U.S. Department of Energy

Vehicle Technologies, EE-2G

1000 Independence Avenue, S.W.

Washington, D.C. 20585-0121

FY2011

EVALUATION OF THE 2010 TOYOTA PRIUS

HYBRID SYNERGY DRIVE SYSTEM

Prepared by:

Oak Ridge National Laboratory

Mitch Olszewski, Program Manager

Submitted to:

Energy Efficiency and Renewable Energy

FreedomCAR and Vehicle Technologies

Vehicle Systems Team

Susan A. Rogers, Technology Development Manager

March 2011

�

ORNL/TM-2010/253

Energy and Transportation Science Division

EVALUATION OF THE

2010 TOYOTA PRIUS

HYBRID SYNERGY

DRIVE SYSTEM

T. A. Burress

S. L. Campbell

C. L. Coomer

C. W. Ayers

A. A. Wereszczak

J. P. Cunningham

L. D. Marlino

L. E. Seiber

H. T. Lin

Publication Date: March 2011

Prepared by the

OAK RIDGE NATIONAL LABORATORY

Oak Ridge, Tennessee 37831

managed by

UT-BATTELLE, LLC

for the

U.S. DEPARTMENT OF ENERGY

Under contract DE-AC05-00OR22725

�

Reports produced after January 1, 1996, are generally available free via the U.S. Department of

Energy (DOE) Information Bridge:

DOCUMENT AVAILABILITY

Web site: http://www.osti.gov/bridge

Reports produced before January 1, 1996, may be purchased by members of the public from the

following source:

National Technical Information Service

5285 Port Royal Road

Springfield, VA 22161

Telephone: 703-605-6000 (1-800-553-6847)

TDD: 703-487-4639

Fax: 703-605-6900

E-mail: info@ntis.fedworld.gov

Web site: http://www.ntis.gov/support/ordernowabout.htm

Reports are available to DOE employees, DOE contractors, Energy Technology Data Exchange

(ETDE) representatives, and International Nuclear Information System (INIS) representatives

from the following source:

Office of Scientific and Technical Information

P.O. Box 62

Oak Ridge, TN 37831

Telephone: 865-576-8401

Fax: 865-576-5728

E-mail: reports@osti.gov

Web site: http://www.osti.gov/contact.html

This report was prepared as an account of work sponsored by an agency of

the United States Government. Neither the United States government nor

any agency thereof, nor any of their employees, makes any warranty,

express or implied, or assumes any legal liability or responsibility for the

accuracy, completeness, or usefulness of any information, apparatus,

product, or process disclosed, or represents that its use would not infringe

privately owned rights. Reference herein to any specific commercial product,

process, or service by trade name, trademark, manufacturer, or otherwise,

does not necessarily constitute or imply its endorsement, recommendation,

or favoring by the United States Government or any agency thereof. The

views and opinions of authors expressed herein do not necessarily state or

reflect those of the United States Government or any agency thereof.

�

TABLE OF CONTENTS

Page

LIST OF FIGURES ..................................................................................................................................... iii

LIST OF TABLES ....................................................................................................................................... vi

ACRONYMS AND ABBREVIATIONS ................................................................................................... vii

1. INTRODUCTION .................................................................................................................................... 1

1.1 PROGRAM OVERVIEW ................................................................................................................. 1

1.2 RESEARCH FACILITIES................................................................................................................ 1

1.3 SCOPE AND OBJECTIVE .............................................................................................................. 2

1.4 APPROACH ..................................................................................................................................... 2

2. HYBRID ELECTRIC DRIVE SYSTEM DESIGN AND PACKAGING................................................ 3

2.1 VEHICLE DESCRIPTION .............................................................................................................. 3

2.1.1 Hybrid Drive System ............................................................................................................ 4

2.2 PCU .................................................................................................................................................. 5

2.2.1 PCU Disassembly ................................................................................................................. 9

2.2.2 PE Module Disassembly .................................................................................................... 17

2.2.3 PE Module Material Analysis ............................................................................................ 24

2.2.4 Capacitor Test Results ....................................................................................................... 27

2.2.4.1 Parameter assessments of the 888µF dc-link smoothing capacitor

module ......................................................................................................28

2.2.4.2 Continuous ripple current tests with large dc-link capacitor module .......33

2.2.4.3 Parameter assessments of battery level filter capacitor ............................35

2.2.4.4 Parameter assessments of the small dc-link capacitor ..............................36

2.3 ECVT .............................................................................................................................................. 37

2.3.1 ECVT Disassembly ............................................................................................................. 38

2.3.2 Motor and Generator Design Assessments ......................................................................... 42

2.3.3 PM Characteristic Assessments ........................................................................................... 48

3. BENCHMARKING TESTS OF 2010 PRIUS PMSM AND PCU ......................................................... 54

3.1 SUBSYSTEM PREPARATION FOR TESTING ......................................................................... 54

3.1.1 Hardware Preparation ......................................................................................................... 54

3.1.2 Instrumentation and DAQ Development ............................................................................ 55

3.1.3 Controller and Interface Development ................................................................................ 57

3.2 BACK-EMF TEST RESULTS ...................................................................................................... 59

3.3 LOCKED ROTOR TEST .............................................................................................................. 60

3.4 PERFORMANCE AND EFFICIENCY EVALUATIONS ........................................................... 62

3.5 CONTINOUS LOAD DURATION TESTS .................................................................................. 69

4. SUMMARY AND CONCLUSIONS ..................................................................................................... 76

REFERENCES ........................................................................................................................................... 78

DISTRIBUTION ......................................................................................................................................... 79

ii

�

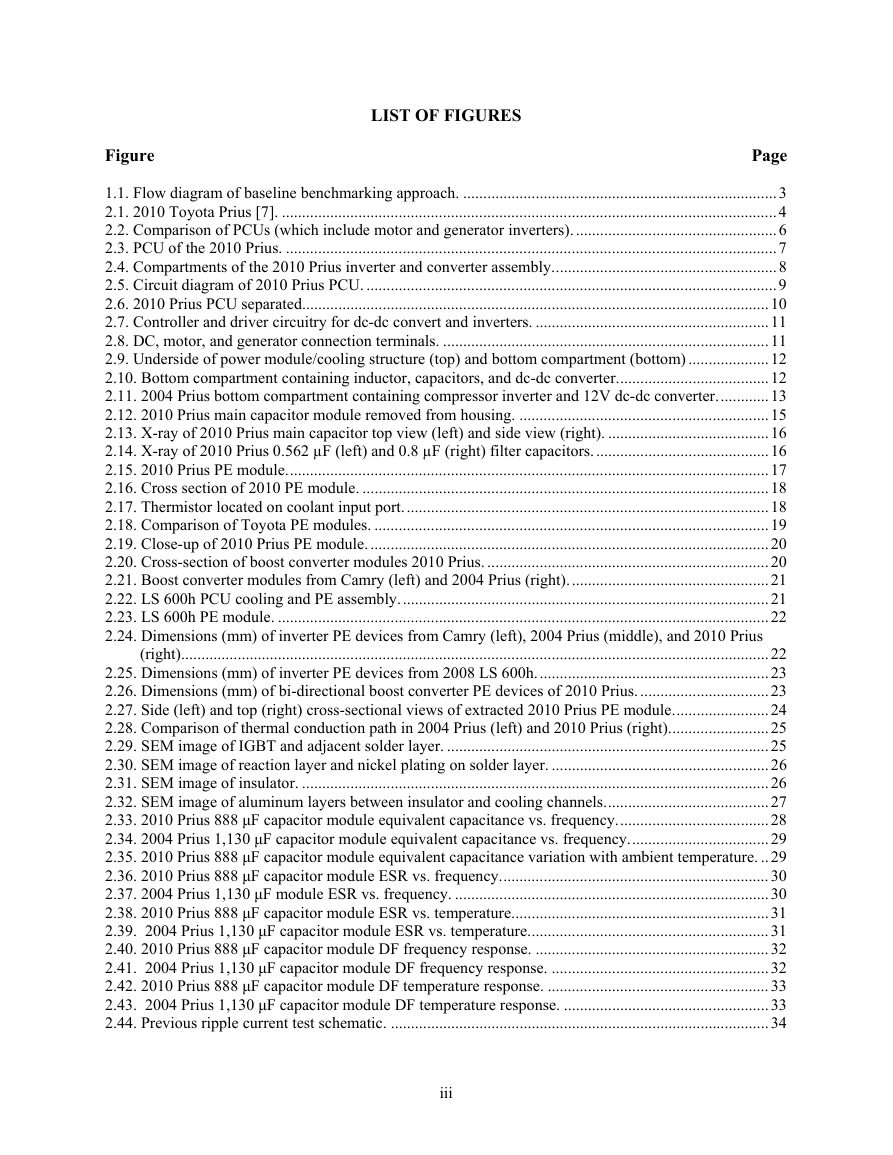

LIST OF FIGURES

Page

Figure

1.1. Flow diagram of baseline benchmarking approach. .............................................................................. 3

2.1. 2010 Toyota Prius [7]. ........................................................................................................................... 4

2.2. Comparison of PCUs (which include motor and generator inverters). .................................................. 6

2.3. PCU of the 2010 Prius. .......................................................................................................................... 7

2.4. Compartments of the 2010 Prius inverter and converter assembly. ....................................................... 8

2.5. Circuit diagram of 2010 Prius PCU. ...................................................................................................... 9

2.6. 2010 Prius PCU separated.................................................................................................................... 10

2.7. Controller and driver circuitry for dc-dc convert and inverters. .......................................................... 11

2.8. DC, motor, and generator connection terminals. ................................................................................. 11

2.9. Underside of power module/cooling structure (top) and bottom compartment (bottom) .................... 12

2.10. Bottom compartment containing inductor, capacitors, and dc-dc converter. ..................................... 12

2.11. 2004 Prius bottom compartment containing compressor inverter and 12V dc-dc converter. ............ 13

2.12. 2010 Prius main capacitor module removed from housing. .............................................................. 15

2.13. X-ray of 2010 Prius main capacitor top view (left) and side view (right). ........................................ 16

2.14. X-ray of 2010 Prius 0.562 µF (left) and 0.8 µF (right) filter capacitors. ........................................... 16

2.15. 2010 Prius PE module. ....................................................................................................................... 17

2.16. Cross section of 2010 PE module. ..................................................................................................... 18

2.17. Thermistor located on coolant input port. .......................................................................................... 18

2.18. Comparison of Toyota PE modules. .................................................................................................. 19

2.19. Close-up of 2010 Prius PE module. ................................................................................................... 20

2.20. Cross-section of boost converter modules 2010 Prius. ...................................................................... 20

2.21. Boost converter modules from Camry (left) and 2004 Prius (right). ................................................. 21

2.22. LS 600h PCU cooling and PE assembly. ........................................................................................... 21

2.23. LS 600h PE module. .......................................................................................................................... 22

2.24. Dimensions (mm) of inverter PE devices from Camry (left), 2004 Prius (middle), and 2010 Prius

(right). ................................................................................................................................................. 22

2.25. Dimensions (mm) of inverter PE devices from 2008 LS 600h. ......................................................... 23

2.26. Dimensions (mm) of bi-directional boost converter PE devices of 2010 Prius. ................................ 23

2.27. Side (left) and top (right) cross-sectional views of extracted 2010 Prius PE module. ....................... 24

2.28. Comparison of thermal conduction path in 2004 Prius (left) and 2010 Prius (right). ........................ 25

2.29. SEM image of IGBT and adjacent solder layer. ................................................................................ 25

2.30. SEM image of reaction layer and nickel plating on solder layer. ...................................................... 26

2.31. SEM image of insulator. .................................................................................................................... 26

2.32. SEM image of aluminum layers between insulator and cooling channels. ........................................ 27

2.33. 2010 Prius 888 μF capacitor module equivalent capacitance vs. frequency. ..................................... 28

2.34. 2004 Prius 1,130 μF capacitor module equivalent capacitance vs. frequency. .................................. 29

2.35. 2010 Prius 888 μF capacitor module equivalent capacitance variation with ambient temperature. .. 29

2.36. 2010 Prius 888 μF capacitor module ESR vs. frequency. .................................................................. 30

2.37. 2004 Prius 1,130 μF module ESR vs. frequency. .............................................................................. 30

2.38. 2010 Prius 888 μF capacitor module ESR vs. temperature. ............................................................... 31

2.39. 2004 Prius 1,130 μF capacitor module ESR vs. temperature. ........................................................... 31

2.40. 2010 Prius 888 μF capacitor module DF frequency response. .......................................................... 32

2.41. 2004 Prius 1,130 μF capacitor module DF frequency response. ...................................................... 32

2.42. 2010 Prius 888 μF capacitor module DF temperature response. ....................................................... 33

2.43. 2004 Prius 1,130 μF capacitor module DF temperature response. ................................................... 33

2.44. Previous ripple current test schematic. .............................................................................................. 34

iii

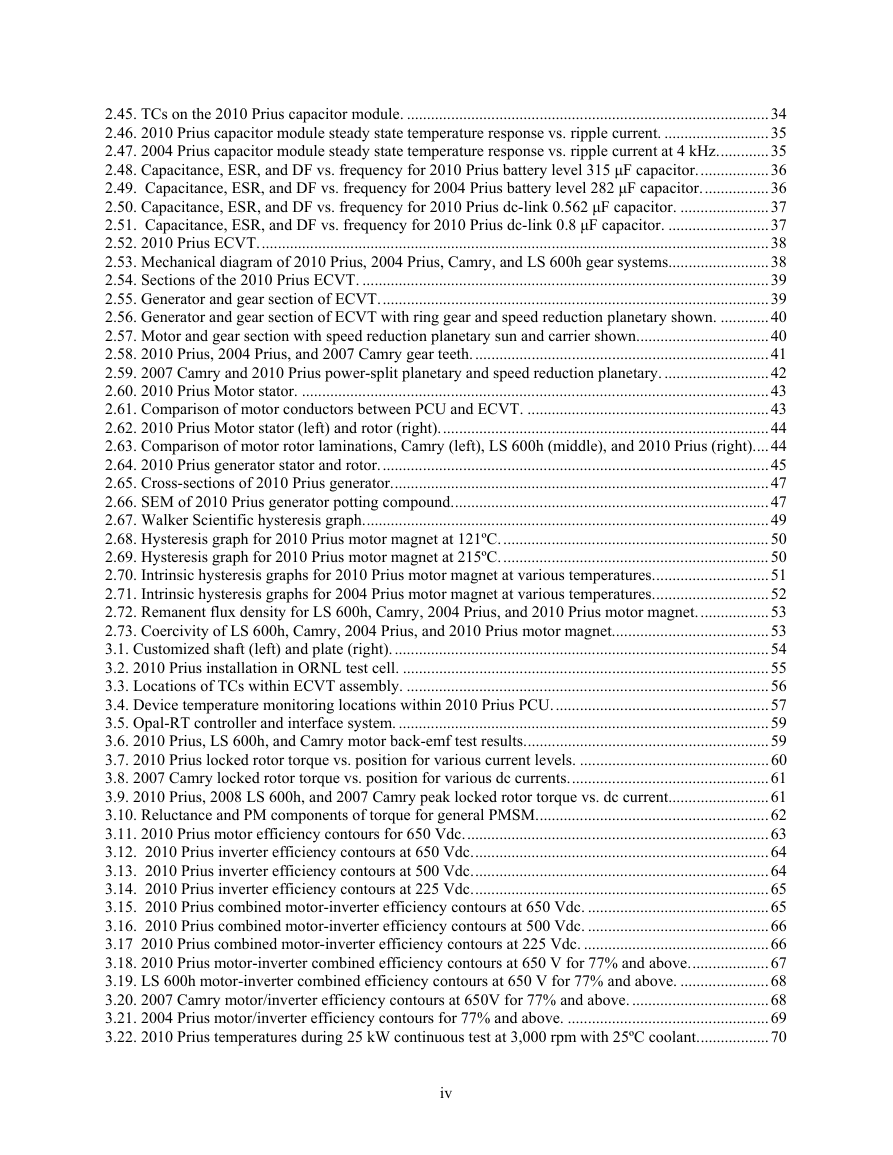

�

2.45. TCs on the 2010 Prius capacitor module. .......................................................................................... 34

2.46. 2010 Prius capacitor module steady state temperature response vs. ripple current. .......................... 35

2.47. 2004 Prius capacitor module steady state temperature response vs. ripple current at 4 kHz. ............ 35

2.48. Capacitance, ESR, and DF vs. frequency for 2010 Prius battery level 315 μF capacitor. ................. 36

2.49. Capacitance, ESR, and DF vs. frequency for 2004 Prius battery level 282 μF capacitor. ................ 36

2.50. Capacitance, ESR, and DF vs. frequency for 2010 Prius dc-link 0.562 μF capacitor. ...................... 37

2.51. Capacitance, ESR, and DF vs. frequency for 2010 Prius dc-link 0.8 μF capacitor. ......................... 37

2.52. 2010 Prius ECVT. .............................................................................................................................. 38

2.53. Mechanical diagram of 2010 Prius, 2004 Prius, Camry, and LS 600h gear systems......................... 38

2.54. Sections of the 2010 Prius ECVT. ..................................................................................................... 39

2.55. Generator and gear section of ECVT. ................................................................................................ 39

2.56. Generator and gear section of ECVT with ring gear and speed reduction planetary shown. ............ 40

2.57. Motor and gear section with speed reduction planetary sun and carrier shown. ................................ 40

2.58. 2010 Prius, 2004 Prius, and 2007 Camry gear teeth. ......................................................................... 41

2.59. 2007 Camry and 2010 Prius power-split planetary and speed reduction planetary. .......................... 42

2.60. 2010 Prius Motor stator. .................................................................................................................... 43

2.61. Comparison of motor conductors between PCU and ECVT. ............................................................ 43

2.62. 2010 Prius Motor stator (left) and rotor (right). ................................................................................. 44

2.63. Comparison of motor rotor laminations, Camry (left), LS 600h (middle), and 2010 Prius (right). ... 44

2.64. 2010 Prius generator stator and rotor. ................................................................................................ 45

2.65. Cross-sections of 2010 Prius generator. ............................................................................................. 47

2.66. SEM of 2010 Prius generator potting compound. .............................................................................. 47

2.67. Walker Scientific hysteresis graph. .................................................................................................... 49

2.68. Hysteresis graph for 2010 Prius motor magnet at 121ºC. .................................................................. 50

2.69. Hysteresis graph for 2010 Prius motor magnet at 215ºC. .................................................................. 50

2.70. Intrinsic hysteresis graphs for 2010 Prius motor magnet at various temperatures. ............................ 51

2.71. Intrinsic hysteresis graphs for 2004 Prius motor magnet at various temperatures. ............................ 52

2.72. Remanent flux density for LS 600h, Camry, 2004 Prius, and 2010 Prius motor magnet. ................. 53

2.73. Coercivity of LS 600h, Camry, 2004 Prius, and 2010 Prius motor magnet. ...................................... 53

3.1. Customized shaft (left) and plate (right). ............................................................................................. 54

3.2. 2010 Prius installation in ORNL test cell. ........................................................................................... 55

3.3. Locations of TCs within ECVT assembly. .......................................................................................... 56

3.4. Device temperature monitoring locations within 2010 Prius PCU. ..................................................... 57

3.5. Opal-RT controller and interface system. ............................................................................................ 59

3.6. 2010 Prius, LS 600h, and Camry motor back-emf test results. ............................................................ 59

3.7. 2010 Prius locked rotor torque vs. position for various current levels. ............................................... 60

3.8. 2007 Camry locked rotor torque vs. position for various dc currents. ................................................. 61

3.9. 2010 Prius, 2008 LS 600h, and 2007 Camry peak locked rotor torque vs. dc current. ........................ 61

3.10. Reluctance and PM components of torque for general PMSM. ......................................................... 62

3.11. 2010 Prius motor efficiency contours for 650 Vdc. ........................................................................... 63

3.12. 2010 Prius inverter efficiency contours at 650 Vdc. ......................................................................... 64

3.13. 2010 Prius inverter efficiency contours at 500 Vdc. ......................................................................... 64

3.14. 2010 Prius inverter efficiency contours at 225 Vdc. ......................................................................... 65

3.15. 2010 Prius combined motor-inverter efficiency contours at 650 Vdc. ............................................. 65

3.16. 2010 Prius combined motor-inverter efficiency contours at 500 Vdc. ............................................. 66

3.17 2010 Prius combined motor-inverter efficiency contours at 225 Vdc. .............................................. 66

3.18. 2010 Prius motor-inverter combined efficiency contours at 650 V for 77% and above. ................... 67

3.19. LS 600h motor-inverter combined efficiency contours at 650 V for 77% and above. ...................... 68

3.20. 2007 Camry motor/inverter efficiency contours at 650V for 77% and above. .................................. 68

3.21. 2004 Prius motor/inverter efficiency contours for 77% and above. .................................................. 69

3.22. 2010 Prius temperatures during 25 kW continuous test at 3,000 rpm with 25ºC coolant. ................. 70

iv

�

3.23. 2010 Prius temperatures during 50 kW continuous test at 5,000 rpm with 50ºC coolant. ................. 70

3.24. 2010 Prius temperatures during 50 kW continuous test at 7,000 rpm with 25ºC coolant. ................. 71

3.25. 2010 Prius 25 kW continuous duration vs. speed with 50ºC coolant. ................................................ 72

3.26. 2010 Prius 50 kW continuous duration vs. speed with 50ºC coolant. ................................................ 72

3.27. 2010 Prius continuous duration at 3,000 rpm with various power levels and coolant temperatures. 73

3.28. 2010 Prius continuous duration at 5,000 rpm with various power levels and coolant temperatures. 73

3.29. LS 600h and Camry continuous duration at 5,000 rpm with various power levels and coolant

temperatures. ...................................................................................................................................... 74

3.30. 2010 Prius continuous duration at 7,000 rpm with various power levels and coolant temperatures. 74

v

�

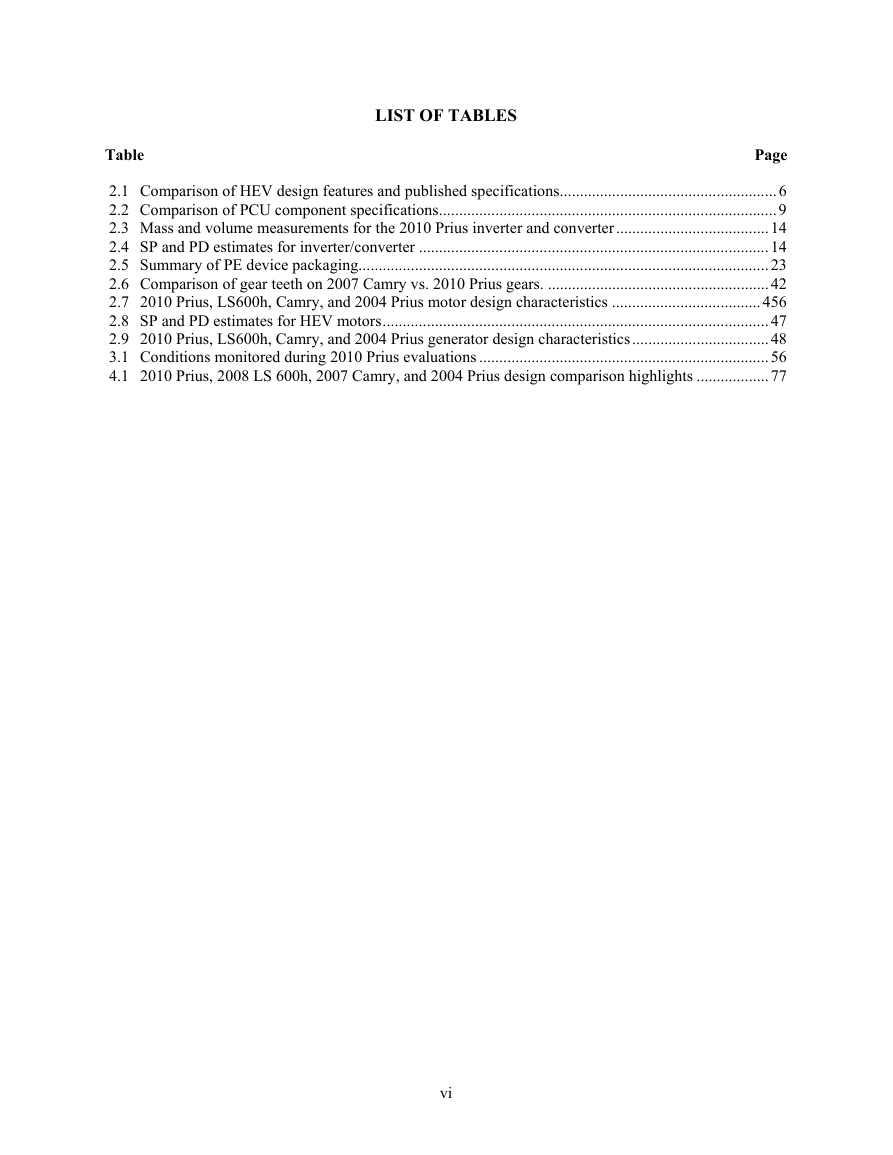

LIST OF TABLES

Page

Table

2.1 Comparison of HEV design features and published specifications ...................................................... 6

2.2 Comparison of PCU component specifications .................................................................................... 9

2.3 Mass and volume measurements for the 2010 Prius inverter and converter ...................................... 14

2.4 SP and PD estimates for inverter/converter ....................................................................................... 14

2.5 Summary of PE device packaging...................................................................................................... 23

2.6 Comparison of gear teeth on 2007 Camry vs. 2010 Prius gears. ....................................................... 42

2.7 2010 Prius, LS600h, Camry, and 2004 Prius motor design characteristics ..................................... 456

2.8 SP and PD estimates for HEV motors ................................................................................................ 47

2.9 2010 Prius, LS600h, Camry, and 2004 Prius generator design characteristics .................................. 48

3.1 Conditions monitored during 2010 Prius evaluations ........................................................................ 56

4.1 2010 Prius, 2008 LS 600h, 2007 Camry, and 2004 Prius design comparison highlights .................. 77

vi

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc