DX200 OPTIONS

INSTRUCTIONS

FOR ETHERNET SERVER FUNCTION:

ADVANCED FEATURE OF DX200 ETHERNET FUNCTION

Upon receipt of the product and prior to initial operation, read these instructions thoroughly, and retain

for future reference.

MOTOMAN INSTRUCTIONS

MOTOMAN-- INSTRUCTIONS

DX200 INSTRUCTIONS

DX200 OPERATOR’S MANUAL

DX200 MAINTENANCE MANUAL

The DX200 Operator’s manual above corresponds to specific usage.

Be sure to use the appropriate manual.

Part Number:

Revision:

165984-1CD

0

MANUAL NO.

HW1481823

0

1/60�

Adavanced Ethernet

Function

165984-1CD

MANDATORY

• This manual explains the Ethernet Server function of the DX200

system. Read this manual carefully and be sure to understand its

contents before handling the DX200.

• General items related to safety are listed in Chapter 1: Safety of the

DX200 Instructions. To ensure correct and safe operation, carefully

read the DX200 Instructions before reading this manual.

CAUTION

• Some drawings in this manual are shown with the protective covers

or shields removed for clarity. Be sure all covers and shields are

replaced before operating this product.

• The drawings and photos in this manual are representative

examples and differences may exist between them and the

delivered product.

• YASKAWA may modify this model without notice when necessary

due to product improvements, modifications, or changes in

specifications. If such modification is made, the manual number will

also be revised.

If your copy of the manual is damaged or lost, contact a YASKAWA

representative to order a new copy. The representatives are listed

on the back cover. Be sure to tell the representative the manual

number listed on the front cover.

•

• YASKAWA is not responsible for incidents arising from unauthorized

modification of its products. Unauthorized modification voids your

product's warranty.

ii

HW1481823

2/60�

165984-1CD

Adavanced Ethernet

Function

Notes for Safe Operation

Read this manual carefully before installation, operation, maintenance, or

inspection of the DX200.

In this manual, the Notes for Safe Operation are classified as

“WARNING”, “CAUTION”, “MANDATORY”, or “PROHIBITED”.

WARNING

CAUTION

MANDATORY

PROHIBITED

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury to

personnel.

Indicates a potentially hazardous

situation which, if not avoided, could

result in minor or moderate injury to

personnel and damage to equipment.

It may also be used to alert against

unsafe practices.

Always be sure to follow explicitly the

items listed under this heading.

Must never be performed.

Even items described as “CAUTION” may result in a serious accident in

some situations.

At any rate, be sure to follow these important items

NOTE To ensure safe and efficient operation at all times, be sure to

follow all instructions, even if not designated as "CAUTION"

and "WARNING".

iii

HW1481823

3/60�

Adavanced Ethernet

Function

165984-1CD

WARNING

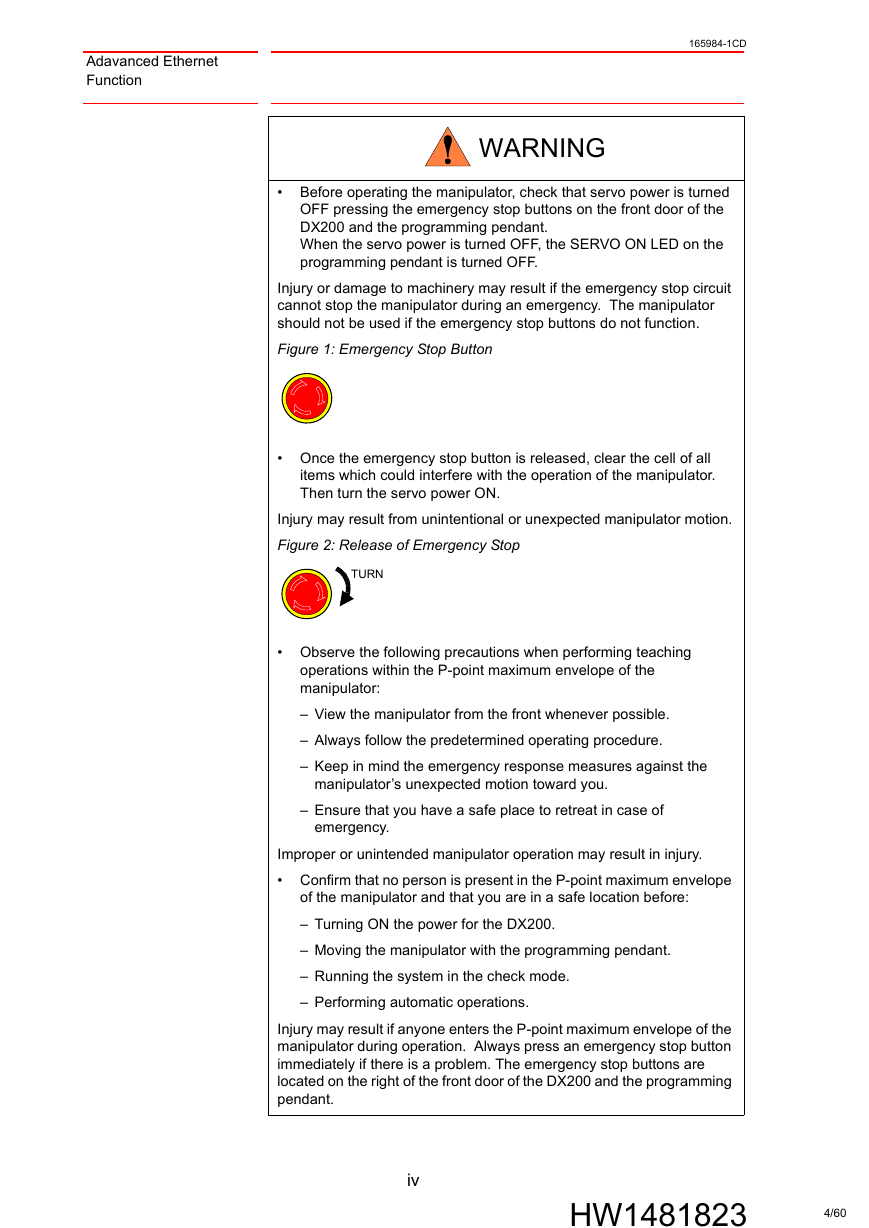

• Before operating the manipulator, check that servo power is turned

OFF pressing the emergency stop buttons on the front door of the

DX200 and the programming pendant.

When the servo power is turned OFF, the SERVO ON LED on the

programming pendant is turned OFF.

Injury or damage to machinery may result if the emergency stop circuit

cannot stop the manipulator during an emergency. The manipulator

should not be used if the emergency stop buttons do not function.

Figure 1: Emergency Stop Button

• Once the emergency stop button is released, clear the cell of all

items which could interfere with the operation of the manipulator.

Then turn the servo power ON.

Injury may result from unintentional or unexpected manipulator motion.

Figure 2: Release of Emergency Stop

TURN

• Observe the following precautions when performing teaching

operations within the P-point maximum envelope of the

manipulator:

– View the manipulator from the front whenever possible.

– Always follow the predetermined operating procedure.

– Keep in mind the emergency response measures against the

manipulator’s unexpected motion toward you.

– Ensure that you have a safe place to retreat in case of

emergency.

Improper or unintended manipulator operation may result in injury.

• Confirm that no person is present in the P-point maximum envelope

of the manipulator and that you are in a safe location before:

– Turning ON the power for the DX200.

– Moving the manipulator with the programming pendant.

– Running the system in the check mode.

– Performing automatic operations.

Injury may result if anyone enters the P-point maximum envelope of the

manipulator during operation. Always press an emergency stop button

immediately if there is a problem. The emergency stop buttons are

located on the right of the front door of the DX200 and the programming

pendant.

iv

HW1481823

4/60�

165984-1CD

Adavanced Ethernet

Function

CAUTION

• Perform the following inspection procedures prior to conducting

manipulator teaching. If problems are found, repair them

immediately, and be sure that all other necessary processing has

been performed.

– Check for problems in manipulator movement.

– Check for damage to insulation and sheathing of external wires.

• Always return the programming pendant to the hook on the DX200

cabinet after use.

The programming pendant can be damaged if it is left in the

manipulator's work area, on the floor, or near fixtures.

• Read and understand the Explanation of Warning Labels in the

DX200 Instructions before operating the manipulator:

Definition of Terms Used Often in This Manual

The MOTOMAN is the YASKAWA industrial robot product.

The MOTOMAN usually consists of the manipulator, the controller, the

programming pendant, and supply cables.

In this manual, the equipment is designated as follows:

Equipment

DX200 controller

DX200 programming pendant

Cable between the manipulator ans the

controller

Manual Designation

DX200

Programming pendant

Manipulator cable

v

HW1481823

5/60�

Adavanced Ethernet

Function

165984-1CD

Descriptions of the programming pendant, buttons, and displays are

shown as follows:

Equipment

Programming

Pendant

Character

Keys

Symbol

Keys

Axis Keys

Number Keys

Keys pressed

simultaneously

Displays

Manual Designation

The keys which have characters printed on

them are denoted with [ ].

ex. [ENTER]

The keys which have a symbol printed on them

are not denoted with [ ] but depicted with a small

picture.

GO BACK

GO BACK

PAGE

PAGE

ex. page key

The cursor key is an exception, and a picture is

not shown.

“Axis Keys” and “Number Keys” are generic

names for the keys for axis operation and

number input.

When two keys are to be pressed

simultaneously, the keys are shown with a “+”

sign between them, ex. [SHIFT]+[COORD]

The menu displayed in the programming

pendant is denoted with { }.

ex. {JOB}

Description of the Operation Procedure

In the explanation of the operation procedure, the expression "Select • • • "

means that the cursor is moved to the object item and the SELECT key is

pressed, or that the item is directly selected by touching the screen.

Registered Trademark

In this manual, names of companies, corporations, or products are

trademarks, registered trademarks, or bland names for each company or

corporation. The indications of (R) and TM are omitted.

vi

HW1481823

6/60�

165984-1CD

Adavanced Ethernet

Function

Table of Contents

1 Introduction ..................................................................................................................................... 1-1

1.1 Features ............................................................................................................................ 1-1

1.1.1 Request of Multiple Processes............................................................................. 1-1

1.1.2 Simplification of Communication Procedure......................................................... 1-1

1.1.3 Communication with Other Than MOTOCOM...................................................... 1-1

1.2 System Outline .................................................................................................................. 1-2

2 System Configuration...................................................................................................................... 2-1

2.1 Setting of Ethernet Function .............................................................................................. 2-1

2.2 Setting of Ethernet Server Function................................................................................... 2-1

2.3 Setting of Transmission Parameters.................................................................................. 2-1

3 Transmission Procedure................................................................................................................. 3-1

3.1 Outline ............................................................................................................................... 3-1

3.1.1 Socket Connection ............................................................................................... 3-2

3.1.2 START Request ................................................................................................... 3-2

3.1.3 Response to START Request .............................................................................. 3-2

3.1.4 Command............................................................................................................. 3-2

3.1.4.1 Command................................................................................................ 3-2

3.1.4.2 Size ......................................................................................................... 3-2

3.1.5 Response to Command........................................................................................ 3-3

3.1.6 Command Data .................................................................................................... 3-3

3.1.7 Answer ................................................................................................................. 3-3

3.1.8 Closing of a Socket .............................................................................................. 3-3

3.2 Command Details .............................................................................................................. 3-4

3.2.1 Status Read Function........................................................................................... 3-4

3.2.1.1 Read/Monitor Command ......................................................................... 3-4

3.2.1.2 Read/Data Access System Command.................................................. 3-11

3.2.2 System Control Function .................................................................................... 3-17

3.2.2.1 Operation System Command................................................................ 3-17

3.2.2.2 Start-Up System Command .................................................................. 3-22

3.2.2.3 Editing System Commands................................................................... 3-30

3.2.2.4 Job Selection System Command .......................................................... 3-37

3.2.3 I/O Read/Write Function..................................................................................... 3-38

3.2.3.1 Read-Out of I/O Signal Status............................................................... 3-38

3.2.3.2 Write-in of I/O Signal Status.................................................................. 3-39

vii

HW1481823

7/60�

Adavanced Ethernet

Function

Table of Contents

165984-1CD

3.3 Transmission Examples...................................................................................................3-40

3.3.1 Read-Out of Status for Mode, Cycle, etc............................................................3-40

3.3.2 Read-Out of I/O Signals for the DX200 ..............................................................3-40

3.3.3 Write-In of I/O Signals for the DX200 .................................................................3-41

3.3.4 Continuous Execution of Multiple Commands....................................................3-42

4 Function Checkout Procedure.........................................................................................................4-1

4.1 Cable Connection Check ...................................................................................................4-1

4.2 Connection Check with Lower Protocol .............................................................................4-2

4.3 Connection Check with telnet ............................................................................................4-3

5 Restrictions .....................................................................................................................................5-1

5.1 Automatic Close of Socket.................................................................................................5-1

5.2 Unavailable Command/Function........................................................................................5-1

5.3 Restrictions on the Number of Sockets..............................................................................5-2

5.4 Restrictions on Text Length ...............................................................................................5-2

5.5 Restrictions on Access from Multiple Host Computers......................................................5-2

viii

HW1481823

8/60�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc