1 Introduction and Overview

1.1 Purpose of this document

1.2 What is “Mechatronics Concept Designer“?

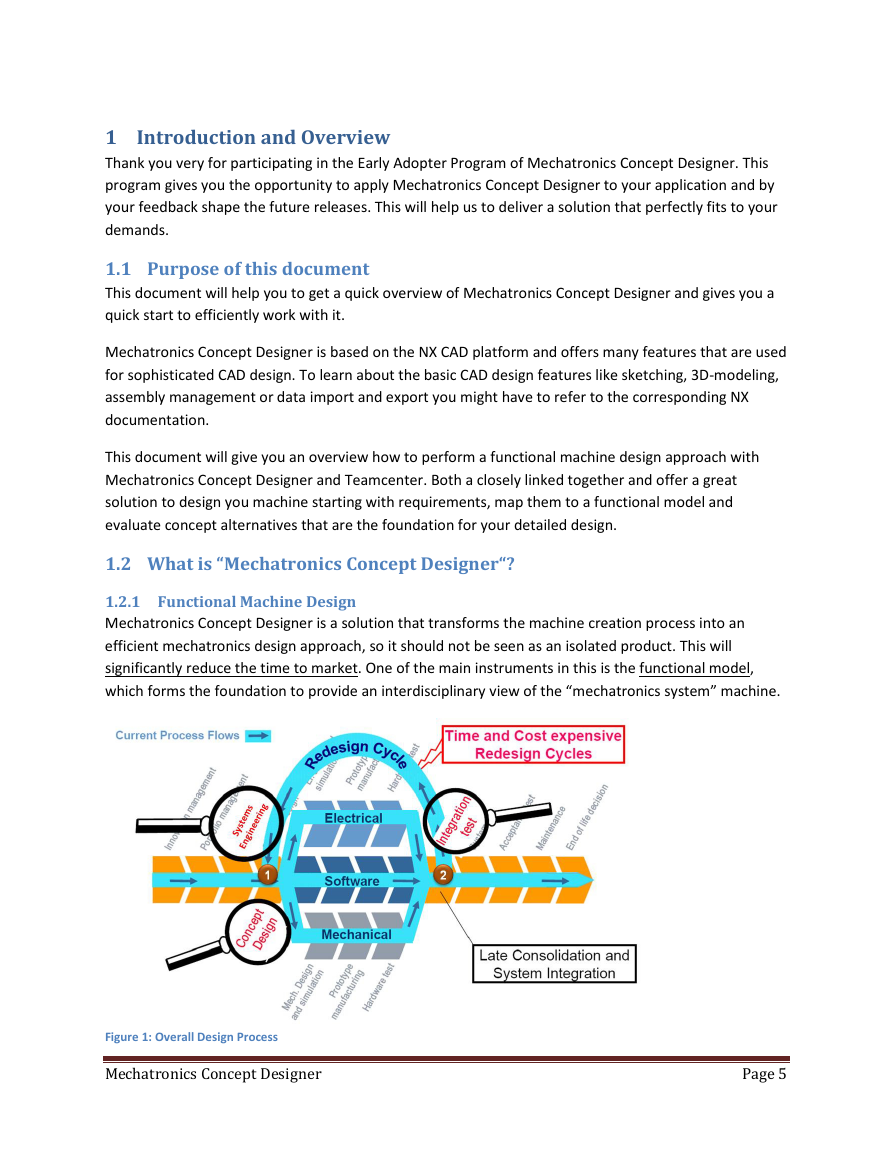

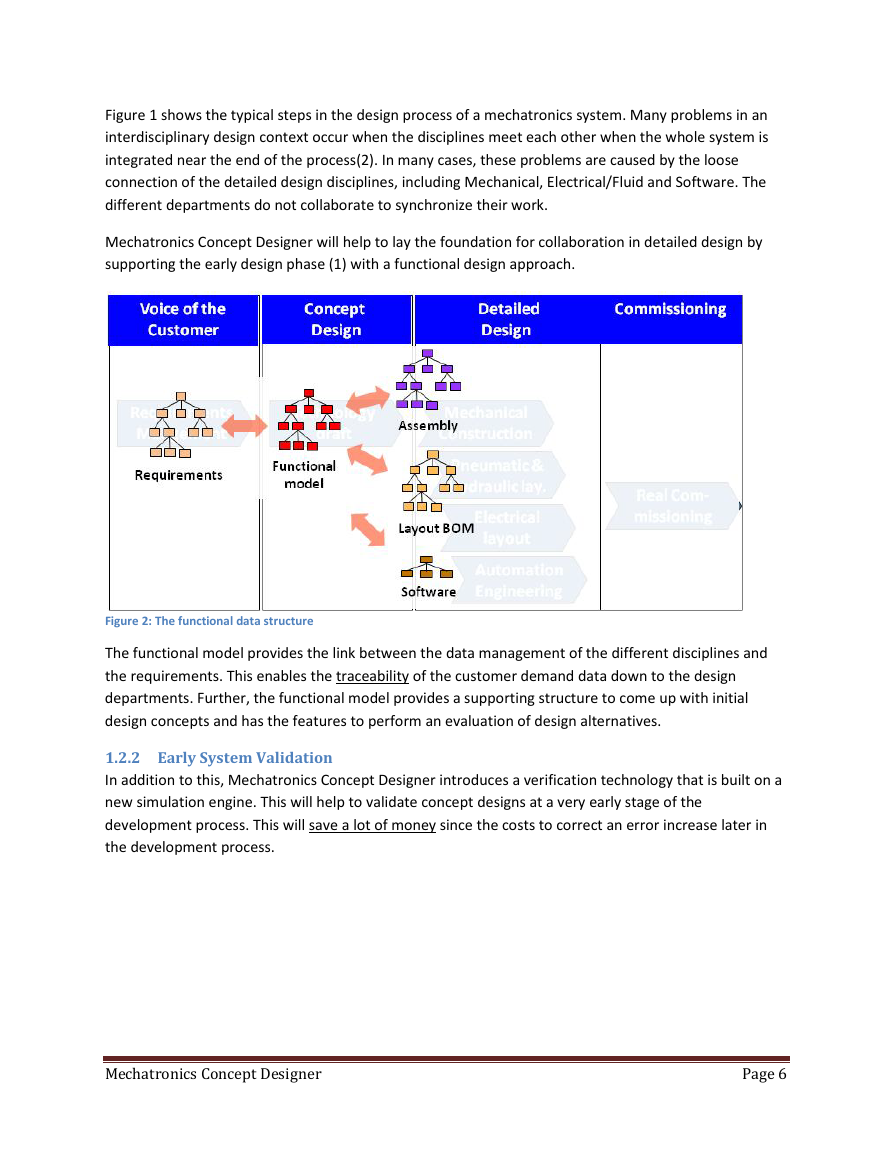

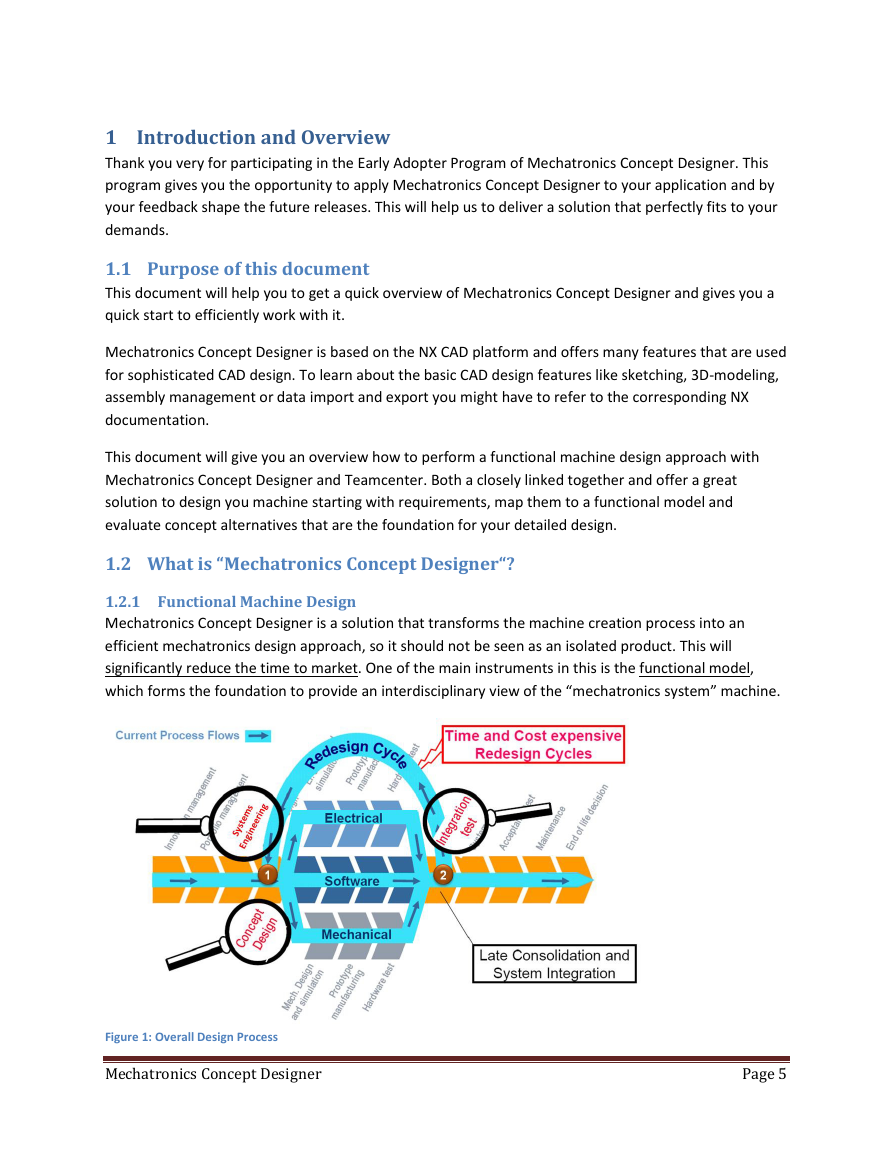

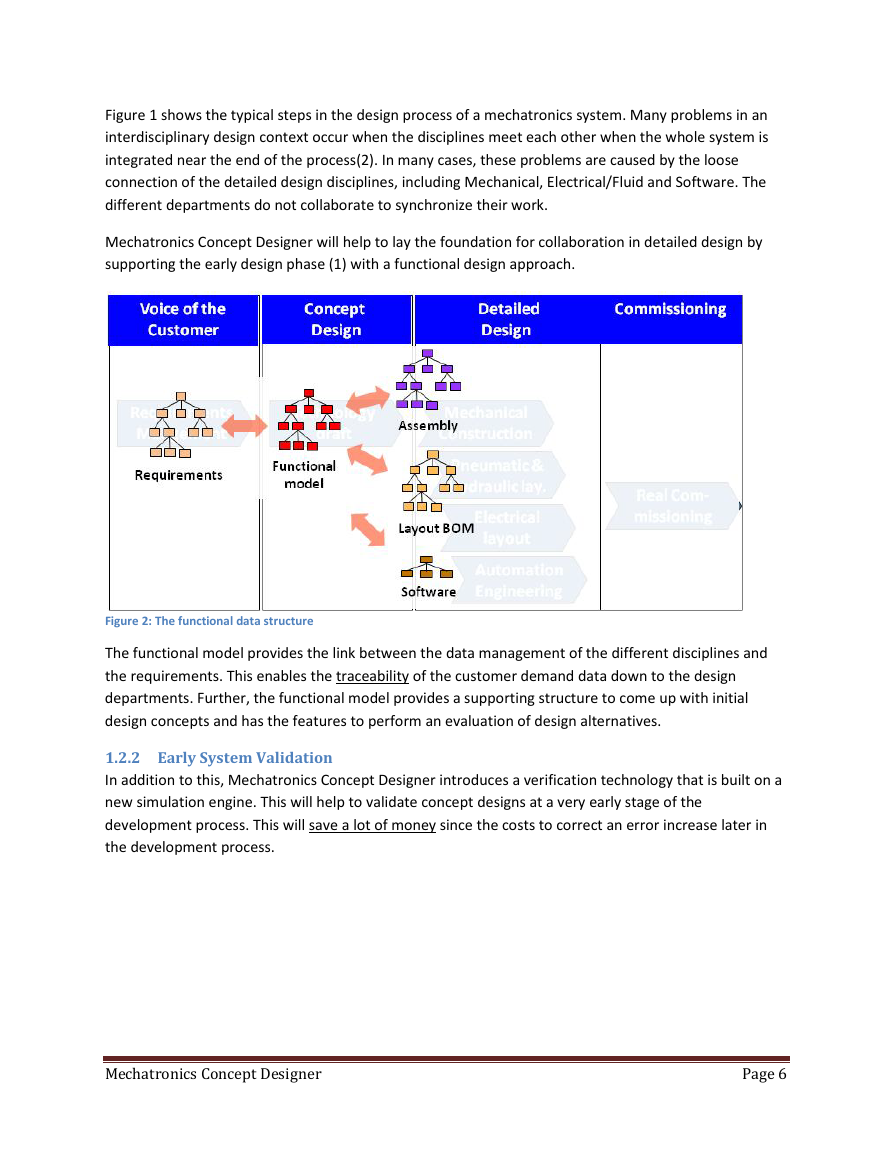

1.2.1 Functional Machine Design

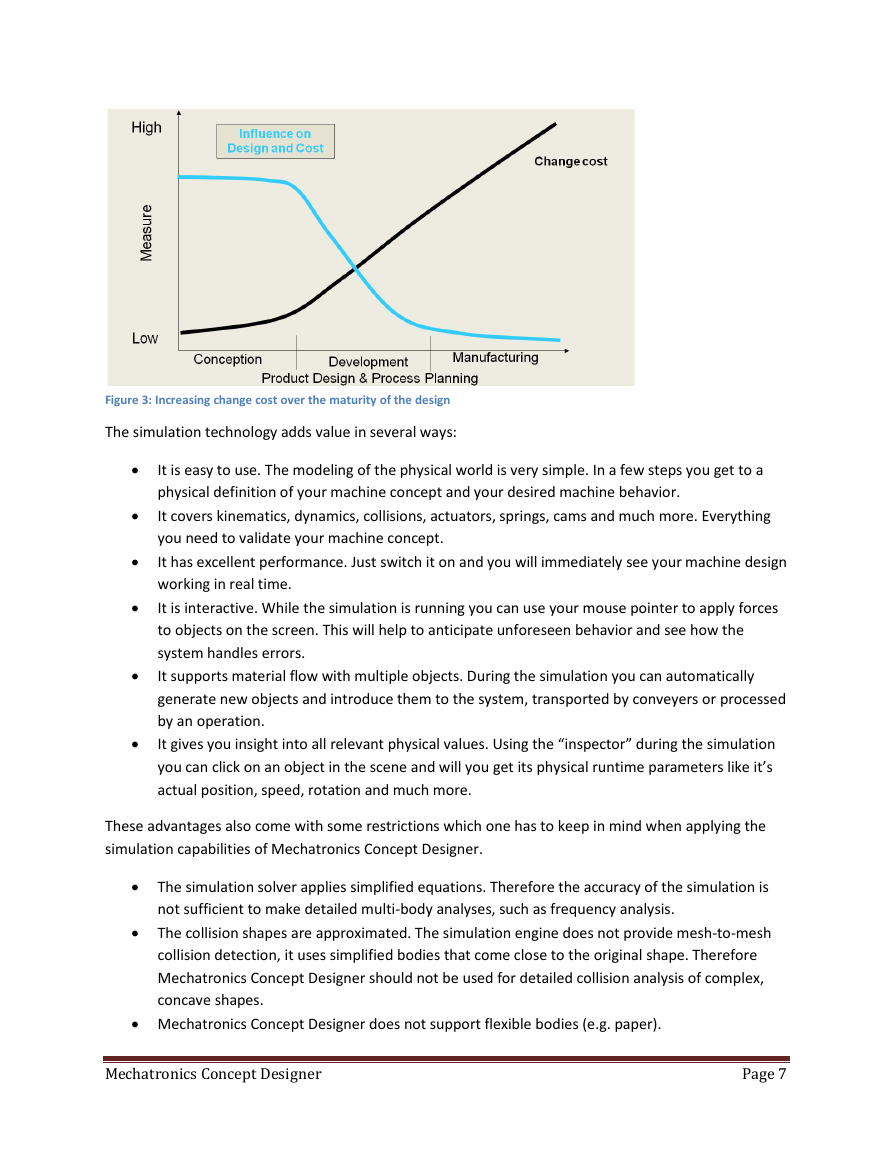

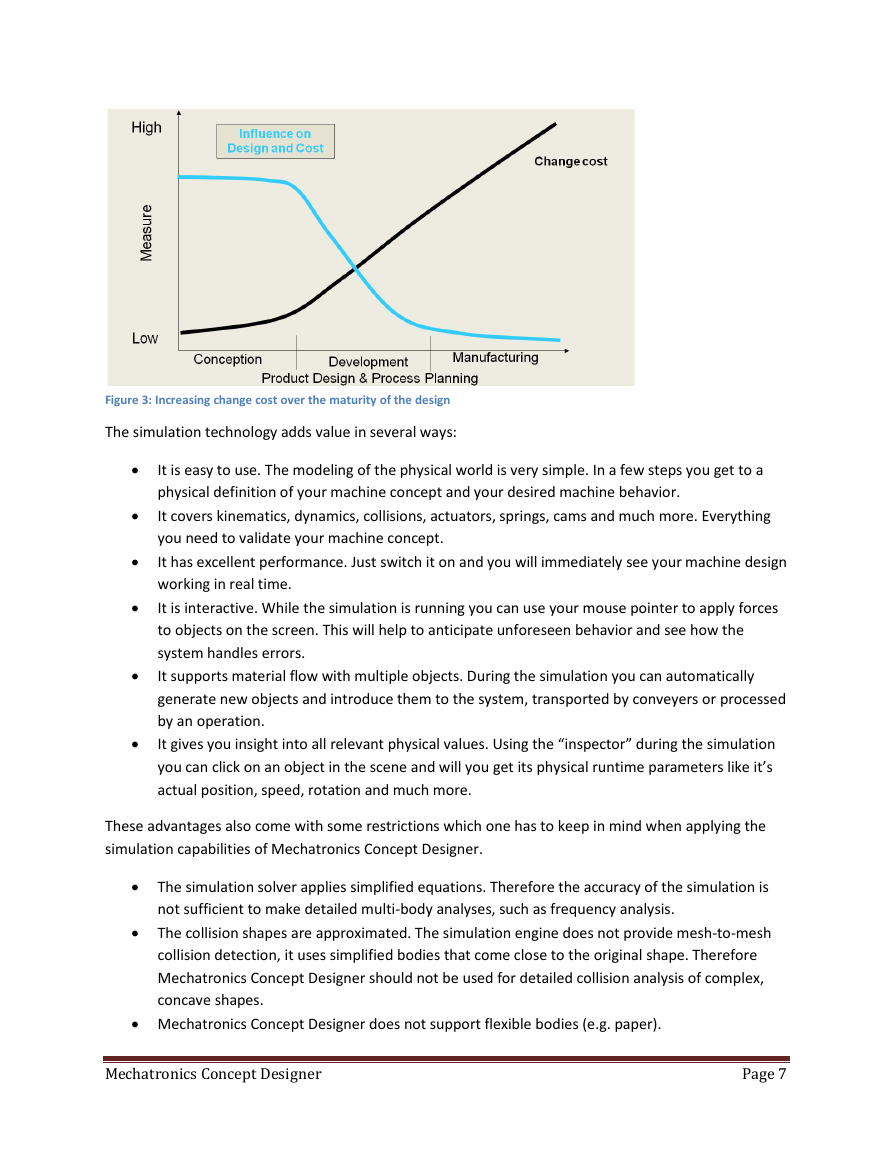

1.2.2 Early System Validation

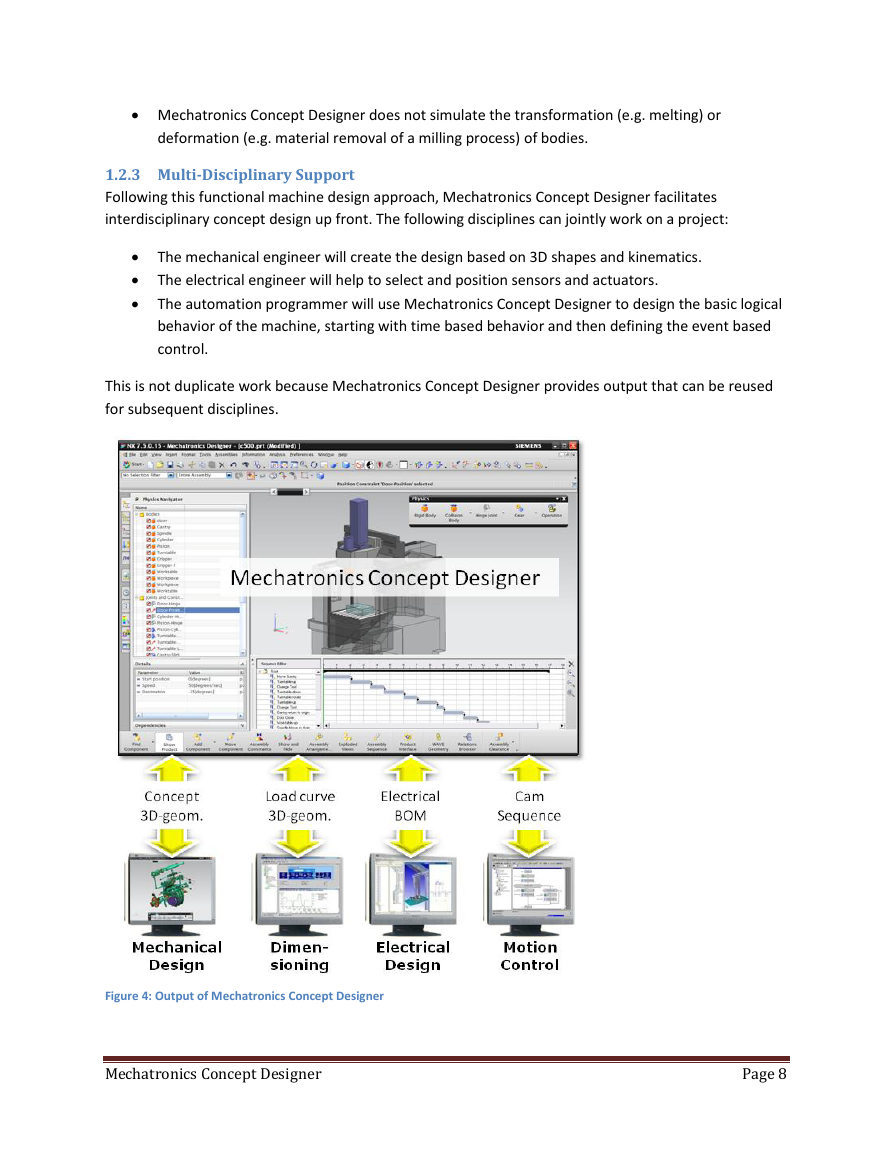

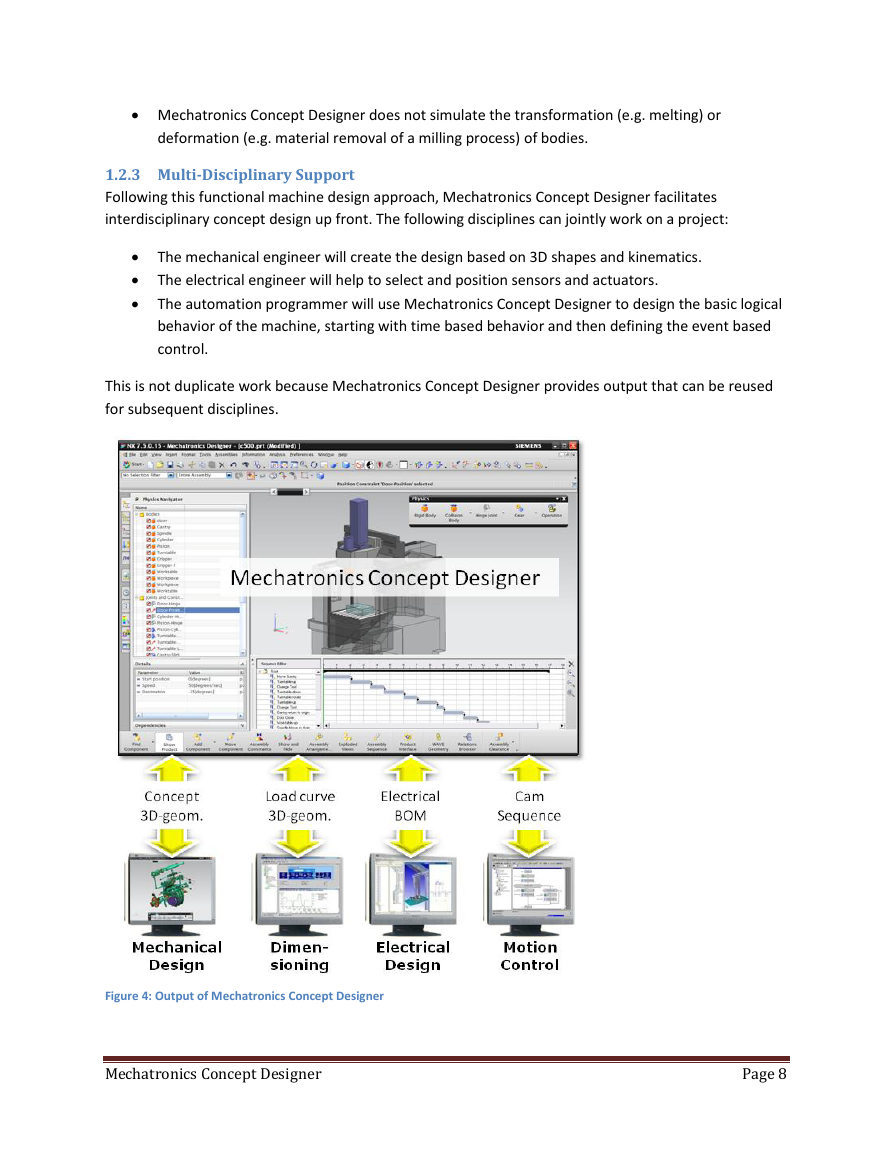

1.2.3 Multi-Disciplinary Support

1.2.4 Modularity and Reuse

1.3 How does “Mechatronics Concept Designer” fit into the design workflow?

2 Quick Start

2.1 The Simulation Engine”

2.2 Simple robot example

2.2.1 Manage requirements

2.2.2 Functional decomposition

2.2.3 Link requirements and functions

2.2.4 Implement functions

2.2.5 Simple Kinematics

2.2.6 Actuators

2.2.7 Time based Operations

2.2.8 Sensors

2.2.9 Event based operations

2.3 Cam example

2.3.1 Define a cam

2.3.2 Inspector

3 The navigators

3.1 The Function Navigator

3.2 The Physics Navigator

3.3 The Sequence Editor

4 Basic Features

4.1 Define design requirements

4.2 Create Functional Model

4.3 Define Mechanical Concept (Geometry)

4.3.1 Define basic principles of the machine based on the rough geometries

4.3.2 Create association link between components and function model

4.4 Define Mechanical Concept (Physics)

4.4.1 Add Physics Properties

4.4.1.1 Rigid Body

4.4.1.2 Collision Body

4.4.1.3 Transport Surface

4.4.1.4 Collision Material

4.4.1.5 Object Source

4.4.1.6 Object Sink

4.4.2 Add Kinematic Behavior

4.4.2.1 Hinge Joint

4.4.2.2 Sliding Joint

4.4.2.3 Ball Joint

4.4.2.4 Cylindrical Joint

4.4.2.5 Fixed Joint

4.4.2.6 Angular Spring Joint

4.4.2.7 Linear Spring Joint

4.4.2.8 Angular Limit Joint

4.4.2.9 Linear Limit Joint

4.4.3 Constraints

4.4.3.1 Breaking Constraint

4.4.3.2 Prevent Collision

4.4.3.3 Change Material

4.5 Add Generalized Actuators

4.5.1 Speed Control

4.5.2 Position Control

4.5.3 Export Sensor and Actuator List

4.6 Define time based controllers

4.6.1 Define operations

4.6.2 Define sequence of operations

4.7 Continuous behavior

4.7.1 Define a Motion Profile

4.7.2 Define a gear

4.7.3 Define a cam

4.8 Add Generalized Sensors

4.8.1 Define a Collision Sensor

4.8.2 Continue to build the sensor/actuator list

4.9 Add event based behavior

4.9.1 Add event based operations

4.9.2 Add a behavioral object

4.10 Knowledge capture and efficient design based on reusable objects

4.11 Monitor the simulation

4.12 Preferences

4.12.1 General

4.12.2 Physics Engine

4.12.3 Inspector

4.13 Instable Simulation

5 Support other design disciplines

5.1 Systems Engineering and Functional Modeling

5.2 Mechanical Design

5.3 Electrical Design

5.4 Software Design

6 Addendum

6.1 EN 61346-2

7 Contact

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc