International Journal of CAD/CAM Vol. 1, No. 1, pp. 11~21 (2002)

Automatic Conversion of Triangular Meshes Into Quadrilateral Meshes with

Directionality

Takayuki Itoh1* and Kenji Shimada2

1IBM Research, Tokyo Research Laboratory

2Mechanical Engineering, Carnegie Mellon University

Abstract - - - - This paper presents a triangular-to-quadrilateral mesh conversion method that can control the directionality of the

output quadrilateral mesh according to a user-specified vector field. Given a triangular mesh and a vector field, the method

first scores all possible quadrilaterals that can be formed by pairs of adjacent triangles, according to their shape and

directionality. It then converts the pairs into quadrilateral elements in order of the scores to form a quadrilateral mesh.

Engineering analyses with finite element methods occasionally require a quadrilateral mesh well aligned along the boundary

geometry or the directionality of some physical phenomena, such as in the directions of a streamline, shock boundary, or force

propagation vectors. The mesh conversion method can control the mesh directionality according to any desired vector fields,

and the method can be used with any existing triangular mesh generators.

Keywords: quadrilateral mesh, triangular mesh, conversion, directionality.

1. Introduction

In some types of finite element method (FEM)

analyses, such as sheet-metal forming simulations and

automobile crash simulations, quadrilateral meshes are

preferable to triangular meshes because they produce

more accurate results more efficiently. Such engineering

analyses occasionally require a quadrilateral mesh well

aligned along the boundary geometry or the directionality

of some physical phenomena, such as along the directions

of a streamline, shock boundary, or force propagation

vectors.

Although there are many approaches to generating

quadrilateral meshes, their capabilities of controlling

the mesh directionality are quite limited. The existing

quadrilateral meshing approaches include: template

matching [1], medial-axis-based decomposition [2], quad-

tree decomposition [3-5], advancing front [6-10], and

triangular-to-quadrilateral mesh conversion [11-21]. In

this paper we focus on the triangle-to-quadrilateral mesh

conversion methods, which take advantage of the benefits

of triangular mesh generation: (1) a fully-automated

meshing process, (2) flexible control of element sizes,

and (3) less computation time than the advancing front

method. The advancing front methods [6-10] and the

triangular-to-quadrilateral mesh conversion methods [18-

20] control mesh directionality, but based only on the

domain boundary; they cannot create a quadrilateral

mesh that aligns well with an arbitrary vector field

*Corresponding author:

E-mail : itot@trl.ibm.com

given by the user.

In this paper we propose a triangular-to-quadrilateral

mesh conversion scheme that can control the mesh

directionality of an output quadrilateral mesh accurately

based on a user-specified vector field. Given a triangular

mesh and a vector field, the method generates a

quadrilateral mesh. It first scores the geometric irregularity

and the directionality error of the quadrilaterals formed

by all possible pairs of adjacent triangular elements in

the input mesh. It then converts pairs of adjacent

triangular elements into quadrilateral elements according

to the weighted sum of the shape irregularity and the

directionality error. The proposed conversion method

can be used with any existing triangular mesh generators.

The remainder of the paper is organized as follows.

After reviewing previous mesh conversion methods in

Section 2, we describe data structures for triangular

meshes and vector fields in Section 3. We then describe

the algorithm of our mesh conversion method in Section

4. After discussing our results in Section 5, we offer

some conclusions in Section 6.

2. Previous Work

Given a triangular mesh, existing triangular-to-

quadrilateral mesh conversion methods [11-21] join

pairs of adjacent triangular elements selectively and then

convert the pairs into quadrilateral elements. The quality

of the output quadrilateral mesh strongly depends on

which pairs of triangular elements are joined. The

shapes of the quadrilateral elements and the number of

triangular elements left in quad-dominant meshes strongly

�

��

International Journal of CAD/CAM Vol. 1, No. 1, pp. 11~21

depend on this selection of triangular pairs.

One of the goals of triangular-to-quadrilateral mesh

conversion is to maximize the number of triangular

pairs. This problem is called maximum matching in graph

theory, and there are algorithms available for solving

this problem. Suppose the connectivity of input triangular

elements is interpreted as an undirected weighted graph,

the graph nodes represent triangular mesh elements,

and graph edges represent connectivity between mesh

elements. Preferable quadrilateral meshes can be obtained

by applying a maximum matching algorithm to non-

bipartite graphs. This process, however, is computationally

expensive, and it does not necessarily create a quad-

dominant mesh suitable for engineering analysis. Another

approach to solving the mesh conversion problem is to

apply integer programming [21], which is also com-

putationally expensive. In most cases a quadrilateral

mesh of sufficient quality for engineering analysis can

be generated without performing maximum matching

or integer programming, as can be seen in many

previously proposed mesh conversion methods.

In the rest of this section we survey and categorize

previous mesh conversion methods. Note that the

common shortfall of these methods is limited control

over mesh directionality. Some of the methods can

align an output mesh along the domain boundaries, but

none can realize a user-defined arbitrary directionality.

2.1. Conversion methods

that minimize

the

number of triangular elements

The methods in this category [11-12] count the

number of unprocessed adjacent triangles for each

triangle and mark those that have only one unprocessed

adjacent triangle as high-priority triangles. These triangles

are then extracted and converted into quadrilateral

elements with their adjacent triangles. The adjacency of

triangles is dynamically updated during the conversion

process, and many triangles are therefore marked as

high-priority triangles during the process. Finally, many

of the marked triangles are converted into quadrilateral

elements yielding a quad-dominant mesh.

Since the goal of these methods is to generate all-

quadrilateral meshes, they also include post-processing

for converting isolated triangles. Heighway [11] proposes

a method that swaps the edges of quadrilaterals lying

between two isolated triangles until the two triangles

become adjacent, as if the two triangles ‘walk’ toward

each other. Johnston et al. [12] describe a method that

subdivides or swaps edges of isolated triangles until they

are locally converted into all-quadrilateral elements.

2.2. Conversion methods that minimize geometric

irregularities

The methods in this category [13-17] first calculate

the values of a scalar function representing the shapes

of the quadrilaterals generated by all possible pairs of

adjacent triangular elements. They then convert the

triangle pairs into quadrilateral elements in order of the

values of this function.

Various functions can be used to evaluate quadrilateral

shapes. Lo et al. [13] propose an evaluation function

defined by the ratio between the shape evaluation

values of the four possible triangles generated by dividing

the quadrilateral by its two diagonals. Borouchaki et al.

[17] propose an evaluation function based on the angles

of the four vertices of each quadrilateral.

2.3. Advancing front-like conversion methods

In many cases, elements along the domain boundary

are the most critical in engineering analysis. Therefore,

it is often desirable that elements are well aligned along

the domain boundary. Quadrilateral meshes with such

well-aligned boundary elements can be generated via

triangular-to-quadrilateral mesh conversion by coupling

triangles of the input mesh along the domain boundary

first.

Shimada et al. [20] devised a method that first clusters

the input triangular mesh into layered sub-domains along

the domain boundary, and then couples the triangles in

each cluster. The method generates a topologically regular

mesh, and the mesh elements’ shapes can be improved

by a smoothing process.

Owen et al. [18-19] propose the ‘Q-Morph’ method,

which visits front of an input triangular mesh in order

and forms quadrilaterals along the visited front edges

by re-connecting some edges around the visited front

edges. This method generates a high quality quadrilateral

mesh well aligned along the domain boundary, similar

to a mesh generated by the advancing front method.

3. Preliminaries

In this section we define the data structures for the

inputs of the proposed mesh conversion method: a

triangular mesh and a desired mesh directionality.

3.1. Data structure of a triangular mesh

We represent a triangular mesh, Mt, as a planar graph,

Mt = (V, T, T, D T),

(1)

¶

consisting of four ordered lists of:

(1) nodes, V=(v1,..., vl),

(2) triangular elements, T=(t1,..., tn),

¶

(3) element boundaries, T=(

tn), which

defines the three surrounding nodes of each

triangle, and

(4) adjacent elements, D T=(D t1, ..., D tn), which gives

at most three adjacent triangles for each triangle.

¶

t1, ...,

¶

¶

V and T are topological entities in a triangular mesh,

and T and D T give topological connections between

topological entities. The i th element of T, denoted as

¶

ti, represents the counter-clockwise ordered list of the

nodes surrounding the i th triangle ti. Similarly, the i th

¶

�

Takayuki Itoh and Kenji Shimada

Automatic Conversion of Triangular Meshes Into Quadrilateral Meshes with Directionality

��

Fig. 1. Triangular mesh representation.

element of the list D T, denoted as D ti, represents the

counter-clockwise ordered list of the triangles adjacent

to the i th triangle ti. The notation D tij represents the j th

adjacent triangle of D ti. The number of adjacent triangles

of ti is denoted by |D ti|.

For example, the representation of the triangular mesh

shown in Fig. 1(a) is:

(2)

Mt=((v1, v2, v3, v4, v5), (t1, t2, t3),

((v1, v2, v3),)(v2, v4, v3), (v2, v5, v4)),

((f , t2, f ), (t3, f , t1), (f , f , t2))),

where f in D T means that there is no triangle adjacent

to a given side. In this example, as implied by the

expression D t1=(f , t2, f ), the triangle t1 has only one

adjacent triangle t2, so the number of adjacent triangles

is one, or |D t1|=1.

In the mesh conversion algorithms given in this paper,

adjacencies between triangles are selectively deleted in

order to make pairs of triangles. Fig. 1(a) shows an

example of nodes and triangles in a mesh, and Fig. 1(b)

shows its adjacencies. To delete the adjacency between

t2 and t3 in Fig. 1(b), D t21 and D t33 are set to f , yielding

a new element adjacency,

D T=((f , t2, f ), (f , f , t1), (f , f , f ))

as shown in Fig. 1(c).

(3)

Our mesh conversion method couples adjacent

triangles, ti and tj, while deleting the adjacency between

ti (or tj) and its other adjacent triangular elements. The

coupling process is repeated until no triangle has an

adjacency with more than one other triangular element.

Edges shared by each pair of triangles are then deleted,

and finally a quad-dominant mesh is generated.

Fig. 2. Quad-dominant to all-quad mesh conversion.

Although the quad-dominant mesh generated by this

mesh conversion method contains a small number of

triangular elements, it can be converted into an all-

quadrilateral mesh by dividing each remaining triangle

into three quadrilaterals and dividing each quadrilateral

into four quadrilaterals, by adding an inside node for

each triangle and by dividing all the edges in two for

both triangles and quadrilaterals, as shown in Fig. 2.

3.2. Data structure for desired mesh directionality

One of the inputs of our method is a vector field that

represents the user’s preferences for mesh directionality.

A simple way to represent a vector field is to use a grid

so that at each grid-point a vector value is defined. In

this paper we assume that the vector field is given as a

two-dimensional grid, G, represented as:

G=(PG, DG)

consisting of two ordered lists of:

(4)

(1) grid-points, PG=((p1,1,...,p1,n),.....,(pm,1,...,pm,n)), and

(2) vector values, DG=((d1,1,...,d1,n),....,(dm,1,...,dm,n)).

As shown in Fig. 3, the grid G has (m-1)� (n-1) cells

and m� n grid-points. The vector value, d, at an

arbitrary point, p, can be calculated by the following

Fig. 3. A 2D grid representing a vector field, and the calculation of a vector value at an arbitrary point.

�

��

International Journal of CAD/CAM Vol. 1, No. 1, pp. 11~21

bi-linear interpolation of vector values assigned to the

grid-points:

d(s,t)=(1-s)((1-t)di,j+tdi,(j+1))+s((1-t)d(i+1), j+td(i+1),(j+1))

(5)

where (s,t) is the parametric coordinate of point p

calculated by projecting a cell that contains point p.

4. Mesh Conversion with Directionality

This section describes the algorithm of our mesh

conversion method. Given a triangular mesh, Mt, and

desired mesh directionality, G, the method first scores

the shapes and directionality of all the possible

quadrilaterals that can be generated by combining pairs

of adjacent triangles. The method then converts the

pairs of triangles to quadrilateral elements in order of

their scores.

Sections 4.1 and 4.2 describe the following two

scalar functions used to score a quadrilateral,

(1) e gi for evaluating the geometric irregularity of

the i th quadrilateral, qi, formed by coupling two

adjacent triangles, and

(2) e di for evaluating the directionality error of the i

th quadrilateral, qi.

We then describe the algorithm to pair triangles in an

input mesh in Section 4.3. We also describe the

algorithm to generate a vector field from a set of input

vector values in Section 4.4. In the rest of this paper we

represent all possible quadrilaterals formed by joining

two adjacent triangular elements and the directions of

the edges of the quadrilaterals as the following ordered

lists of:

(1) quadrilaterals, Q=(q1,..., qn), and

(2) directions of the quadrilaterals’ edges, E=((e1,1,

e1,2, e1,3, e1,4),...,(en,1, en,2, en,3, en,4)).

4.1. Scalar function eeee g for measuring the geometric

irregularity of quadrilaterals

In order to measure the geometric irregularity of the i th

quadrilateral, qi, we define the following scalar function:

e gi 1

–=

2

ri

----

Ri

(6)

Here, as shown in Fig. 4, ri is the radius of the

minimum inscribed circle, the smallest circle tangent to

at least three edges of an element, and Ri is the radius

of the maximum circumcircle, the largest circle that

goes through at least three vertices of qi. The radius

ratio of the two circles, ri /Ri, takes its maximum value

1 2⁄

for a square, and minimum value 0 for a highly

irregular quadrilateral. Therefore, the value of e gi is 0 in

the best case, and 1 in the worst case.

4.2. Scalar function

eeee d for measuring the

directionality error of quadrilaterals

In order to measure the directionality error of the i th

quadrilateral, qi, we define the following scalar function:

e di

2+(

2

=

4–Ł

) 1

1

---

4

k 1=

{

}

)

,

max ei k, di

ei k, N di

-------------------------------------------------------------

ei k,

(

(7)

As also shown in Fig. 5, di denotes the unit vector

obtained from the input vector field at the center of

the quadrilateral element, and N denotes the unit

normal vector of the quadrilateral element. The value

� (N� di)|} takes its maximum value

max{|ei,k

1 for an edge perfectly aligned along the given vector,

and minimum value

when the edge and the

desired direction form an angle of 45 degrees. Therefore,

the value of e di is 0 in the best case, and 1 in the worst

case.

� di|, |ei,k

1 2⁄

4.3. Coupling of

quadrilaterals

triangle pairs

to

form

Two previous sections defined two scalar functions,

e gi and e di, that measure the geometric irregularity and

directionality error, respectively. By taking a weighted

sum of these two functions, we define the following

metric, e i, that decides the order of coupling triangles:

e i=(1-a)e gi+ae di

0� a� 1

(8)

where a is a user-defined weighting factor representing

the relative importance of the two measurements. Lower

values of a give greater importance to shape regularity than

directionality. Values of e i for all possible quadrilaterals

are first calculated in our algorithm, since they do not

change during the entire coupling process. All possible

quadrilaterals are then inserted into a list, L, and sorted

Fig. 4. Function for evaluating the geometric irregularity of a

quadrilateral.

Fig. 5. Function for evaluating the directionality error of a

quadrilateral.

·

ł

�

Takayuki Itoh and Kenji Shimada

Automatic Conversion of Triangular Meshes Into Quadrilateral Meshes with Directionality

��

Fig. 6. Pseudo code for the mesh conversion method.

by their e i values.

The quadrilaterals are then extracted from list L in

the order of their e i values. Suppose two triangles, ta

and tb, form an extracted quadrilateral, ta and tb’s other

adjacencies need to be deleted. This process is repeated

until the list L becomes empty, and finally no triangle has

an adjacency with more than one other triangular

element. Edges shared by each pair of triangles are then

deleted to form a quad-dominant mesh. The complete

procedure for the above algorithm is given in Fig. 6.

Although an output quad-dominant mesh generated

by the above algorithm still contains a small number of

triangular elements, the mesh can be converted into an

all-quadrilateral mesh by applying the templates shown

in Fig. 2.

4.4. Automated vector field generation

Although the mesh conversion algorithm described in

the previous section requires a desired mesh directionality

as a vector field, this vector field need not be provided

by the user at all, or it may be provided at only a set of

selected locations in the mesh domain. This section

describes a method for generating a vector field

automatically in these situations.

Suppose that desired mesh directionality is provided

by the user as vector values at a set of points in the

mesh domain. We denote these points and vector values

as :

(1) points, PP=(p1,...,pl), and

(2) Vector values, DP=(d1,...,dl),

where l is the number of the given points at which the

desired mesh directionality is specified.

Our implementation assigns vector values to the grid-

points of grid G to represent a vector field defined over

the entire mesh domain and well aligned along the

vector values Dp . We calculate a vector value, di,j, that

is the vector value at a grid-point, gi,j, of a two-

dimensional grid using the following formula:

l

=

di j,

k 1=

dk

-------------

2

ei j k, ,

(9)

where dk is the given unit vector at point pk, and ei,j,k is

the vector from point pk to grid-point gi, j as shown in

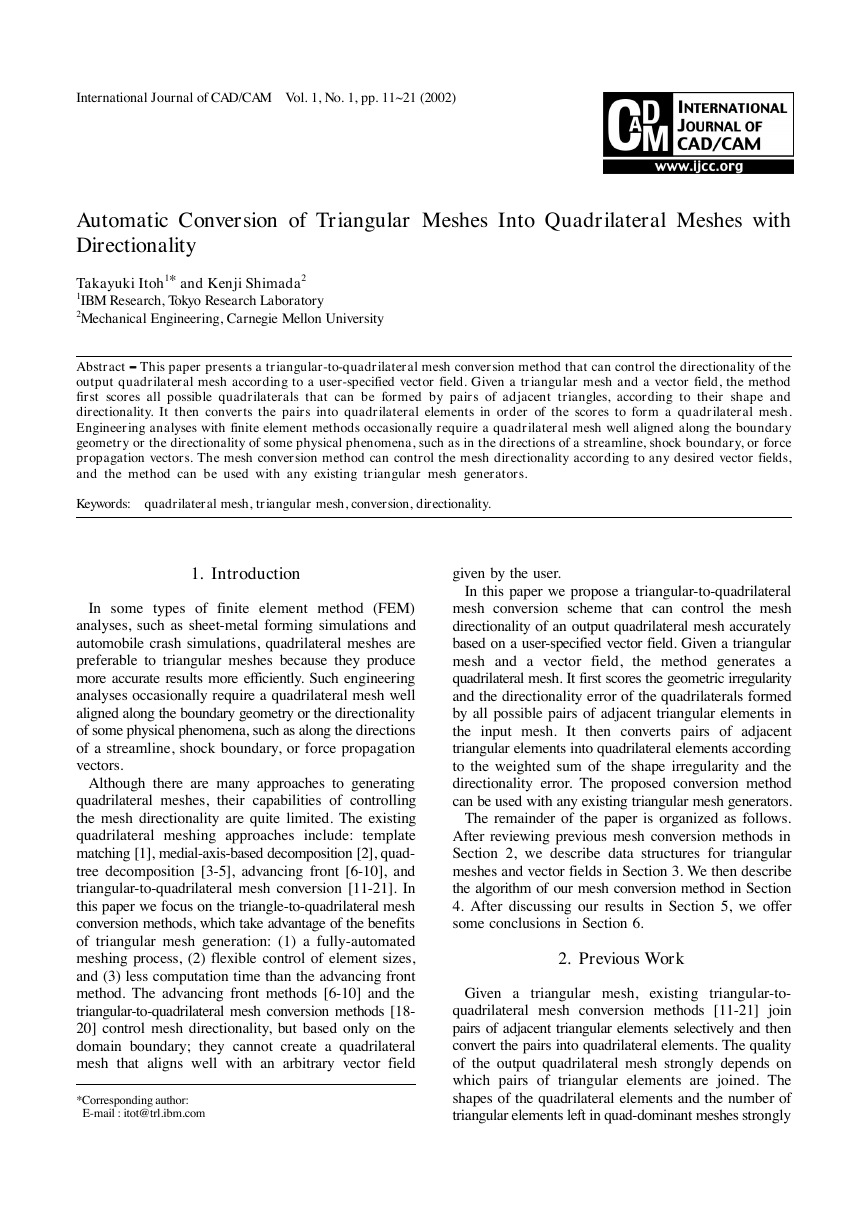

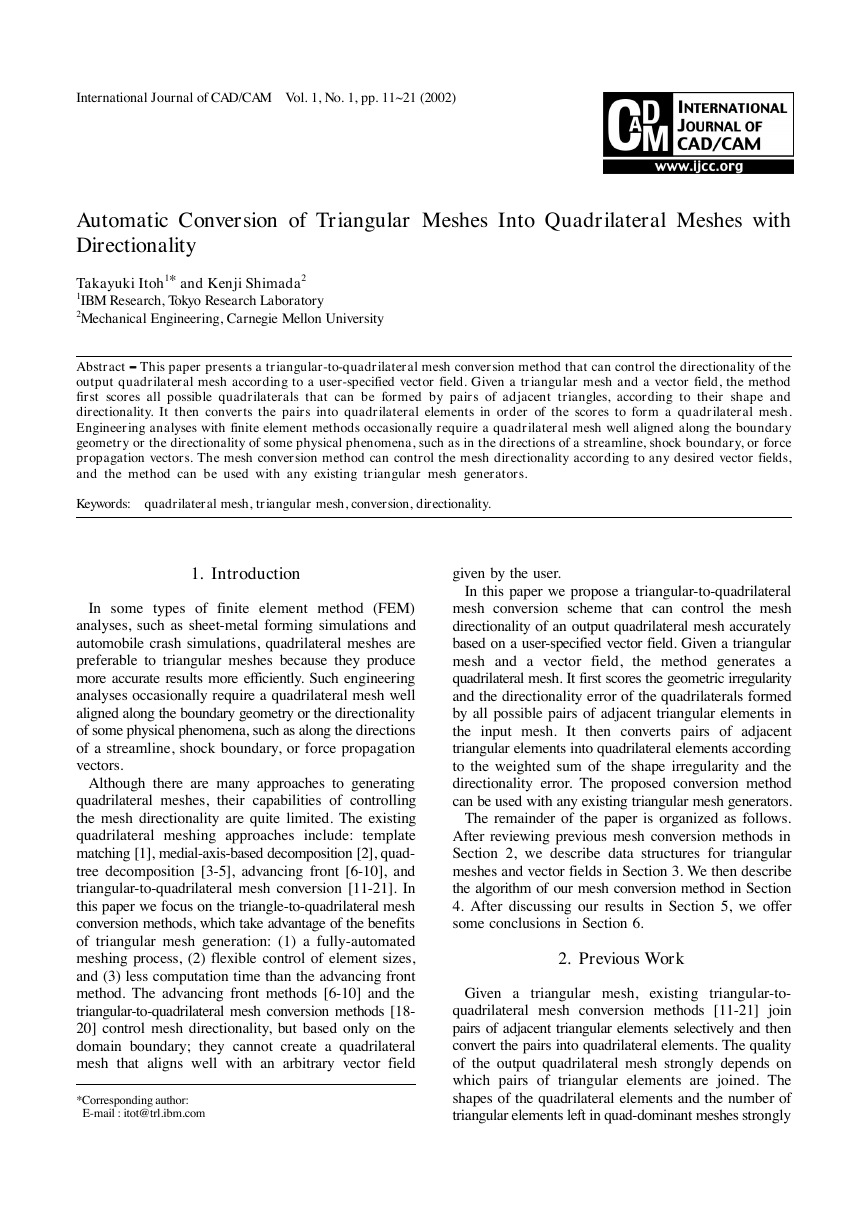

Fig. 7(a). Fig. 7(b) shows an example of a set of input

vector values, and Fig. 7(c) shows a complete vector

field calculated from the set of input vector values.

This vector averaging technique works best when the

input vectors are evenly spaced. When a region has

many input vectors clustered together, they tend to

outweigh other input vectors. This problem can be

avoided by limiting the maximum number of vectors

used in a local region.

If it is desirable that the elements be well aligned

along the domain boundary, like meshes generated by

the advancing front method, our mesh conversion method

can generate such meshes by automatically generating

a vector field along the domain boundary using the

same method described above. To generate such a vector

field we take a set of points on the domain boundary

and assign vector values at these points according to

the boundary direction.

�

��

International Journal of CAD/CAM Vol. 1, No. 1, pp. 11~21

Fig. 7. Calculation of a vector field from a set of vector values.

5. Results

The new mesh conversion method was implemented

in C++ on Unix Workstations (IBM AIX 4.3.2 and SGI

IRIX 6.2) and on Windows NT/95/98 PCs.

In order to evaluate the quality of the meshes generated

by our conversion algorithm, we define topological

irregularity, e i, in addition to the geometric irregularity,

e g, and directionality error, e d, as defined in Section 4.

We measure the overall geometric irregularity of an

output quadrilateral mesh by taking the average of the

geometric irregularity of each element, e gi, as defined

in Section 4.1:

e g

m=

1

----

m

i 0=

e gi

(10)

where m is the number of quadrilateral elements. Since

the value e gi takes its minimum value 0 for a square

element, a smaller value of

indicates a more

geometrically regular mesh.

e g

We measure the overall directionality error of an

output quadrilateral mesh by taking the average of the

directionality error of each element, e di, as defined in

Section 4.2:

e d

m=

1

----

m

i 0=

e di

(11)

Because the value e di takes its minimum value 0 for

an element perfectly aligned along a given vector field,

a smaller value of

indicates a better-aligned mesh.

e d

For topological irregularity, we define the following

metric:

e t

n=

1

---

n

i 0=

d vi D–

(12)

where D=4 for the internal nodes of a quadrilateral

mesh, D=2 for the boundary nodes of a quadrilateral

mesh, n denotes the number of nodes, and d vi denotes

the number of nodes adjacent to i th node vi. The

topological irregularity

has a positive value that

measures how much the mesh differs topologically

from a perfectly structured grid mesh. The smaller the

value of

, the more regular the mesh.

e t

e t

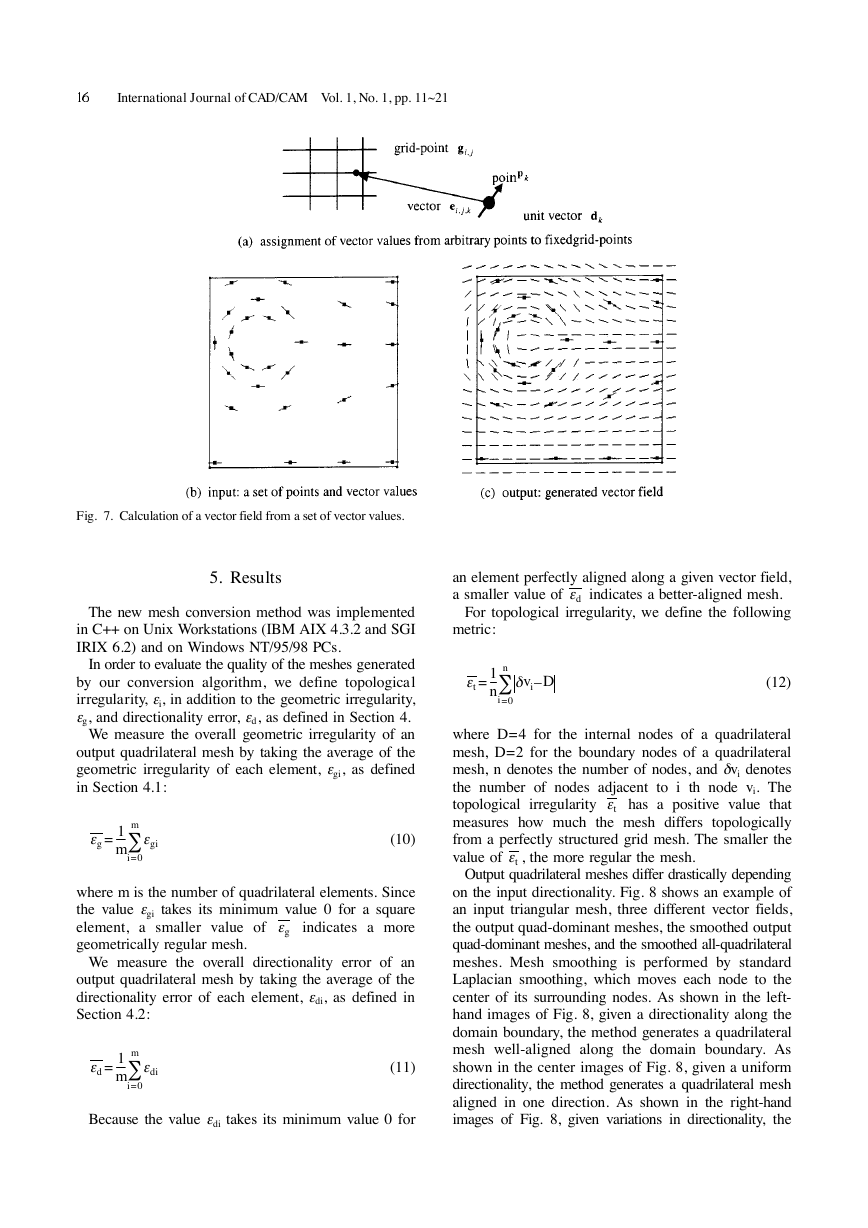

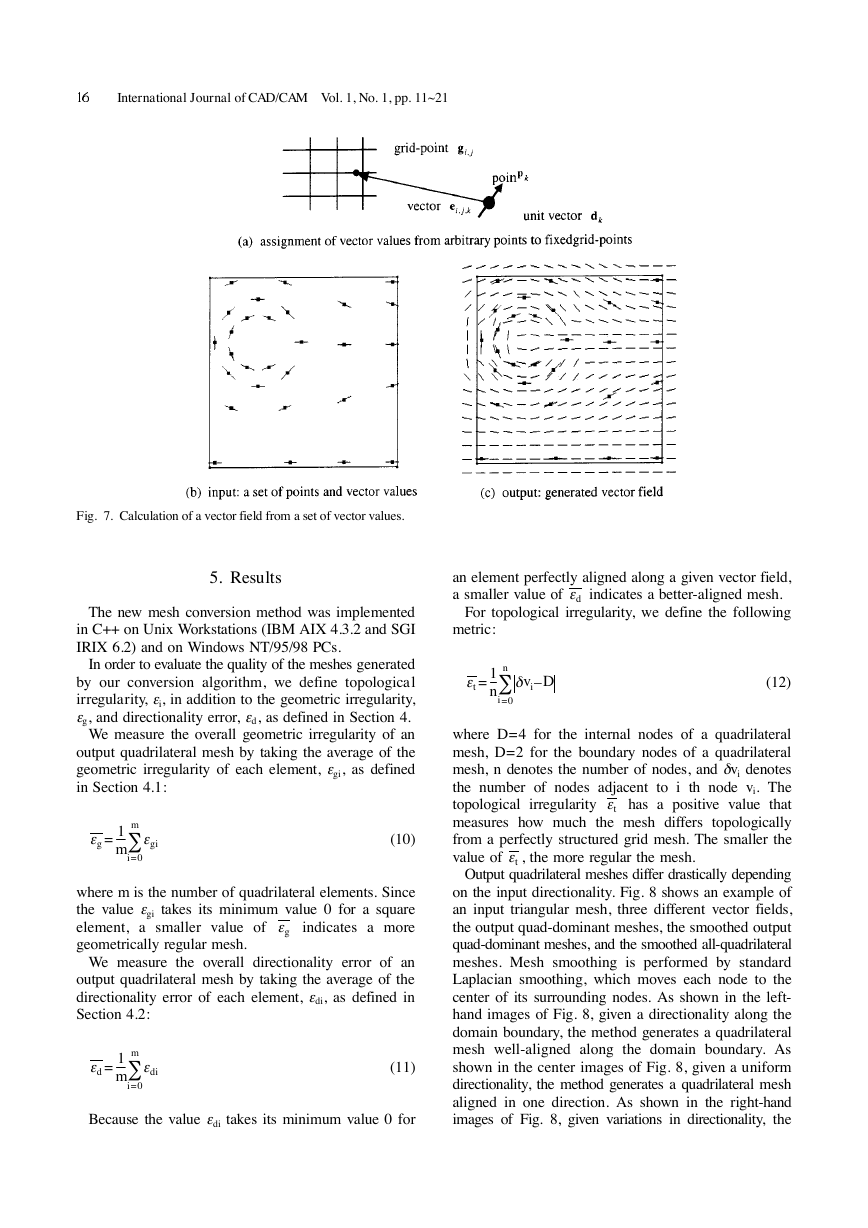

Output quadrilateral meshes differ drastically depending

on the input directionality. Fig. 8 shows an example of

an input triangular mesh, three different vector fields,

the output quad-dominant meshes, the smoothed output

quad-dominant meshes, and the smoothed all-quadrilateral

meshes. Mesh smoothing is performed by standard

Laplacian smoothing, which moves each node to the

center of its surrounding nodes. As shown in the left-

hand images of Fig. 8, given a directionality along the

domain boundary, the method generates a quadrilateral

mesh well-aligned along the domain boundary. As

shown in the center images of Fig. 8, given a uniform

directionality, the method generates a quadrilateral mesh

aligned in one direction. As shown in the right-hand

images of Fig. 8, given variations in directionality, the

�

Takayuki Itoh and Kenji Shimada

Automatic Conversion of Triangular Meshes Into Quadrilateral Meshes with Directionality

��

Fig. 8. Output quadrilateral meshes are well-aligned along the input mesh directionality.

method generates a quadrilateral mesh that aligns along

the various directions.

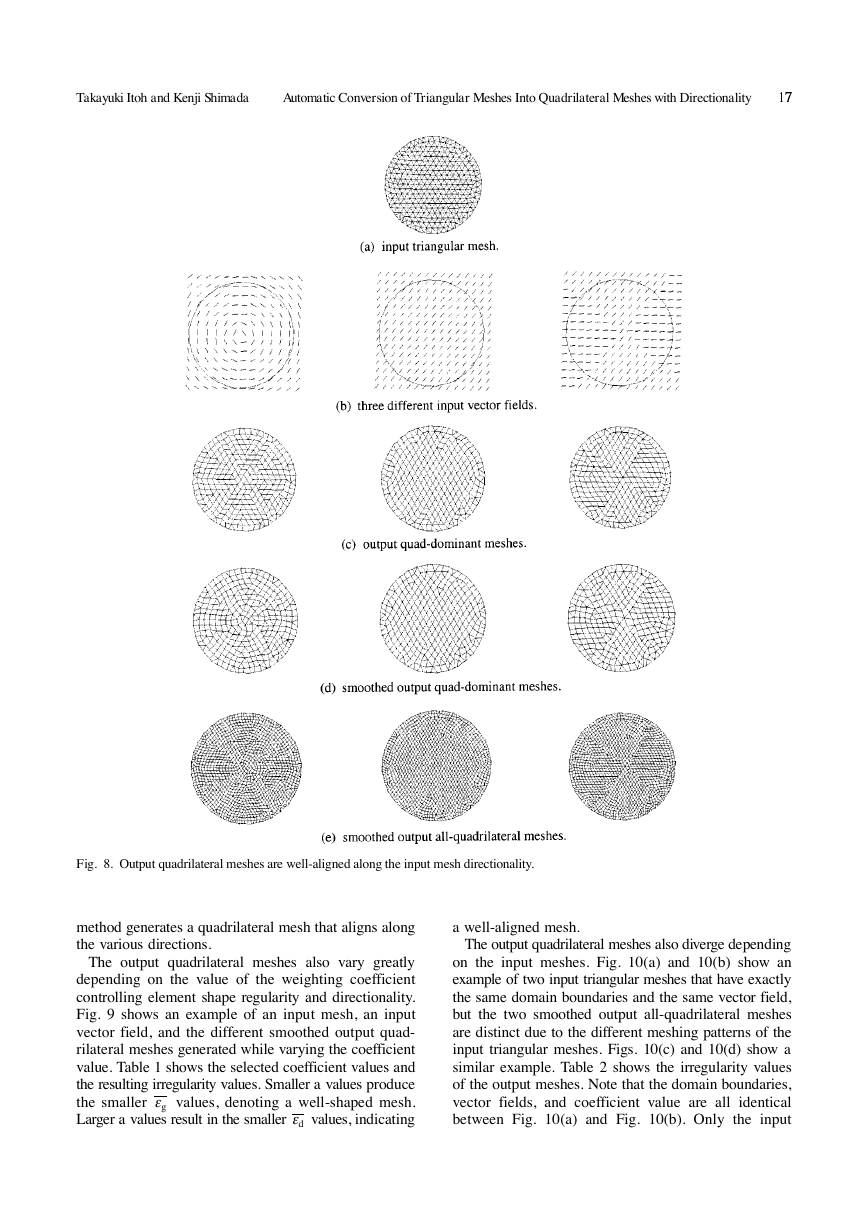

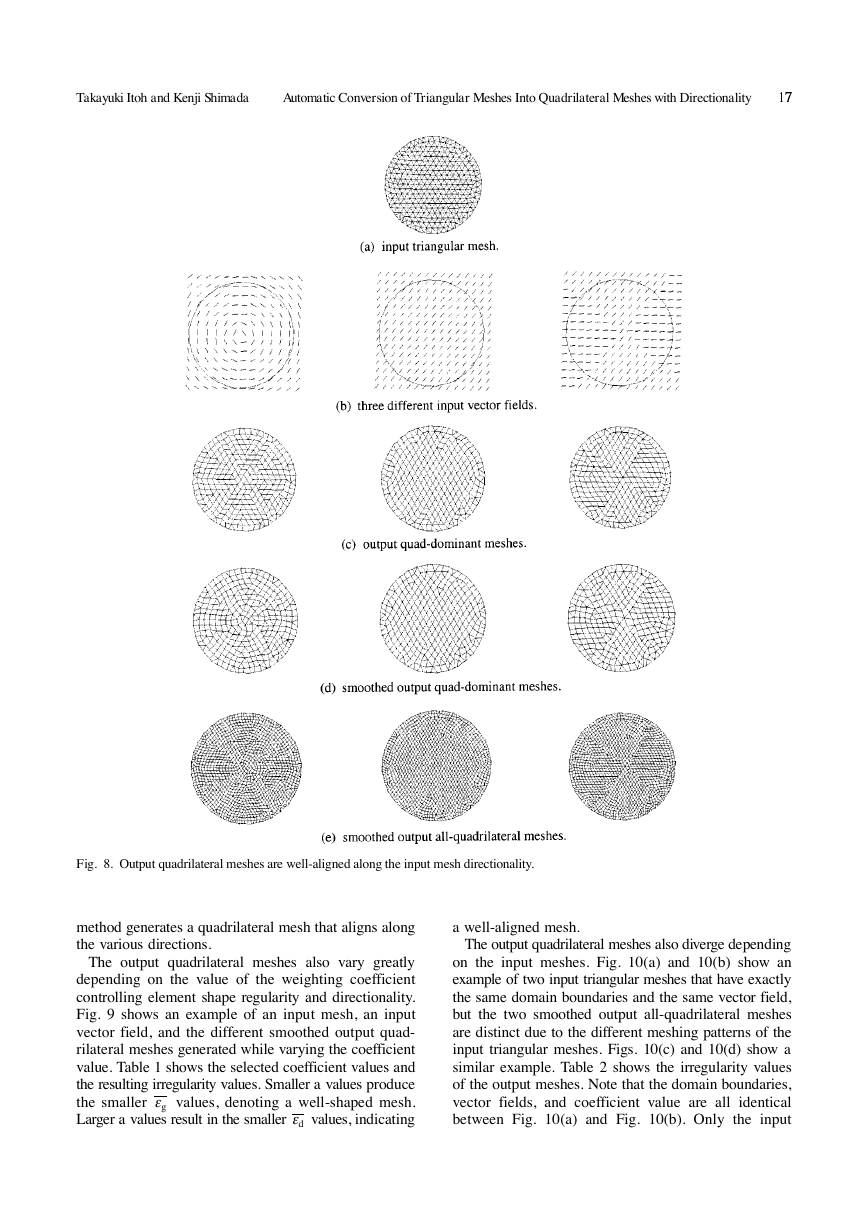

The output quadrilateral meshes also vary greatly

depending on the value of the weighting coefficient

controlling element shape regularity and directionality.

Fig. 9 shows an example of an input mesh, an input

vector field, and the different smoothed output quad-

rilateral meshes generated while varying the coefficient

value. Table 1 shows the selected coefficient values and

the resulting irregularity values. Smaller a values produce

values, denoting a well-shaped mesh.

the smaller

Larger a values result in the smaller

values, indicating

e g

e d

a well-aligned mesh.

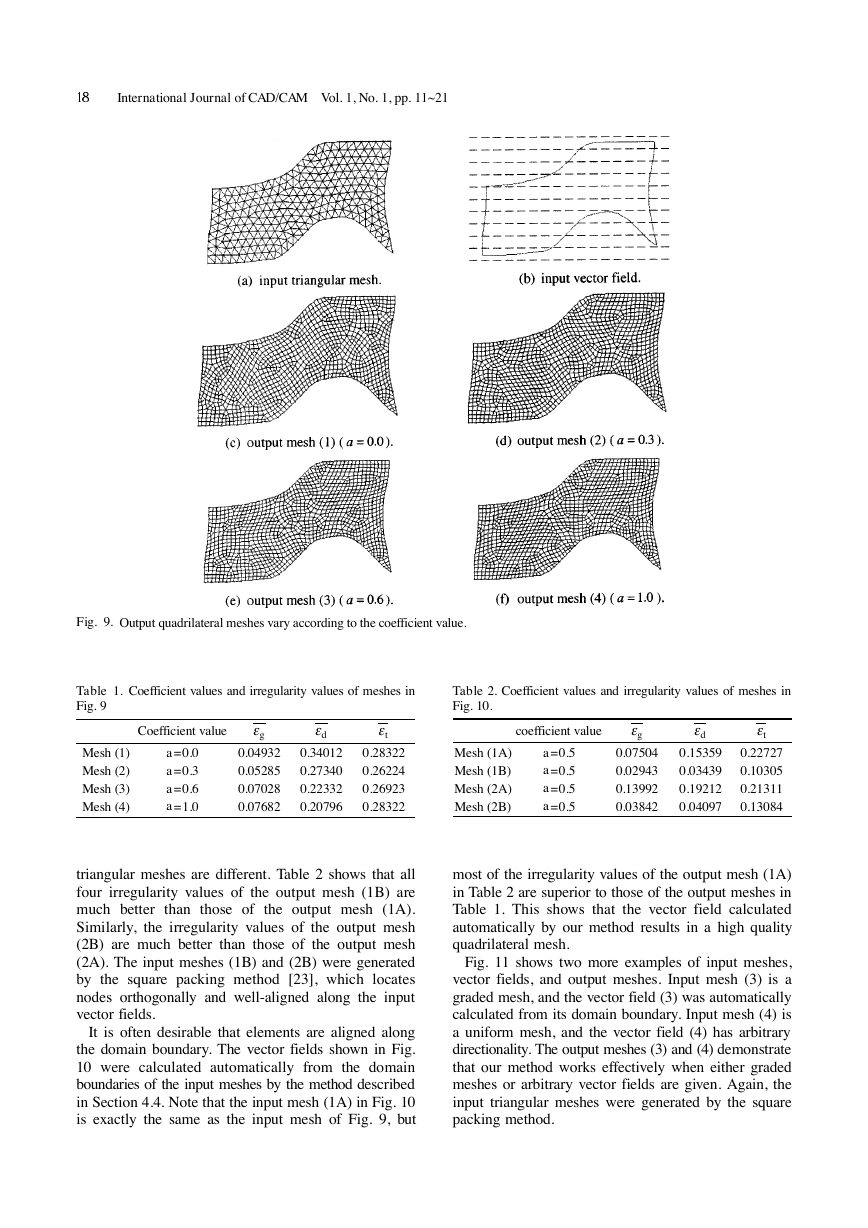

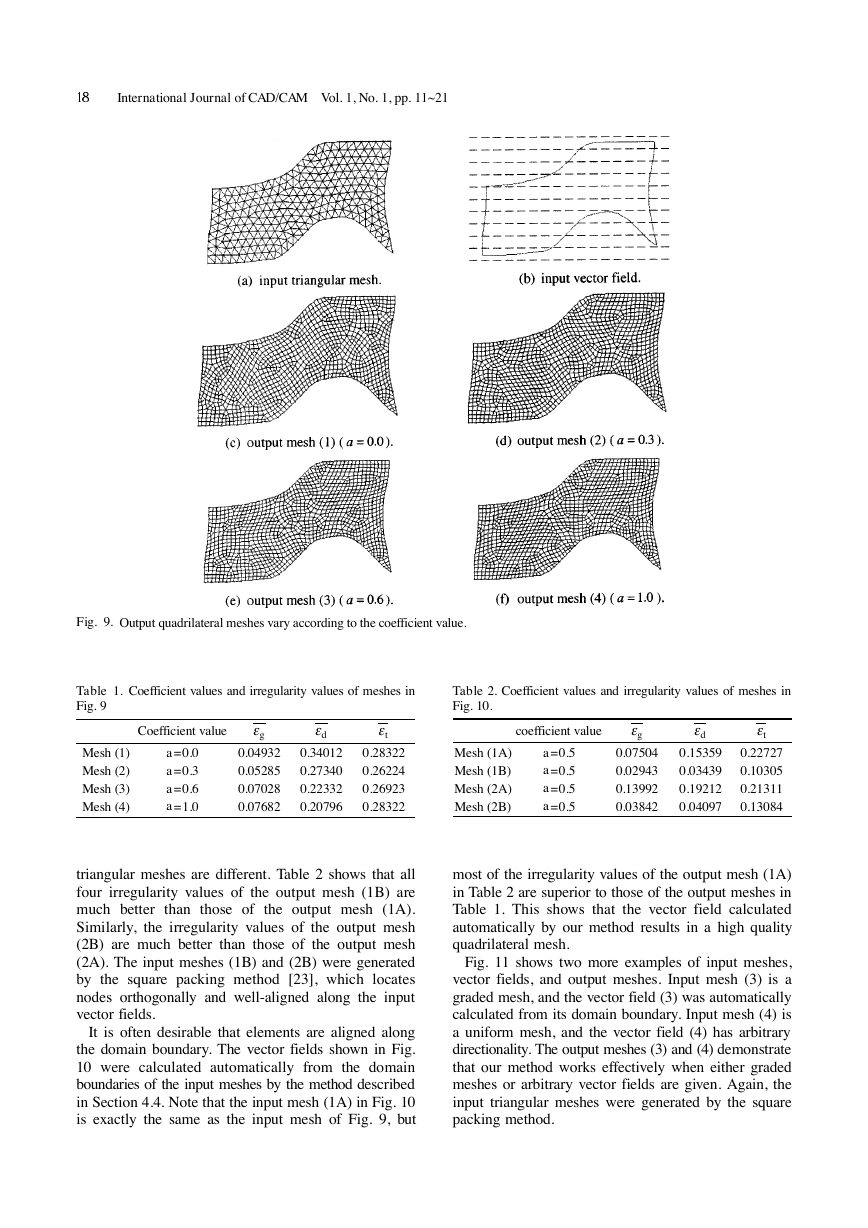

The output quadrilateral meshes also diverge depending

on the input meshes. Fig. 10(a) and 10(b) show an

example of two input triangular meshes that have exactly

the same domain boundaries and the same vector field,

but the two smoothed output all-quadrilateral meshes

are distinct due to the different meshing patterns of the

input triangular meshes. Figs. 10(c) and 10(d) show a

similar example. Table 2 shows the irregularity values

of the output meshes. Note that the domain boundaries,

vector fields, and coefficient value are all identical

between Fig. 10(a) and Fig. 10(b). Only the input

�

��

International Journal of CAD/CAM Vol. 1, No. 1, pp. 11~21

Fig. 9. Output quadrilateral meshes vary according to the coefficient value.

Table 1. Coefficient values and irregularity values of meshes in

Fig. 9

Table 2. Coefficient values and irregularity values of meshes in

Fig. 10.

Coefficient value

Mesh (1)

Mesh (2)

Mesh (3)

Mesh (4)

a=0.0

a=0.3

a=0.6

a=1.0

e g

0.04932

0.05285

0.07028

0.07682

e d

0.34012

0.27340

0.22332

0.20796

e t

0.28322

0.26224

0.26923

0.28322

coefficient value

Mesh (1A)

Mesh (1B)

Mesh (2A)

Mesh (2B)

a=0.5

a=0.5

a=0.5

a=0.5

e g

0.07504

0.02943

0.13992

0.03842

e d

0.15359

0.03439

0.19212

0.04097

e t

0.22727

0.10305

0.21311

0.13084

triangular meshes are different. Table 2 shows that all

four irregularity values of the output mesh (1B) are

much better than those of the output mesh (1A).

Similarly, the irregularity values of the output mesh

(2B) are much better than those of the output mesh

(2A). The input meshes (1B) and (2B) were generated

by the square packing method [23], which locates

nodes orthogonally and well-aligned along the input

vector fields.

It is often desirable that elements are aligned along

the domain boundary. The vector fields shown in Fig.

10 were calculated automatically from the domain

boundaries of the input meshes by the method described

in Section 4.4. Note that the input mesh (1A) in Fig. 10

is exactly the same as the input mesh of Fig. 9, but

most of the irregularity values of the output mesh (1A)

in Table 2 are superior to those of the output meshes in

Table 1. This shows that the vector field calculated

automatically by our method results in a high quality

quadrilateral mesh.

Fig. 11 shows two more examples of input meshes,

vector fields, and output meshes. Input mesh (3) is a

graded mesh, and the vector field (3) was automatically

calculated from its domain boundary. Input mesh (4) is

a uniform mesh, and the vector field (4) has arbitrary

directionality. The output meshes (3) and (4) demonstrate

that our method works effectively when either graded

meshes or arbitrary vector fields are given. Again, the

input triangular meshes were generated by the square

packing method.

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc