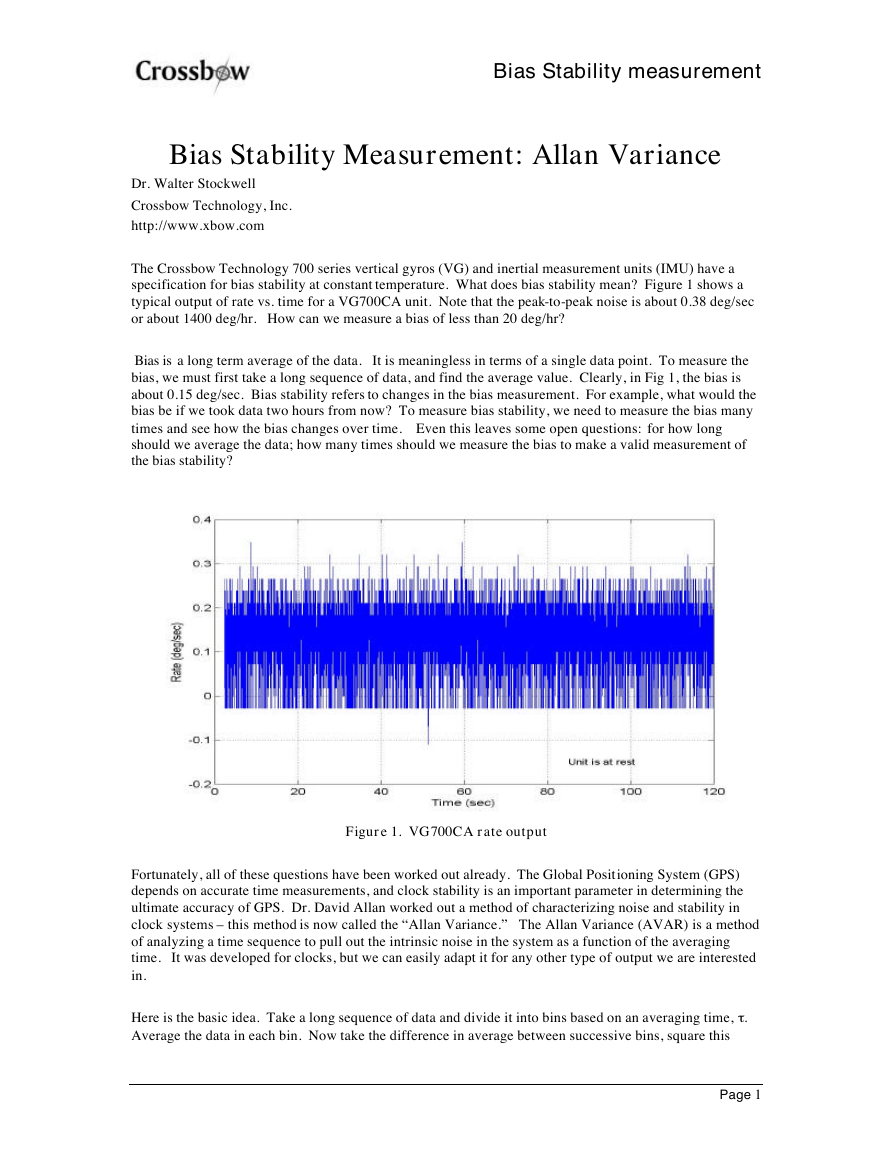

Here is the basic idea. Take a long sequence of data and divide it into bins based on an averaging time, t .

Average the data in each bin. Now take the difference in average between successive bins, square this

Page 1

�

Bias Stability measurement

number, add them all up, and divide by a rescaling factor. Take the square root of the result. You now

have a quantitative measure of how much the average value changed at that particular value of averaging

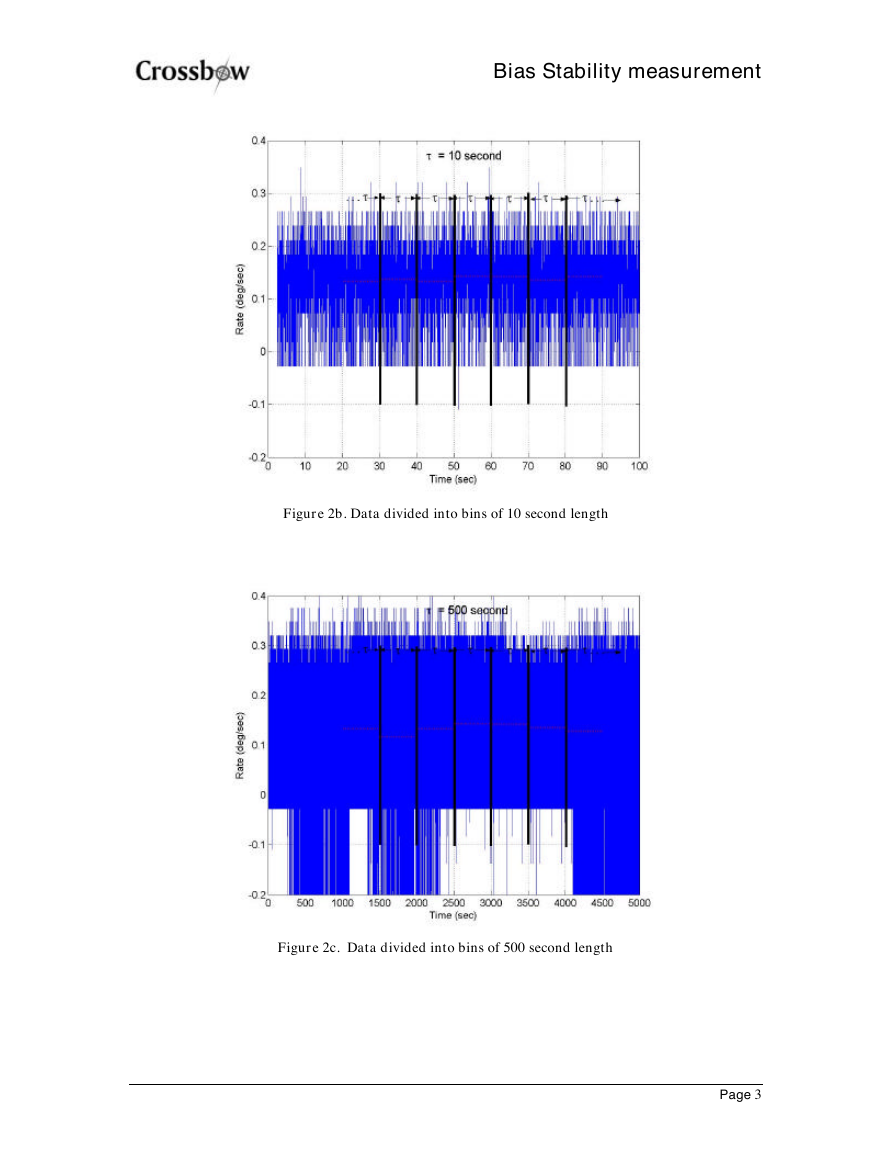

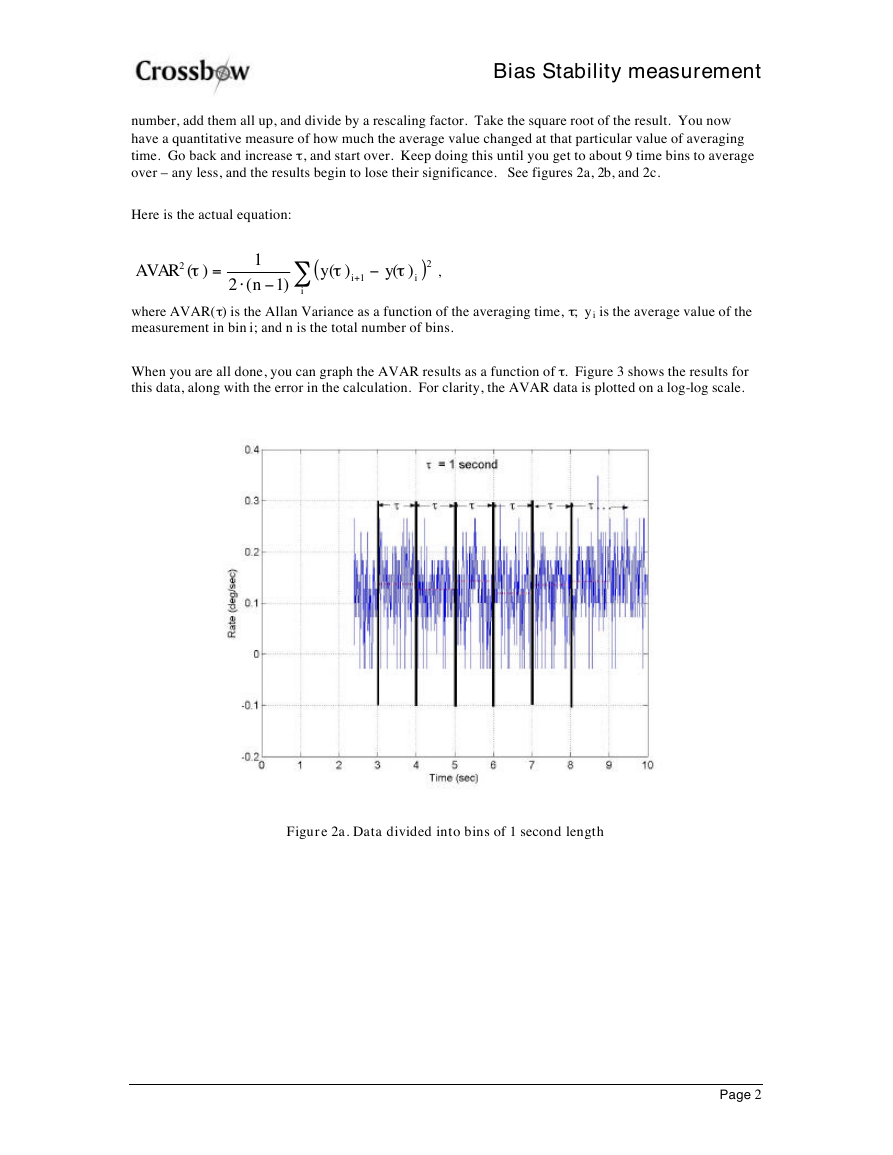

time. Go back and increase t , and start over. Keep doing this until you get to about 9 time bins to average

over – any less, and the results begin to lose their significance. See figures 2a, 2b, and 2c.

Here is the actual equation:

AVAR

2

t

)(

=

1

n

(2

)1

i

(

y

t

)(

+

1

i

t

)(

y

i

)

2

,

where AVAR(t ) is the Allan Variance as a function of the averaging time, t ; yi is the average value of the

measurement in bin i; and n is the total number of bins.

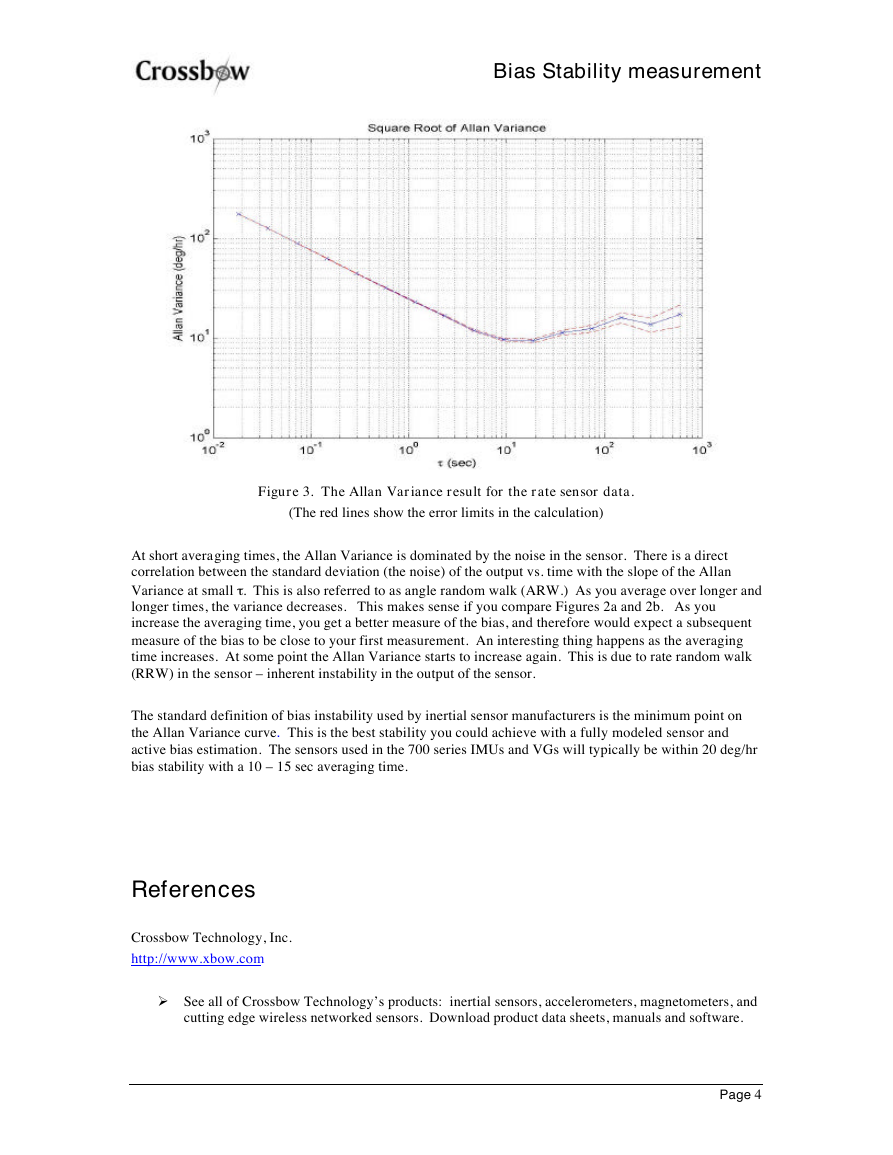

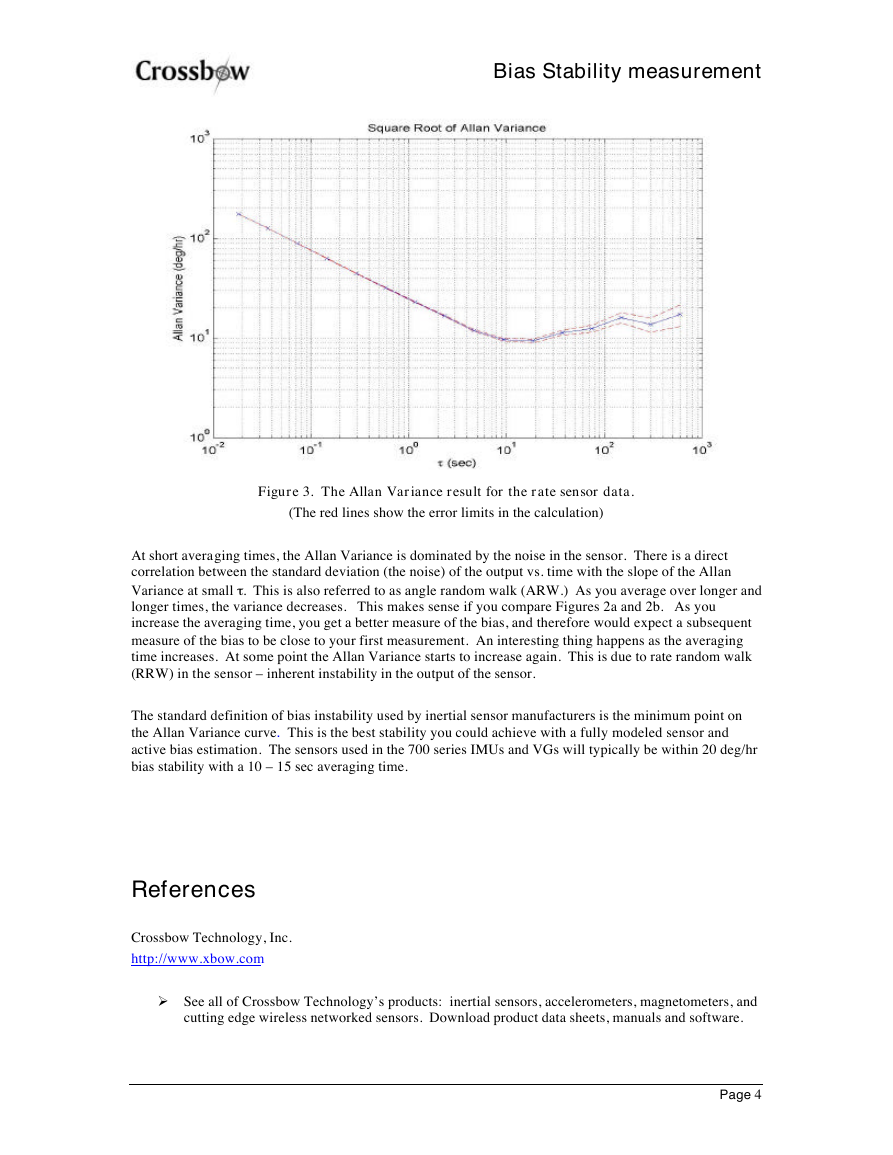

When you are all done, you can graph the AVAR results as a function of t . Figure 3 shows the results for

this data, along with the error in the calculation. For clarity, the AVAR data is plotted on a log-log scale.

Figure 2a. Data divided into bins of 1 second length

Page 2

-

-

�

Bias Stability measurement

Figure 2b. Data divided into bins of 10 second length

Figure 2c. Data divided into bins of 500 second length

Page 3

�

Bias Stability measurement

Figure 3. The Allan Variance result for the rate sensor data.

(The red lines show the error limits in the calculation)

At short averaging times, the Allan Variance is dominated by the noise in the sensor. There is a direct

correlation between the standard deviation (the noise) of the output vs. time with the slope of the Allan

Variance at small t . This is also referred to as angle random walk (ARW.) As you average over longer and

longer times, the variance decreases. This makes sense if you compare Figures 2a and 2b. As you

increase the averaging time, you get a better measure of the bias, and therefore would expect a subsequent

measure of the bias to be close to your first measurement. An interesting thing happens as the averaging

time increases. At some point the Allan Variance starts to increase again. This is due to rate random walk

(RRW) in the sensor – inherent instability in the output of the sensor.

The standard definition of bias instability used by inertial sensor manufacturers is the minimum point on

the Allan Variance curve. This is the best stability you could achieve with a fully modeled sensor and

active bias estimation. The sensors used in the 700 series IMUs and VGs will typically be within 20 deg/hr

bias stability with a 10 – 15 sec averaging time.

References

Crossbow Technology, Inc.

http://www.xbow.com

See all of Crossbow Technology’s products: inertial sensors, accelerometers, magnetometers, and

cutting edge wireless networked sensors. Download product data sheets, manuals and software.

Page 4

�

Dr. David Allan’s website about Allan Variance Calculations.

http://www.allanstime.com/AllanVariance/index.html

Bias Stability measurement

This website is a good place to start in understanding the Allan Variance. He has equations, a

good explanation, and links to applications and technical discussions.

IEEE Std 952-1997, "Guide and Test Procedure for Single Axis Interferometric Fiber Optic Gyros," IEEE,

1997, p.63.

IEEE standard for defining methods to characterize FOG sensors. Includes a long appendix describing the

Allan Variance measurement in more detail.

Page 5

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc