TwinCAT NC PTP 实用教程

目 录

1 TwinCAT NC PTP 系统概述.....................................................................................................7

1.1 TwinCAT NC PTP 与 TwinCAT PLC 的关系........................................................................8

1.2 TwinCAT NC PTP 控制的轴的类型和数量..........................................................................9

1.3 TwinCAT NC PTP 的控制周期 ...........................................................................................10

1.4 TwinCAT NC PTP 的配置、编程、调试............................................................................11

2 TwinCAT NC 轴的配置..........................................................................................................12

2.1 添加一个 Axis......................................................................................................................12

2.2 NC 轴的参数设置................................................................................................................14

2.2.1 Enc 编码器设置................................................................................................................14

2.2.2 Drive 驱动器设置.............................................................................................................18

2.2.3 Ctrl 控制参数设置............................................................................................................20

2.2.4 NC 轴参数的 ADS 信息 ..................................................................................................24

2.3 NC 轴与 PLC 程序的对应...................................................................................................25

2.4 NC 轴的导出和导入............................................................................................................26

2.5 编码器轴 Encoder Axis.......................................................................................................26

2.6 时间轴 Time Generator .......................................................................................................27

3 TwinCAT NC 轴的调试..........................................................................................................28

3.1 Axis 调试界面......................................................................................................................28

3.1.1 General ..............................................................................................................................28

3.1.2

Settings..............................................................................................................................29

3.1.3

Parameter...........................................................................................................................30

3.1.4 Dynamic ............................................................................................................................33

3.1.5 Online................................................................................................................................34

3.1.6

Functions ...........................................................................................................................35

3.1.7 Coupling............................................................................................................................35

3.1.8 Compensation....................................................................................................................36

3.2 使能和点动 ..........................................................................................................................37

3.2.1 准备工作...........................................................................................................................37

3.2.2 使能...................................................................................................................................37

3.2.3 点动...................................................................................................................................38

3.3 Function 测试 .......................................................................................................................39

3.4 调试动态性能 Dynamics .....................................................................................................40

3.5 齿轮联动 ..............................................................................................................................41

3.6 凸轮联动 ..............................................................................................................................42

3.6.1 Cam Table 示例.................................................................................................................42

3.6.2 安装 Cam Design Tool......................................................................................................42

3.6.3 编辑 Cam Table 表............................................................................................................42

3.6.4 载入 Cam Table 表............................................................................................................47

3.6.5 准备运行 Cam Table 表....................................................................................................48

3.6.6 在 Scope View 中观察 Cam 运行情况.............................................................................49

3.7 位置补偿 ..............................................................................................................................52

- 1 -

�

TwinCAT NC PTP 实用教程

3.8 飞锯 ......................................................................................................................................54

4 编写 NC 单轴控制的 PLC 程序 ............................................................................................55

4.1 准备工作 ..............................................................................................................................55

4.1.1 引用引用 TcMc.lib............................................................................................................55

4.1.2 声明 PLC_TO_NC 及 NC_TO_PLC 类型的变量...........................................................55

4.1.3

PLC 程序说明...................................................................................................................56

4.2 轴的管理 ..............................................................................................................................57

4.2.1 使能 MC_Power...............................................................................................................57

4.2.2 复位 MC_Reset................................................................................................................58

4.2.3 读取当前位置 MC_ReadActualPosition.........................................................................58

4.2.4 设置当前位置 MC_SetActualPosition ............................................................................58

4.3 轴的动作 ..............................................................................................................................59

4.3.1 匀速运动 MC_MoveVelocity ...........................................................................................59

4.3.2 绝对定位 MC_MoveAbsolute ..........................................................................................60

4.3.3 相对定位 MC_MoveRelative ...........................................................................................60

4.3.4 点动 MC_Jog ....................................................................................................................61

4.3.5 停止 MC_Stop ..................................................................................................................62

4.3.6 模长内定位 MC_MoveModulo........................................................................................62

4.3.7 重置目标位置和速度 MC_NewPosAndVelo ..................................................................64

4.3.8 重置目标位置 MC_NewPos.............................................................................................65

4.4 寻参 MC_Home ..................................................................................................................65

4.4.1 可选的寻参方式...............................................................................................................65

4.4.2 寻参过程...........................................................................................................................66

4.4.3 几种寻参方式的比较.......................................................................................................67

4.4.4 寻参功能块 MC_Home ....................................................................................................69

4.4.5 寻参的速度.......................................................................................................................70

4.4.6 参考点的位置...................................................................................................................70

4.5 位置外部设定值发生器(External set value generation) ................................................71

4.5.1 MC_ExtSetPointGenEnable..............................................................................................71

4.5.2 MC_ExtSetPointGenDisable.............................................................................................72

4.5.3 MC_ExtSetPointGenFeed .................................................................................................72

4.6 位置补偿 ..............................................................................................................................74

4.6.1 MC_MoveSuperImposedExt.............................................................................................74

4.6.2 适用位置补偿的场合.......................................................................................................75

4.7 TwinCAT NC 全闭环控制. ..................................................................................................79

4.8 从 PLC 程序修改 NC 轴的参数设置..................................................................................83

4.9 轴的状态函数 ......................................................................................................................85

5 编写 NC 多轴联动程序 .........................................................................................................87

5.1 电子齿轮 ..............................................................................................................................87

5.1.1 齿轮耦合...........................................................................................................................87

5.1.2 齿轮解耦...........................................................................................................................88

5.2 电子凸轮 ..............................................................................................................................90

5.2.1 凸轮表 Cam Table............................................................................................................90

5.2.2 凸轮表的耦合与解耦.......................................................................................................90

- 2 -

�

TwinCAT NC PTP 实用教程

5.2.3 扩展凸轮耦合...................................................................................................................91

5.2.4 凸轮缩放...........................................................................................................................93

5.2.5 凸轮在线修改的激活模式 ...............................................................................................93

5.2.6 凸轮缩放的模式...............................................................................................................95

5.2.7 从文件装载凸轮表...........................................................................................................97

5.2.8 修改凸轮表的关键点.......................................................................................................98

5.3 收放卷及张力控制 ..............................................................................................................99

5.3.1 功能块...............................................................................................................................99

5.3.2 张力控制的原理框图.....................................................................................................100

5.4 万能飞锯 ............................................................................................................................102

5.4.1.

Interfaces 接口 ...............................................................................................................103

5.4.2. 速度同步.........................................................................................................................103

5.4.3. 位置同步.........................................................................................................................104

5.4.4. 在 PLC 程序中实现飞锯功能........................................................................................104

5.4.5. 同步模式.........................................................................................................................107

5.4.6. 飞锯同步特征值 FlyingSawCharacValues.....................................................................108

5.5 TwinCAT NC Fifo...............................................................................................................110

5.5.1 配置 TwinCAT NC Fifo 组 .............................................................................................110

5.5.2

Fifo 控制的 PLC 程序....................................................................................................112

6 TwinCAT NC 控制 AX5000.................................................................................................114

6.1 AX5000 功能介绍..............................................................................................................114

6.2 AX5000 接线说明..............................................................................................................115

6.3 在 System Manager 中配置和调试 AX5000.....................................................................115

6.3.1 安装 AX5000 配置工具 .................................................................................................115

6.3.2 更新 Firmware ................................................................................................................115

6.3.3 Drive Manager 界面介绍................................................................................................116

6.3.4 扫描 AX5000 ..................................................................................................................118

6.3.5 配置 AX5000, ..............................................................................................................121

6.3.6 配置 TwinCAT NC 轴。.................................................................................................122

6.3.7 AX5000 的工作模式 OP Mode ......................................................................................125

6.3.8 AX5000 的 Process Data.................................................................................................127

6.4 从 PLC 程序中访问 AX5000 的参数 ...............................................................................127

6.5 从 PLC 程序控制 AX5000 硬件动作。............................................................................127

6.6 AX5000 的 PID 参数调整。 .............................................................................................128

6.6.1 准备工作.........................................................................................................................128

6.6.2 在 Scope View 中设置监视的变量................................................................................132

6.6.3 AX5000 速度环调节 ......................................................................................................133

6.6.4 AX5000 位置环调节 ......................................................................................................138

6.6.5 保存调试结果.................................................................................................................144

7 AX5000 带第三方电机 .........................................................................................................145

7.1 第三方同步电机 ................................................................................................................145

7.1.1 准备电机文件.................................................................................................................145

7.1.2 扫描 AX5000 驱动器 .....................................................................................................146

7.1.3 选择电机类型.................................................................................................................147

- 3 -

�

TwinCAT NC PTP 实用教程

7.1.4 校正磁偏角.....................................................................................................................150

7.1.5 将磁偏角的校正结果手动输入 Startup List..................................................................151

7.1.6 检查磁偏角设置值与实际值的偏差 .............................................................................154

7.1.7 导出电机参数文件(可选) .........................................................................................155

7.2 同步电机调试中的其它注意事项(可选).....................................................................156

7.2.1 接线.................................................................................................................................156

7.2.2 如何确定编码器极数? ...................................................................................................156

7.2.3 如何确定电机极对数? ...................................................................................................156

7.2.4 松开抱闸.........................................................................................................................157

7.2.5 编码器类型与磁偏角的关系 .........................................................................................157

7.2.6 关于几种反馈类型.........................................................................................................157

7.2.7 编码器与电机的方向一致性 .........................................................................................158

7.2.8 Commutation 的原理:.....................................................................................................158

7.2.9 直流母线电压和电压常数 .............................................................................................158

7.3 第三方异步电机 ................................................................................................................159

8 TwinCAT NC 通过 KL2531/KL2541 端子模块控制步进电机 ..........................................167

8.1 KL2531/KL2541 功能介绍................................................................................................167

8.2 使用 TwinCAT NC 控制之前的准备工作 ........................................................................168

8.2.1 KL2531/KL2541 的接线 ................................................................................................168

8.2.2 参数设置.........................................................................................................................169

8.3 脱离 PLC 及 NC 测试硬件................................................................................................173

8.4 在 System Manager 中配置 KL2531/3541 类型的轴 .......................................................174

8.4.1 TwinCAT NC Axis 设置..................................................................................................174

8.5 使用 TwinCAT NC 控制步进电机轴 ................................................................................179

8.6 从 PLC 程序访问 KL2531/3541 的参数...........................................................................179

8.6.1 KL2531/KL2541 的 Process Data...................................................................................179

8.6.2 功能块 FB_RegisterComKL25xx...................................................................................179

8.7 专用功能块 MC_PowerStepper.........................................................................................180

9 第三方驱动:经脉冲输出模块 KL2521..............................................................................182

9.1 KL2521 功能介绍 ..............................................................................................................182

9.2 硬件准备 ............................................................................................................................182

9.3 KL2521 参数设置 ..............................................................................................................183

9.4 驱动器参数设置 ................................................................................................................184

9.5 调节驱动器的速度环 PID .................................................................................................184

9.6 在 System Manager 中配置 KL2521 类型的轴 ................................................................185

9.6.1 编码器设置.....................................................................................................................185

9.6.2 驱动器设置.....................................................................................................................185

9.6.3 NC 轴参数设置 ..............................................................................................................186

9.7 使用 TwinCAT NC 通过脉冲输出模块控制第三方伺服.................................................186

9.8 KL2521 的参数化 ..............................................................................................................186

10 第三方驱动:CanOpen(DS402)......................................................................................187

10.1 CanOpen(DS402)介绍........................................................................................................187

10.2 硬件准备 ............................................................................................................................187

10.3 驱动器参数设置 ................................................................................................................187

- 4 -

�

TwinCAT NC PTP 实用教程

10.4 在 System Manager 中配置 CanOpen(DS402)类型的轴..................................................189

10.4.1 轴的类型设置.................................................................................................................189

10.4.2 扫描或添加 CanOpen 主站及从站. ...............................................................................190

10.4.3 PDO 参数设置................................................................................................................190

10.4.4 TwinCAT NC 参数设置..................................................................................................193

10.5 CanOpen(DS402)型驱动器的参数化................................................................................197

10.5.1 CanOpen 驱动器的参数化.............................................................................................197

10.5.2 CanOpen Over EtherCAT 驱动器的参数化...................................................................198

11 第三方驱动:经模拟量输出模块........................................................................................199

11.1 硬件要求 ............................................................................................................................199

11.2 驱动器参数设置 ................................................................................................................199

11.3 在 System Manager 中配置和调试....................................................................................200

11.4 调节驱动器的速度环 PID .................................................................................................203

11.5 使用 TwinCAT NC 通过模拟量控制第三方伺服. ...........................................................203

12 编程软件................................................................................................................................204

12.1 准备工作 ............................................................................................................................204

12.2 安装 TwinCAT 软件...........................................................................................................204

12.3 编程 PC 与控制器的连接..................................................................................................209

12.4 用 TwinCAT 开发第一个项目...........................................................................................214

12.5 调试画面 TwinCAT HMI...................................................................................................221

文本和图形...................................................................................................................................222

按钮(Button)............................................................................................................................224

数组的显示...................................................................................................................................224

- 5 -

�

TwinCAT NC PTP 实用教程

修订记录

2011-5-21,第十章,TwinCAT NC 通过现场总线控制第三方伺服驱动器。

整章修改

2011-5-24,第五章,编写 NC 多轴联动程序。

增加 5.5 TwinCAT NC Fifo

- 6 -

�

TwinCAT NC PTP 实用教程

修订记录

1 TwinCAT NC PTP 系统概述

TwinCAT NC PTP 是 Beckhoff 公司的运动控制软件的名称,从字面来看,TwinCAT 是“The Windows

Control and Automation Technology”的缩写,即基于 Windows 操作系统的自动化控制技术,

而 NC PTP 是“Numerical Control Point To Point”的缩写,实际上,NC(Numerical Control)

是自控领域的一个专业术语,意思是“运动控制”,NC PTP 就是点对点的运动控制。

TwinCAT NC 是基于 PC 的纯软件的运动控制方式。它实现的功能,与市面上的运动控制模块、

运动控制卡等硬件类似,但比后者更加灵活和强大。

TwinCAT NC 有 PTP 和 NC I 两个级别,PTP 即点对点控制方式,可控制单轴的动作,也可以实

现两轴之间的电子齿轮、电子凸轮同步,在此基础上,Beckhoff 还提供 Dancer Control(张

力控制)、Flying Saw(飞锯)等双轴联动方式。控制单轴动作时,既可以给定目标位置和最

大速度,由 TwinCAT NC 根据加速度限值等参数来完成路径规划,也可以由用户自己做好路径

规划,在每个 PLC 周期把目标位置发送给 TwinCAT NC 去执行。绝大多数情况下,用户使用前

一种方式,仅当电机转动距离与位置反馈为非线性关系时,才使用后者。

而 TwinCAT NC I 除了能够实现 TwinCAT NC PTP 的所有功能之外,还可以实现多轴之间的直线、

圆弧和空间螺旋插补。在本书中仅讨论 TwinCAT NC PTP 的原理和应用。

- 7 -

�

TwinCAT NC PTP 实用教程

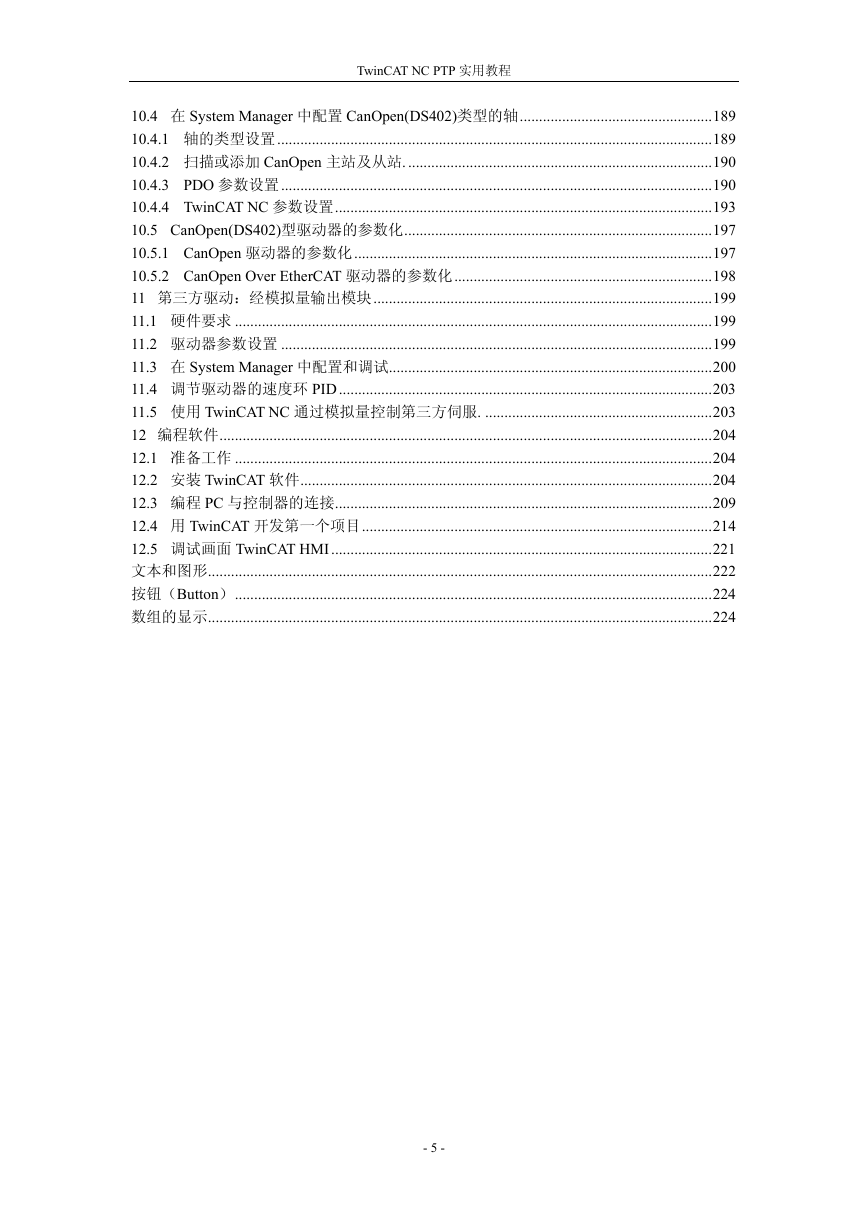

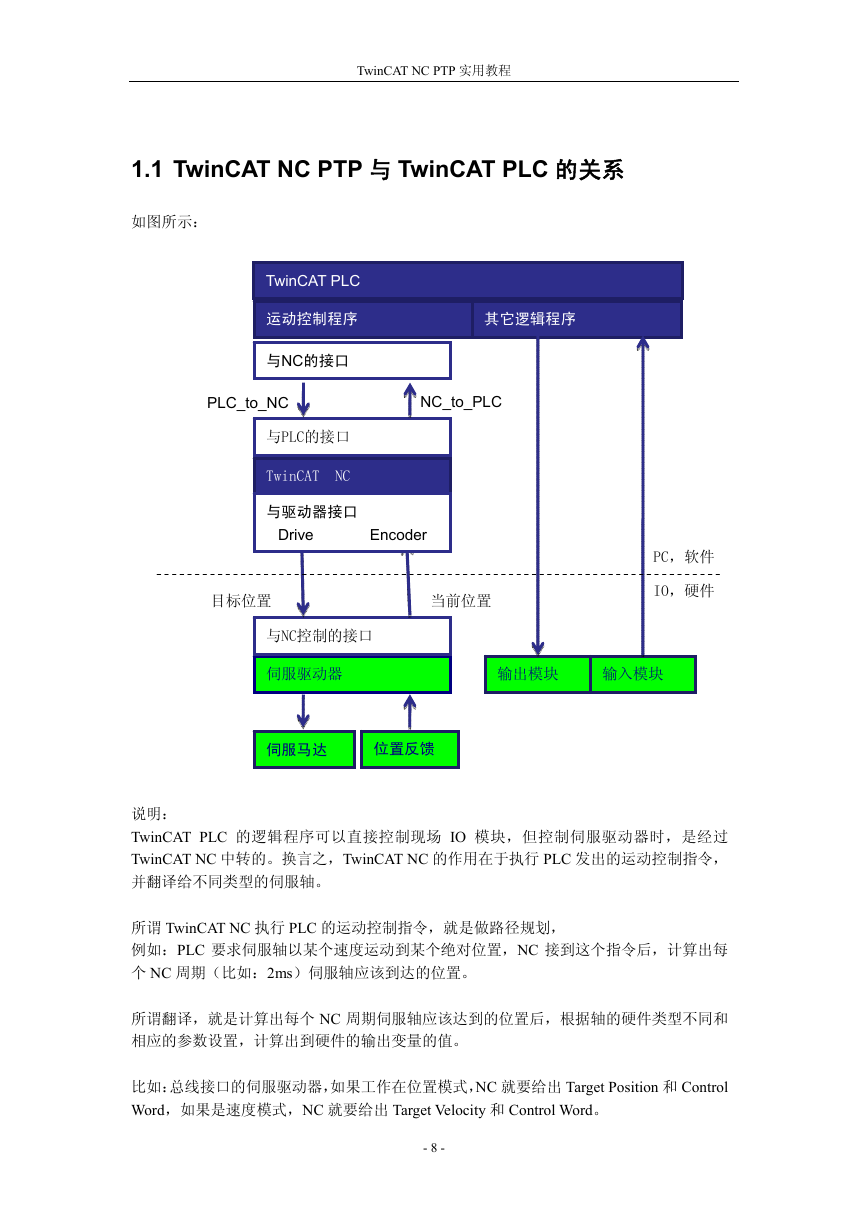

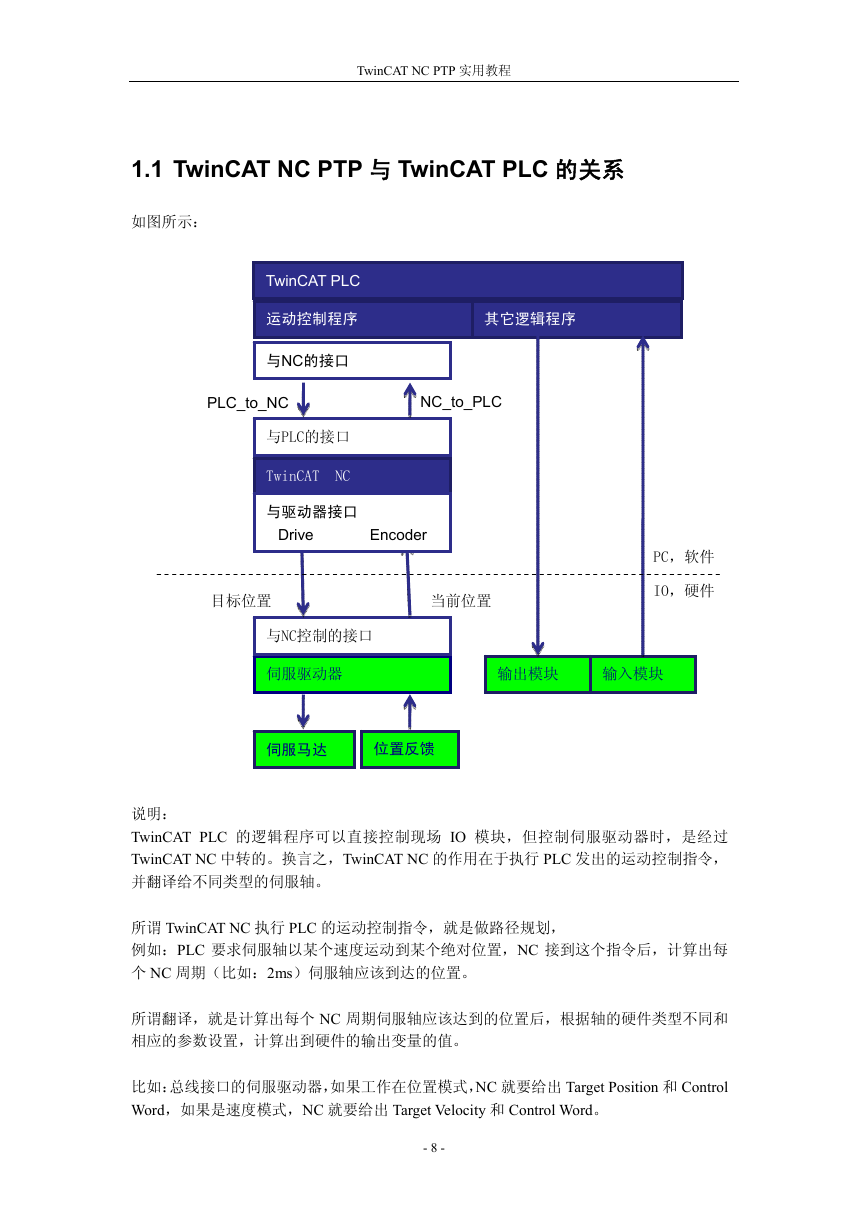

1.1 TwinCAT NC PTP 与 TwinCAT PLC 的关系

如图所示:

TwinCAT PLC

运动控制程序

与NC的接口

其它逻辑程序

PLC_to_NC

NC_to_PLC

与PLC的接口

TwinCAT NC

与驱动器接口

Drive

Encoder

目标位置

当前位置

与NC控制的接口

PC,软件

IO,硬件

伺服驱动器

输出模块

输入模块

伺服马达

位置反馈

说明:

TwinCAT PLC 的逻辑程序可以直接控制现场 IO 模块,但控制伺服驱动器时,是经过

TwinCAT NC 中转的。换言之,TwinCAT NC 的作用在于执行 PLC 发出的运动控制指令,

并翻译给不同类型的伺服轴。

所谓 TwinCAT NC 执行 PLC 的运动控制指令,就是做路径规划,

例如:PLC 要求伺服轴以某个速度运动到某个绝对位置,NC 接到这个指令后,计算出每

个 NC 周期(比如:2ms)伺服轴应该到达的位置。

所谓翻译,就是计算出每个 NC 周期伺服轴应该达到的位置后,根据轴的硬件类型不同和

相应的参数设置,计算出到硬件的输出变量的值。

比如:总线接口的伺服驱动器,如果工作在位置模式,NC 就要给出 Target Position 和 Control

Word,如果是速度模式,NC 就要给出 Target Velocity 和 Control Word。

- 8 -

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc