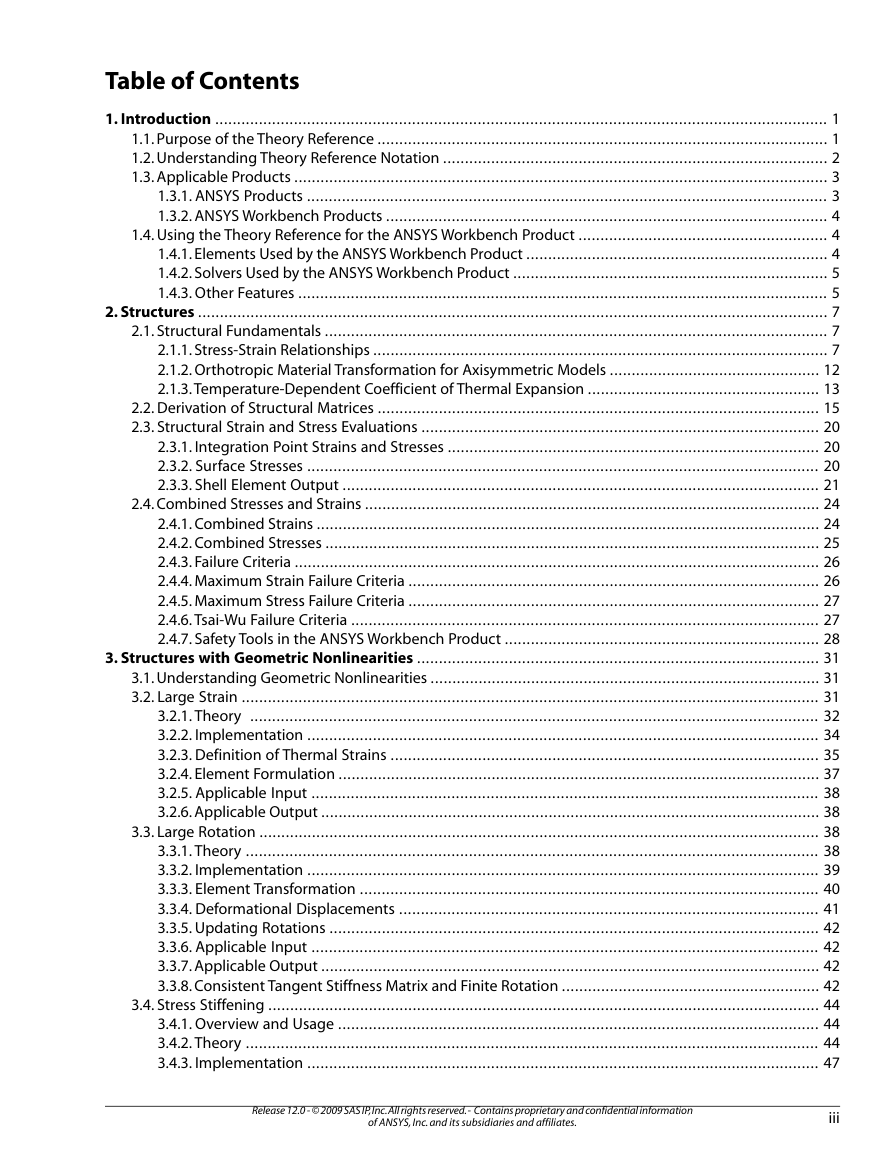

Theory Reference for the Mechanical APDL and Mechanical Applications

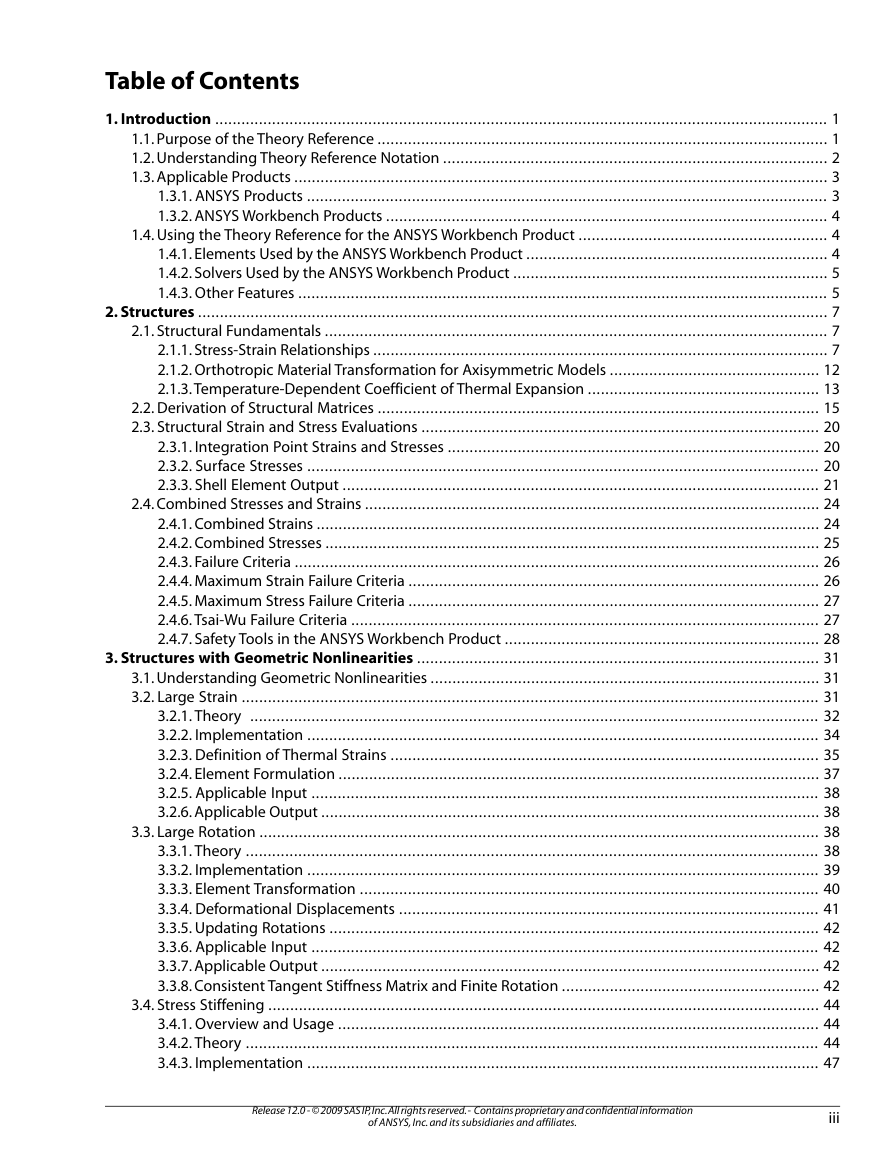

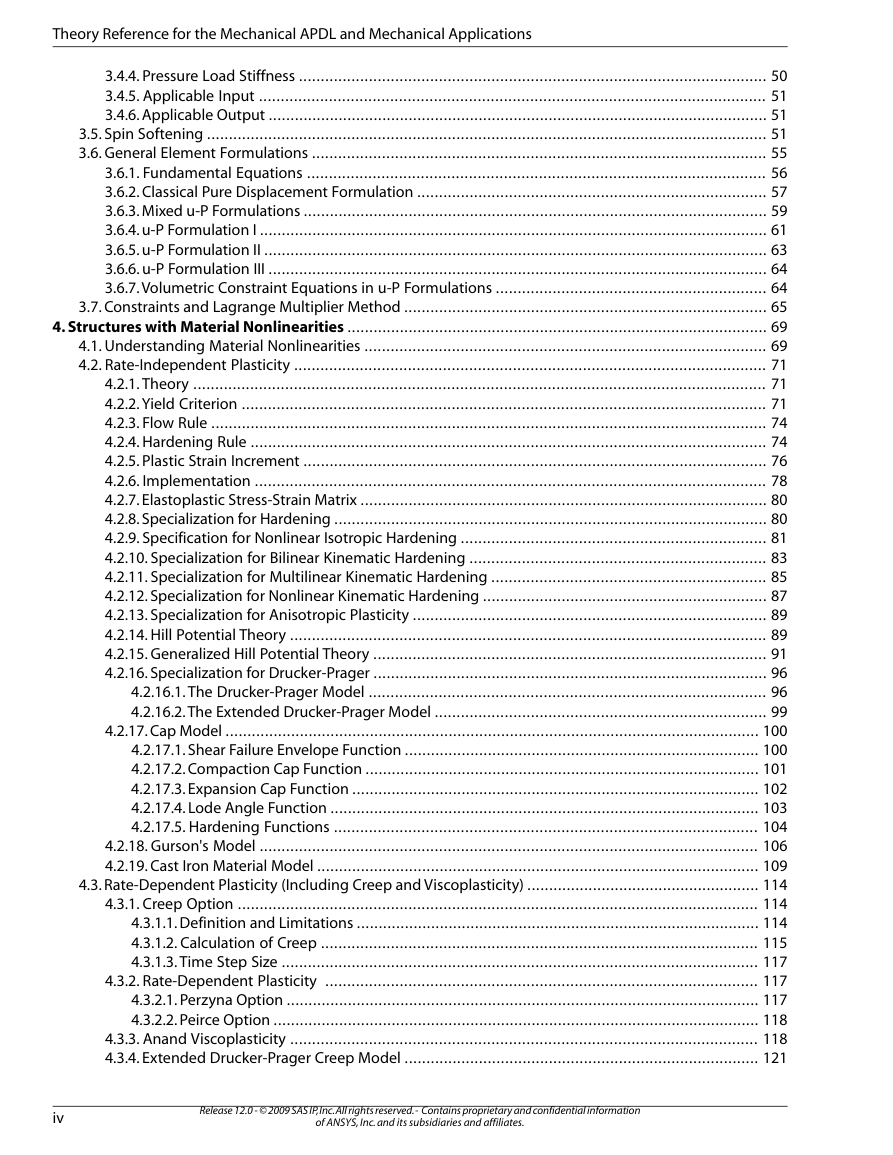

Table of Contents

Chapter 1: Introduction

1.1. Purpose of the Theory Reference

1.2. Understanding Theory Reference Notation

1.3. Applicable Products

1.3.1. ANSYS Products

1.3.2. ANSYS Workbench Products

1.4. Using the Theory Reference for the ANSYS Workbench Product

1.4.1. Elements Used by the ANSYS Workbench Product

1.4.2. Solvers Used by the ANSYS Workbench Product

1.4.3. Other Features

Chapter 2: Structures

2.1. Structural Fundamentals

2.1.1. Stress-Strain Relationships

2.1.2. Orthotropic Material Transformation for Axisymmetric Models

2.1.3. Temperature-Dependent Coefficient of Thermal Expansion

2.2. Derivation of Structural Matrices

2.3. Structural Strain and Stress Evaluations

2.3.1. Integration Point Strains and Stresses

2.3.2. Surface Stresses

2.3.3. Shell Element Output

2.4. Combined Stresses and Strains

2.4.1. Combined Strains

2.4.2. Combined Stresses

2.4.3. Failure Criteria

2.4.4. Maximum Strain Failure Criteria

2.4.5. Maximum Stress Failure Criteria

2.4.6. Tsai-Wu Failure Criteria

2.4.7. Safety Tools in the ANSYS Workbench Product

Chapter 3: Structures with Geometric Nonlinearities

3.1. Understanding Geometric Nonlinearities

3.2. Large Strain

3.2.1. Theory

3.2.2. Implementation

3.2.3. Definition of Thermal Strains

3.2.4. Element Formulation

3.2.5. Applicable Input

3.2.6. Applicable Output

3.3. Large Rotation

3.3.1. Theory

3.3.2. Implementation

3.3.3. Element Transformation

3.3.4. Deformational Displacements

3.3.5. Updating Rotations

3.3.6. Applicable Input

3.3.7. Applicable Output

3.3.8. Consistent Tangent Stiffness Matrix and Finite Rotation

3.4. Stress Stiffening

3.4.1. Overview and Usage

3.4.2. Theory

3.4.3. Implementation

3.4.4. Pressure Load Stiffness

3.4.5. Applicable Input

3.4.6. Applicable Output

3.5. Spin Softening

3.6. General Element Formulations

3.6.1. Fundamental Equations

3.6.2. Classical Pure Displacement Formulation

3.6.3. Mixed u-P Formulations

3.6.4. u-P Formulation I

3.6.5. u-P Formulation II

3.6.6. u-P Formulation III

3.6.7. Volumetric Constraint Equations in u-P Formulations

3.7. Constraints and Lagrange Multiplier Method

Chapter 4: Structures with Material Nonlinearities

4.1. Understanding Material Nonlinearities

4.2. Rate-Independent Plasticity

4.2.1. Theory

4.2.2. Yield Criterion

4.2.3. Flow Rule

4.2.4. Hardening Rule

4.2.5. Plastic Strain Increment

4.2.6. Implementation

4.2.7. Elastoplastic Stress-Strain Matrix

4.2.8. Specialization for Hardening

4.2.9. Specification for Nonlinear Isotropic Hardening

4.2.10. Specialization for Bilinear Kinematic Hardening

4.2.11. Specialization for Multilinear Kinematic Hardening

4.2.12. Specialization for Nonlinear Kinematic Hardening

4.2.13. Specialization for Anisotropic Plasticity

4.2.14. Hill Potential Theory

4.2.15. Generalized Hill Potential Theory

4.2.16. Specialization for Drucker-Prager

4.2.16.1. The Drucker-Prager Model

4.2.16.2. The Extended Drucker-Prager Model

4.2.17. Cap Model

4.2.17.1. Shear Failure Envelope Function

4.2.17.2. Compaction Cap Function

4.2.17.3. Expansion Cap Function

4.2.17.4. Lode Angle Function

4.2.17.5. Hardening Functions

4.2.18. Gurson's Model

4.2.19. Cast Iron Material Model

4.3. Rate-Dependent Plasticity (Including Creep and Viscoplasticity)

4.3.1. Creep Option

4.3.1.1. Definition and Limitations

4.3.1.2. Calculation of Creep

4.3.1.3. Time Step Size

4.3.2. Rate-Dependent Plasticity

4.3.2.1. Perzyna Option

4.3.2.2. Peirce Option

4.3.3. Anand Viscoplasticity

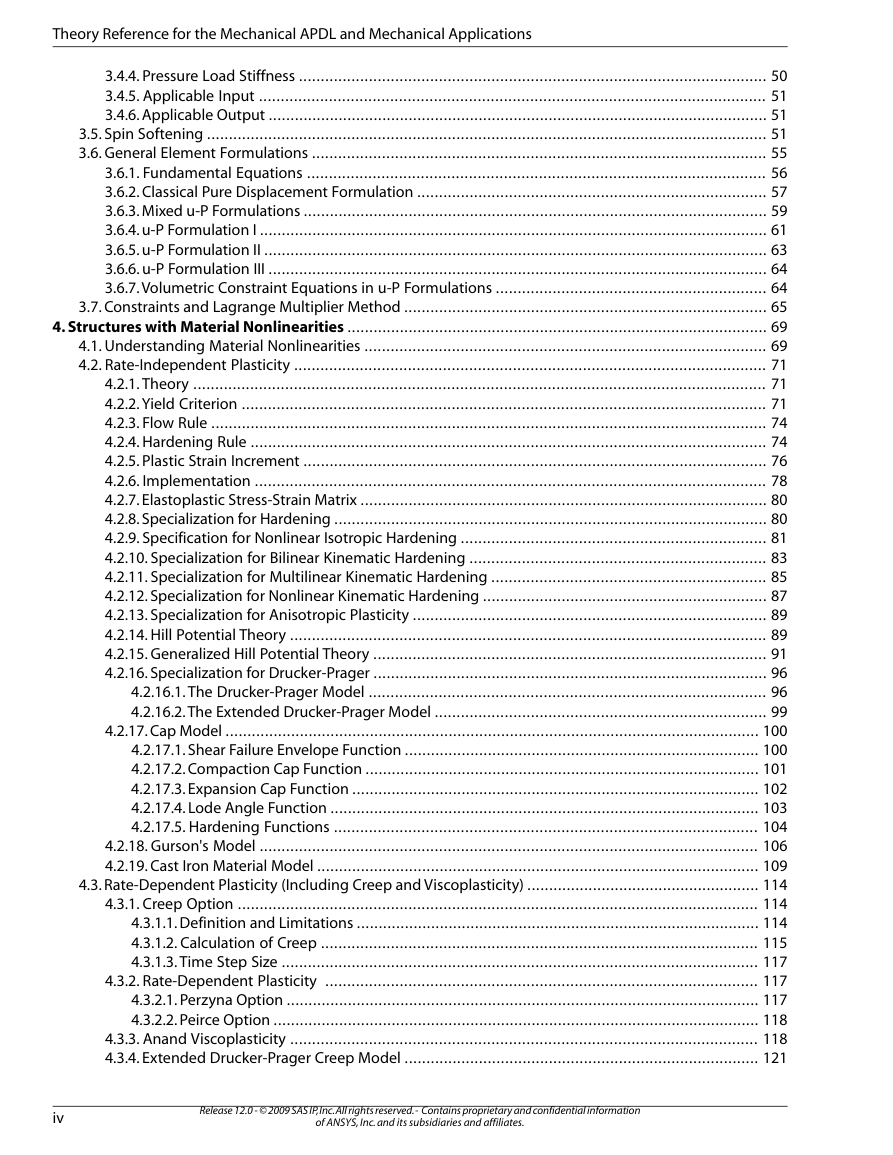

4.3.4. Extended Drucker-Prager Creep Model

4.3.4.1. Inelastic Strain Rate Decomposition

4.3.4.2. Yielding and Hardening Conditions

4.3.4.3. Creep Measurements

4.3.4.4. Equivalent Creep Stress

4.3.4.5. Elastic Creeping and Stress Projection

4.4. Gasket Material

4.4.1. Stress and Deformation

4.4.2. Material Definition

4.4.3. Thermal Deformation

4.5. Nonlinear Elasticity

4.5.1. Overview and Guidelines for Use

4.6. Shape Memory Alloy

4.6.1. The Continuum Mechanics Model

4.7. Hyperelasticity

4.7.1. Finite Strain Elasticity

4.7.2. Deviatoric-Volumetric Multiplicative Split

4.7.3. Isotropic Hyperelasticity

4.7.3.1. Neo-Hookean

4.7.3.2. Mooney-Rivlin

4.7.3.3. Polynomial Form

4.7.3.4. Ogden Potential

4.7.3.5. Arruda-Boyce Model

4.7.3.6. Gent Model

4.7.3.7. Yeoh Model

4.7.3.8. Ogden Compressible Foam Model

4.7.3.9. Blatz-Ko Model

4.7.4. Anisotropic Hyperelasticity

4.7.5. USER Subroutine

4.7.6. Output Quantities

4.7.7. Hyperelasticity Material Curve Fitting

4.7.7.1. Uniaxial Tension (Equivalently, Equibiaxial Compression)

4.7.7.2. Equibiaxial Tension (Equivalently, Uniaxial Compression)

4.7.7.3. Pure Shear

4.7.7.4. Volumetric Deformation

4.7.7.5. Least Squares Fit Analysis

4.7.8. Material Stability Check

4.8. Bergstrom-Boyce

4.9. Mullins Effect

4.9.1. The Pseudo-elastic Model

4.10. Viscoelasticity

4.10.1. Small Strain Viscoelasticity

4.10.2. Constitutive Equations

4.10.3. Numerical Integration

4.10.4. Thermorheological Simplicity

4.10.5. Large-Deformation Viscoelasticity

4.10.6. Visco-Hypoelasticity

4.10.7. Large Strain Viscoelasticity

4.10.8. Shift Functions

4.10.8.1. Williams-Landel-Ferry Shift Function

4.10.8.2. Tool-Narayanaswamy Shift Function

4.10.8.3. Tool-Narayanaswamy Shift Function with Fictive Temperature

4.10.8.4. User-Defined Shift Function

4.11. Concrete

4.11.1. The Domain (Compression - Compression - Compression)

4.11.2. The Domain (Tension - Compression - Compression)

4.11.3. The Domain (Tension - Tension - Compression)

4.11.4. The Domain (Tension - Tension - Tension)

4.12. Swelling

4.13. Cohesive Zone Material Model

4.13.1. Interface Elements

4.13.1.1. Material Model - Exponential Behavior

4.13.2. Contact Elements

4.13.2.1. Material Model - Bilinear Behavior

Chapter 5: Electromagnetics

5.1. Electromagnetic Field Fundamentals

5.1.1. Magnetic Scalar Potential

5.1.2. Solution Strategies

5.1.2.1. RSP Strategy

5.1.2.2. DSP Strategy

5.1.2.3. GSP Strategy

5.1.3. Magnetic Vector Potential

5.1.4. Limitation of the Node-Based Vector Potential

5.1.5. Edge-Based Magnetic Vector Potential

5.1.6. Harmonic Analysis Using Complex Formalism

5.1.7. Nonlinear Time-Harmonic Magnetic Analysis

5.1.8. Electric Scalar Potential

5.1.8.1. Quasistatic Electric Analysis

5.1.8.2. Electrostatic Analysis

5.2. Derivation of Electromagnetic Matrices

5.2.1. Magnetic Scalar Potential

5.2.1.1. Degrees of freedom

5.2.1.2. Coefficient Matrix

5.2.1.3. Applied Loads

5.2.2. Magnetic Vector Potential

5.2.2.1. Degrees of Freedom

5.2.2.2. Coefficient Matrices

5.2.2.3. Applied Loads

5.2.3. Edge-Based Magnetic Vector Potential

5.2.4. Electric Scalar Potential

5.2.4.1. Quasistatic Electric Analysis

5.2.4.2. Electrostatic Analysis

5.3. Electromagnetic Field Evaluations

5.3.1. Magnetic Scalar Potential Results

5.3.2. Magnetic Vector Potential Results

5.3.3. Edge-Based Magnetic Vector Potential

5.3.4. Magnetic Forces

5.3.4.1. Lorentz forces

5.3.4.2. Maxwell Forces

5.3.4.2.1. Surface Integral Method

5.3.4.2.2. Volumetric Integral Method

5.3.4.3. Virtual Work Forces

5.3.4.3.1. Element Shape Method

5.3.4.3.2. Nodal Perturbation Method

5.3.5. Joule Heat in a Magnetic Analysis

5.3.6. Electric Scalar Potential Results

5.3.6.1. Quasistatic Electric Analysis

5.3.6.2. Electrostatic Analysis

5.3.7. Electrostatic Forces

5.3.8. Electric Constitutive Error

5.4. Voltage Forced and Circuit-Coupled Magnetic Field

5.4.1. Voltage Forced Magnetic Field

5.4.2. Circuit-Coupled Magnetic Field

5.5. High-Frequency Electromagnetic Field Simulation

5.5.1. High-Frequency Electromagnetic Field FEA Principle

5.5.2. Boundary Conditions and Perfectly Matched Layers (PML)

5.5.2.1. PEC Boundary Condition

5.5.2.2. PMC Boundary Condition

5.5.2.3. Impedance Boundary Condition

5.5.2.4. Perfectly Matched Layers

5.5.2.5. Periodic Boundary Condition

5.5.3. Excitation Sources

5.5.3.1. Waveguide Modal Sources

5.5.3.2. Current Excitation Source

5.5.3.3. Plane Wave Source

5.5.3.4. Surface Magnetic Field Source

5.5.3.5. Electric Field Source

5.5.4. High-Frequency Parameters Evaluations

5.5.4.1. Electric Field

5.5.4.2. Magnetic Field

5.5.4.3. Poynting Vector

5.5.4.4. Power Flow

5.5.4.5. Stored Energy

5.5.4.6. Dielectric Loss

5.5.4.7. Surface Loss

5.5.4.8. Quality Factor

5.5.4.9. Voltage

5.5.4.10. Current

5.5.4.11. Characteristic Impedance

5.5.4.12. Scattering Matrix (S-Parameter)

5.5.4.13. Surface Equivalence Principle

5.5.4.14. Radar Cross Section (RCS)

5.5.4.15. Antenna Pattern

5.5.4.16. Antenna Radiation Power

5.5.4.17. Antenna Directive Gain

5.5.4.18. Antenna Power Gain

5.5.4.19. Antenna Radiation Efficiency

5.5.4.20. Electromagnetic Field of Phased Array Antenna

5.5.4.21. Specific Absorption Rate (SAR)

5.5.4.22. Power Reflection and Transmission Coefficient

5.5.4.23. Reflection and Transmission Coefficient in Periodic Structure

5.5.4.24. The Smith Chart

5.5.4.25. Conversion Among Scattering Matrix (S-parameter), Admittance Matrix (Y-parameter), and Impedance Matrix (Z-parameter)

5.5.4.26. RLCG Synthesized Equivalent Circuit of an M-port Full Wave Electromagnetic Structure

5.6. Inductance, Flux and Energy Computation by LMATRIX and SENERGY Macros

5.6.1. Differential Inductance Definition

5.6.2. Review of Inductance Computation Methods

5.6.3. Inductance Computation Method Used

5.6.4. Transformer and Motion Induced Voltages

5.6.5. Absolute Flux Computation

5.6.6. Inductance Computations

5.6.7. Absolute Energy Computation

5.7. Electromagnetic Particle Tracing

5.8. Capacitance Computation

5.9. Open Boundary Analysis with a Trefftz Domain

5.10. Conductance Computation

Chapter 6: Heat Flow

6.1. Heat Flow Fundamentals

6.1.1. Conduction and Convection

6.1.2. Radiation

6.1.2.1. View Factors

6.1.2.2. Radiation Usage

6.2. Derivation of Heat Flow Matrices

6.3. Heat Flow Evaluations

6.3.1. Integration Point Output

6.3.2. Surface Output

6.4. Radiation Matrix Method

6.4.1. Non-Hidden Method

6.4.2. Hidden Method

6.4.3. View Factors of Axisymmetric Bodies

6.4.4. Space Node

6.5. Radiosity Solution Method

6.5.1. View Factor Calculation - Hemicube Method

Chapter 7: Fluid Flow

7.1. Fluid Flow Fundamentals

7.1.1. Continuity Equation

7.1.2. Momentum Equation

7.1.3. Compressible Energy Equation

7.1.4. Incompressible Energy Equation

7.1.5. Turbulence

7.1.5.1. Zero Equation Model

7.1.5.2. Standard k-epsilon Model

7.1.5.3. RNG Turbulence Model

7.1.5.4. NKE Turbulence Model

7.1.5.5. GIR Turbulence Model

7.1.5.6. SZL Turbulence Model

7.1.5.7. Standard k-omega Model

7.1.5.8. SST Turbulence Model

7.1.5.9. Near-Wall Treatment

7.1.6. Pressure

7.1.7. Multiple Species Transport

7.1.8. Arbitrary Lagrangian-Eulerian (ALE) Formulation

7.2. Derivation of Fluid Flow Matrices

7.2.1. Discretization of Equations

7.2.2. Transient Term

7.2.3. Advection Term

7.2.3.1. Monotone Streamline Upwind Approach (MSU)

7.2.3.2. Streamline Upwind/Petro-Galerkin Approach (SUPG)

7.2.3.3. Collocated Galerkin Approach (COLG)

7.2.4. Diffusion Terms

7.2.5. Source Terms

7.2.6. Segregated Solution Algorithm

7.3. Volume of Fluid Method for Free Surface Flows

7.3.1. Overview

7.3.2. CLEAR-VOF Advection

7.3.3. CLEAR-VOF Reconstruction

7.3.4. Treatment of Finite Element Equations

7.3.5. Treatment of Volume Fraction Field

7.3.6. Treatment of Surface Tension Field

7.4. Fluid Solvers

7.5. Overall Convergence and Stability

7.5.1. Convergence

7.5.2. Stability

7.5.2.1. Relaxation

7.5.2.2. Inertial Relaxation

7.5.2.3. Artificial Viscosity

7.5.3. Residual File

7.5.4. Modified Inertial Relaxation

7.6. Fluid Properties

7.6.1. Density

7.6.2. Viscosity

7.6.3. Thermal Conductivity

7.6.4. Specific Heat

7.6.5. Surface Tension Coefficient

7.6.6. Wall Static Contact Angle

7.6.7. Multiple Species Property Options

7.7. Derived Quantities

7.7.1. Mach Number

7.7.2. Total Pressure

7.7.3. Y-Plus and Wall Shear Stress

7.7.4. Stream Function

7.7.4.1. Cartesian Geometry

7.7.4.2. Axisymmetric Geometry (about x)

7.7.4.3. Axisymmetric Geometry (about y)

7.7.4.4. Polar Coordinates

7.7.5. Heat Transfer Film Coefficient

7.7.5.1. Matrix Procedure

7.7.5.2. Thermal Gradient Procedure

7.7.5.3. Film Coefficient Evaluation

7.8. Squeeze Film Theory

7.8.1. Flow Between Flat Surfaces

7.8.2. Flow in Channels

7.9. Slide Film Theory

Chapter 8: Acoustics

8.1. Acoustic Fluid Fundamentals

8.1.1. Governing Equations

8.1.2. Discretization of the Lossless Wave Equation

8.2. Derivation of Acoustics Fluid Matrices

8.3. Absorption of Acoustical Pressure Wave

8.3.1. Addition of Dissipation due to Damping at the Boundary

8.4. Acoustics Fluid-Structure Coupling

8.5. Acoustics Output Quantities

Chapter 9: This chapter intentionally omitted.

Chapter 10: This chapter intentionally omitted.

Chapter 11: Coupling

11.1. Coupled Effects

11.1.1. Elements

11.1.1.1. Advantages

11.1.1.2. Disadvantages

11.1.2. Coupling Methods

11.1.2.1. Thermal-Structural Analysis

11.1.2.2. Magneto-Structural Analysis (Vector Potential)

11.1.2.3. Magneto-Structural Analysis (Scalar Potential)

11.1.2.4. Electromagnetic Analysis

11.1.2.5. Electro-Thermo-Structural Analysis

11.1.2.6. Electro-Magneto-Thermo-Structural Analysis

11.1.2.7. Electro-Magneto-Thermal Analysis

11.1.2.8. Piezoelectric Analysis

11.1.2.9. Electroelastic Analysis

11.1.2.10. Thermo-Piezoelectric Analysis

11.1.2.11. Piezoresistive Analysis

11.1.2.12. Thermo-Pressure Analysis

11.1.2.13. Velocity-Thermo-Pressure Analysis

11.1.2.14. Pressure-Structural (Acoustic) Analysis

11.1.2.15. Thermo-Electric Analysis

11.1.2.16. Magnetic-Thermal Analysis

11.1.2.17. Circuit-Magnetic Analysis

11.2. Thermoelasticity

11.3. Piezoelectrics

11.4. Electroelasticity

11.5. Piezoresistivity

11.6. Thermoelectrics

11.7. Review of Coupled Electromechanical Methods

11.8. Porous Media Flow

Chapter 12: Shape Functions

12.1. Understanding Shape Function Labels

12.2. 2-D Lines

12.2.1. 2-D Lines without RDOF

12.2.2. 2-D Lines with RDOF

12.3. 3-D Lines

12.3.1. 3-D 2-Node Lines without RDOF

12.3.2. 3-D 2-Node Lines with RDOF

12.3.3. 3-D 3-Node Lines

12.3.4. 3-D 4-Node Lines

12.4. Axisymmetric Shells

12.4.1. Axisymmetric Shell without ESF

12.5. Axisymmetric Harmonic Shells

12.5.1. Axisymmetric Harmonic Shells without ESF

12.5.2. Axisymmetric Harmonic Shells with ESF

12.6. 3-D Shells

12.6.1. 3-D 3-Node Triangular Shells without RDOF (CST)

12.6.2. 3-D 6-Node Triangular Shells without RDOF (LST)

12.6.3. 3-D 3-Node Triangular Shells with RDOF but without SD

12.6.4. 3-D 4-Node Quadrilateral Shells without RDOF and without ESF (Q4)

12.6.5. 3-D 4-Node Quadrilateral Shells without RDOF but with ESF (QM6)

12.6.6. 3-D 8-Node Quadrilateral Shells without RDOF

12.6.7. 3-D 4-Node Quadrilateral Shells with RDOF but without SD and without ESF

12.6.8. 3-D 4-Node Quadrilateral Shells with RDOF but without SD and with ESF

12.7. 2-D and Axisymmetric Solids

12.7.1. 2-D and Axisymmetric 3 Node Triangular Solids (CST)

12.7.2. 2-D and Axisymmetric 6 Node Triangular Solids (LST)

12.7.3. 2-D and Axisymmetric 4 Node Quadrilateral Solid without ESF (Q4)

12.7.4. 2-D and Axisymmetric 4 Node Quadrilateral Solids with ESF (QM6)

12.7.5. 2-D and Axisymmetric 8 Node Quadrilateral Solids (Q8)

12.7.6. 2-D and Axisymmetric 4 Node Quadrilateral Infinite Solids

12.7.6.1. Lagrangian Isoparametric Shape Functions

12.7.6.2. Mapping Functions

12.7.7. 2-D and Axisymmetric 8 Node Quadrilateral Infinite Solids

12.7.7.1. Lagrangian Isoparametric Shape Functions

12.7.7.2. Mapping Functions

12.8. Axisymmetric Harmonic Solids

12.8.1. Axisymmetric Harmonic 3 Node Triangular Solids

12.8.2. Axisymmetric Harmonic 6 Node Triangular Solids

12.8.3. Axisymmetric Harmonic 4 Node Quadrilateral Solids without ESF

12.8.4. Axisymmetric Harmonic 4 Node Quadrilateral Solids with ESF

12.8.5. Axisymmetric Harmonic 8 Node Quadrilateral Solids

12.9. 3-D Solids

12.9.1. 4 Node Tetrahedra

12.9.2. 4 Node Tetrahedra by Condensation

12.9.3. 10 Node Tetrahedra

12.9.4. 10 Node Tetrahedra by Condensation

12.9.5. 5 Node Pyramids by Condensation

12.9.6. 13 Node Pyramids by Condensation

12.9.7. 6 Node Wedges without ESF by Condensation

12.9.8. 6 Node Wedges with ESF by Condensation

12.9.9. 15 Node Wedges by Condensation

12.9.10. 15 Node Wedges Based on Wedge Shape Functions

12.9.11. 8 Node Bricks without ESF

12.9.12. 8 Node Bricks with ESF

12.9.13. 20 Node Bricks

12.9.14. 8 Node Infinite Bricks

12.9.14.1. Lagrangian Isoparametric Shape Functions

12.9.14.2. Mapping Functions

12.9.15. 3-D 20 Node Infinite Bricks

12.9.15.1. Lagrangian Isoparametric Shape Functions

12.9.15.2. Mapping Functions

12.9.16. General Axisymmetric Solids

12.9.16.1. General Axisymmetric Solid with 4 Base Nodes

12.9.16.2. General Axisymmetric Solid with 3 Base Nodes

12.9.16.3. General Axisymmetric Solid with 8 Base Nodes

12.9.16.4. General Axisymmetric Solid with 6 Base Nodes

12.10. Low FrequencyElectromagnetic Edge Elements

12.10.1. 3-D 20 Node Brick (SOLID117)

12.11. High Frequency Electromagnetic Tangential Vector Elements

12.11.1. Tetrahedral Elements (HF119)

12.11.2. Hexahedral Elements (HF120)

12.11.3. Triangular Elements (HF118)

12.11.4. Quadrilateral Elements (HF118)

Chapter 13: Element Tools

13.1. Element Shape Testing

13.1.1. Overview

13.1.2. 3-D Solid Element Faces and Cross-Sections

13.1.3. Aspect Ratio

13.1.4. Aspect Ratio Calculation for Triangles

13.1.5. Aspect Ratio Calculation for Quadrilaterals

13.1.6. Angle Deviation

13.1.7. Angle Deviation Calculation

13.1.8. Parallel Deviation

13.1.9. Parallel Deviation Calculation

13.1.10. Maximum Corner Angle

13.1.11. Maximum Corner Angle Calculation

13.1.12. Jacobian Ratio

13.1.12.1. Jacobian Ratio Calculation

13.1.13. Warping Factor

13.1.13.1. Warping Factor Calculation for Quadrilateral Shell Elements

13.1.13.2. Warping Factor Calculation for 3-D Solid Elements

13.2. Integration Point Locations

13.2.1. Lines (1, 2, or 3 Points)

13.2.2. Quadrilaterals (2 x 2 or 3 x 3 Points)

13.2.3. Bricks and Pyramids (2 x 2 x 2 Points)

13.2.4. Triangles (1, 3, or 6 Points)

13.2.5. Tetrahedra (1, 4, 5, or 11 Points)

13.2.6. Triangles and Tetrahedra (2 x 2 or 2 x 2 x 2 Points)

13.2.7. Wedges (3 x 2 or 3 x 3 Points)

13.2.8. Wedges (2 x 2 x 2 Points)

13.2.9. Bricks (14 Points)

13.2.10. Nonlinear Bending (5 Points)

13.2.11. General Axisymmetric Elements

13.3. Temperature-Dependent Material Properties

13.4. Positive Definite Matrices

13.4.1. Matrices Representing the Complete Structure

13.4.2. Element Matrices

13.5. Lumped Matrices

13.5.1. Diagonalization Procedure

13.5.2. Limitations of Lumped Mass Matrices

13.6. Reuse of Matrices

13.6.1. Element Matrices

13.6.2. Structure Matrices

13.6.3. Override Option

13.7. Hydrodynamic Loads on Line Elements

13.8. Nodal and Centroidal Data Evaluation

Chapter 14: Element Library

14.1. LINK1 - 2-D Spar (or Truss)

14.1.1. Assumptions and Restrictions

14.1.2. Other Applicable Sections

14.2. Not Documented

14.3. BEAM3 - 2-D Elastic Beam

14.3.1. Element Matrices and Load Vectors

14.3.2. Stress Calculation

14.4. BEAM4 - 3-D Elastic Beam

14.4.1. Stiffness and Mass Matrices

14.4.2. Gyroscopic Damping Matrix

14.4.3. Pressure and Temperature Load Vector

14.4.4. Local to Global Conversion

14.4.5. Stress Calculations

14.5. SOLID5 - 3-D Coupled-Field Solid

14.5.1. Other Applicable Sections

14.6. Not Documented

14.7. COMBIN7 - Revolute Joint

14.7.1. Element Description

14.7.2. Element Matrices

14.7.3. Modification of Real Constants

14.8. LINK8 - 3-D Spar (or Truss)

14.8.1. Assumptions and Restrictions

14.8.2. Element Matrices and Load Vector

14.8.3. Force and Stress

14.9. INFIN9 - 2-D Infinite Boundary

14.9.1. Introduction

14.9.2. Theory

14.10. LINK10 - Tension-only or Compression-only Spar

14.10.1. Assumptions and Restrictions

14.10.2. Element Matrices and Load Vector

14.11. LINK11 - Linear Actuator

14.11.1. Assumptions and Restrictions

14.11.2. Element Matrices and Load Vector

14.11.3. Force, Stroke, and Length

14.12. CONTAC12 - 2-D Point-to-Point Contact

14.12.1. Element Matrices

14.12.2. Orientation of the Element

14.12.3. Rigid Coulomb Friction

14.13. PLANE13 - 2-D Coupled-Field Solid

14.13.1. Other Applicable Sections

14.14. COMBIN14 - Spring-Damper

14.14.1. Types of Input

14.14.2. Stiffness Pass

14.14.3. Output Quantities

14.15. Not Documented

14.16. PIPE16 - Elastic Straight Pipe

14.16.1. Other Applicable Sections

14.16.2. Assumptions and Restrictions

14.16.3. Stiffness Matrix

14.16.4. Mass Matrix

14.16.5. Gyroscopic Damping Matrix

14.16.6. Stress Stiffness Matrix

14.16.7. Load Vector

14.16.8. Stress Calculation

14.17. PIPE17 - Elastic Pipe Tee

14.17.1. Other Applicable Sections

14.18. PIPE18 - Elastic Curved Pipe

14.18.1. Other Applicable Sections

14.18.2. Stiffness Matrix

14.18.3. Mass Matrix

14.18.4. Load Vector

14.18.5. Stress Calculations

14.19. Not Documented

14.20. PIPE20 - Plastic Straight Thin-Walled Pipe

14.20.1. Assumptions and Restrictions

14.20.2. Other Applicable Sections

14.20.3. Stress and Strain Calculation

14.21. MASS21 - Structural Mass

14.22. Not Documented

14.23. BEAM23 - 2-D Plastic Beam

14.23.1. Other Applicable Sections

14.23.2. Integration Points

14.23.3. Tangent Stiffness Matrix for Plasticity

14.23.4. Newton-Raphson Load Vector

14.23.5. Stress and Strain Calculation

14.24. BEAM24 - 3-D Thin-walled Beam

14.24.1. Assumptions and Restrictions

14.24.2. Other Applicable Sections

14.24.3. Temperature Distribution Across Cross-Section

14.24.4. Calculation of Cross-Section Section Properties

14.24.5. Offset Transformation

14.25. PLANE25 - Axisymmetric-Harmonic 4-Node Structural Solid

14.25.1. Other Applicable Sections

14.25.2. Assumptions and Restrictions

14.25.3. Use of Temperature

14.26. Not Documented

14.27. MATRIX27 - Stiffness, Damping, or Mass Matrix

14.27.1. Assumptions and Restrictions

14.28. SHELL28 - Shear/Twist Panel

14.28.1. Assumptions and Restrictions

14.28.2. Commentary

14.28.3. Output Terms

14.29. FLUID29 - 2-D Acoustic Fluid

14.29.1. Other Applicable Sections

14.30. FLUID30 - 3-D Acoustic Fluid

14.30.1. Other Applicable Sections

14.31. LINK31 - Radiation Link

14.31.1. Standard Radiation (KEYOPT(3) = 0)

14.31.2. Empirical Radiation (KEYOPT(3) = 1)

14.31.3. Solution

14.32. LINK32 - 2-D Conduction Bar

14.32.1. Other Applicable Sections

14.32.2. Matrices and Load Vectors

14.33. LINK33 - 3-D Conduction Bar

14.33.1. Other Applicable Sections

14.33.2. Matrices and Load Vectors

14.33.3. Output

14.34. LINK34 - Convection Link

14.34.1. Conductivity Matrix

14.34.2. Output

14.35. PLANE35 - 2-D 6-Node Triangular Thermal Solid

14.35.1. Other Applicable Sections

14.36. SOURC36 - Current Source

14.36.1. Description

14.37. COMBIN37 - Control

14.37.1. Element Characteristics

14.37.2. Element Matrices

14.37.3. Adjustment of Real Constants

14.37.4. Evaluation of Control Parameter

14.38. FLUID38 - Dynamic Fluid Coupling

14.38.1. Description

14.38.2. Assumptions and Restrictions

14.38.3. Mass Matrix Formulation

14.38.4. Damping Matrix Formulation

14.39. COMBIN39 - Nonlinear Spring

14.39.1. Input

14.39.2. Element Stiffness Matrix and Load Vector

14.39.3. Choices for Element Behavior

14.40. COMBIN40 - Combination

14.40.1. Characteristics of the Element

14.40.2. Element Matrices for Structural Applications

14.40.3. Determination of F1 and F2 for Structural Applications

14.40.4. Thermal Analysis

14.41. SHELL41 - Membrane Shell

14.41.1. Assumptions and Restrictions

14.41.2. Wrinkle Option

14.42. PLANE42 - 2-D Structural Solid

14.42.1. Other Applicable Sections

14.43. Not Documented

14.44. BEAM44 - 3-D Elastic Tapered Unsymmetric Beam

14.44.1. Other Applicable Sections

14.44.2. Assumptions and Restrictions

14.44.3. Tapered Geometry

14.44.4. Shear Center Effects

14.44.5. Offset at the Ends of the Member

14.44.6. End Moment Release

14.44.7. Local to Global Conversion

14.44.8. Stress Calculations

14.45. SOLID45 - 3-D Structural Solid

14.45.1. Other Applicable Sections

14.46. Not Documented

14.47. INFIN47 - 3-D Infinite Boundary

14.47.1. Introduction

14.47.2. Theory

14.47.3. Reduced Scalar Potential

14.47.4. Difference Scalar Potential

14.47.5. Generalized Scalar Potential

14.48. Not Documented

14.49. Not Documented

14.50. MATRIX50 - Superelement (or Substructure)

14.50.1. Other Applicable Sections

14.51. Not Documented

14.52. CONTAC52 - 3-D Point-to-Point Contact

14.52.1. Other Applicable Sections

14.52.2. Element Matrices

14.52.3. Orientation of Element

14.53. PLANE53 - 2-D 8-Node Magnetic Solid

14.53.1. Other Applicable Sections

14.53.2. Assumptions and Restrictions

14.53.3. VOLT DOF in 2-D and Axisymmetric Skin Effect Analysis

14.54. BEAM54 - 2-D Elastic Tapered Unsymmetric Beam

14.54.1. Derivation of Matrices

14.55. PLANE55 - 2-D Thermal Solid

14.55.1. Other Applicable Sections

14.55.2. Mass Transport Option

14.56. Not Documented

14.57. SHELL57 - Thermal Shell

14.57.1. Other Applicable Sections

14.58. Not Documented

14.59. PIPE59 - Immersed Pipe or Cable

14.59.1. Overview of the Element

14.59.2. Location of the Element

14.59.3. Stiffness Matrix

14.59.4. Mass Matrix

14.59.5. Load Vector

14.59.6. Hydrostatic Effects

14.59.7. Hydrodynamic Effects

14.59.8. Stress Output

14.60. PIPE60 - Plastic Curved Thin-Walled Pipe

14.60.1. Assumptions and Restrictions

14.60.2. Other Applicable Sections

14.60.3. Load Vector

14.60.4. Stress Calculations

14.61. SHELL61 - Axisymmetric-Harmonic Structural Shell

14.61.1. Other Applicable Sections

14.61.2. Assumptions and Restrictions

14.61.3. Stress, Force, and Moment Calculations

14.62. SOLID62 - 3-D Magneto-Structural Solid

14.62.1. Other Applicable Sections

14.63. SHELL63 - Elastic Shell

14.63.1. Other Applicable Sections

14.63.2. Foundation Stiffness

14.63.3. In-Plane Rotational Stiffness

14.63.4. Warping

14.63.5. Options for Non-Uniform Material

14.63.6. Extrapolation of Results to the Nodes

14.64. Not Documented

14.65. SOLID65 - 3-D Reinforced Concrete Solid

14.65.1. Assumptions and Restrictions

14.65.2. Description

14.65.3. Linear Behavior - General

14.65.4. Linear Behavior - Concrete

14.65.5. Linear Behavior - Reinforcement

14.65.6. Nonlinear Behavior - Concrete

14.65.7. Modeling of a Crack

14.65.8. Modeling of Crushing

14.65.9. Nonlinear Behavior - Reinforcement

14.66. Not Documented

14.67. PLANE67 - 2-D Coupled Thermal-Electric Solid

14.67.1. Other Applicable Sections

14.68. LINK68 - Coupled Thermal-Electric Line

14.68.1. Other Applicable Sections

14.69. SOLID69 - 3-D Coupled Thermal-Electric Solid

14.69.1. Other Applicable Sections

14.70. SOLID70 - 3-D Thermal Solid

14.70.1. Other Applicable Sections

14.70.2. Fluid Flow in a Porous Medium

14.71. MASS71 - Thermal Mass

14.71.1. Specific Heat Matrix

14.71.2. Heat Generation Load Vector

14.72. Not Documented

14.73. Not Documented

14.74. Not Documented

14.75. PLANE75 - Axisymmetric-Harmonic 4-Node Thermal Solid

14.75.1. Other Applicable Sections

14.76. Not Documented

14.77. PLANE77 - 2-D 8-Node Thermal Solid

14.77.1. Other Applicable Sections

14.77.2. Assumptions and Restrictions

14.78. PLANE78 - Axisymmetric-Harmonic 8-Node Thermal Solid

14.78.1. Other Applicable Sections

14.78.2. Assumptions and Restrictions

14.79. FLUID79 - 2-D Contained Fluid

14.79.1. Other Applicable Sections

14.80. FLUID80 - 3-D Contained Fluid

14.80.1. Other Applicable Sections

14.80.2. Assumptions and Restrictions

14.80.3. Material Properties

14.80.4. Free Surface Effects

14.80.5. Other Assumptions and Limitations

14.81. FLUID81 - Axisymmetric-Harmonic Contained Fluid

14.81.1. Other Applicable Sections

14.81.2. Assumptions and Restrictions

14.81.3. Load Vector Correction

14.82. PLANE82 - 2-D 8-Node Structural Solid

14.82.1. Other Applicable Sections

14.82.2. Assumptions and Restrictions

14.83. PLANE83 - Axisymmetric-Harmonic 8-Node Structural Solid

14.83.1. Other Applicable Sections

14.83.2. Assumptions and Restrictions

14.84. Not Documented

14.85. Not Documented

14.86. Not Documented

14.87. SOLID87 - 3-D 10-Node Tetrahedral Thermal Solid

14.87.1. Other Applicable Sections

14.88. Not Documented

14.89. Not Documented

14.90. SOLID90 - 3-D 20-Node Thermal Solid

14.90.1. Other Applicable Sections

14.91. Not Documented

14.92. SOLID92 - 3-D 10-Node Tetrahedral Structural Solid

14.92.1. Other Applicable Sections

14.93. Not Documented

14.94. CIRCU94 - Piezoelectric Circuit

14.94.1. Electric Circuit Elements

14.94.2. Piezoelectric Circuit Element Matrices and Load Vectors

14.95. SOLID95 - 3-D 20-Node Structural Solid

14.95.1. Other Applicable Sections

14.96. SOLID96 - 3-D Magnetic Scalar Solid

14.96.1. Other Applicable Sections

14.97. SOLID97 - 3-D Magnetic Solid

14.97.1. Other Applicable Sections

14.98. SOLID98 - Tetrahedral Coupled-Field Solid

14.98.1. Other Applicable Sections

14.99. Not Documented

14.100. Not Documented

14.101. Not Documented

14.102. Not Documented

14.103. Not Documented

14.104. Not Documented

14.105. Not Documented

14.106. Not Documented

14.107. Not Documented

14.108. Not Documented

14.109. TRANS109 - 2-D Electromechanical Transducer

14.110. INFIN110 - 2-D Infinite Solid

14.110.1. Mapping Functions

14.110.2. Matrices

14.111. INFIN111 - 3-D Infinite Solid

14.111.1. Other Applicable Sections

14.112. Not Documented

14.113. Not Documented

14.114. Not Documented

14.115. INTER115 - 3-D Magnetic Interface

14.115.1. Element Matrix Derivation

14.115.2. Formulation

14.116. FLUID116 - Coupled Thermal-Fluid Pipe

14.116.1. Assumptions and Restrictions

14.116.2. Combined Equations

14.116.3. Thermal Matrix Definitions

14.116.4. Fluid Equations

14.117. SOLID117 - 3-D 20-Node Magnetic Edge

14.117.1. Other Applicable Sections

14.117.2. Matrix Formulation of Low Frequency Edge Element and Tree Gauging

14.118. Not Documented

14.119. HF119 - 3-D High-Frequency Magnetic Tetrahedral Solid

14.119.1. Other Applicable Sections

14.119.2. Solution Shape Functions - H (curl) Conforming Elements

14.120. HF120 - High-Frequency Magnetic Brick Solid

14.120.1. Other Applicable Sections

14.120.2. Solution Shape Functions - H(curl) Conforming Element

14.121. PLANE121 - 2-D 8-Node Electrostatic Solid

14.121.1. Other Applicable Sections

14.121.2. Assumptions and Restrictions

14.122. SOLID122 - 3-D 20-Node Electrostatic Solid

14.122.1. Other Applicable Sections

14.123. SOLID123 - 3-D 10-Node Tetrahedral Electrostatic Solid

14.123.1. Other Applicable Sections

14.124. CIRCU124 - Electric Circuit

14.124.1. Electric Circuit Elements

14.124.2. Electric Circuit Element Matrices

14.125. CIRCU125 - Diode

14.125.1. Diode Elements

14.125.2. Norton Equivalents

14.125.3. Element Matrix and Load Vector

14.126. TRANS126 - Electromechanical Transducer

14.127. SOLID127 - 3-D Tetrahedral Electrostatic Solid p-Element

14.127.1. Other Applicable Sections

14.128. SOLID128 - 3-D Brick Electrostatic Solid p-Element

14.128.1. Other Applicable Sections

14.129. FLUID129 - 2-D Infinite Acoustic

14.129.1. Other Applicable Sections

14.130. FLUID130 - 3-D Infinite Acoustic

14.130.1. Mathematical Formulation and F.E. Discretization

14.130.2. Finite Element Discretization

14.131. SHELL131 - 4-Node Layered Thermal Shell

14.131.1. Other Applicable Sections

14.132. SHELL132 - 8-Node Layered Thermal Shell

14.132.1. Other Applicable Sections

14.133. Not Documented

14.134. Not Documented

14.135. Not Documented

14.136. FLUID136 - 3-D Squeeze Film Fluid Element

14.136.1. Other Applicable Sections

14.136.2. Assumptions and Restrictions

14.137. Not Documented

14.138. FLUID138 - 3-D Viscous Fluid Link Element

14.138.1. Other Applicable Sections

14.139. FLUID139 - 3-D Slide Film Fluid Element

14.139.1. Other Applicable Sections

14.140. Not Documented

14.141. FLUID141 - 2-D Fluid-Thermal

14.141.1. Other Applicable Sections

14.142. FLUID142 - 3-D Fluid-Thermal

14.142.1. Other Applicable Sections

14.142.2. Distributed Resistance Main Diagonal Modification

14.142.3. Turbulent Kinetic Energy Source Term Linearization

14.142.4. Turbulent Kinetic Energy Dissipation Rate

14.143. Not Documented

14.144. ROM144 - Reduced Order Electrostatic-Structural

14.144.1. Element Matrices and Load Vectors

14.144.2. Combination of Modal Coordinates and Nodal Displacement at Master Nodes

14.144.3. Element Loads

14.145. PLANE145 - 2-D Quadrilateral Structural Solid p-Element

14.145.1. Other Applicable Sections

14.146. PLANE146 - 2-D Triangular Structural Solid p-Element

14.146.1. Other Applicable Sections

14.147. SOLID147 - 3-D Brick Structural Solid p-Element

14.147.1. Other Applicable Sections

14.148. SOLID148 - 3-D Tetrahedral Structural Solid p-Element

14.148.1. Other Applicable Sections

14.149. Not Documented

14.150. SHELL150 - 8-Node Structural Shell p-Element

14.150.1. Other Applicable Sections

14.150.2. Assumptions and Restrictions

14.150.3. Stress-Strain Relationships

14.151. SURF151 - 2-D Thermal Surface Effect

14.152. SURF152 - 3-D Thermal Surface Effect

14.152.1. Matrices and Load Vectors

14.152.2. Adiabatic Wall Temperature as Bulk Temperature

14.152.3. Film Coefficient Adjustment

14.152.4. Radiation Form Factor Calculation

14.153. SURF153 - 2-D Structural Surface Effect

14.154. SURF154 - 3-D Structural Surface Effect

14.155. Not Documented

14.156. SURF156 - 3-D Structural Surface Line Load Effect

14.157. SHELL157 - Thermal-Electric Shell

14.157.1. Other Applicable Sections

14.158. Not Documented

14.159. Not Documented

14.160. LINK160 - Explicit 3-D Spar (or Truss)

14.161. BEAM161 - Explicit 3-D Beam

14.162. PLANE162 - Explicit 2-D Structural Solid

14.163. SHELL163 - Explicit Thin Structural Shell

14.164. SOLID164 - Explicit 3-D Structural Solid

14.165. COMBI165 - Explicit Spring-Damper

14.166. MASS166 - Explicit 3-D Structural Mass

14.167. LINK167 - Explicit Tension-Only Spar

14.168. SOLID168 - Explicit 3-D 10-Node Tetrahedral Structural Solid

14.169. TARGE169 - 2-D Target Segment

14.169.1. Other Applicable Sections

14.169.2. Segment Types

14.170. TARGE170 - 3-D Target Segment

14.170.1. Introduction

14.170.2. Segment Types

14.170.3. Reaction Forces

14.171. CONTA171 - 2-D 2-Node Surface-to-Surface Contact

14.171.1. Other Applicable Sections

14.172. CONTA172 - 2-D 3-Node Surface-to-Surface Contact

14.172.1. Other Applicable Sections

14.173. CONTA173 - 3-D 4-Node Surface-to-Surface Contact

14.173.1. Other Applicable Sections

14.174. CONTA174 - 3-D 8-Node Surface-to-Surface Contact

14.174.1. Introduction

14.174.2. Contact Kinematics

14.174.3. Frictional Model

14.174.4. Contact Algorithm

14.174.5. Energy and Momentum Conserving Contact

14.174.6. Debonding

14.174.7. Thermal/Structural Contact

14.174.8. Electric Contact

14.174.9. Magnetic Contact

14.175. CONTA175 - 2-D/3-D Node-to-Surface Contact

14.175.1. Other Applicable Sections

14.175.2. Contact Models

14.175.3. Contact Forces

14.176. CONTA176 - 3-D Line-to-Line Contact

14.176.1. Other Applicable Sections

14.176.2. Contact Kinematics

14.176.3. Contact Forces

14.177. CONTA177 - 3-D Line-to-Surface Contact

14.177.1. Other Applicable Sections

14.177.2. Contact Forces

14.178. CONTA178 - 3-D Node-to-Node Contact

14.178.1. Introduction

14.178.2. Contact Algorithms

14.178.3. Element Damper

14.179. PRETS179 - Pretension

14.179.1. Introduction

14.179.2. Assumptions and Restrictions

14.180. LINK180 - 3-D Spar (or Truss)

14.180.1. Assumptions and Restrictions

14.180.2. Element Mass Matrix

14.181. SHELL181 - 4-Node Shell

14.181.1. Other Applicable Sections

14.181.2. Assumptions and Restrictions

14.181.3. Assumed Displacement Shape Functions

14.181.4. Membrane Option

14.181.5. Warping

14.182. PLANE182 - 2-D 4-Node Structural Solid

14.182.1. Other Applicable Sections

14.182.2. Theory

14.183. PLANE183 - 2-D 8-Node Structural Solid

14.183.1. Other Applicable Sections

14.183.2. Assumptions and Restrictions

14.184. MPC184 - Multipoint Constraint

14.184.1. Slider Element

14.184.2. Joint Elements

14.185. SOLID185 - 3-D 8-Node Structural Solid

14.185.1. SOLID185 - 3-D 8-Node Structural Solid

14.185.2. SOLID185 - 3-D 8-Node Layered Solid

14.185.3. Other Applicable Sections

14.185.4. Theory

14.186. SOLID186 - 3-D 20-Node Homogenous/Layered Structural Solid

14.186.1. SOLID186 - 3-D 20-Node Homogenous Structural Solid

14.186.2. SOLID186 - 3-D 20-Node Layered Structural Solid

14.186.3. Other Applicable Sections

14.187. SOLID187 - 3-D 10-Node Tetrahedral Structural Solid

14.187.1. Other Applicable Sections

14.188. BEAM188 - 3-D 2-Node Beam

14.188.1. Assumptions and Restrictions

14.188.2. Stress Evaluation

14.189. BEAM189 - 3-D 3-Node Beam

14.190. SOLSH190 - 3-D 8-Node Layered Solid Shell

14.190.1. Other Applicable Sections

14.190.2. Theory

14.191. Not Documented

14.192. INTER192 - 2-D 4-Node Gasket

14.192.1. Other Applicable Sections

14.193. INTER193 - 2-D 6-Node Gasket

14.193.1. Other Applicable Sections

14.194. INTER194 - 3-D 16-Node Gasket

14.194.1. Element Technology

14.195. INTER195 - 3-D 8-Node Gasket

14.195.1. Other Applicable Sections

14.196. Not Documented

14.197. Not Documented

14.198. Not Documented

14.199. Not Documented

14.200. Not Documented

14.201. Not Documented

14.202. INTER202 - 2-D 4-Node Cohesive

14.202.1. Other Applicable Sections

14.203. INTER203 - 2-D 6-Node Cohesive

14.203.1. Other Applicable Sections

14.204. INTER204 - 3-D 16-Node Cohesive

14.204.1. Element Technology

14.205. INTER205 - 3-D 8-Node Cohesive

14.205.1. Other Applicable Sections

14.206. Not Documented

14.207. Not Documented

14.208. SHELL208 - 2-Node Axisymmetric Shell

14.208.1. Other Applicable Sections

14.208.2. Assumptions and Restrictions

14.209. SHELL209 - 3-Node Axisymmetric Shell

14.209.1. Other Applicable Sections

14.209.2. Assumptions and Restrictions

14.210. Not Documented

14.211. Not Documented

14.212. CPT212 - 2-D 4-Node Coupled Pore-Pressure Mechanical Solid

14.212.1. Other Applicable Sections

14.213. CPT213 - 2-D 8-Node Coupled Pore-Pressure Mechanical Solid

14.213.1. Other Applicable Sections

14.213.2. Assumptions and Restrictions

14.214. COMBI214 - 2-D Spring-Damper Bearing

14.214.1. Matrices

14.214.2. Output Quantities

14.215. CPT215 - 3-D 8-Node Coupled Pore-Pressure Mechanical Solid

14.215.1. Other Applicable Sections

14.216. CPT216 - 3-D 20-Node Coupled Pore-Pressure Mechanical Solid

14.216.1. Other Applicable Sections

14.217. CPT217 - 3-D 10-Node Coupled Pore-Pressure Mechanical Solid

14.217.1. Other Applicable Sections

14.218. Not Documented

14.219. Not Documented

14.220. Not Documented

14.221. Not Documented

14.222. Not Documented

14.223. PLANE223 - 2-D 8-Node Coupled-Field Solid

14.223.1. Other Applicable Sections

14.224. Not Documented

14.225. Not Documented

14.226. SOLID226 - 3-D 20-Node Coupled-Field Solid

14.226.1. Other Applicable Sections

14.227. SOLID227 - 3-D 10-Node Coupled-Field Solid

14.227.1. Other Applicable Sections

14.228. Not Documented

14.229. Not Documented

14.230. PLANE230 - 2-D 8-Node Electric Solid

14.230.1. Other Applicable Sections

14.230.2. Assumptions and Restrictions

14.231. SOLID231 - 3-D 20-Node Electric Solid

14.231.1. Other Applicable Sections

14.232. SOLID232 - 3-D 10-Node Tetrahedral Electric Solid

14.232.1. Other Applicable Sections

14.233. Not Documented

14.234. Not Documented

14.235. Not Documented

14.236. SOLID236 - 3-D 20-Node Electromagnetic Solid

14.236.1. Other Applicable Sections

14.237. SOLID237 - 3-D 10-Node Electromagnetic Solid

14.237.1. Other Applicable Sections

14.238. Not Documented

14.239. Not Documented

14.240. Not Documented

14.241. Not Documented

14.242. Not Documented

14.243. Not Documented

14.244. Not Documented

14.245. Not Documented

14.246. Not Documented

14.247. Not Documented

14.248. Not Documented

14.249. Not Documented

14.250. Not Documented

14.251. SURF251 - 2-D Radiosity Surface

14.252. SURF252 - 3-D Thermal Radiosity Surface

14.253. Not Documented

14.254. Not Documented

14.255. Not Documented

14.256. Not Documented

14.257. Not Documented

14.258. Not Documented

14.259. Not Documented

14.260. Not Documented

14.261. Not Documented

14.262. Not Documented

14.263. Not Documented

14.264. REINF264 - 3-D Discrete Reinforcing

14.264.1. Other Applicable Sections

14.265. REINF265 - 3-D Smeared Reinforcing

14.265.1. Other Applicable Sections

14.265.2. Stiffness and Mass Matrices of a Reinforcing Layer

14.266. Not Documented

14.267. Not Documented

14.268. Not Documented

14.269. Not Documented

14.270. Not Documented

14.271. Not Documented

14.272. SOLID272 - General Axisymmetric Solid with 4 Base Nodes

14.272.1. Other Applicable Sections

14.272.2. Assumptions and Restrictions

14.273. SOLID273 - General Axisymmetric Solid with 8 Base Nodes

14.273.1. Other Applicable Sections

14.273.2. Assumptions and Restrictions

14.274. Not Documented

14.275. Not Documented

14.276. Not Documented

14.277. Not Documented

14.278. Not Documented

14.279. Not Documented

14.280. Not Documented

14.281. SHELL281 - 8-Node Shell

14.281.1. Other Applicable Sections

14.281.2. Assumptions and Restrictions

14.281.3. Membrane Option

14.282. Not Documented

14.283. Not Documented

14.284. Not Documented

14.285. SOLID285 - 3-D 4-Node Tetrahedral Structural Solid with Nodal Pressures

14.285.1. Other Applicable Sections

14.285.2. Theory

14.286. Not Documented

14.287. Not Documented

14.288. PIPE288 - 3-D 2-Node Pipe

14.288.1. Assumptions and Restrictions

14.288.2. Ocean Effects

14.288.2.1. Location of the Element

14.288.2.2. Load Vector

14.288.2.3. Hydrostatic Effects

14.288.2.4. Hydrodynamic Effects

14.288.3. Stress Evaluation

14.289. PIPE289 - 3-D 3-Node Pipe

14.290. ELBOW290 - 3-D 3-Node Elbow

14.290.1. Other Applicable Sections

14.290.2. Assumptions and Restrictions

Chapter 15: Analysis Tools

15.1. Acceleration Effect

15.2. Inertia Relief

15.3. Damping Matrices

15.4. Rotating Structures

15.4.1. Coriolis Matrix and Coriolis Force in a Rotating Reference Frame

15.4.2. Gyroscopic Matrix in a Stationary Reference Frame

15.4.2.1. Kinetic Energy for the Gyroscopic Matrix Calculation of Lumped Mass and Legacy Beam Element

15.4.2.2. General Expression of the Kinetic Energy for the Gyroscopic Matrix Calculation

15.4.3. Rotating Damping Matrix in a Stationary Reference Frame

15.5. Element Reordering

15.5.1. Reordering Based on Topology with a Program-Defined Starting Surface

15.5.2. Reordering Based on Topology with a User- Defined Starting Surface

15.5.3. Reordering Based on Geometry

15.5.4. Automatic Reordering

15.6. Automatic Master Degrees of Freedom Selection

15.7. Automatic Time Stepping

15.7.1. Time Step Prediction

15.7.2. Time Step Bisection

15.7.3. The Response Eigenvalue for 1st Order Transients

15.7.4. The Response Frequency for Structural Dynamics

15.7.5. Creep Time Increment

15.7.6. Plasticity Time Increment

15.7.7. Midstep Residual for Structural Dynamic Analysis

15.8. Solving for Unknowns and Reactions

15.8.1. Reaction Forces

15.8.2. Disequilibrium

15.9. Equation Solvers

15.9.1. Direct Solvers

15.9.2. Sparse Direct Solver

15.9.3. Iterative Solver

15.10. Mode Superposition Method

15.10.1. Modal Damping

15.10.2. Residual Vector Method

15.11. Extraction of Modal Damping Parameter for Squeeze Film Problems

15.12. Reduced Order Modeling of Coupled Domains

15.12.1. Selection of Modal Basis Functions

15.12.2. Element Loads

15.12.3. Mode Combinations for Finite Element Data Acquisition and Energy Computation

15.12.4. Function Fit Methods for Strain Energy

15.12.5. Coupled Electrostatic-Structural Systems

15.12.6. Computation of Capacitance Data and Function Fit

15.13. Newton-Raphson Procedure

15.13.1. Overview

15.13.2. Convergence

15.13.3. Predictor

15.13.4. Adaptive Descent

15.13.5. Line Search

15.13.6. Arc-Length Method

15.14. Constraint Equations

15.14.1. Derivation of Matrix and Load Vector Operations

15.15. This section intentionally omitted

15.16. Eigenvalue and Eigenvector Extraction

15.16.1. Reduced Method

15.16.1.1. Transformation of the Generalized Eigenproblem to a Standard Eigenproblem

15.16.1.2. Reduce [A] to Tridiagonal Form

15.16.1.3. Eigenvalue Calculation

15.16.1.4. Eigenvector Calculation

15.16.1.5. Eigenvector Transformation

15.16.2. Supernode Method

15.16.3. Block Lanczos

15.16.4. PCG Lanczos

15.16.5. Unsymmetric Method

15.16.6. Damped Method

15.16.7. QR Damped Method

15.16.8. Shifting

15.16.9. Repeated Eigenvalues

15.16.10. Complex Eigensolutions

15.17. Analysis of Cyclic Symmetric Structures

15.17.1. Modal Analysis

15.17.2. Complete Mode Shape Derivation

15.17.3. Cyclic Symmetry Transformations

15.18. Mass Moments of Inertia

15.18.1. Accuracy of the Calculations

15.18.2. Effect of KSUM, LSUM, ASUM, and VSUM Commands

15.19. Energies

15.20. ANSYS Workbench Product Adaptive Solutions

Chapter 16: This chapter intentionally omitted.

Chapter 17: Analysis Procedures

17.1. Static Analysis

17.1.1. Assumptions and Restrictions

17.1.2. Description of Structural Systems

17.1.3. Description of Thermal, Magnetic and Other First Order Systems

17.2. Transient Analysis

17.2.1. Assumptions and Restrictions

17.2.2. Description of Structural and Other Second Order Systems

17.2.2.1. Solution

17.2.3. Description of Thermal, Magnetic and Other First Order Systems

17.3. Mode-Frequency Analysis

17.3.1. Assumptions and Restrictions

17.3.2. Description of Analysis

17.4. Harmonic Response Analyses

17.4.1. Assumptions and Restrictions

17.4.2. Description of Analysis

17.4.3. Complex Displacement Output

17.4.4. Nodal and Reaction Load Computation

17.4.5. Solution

17.4.5.1. Full Solution Method

17.4.5.2. Reduced Solution Method

17.4.5.2.1. Expansion Pass

17.4.5.3. Mode Superposition Method

17.4.5.3.1. Expansion Pass

17.4.6. Variational Technology Method

17.4.6.1. Viscous or Hysteretic Damping

17.4.7. Automatic Frequency Spacing

17.4.8. Rotating Forces on Rotating Structures

17.4.8.1. General Asynchronous Rotating Force

17.4.8.2. Specific Synchronous Forces: Mass Unbalance

17.5. Buckling Analysis

17.5.1. Assumptions and Restrictions

17.5.2. Description of Analysis

17.6. Substructuring Analysis

17.6.1. Assumptions and Restrictions (within Superelement)

17.6.2. Description of Analysis

17.6.3. Statics

17.6.4. Transients

17.6.5. Component Mode Synthesis (CMS)

17.7. Spectrum Analysis

17.7.1. Assumptions and Restrictions

17.7.2. Description of Analysis

17.7.3. Single-Point Response Spectrum

17.7.4. Damping

17.7.5. Participation Factors and Mode Coefficients

17.7.6. Combination of Modes

17.7.6.1. Complete Quadratic Combination Method

17.7.6.2. Grouping Method

17.7.6.3. Double Sum Method

17.7.6.4. SRSS Method

17.7.6.5. NRL-SUM Method

17.7.6.6. Rosenblueth Method

17.7.7. Reduced Mass Summary

17.7.8. Effective Mass and Cumulative Mass Fraction

17.7.9. Dynamic Design Analysis Method

17.7.10. Random Vibration Method

17.7.11. Description of Method

17.7.12. Response Power Spectral Densities and Mean Square Response

17.7.12.1. Dynamic Part

17.7.12.2. Pseudo-Static Part

17.7.12.3. Covariance Part

17.7.12.4. Equivalent Stress Mean Square Response

17.7.13. Cross Spectral Terms for Partially Correlated Input PSDs

17.7.14. Spatial Correlation

17.7.15. Wave Propagation

17.7.16. Multi-Point Response Spectrum Method

17.7.17. Missing Mass Response

17.7.18. Rigid Responses

Chapter 18: Preprocessing and Postprocessing Tools

18.1. Integration and Differentiation Procedures

18.1.1. Single Integration Procedure

18.1.2. Double Integration Procedure

18.1.3. Differentiation Procedure

18.1.4. Double Differentiation Procedure

18.2. Fourier Coefficient Evaluation

18.3. Statistical Procedures

18.3.1. Mean, Covariance, Correlation Coefficient

18.3.2. Random Samples of a Uniform Distribution

18.3.3. Random Samples of a Gaussian Distribution

18.3.4. Random Samples of a Triangular Distribution

18.3.5. Random Samples of a Beta Distribution

18.3.6. Random Samples of a Gamma Distribution

Chapter 19: Postprocessing

19.1. POST1 - Derived Nodal Data Processing

19.1.1. Derived Nodal Data Computation

19.2. POST1 - Vector and Surface Operations

19.2.1. Vector Operations

19.2.2. Surface Operations

19.3. POST1 - Path Operations

19.3.1. Defining the Path

19.3.2. Defining Orientation Vectors of the Path

19.3.3. Mapping Nodal and Element Data onto the Path

19.3.4. Operating on Path Data

19.4. POST1 - Stress Linearization

19.4.1. Cartesian Case

19.4.2. Axisymmetric Case (General)

19.4.3. Axisymmetric Case

19.5. POST1 - Fatigue Module

19.6. POST1 - Electromagnetic Macros

19.6.1. Flux Passing Thru a Closed Contour

19.6.2. Force on a Body

19.6.3. Magnetomotive Forces

19.6.4. Power Loss

19.6.5. Terminal Parameters for a Stranded Coil

19.6.6. Energy Supplied

19.6.7. Terminal Inductance

19.6.8. Flux Linkage

19.6.9. Terminal Voltage

19.6.10. Torque on a Body

19.6.11. Energy in a Magnetic Field

19.6.12. Relative Error in Electrostatic or Electromagnetic Field Analysis

19.6.12.1. Electrostatics

19.6.12.1.1. Electric Field

19.6.12.1.2. Electric Flux Density

19.6.12.2. Electromagnetics

19.6.12.2.1. Magnetic Field Intensity

19.6.12.2.2. Magnetic Flux Density

19.6.13. SPARM Macro-Parameters

19.6.14. Electromotive Force

19.6.15. Impedance of a Device

19.6.16. Computation of Equivalent Transmission-line Parameters

19.6.17. Quality Factor

19.7. POST1 - Error Approximation Technique

19.7.1. Error Approximation Technique for Displacement-Based Problems

19.7.2. Error Approximation Technique for Temperature-Based Problems

19.7.3. Error Approximation Technique for Magnetics-Based Problems

19.8. POST1 - Crack Analysis

19.9. POST1 - Harmonic Solid and Shell Element Postprocessing

19.9.1. Thermal Solid Elements (PLANE75, PLANE78)

19.9.2. Structural Solid Elements (PLANE25, PLANE83)

19.9.3. Structural Shell Element (SHELL61)

19.10. POST26 - Data Operations

19.11. POST26 - Response Spectrum Generator (RESP)

19.11.1. Time Step Size

19.12. POST1 and POST26 - Interpretation of Equivalent Strains

19.12.1. Physical Interpretation of Equivalent Strain

19.12.2. Elastic Strain

19.12.3. Plastic Strain

19.12.4. Creep Strain

19.12.5. Total Strain

19.13. POST26 - Response Power Spectral Density

19.14. POST26 - Computation of Covariance

19.15. POST1 and POST26 – Complex Results Postprocessing

19.16. POST1 - Modal Assurance Criterion (MAC)

Chapter 20: Design Optimization

20.1. Introduction to Design Optimization

20.1.1. Feasible Versus Infeasible Design Sets

20.1.2. The Best Design Set

20.1.3. Optimization Methods and Design Tools

20.1.3.1. Single-Loop Analysis Tool

20.1.3.2. Random Tool

20.1.3.3. Sweep Tool

20.1.3.4. Factorial Tool

20.1.3.5. Gradient Tool

20.2. Subproblem Approximation Method

20.2.1. Function Approximations

20.2.2. Minimizing the Subproblem Approximation

20.2.3. Convergence

20.3. First Order Optimization Method

20.3.1. The Unconstrained Objective Function

20.3.2. The Search Direction

20.3.3. Convergence

20.4. Topological Optimization

20.4.1. General Optimization Problem Statement

20.4.2. Maximum Static Stiffness Design

20.4.3. Minimum Volume Design

20.4.4. Maximum Dynamic Stiffness Design

20.4.4.1. Weighted Formulation

20.4.4.2. Reciprocal Formulation

20.4.4.3. Euclidean Norm Formulation

20.4.5. Element Calculations

Chapter 21: Probabilistic Design

21.1. Uses for Probabilistic Design

21.2. Probabilistic Modeling and Preprocessing

21.2.1. Statistical Distributions for Random Input Variables

21.2.1.1. Gaussian (Normal) Distribution

21.2.1.2. Truncated Gaussian Distribution

21.2.1.3. Lognormal Distribution

21.2.1.4. Triangular Distribution

21.2.1.5. Uniform Distribution

21.2.1.6. Exponential Distribution

21.2.1.7. Beta Distribution

21.2.1.8. Gamma Distribution

21.2.1.9. Weibull Distribution

21.3. Probabilistic Methods

21.3.1. Introduction

21.3.2. Common Features for all Probabilistic Methods

21.3.2.1. Random Numbers with Standard Uniform Distribution

21.3.2.2. Non-correlated Random Numbers with an Arbitrary Distribution

21.3.2.3. Correlated Random Numbers with an Arbitrary Distribution

21.3.3. Monte Carlo Simulation Method

21.3.3.1. Direct Monte Carlo Simulation

21.3.3.2. Latin Hypercube Sampling

21.3.4. The Response Surface Method

21.3.4.1. Central Composite Design

21.3.4.2. Box-Behnken Matrix Design

21.4. Regression Analysis for Building Response Surface Models

21.4.1. General Definitions

21.4.2. Linear Regression Analysis

21.4.3. F-Test for the Forward-Stepwise-Regression

21.4.4. Transformation of Random Output Parameter Values for Regression Fitting

21.4.5. Goodness-of-Fit Measures

21.4.5.1. Error Sum of Squares SSE

21.4.5.2. Coefficient of Determination R2

21.4.5.3. Maximum Absolute Residual

21.5. Probabilistic Postprocessing

21.5.1. Statistical Procedures

21.5.1.1. Mean Value

21.5.1.2. Standard Deviation

21.5.1.3. Minimum and Maximum Values

21.5.2. Correlation Coefficient Between Sampled Data

21.5.2.1. Pearson Linear Correlation Coefficient

21.5.2.2. Spearman Rank-Order Correlation Coefficient

21.5.3. Cumulative Distribution Function

21.5.4. Evaluation of Probabilities From the Cumulative Distribution Function

21.5.5. Inverse Cumulative Distribution Function

Bibliography

Index

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc