SPL06-001

Digital pressure sensor

Tel: + 86 536 8525155

Fax: + 86 536 8525000

E- Mail: goertek@goertek.com

Website: http://www.goertekacoustics.com

Address: No.268 Dongfang Road, High-Tech Industry

Development District, Weifang, Shandong, P.R.C

_________________________ ____________________________________________ __

Version 2.0

1 / 31

CONFIDENTIAL�

Restricted

1. Security warning

The information contained in this document is the exclusive property of GoerTek Inc. and should not be

disclosed to any third party without the written consent of GoerTek Inc.

2. Publication history

Version

Date

Description

Author

Approved

1.0

2015.12.18

New design

Wiming

Sammy

2.0

2016.3.14

① Update ○G Marking

② Replace the cover

③ Update peak current

④ Update Marking

instructions

Wiming

Sammy

_________________________ ____________________________________________ __

Version 2.0

2 / 31

CONFIDENTIAL�

Index of Contents

1.

2.

INTRODUCTION ............................................................................................................................................................. 5

TEST CONDITION ........................................................................................................................................................... 6

3. ABSOLUTE MAXIMUM RATINGS .................................................................................................................................... 6

4.

ELECTRICAL CHARACTERISTICS ...................................................................................................................................... 6

5. OPERATION ................................................................................................................................................................... 8

5.1

OPERATING MODES ...................................................................................................................................................... 8

5.2 MEASUREMENT PRECISION AND RATE .......................................................................................................................... 8

5.3

SENSOR INTERFACE ...................................................................................................................................................... 9

INTERRUPT ................................................................................................................................................................... 9

5.4

FIFO OPERATION ......................................................................................................................................................... 9

5.5

5.6

CALIBRATION AND MEASUREMENT COMPENSATION .................................................................................................. 10

How to Calculate Compensated Pressure Values .......................................................................................... 10

How to Calculate Compensated Temperature Values ........................................................................................ 10

Compensation Scale Factors ............................................................................................................................. 10

5.6.1

5.6.2

5.6.3

6. APPLICATIONS ............................................................................................................................................................. 11

6.1 MEASUREMENT SETTINGS AND USE CASE EXAMPLES ................................................................................................ 11

6.2

APPLICATION CIRCUIT EXAMPLE ................................................................................................................................ 12

CALCULATING ABSOLUTE ALTITUDE AND CALCULATING PRESSURE AT SEA LEVEL ...................................................... 13

6.3

7. REGISTER MAP ............................................................................................................................................................ 14

8. REGISTER DESCRIPTION ............................................................................................................................................... 15

8.1

PRESSURE DATA (PRS_BN) ........................................................................................................................................ 15

8.1.1 PRS_B2.................................................................................................................................................................. 15

8.1.2 PRS_B1.................................................................................................................................................................. 15

8.1.3 PRS_B0.................................................................................................................................................................. 15

TEMPERATURE DATA (TMP_TN) ................................................................................................................................ 16

8.2.1 TMP_B2 ................................................................................................................................................................ 16

8.2.2 TMP_B1 ................................................................................................................................................................ 16

8.2.3 TMP_B0 ................................................................................................................................................................ 17

PRESSURE CONFIGURATION (PRS_CFG) .................................................................................................................... 17

TEMPERATURE CONFIGURATION (TMP_CFG) ........................................................................................................... 19

SENSOR OPERATING MODE AND STATUS (MEAS_CFG) ......................................................................................... 20

INTERRUPT AND FIFO CONFIGURATION (CFG_REG) ................................................................................................. 21

INTERRUPT STATUS (INT_STS) .................................................................................................................................. 22

8.2

8.3

8.4

8.5

8.6

8.7

_________________________ ____________________________________________ __

Version 2.0

3 / 31

CONFIDENTIAL�

8.8

FIFO STATUS (FIFO_STS) ......................................................................................................................................... 22

8.9

SOFT RESET AND FIFO FLUSH (RESET)..................................................................................................................... 23

8.10

PRODUCT AND REVISION ID (ID)................................................................................................................................ 23

8.11 CALIBRATION COEFFICIENTS (COEF) ........................................................................................................................ 23

8.12 COEFFICIENT SOURCE ................................................................................................................................................ 24

9. MECHANICAL CHARACTERISTICS ................................................................................................................................. 25

PIN CONFIGURATION ................................................................................................................................................... 25

9.1

OUTLINE DIMENSIONS ................................................................................................................................................ 26

9.2

9.3 MARKING INSTRUCTIONS ............................................................................................................................................... 27

10.

11.

12.

STORAGE AND TRANSPORTATION ........................................................................................................................... 28

SOLDERING RECOMMENDATION ............................................................................................................................. 28

PACKAGE SPECIFICATIONS ....................................................................................................................................... 29

_________________________ ____________________________________________ __

Version 2.0

4 / 31

CONFIDENTIAL�

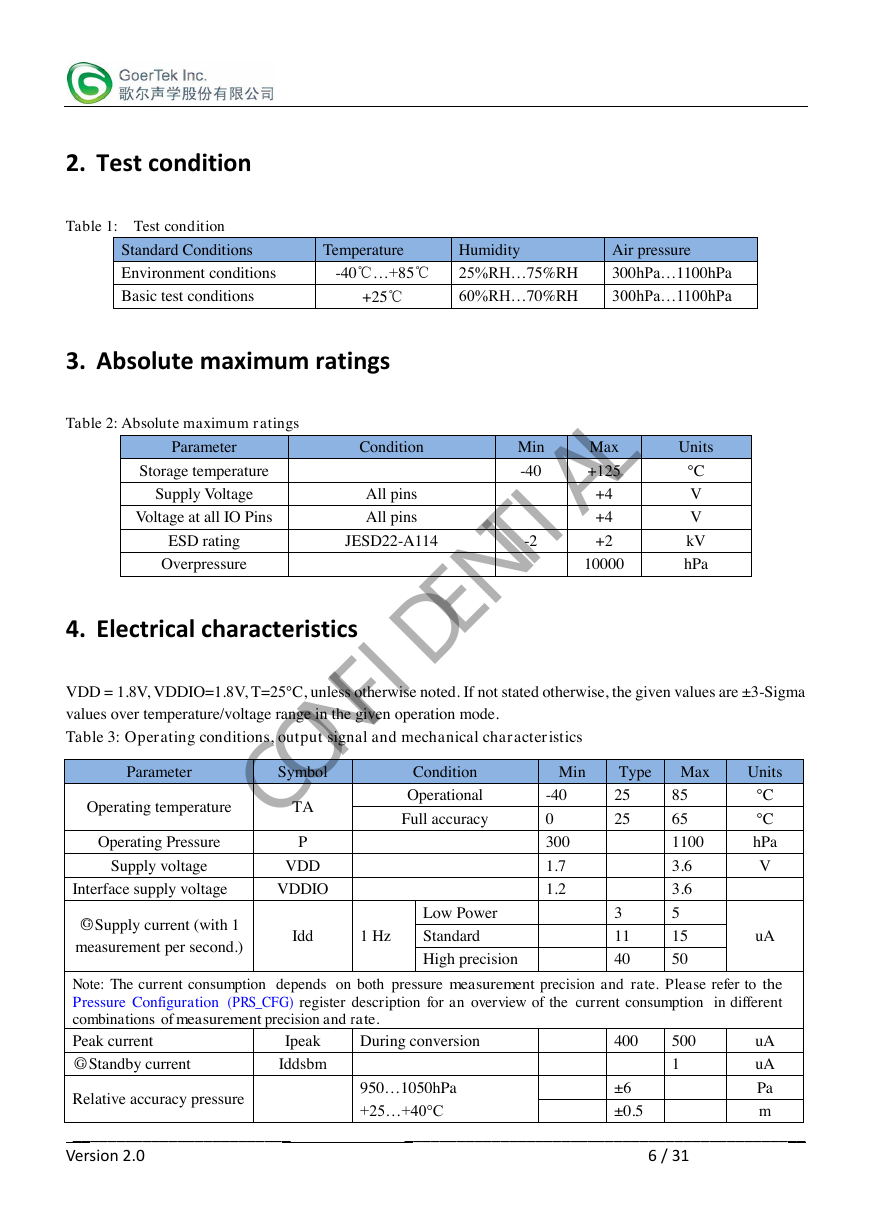

1. Introduction

The SPL06-001 is a miniaturized Digital Barometric Air Pressure Sensor with a high accuracy and a low current

consumption. The SPL06-001 is both a pressure and a temperature sensor. The pressure sensor element is based on

a capacitive sensing principle which guarantees a high precision during temperature changes. The small package

makes the SPL06-001 ideal for mobile applications and wearable devices.

The SPL06-001‘s internal signal processor converts the output from the pressure and temperature sensor elements

to 24-bit results. Each pressure sensor has been calibrated individually and contains calibration coefficients. The

coefficients are used in the application to convert the measurement results to true pressure and temperature values.

The SPL06-001 has a FIFO that can store the latest 32 measurements. By using the FIFO, the host processor can

remain in a sleep mode for a longer period of time between readouts. This can reduce the overall system power

consumption.

Sensor measurements and calibration coefficients are available through the serial I2C interface.

Key features

Pressure range: 300 ... 1100hPa (+9000m ... -500m relating to sea level)

Temperature Range: -40…+85°C

Supply voltage: 1.7 ... 3.6V (VDD), 1.2 ... 3.6V (VDDIO)

Package: LGA package with metal lid

Small footprint: 2.5mm x 2.0mm; Super-flat: 0.95mm height

Relative accuracy: ±0.06hPa, equiv. to ±0.5 m

Ab solute accuracy: typ. ±1hPa (300 … 1100hPa)

Temperature accuracy: ± 0.5°C.

Pressure temperature sensitivity: < 0.5Pa/K

Measurement time: Typical: 28 ms. Minimum: 3 ms.

Average current consumption: High precision: 60 µA, Low power: 3 µA, Standby: <1 µA.

I2C interface (up to 3.4 MHz), Embedded 24-bit ADC

FIFO: Stores latest 32 pressure or temperature measurements.

Pb-free, halogen-free and RoHS compliant

MSL 1

In- and out-door navigation

Typical applications

Enhancement of GPS navigation (dead-reckoning, slope detection, etc.)

Leisure and sports

Weather forecast

Vertical velocity indication (rise/sink speed)

_________________________ ____________________________________________ __

Version 2.0

5 / 31

CONFIDENTIAL�

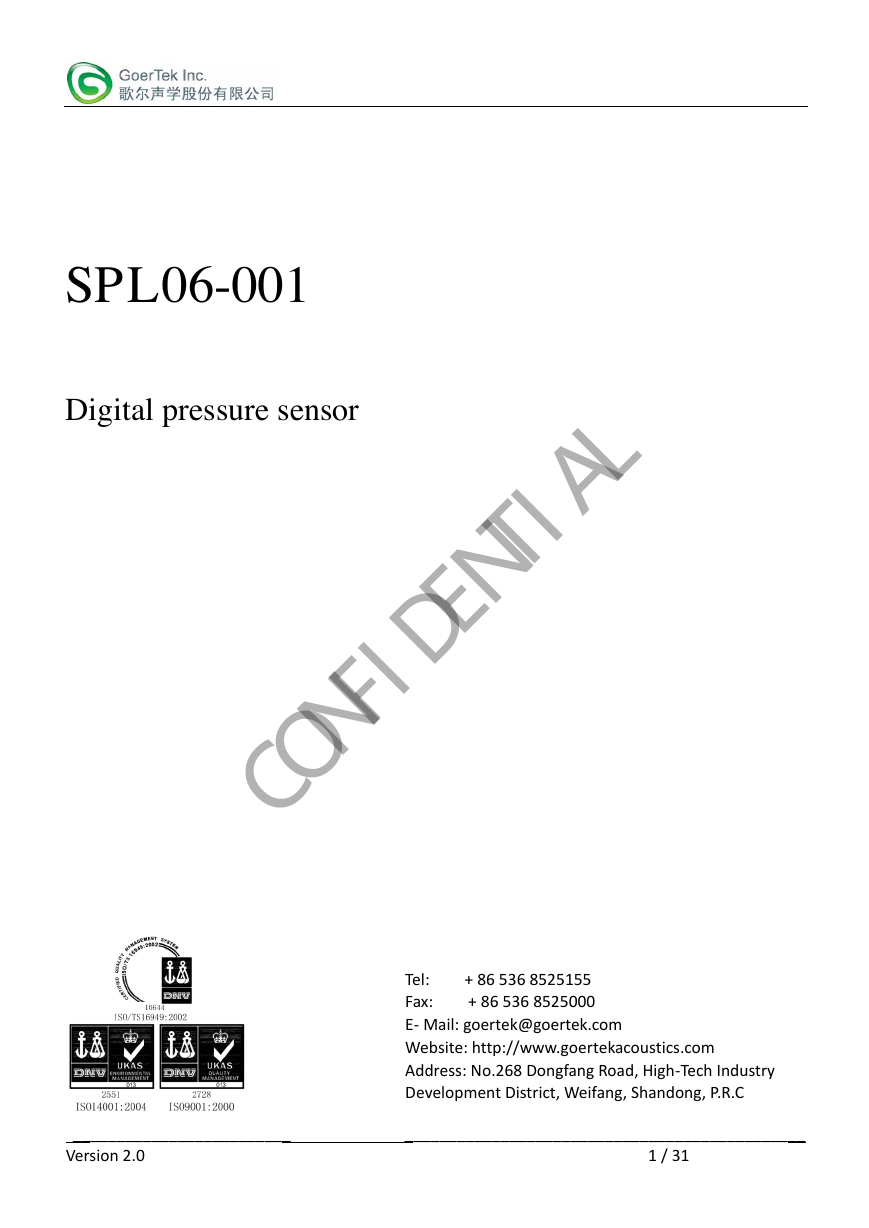

2. Test condition

Table 1: Test condition

Standard Conditions

Temperature

Humidity

Air pressure

Environment conditions

-40℃…+85℃

25%RH…75%RH

300hPa…1100hPa

Basic test conditions

+25℃

60%RH…70%RH

300hPa…1100hPa

3. Absolute maximum ratings

Table 2: Absolute maximum ratings

Parameter

Storage temperature

Supply Voltage

Voltage at all IO Pins

ESD rating

Overpressure

Condition

All pins

All pins

JESD22-A114

Min

-40

-2

Max

+125

+4

+4

+2

10000

Units

°C

V

V

kV

hPa

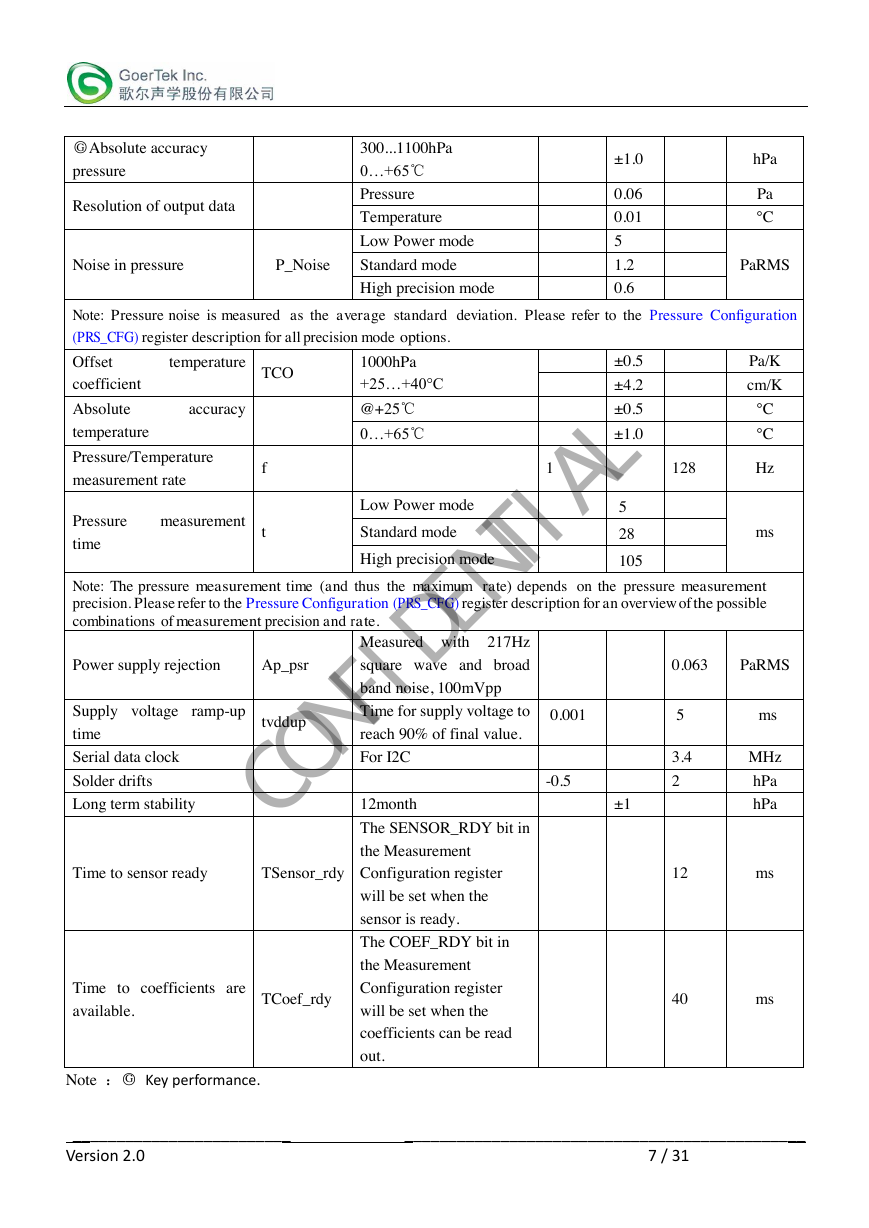

4. Electrical characteristics

VDD = 1.8V, VDDIO=1.8V, T=25°C, unless otherwise noted. If not stated otherwise, the given values are ±3-Sigma

values over temperature/voltage range in the given operation mode.

Table 3: Operating conditions, output signal and mechanical characteristics

Parameter

Symbol

Operating temperature

Operating Pressure

Supply voltage

TA

P

VDD

Interface supply voltage

VDDIO

Condition

Operational

Full accuracy

○G Supply current (with 1

measurement per second.)

Low Power

Idd

1 Hz

Standard

High precision

Min

Type Max

Units

-40

0

300

1.7

1.2

25

25

3

11

40

85

65

1100

3.6

3.6

5

15

50

°C

°C

hPa

V

uA

Note: The current consumption depends on both pressure measurement precision and rate. Please refer to the

Pressure Configuration (PRS_CFG) register description for an overview of the current consumption in different

combinations of measurement precision and rate.

Peak current

○G Standby current

During conversion

Iddsbm

Ipeak

uA

uA

400

500

1

Relative accuracy pressure

950…1050hPa

+25…+40°C

±6

±0.5

Pa

m

_________________________ ____________________________________________ __

Version 2.0

6 / 31

CONFIDENTIAL�

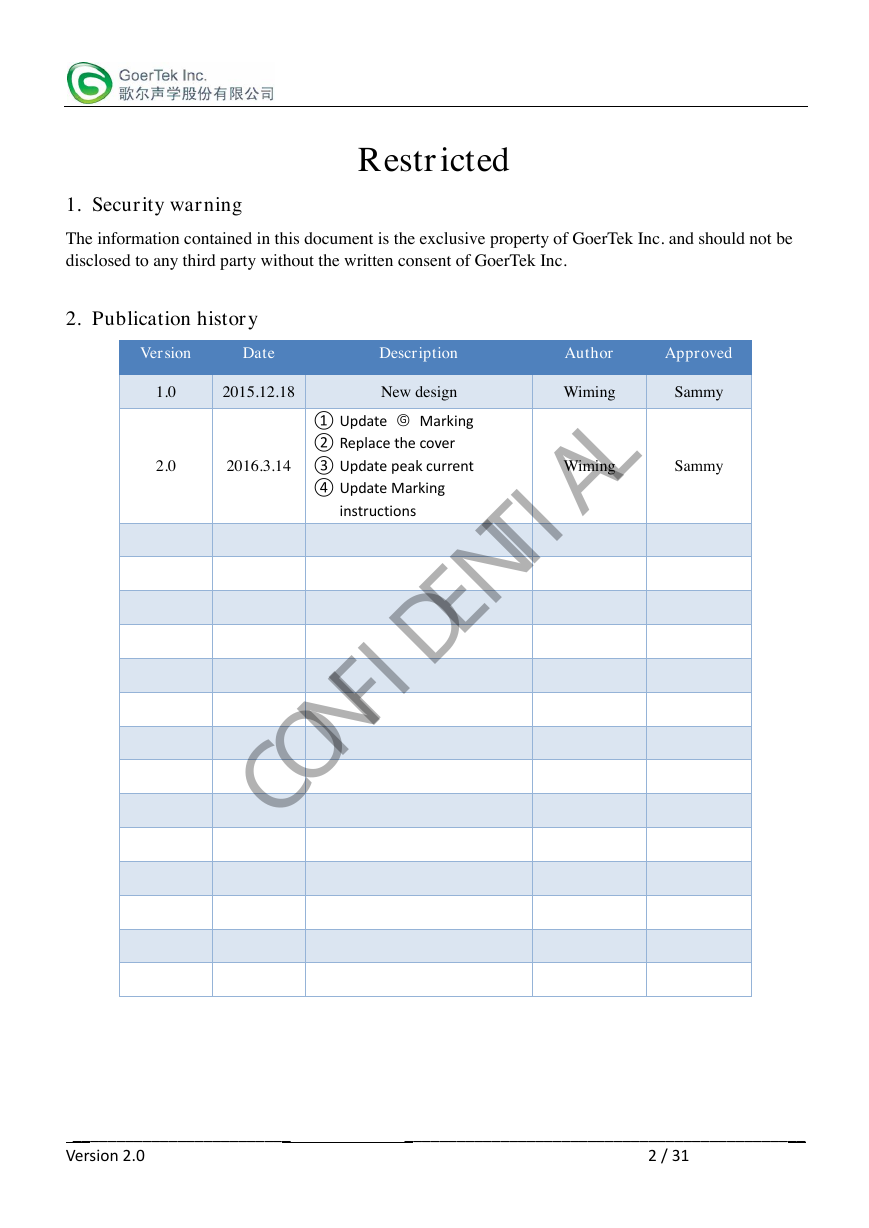

○G Absolute accuracy

pressure

Resolution of output data

300...1100hPa

0…+65℃

Pressure

Temperature

Low Power mode

Noise in pressure

P_Noise

Standard mode

High precision mode

±1.0

0.06

0.01

5

1.2

0.6

hPa

Pa

°C

PaRMS

Note: Pressure noise is measured as the average standard deviation. Please refer to the Pressure Configuration

(PRS_CFG) register description for all precision mode options.

Offset

temperature

coefficient

TCO

Absolute

accuracy

temperature

Pressure/Temperature

measurement rate

Pressure

measurement

time

f

t

1000hPa

+25…+40°C

@+25℃

0…+65℃

Low Power mode

Standard mode

High precision mode

1

±0.5

±4.2

±0.5

±1.0

5

28

105

128

Pa/K

cm/K

°C

°C

Hz

ms

Note: The pressure measurement time (and thus the maximum rate) depends on the pressure measurement

precision. Please refer to the Pressure Configuration (PRS_CFG) register description for an overview of the possible

combinations of measurement precision and rate.

Power supply rejection

Ap_psr

square wave and broad

Measured with 217Hz

±1

0.063

PaRMS

5

3.4

2

ms

MHz

hPa

hPa

12

ms

40

ms

-0.5

Supply voltage ramp-up

time

Serial data clock

Solder drifts

Long term stability

band noise, 100mVpp

tvddup

Time for supply voltage to

0.001

reach 90% of final value.

For I2C

12month

The SENSOR_RDY bit in

the Measurement

Time to sensor ready

TSensor_rdy

Configuration register

will be set when the

sensor is ready.

The COEF_RDY bit in

the Measurement

Configuration register

will be set when the

coefficients can be read

out.

Time to coefficients are

available.

TCoef_rdy

Note :○G Key performance.

_________________________ ____________________________________________ __

Version 2.0

7 / 31

CONFIDENTIAL�

5. Operation

5.1 Operating Modes

The SPL06-001 supports 3 different modes of operation: Standby, Command, and Background mode.

• Standby Mode

- Default mode after power on or reset. No measurements are performed.

- All registers and compensation coefficients are accessible.

• Command Mode

- One temperature or pressure measurement is performed according to the selected precision.

- The sensor will return to Standby Mode when the measurement is finished, and the measurement result

will be available in the data registers.

• Background Mode

- Pressure and/or temperature measurements are performed continuously according to the selected

measurement precision and rate. The temperature measurement is performed immediately after the

pressure measurement.

- The FIFO can be used to store 32 measurement results and minimize the number of times the sensor must

be accessed to read out the results.

Note: Operation mode and measurement type are set in the Sensor Operating Mode and Status (MEAS_CFG) register.

5.2 Measurement Precision and Rate

Different applications require different measurement precision and measurement rates. Some applications, like

weather stations, require lower precision and measurement rates than for instance indoor navigation and sports

applications.

The SPL06-001's measurement precision and rate (in background mode) can be configured to match the

requirements of the application in which it is being used. This reduces current consumption of the sensor and

the system.

In order to achieve a higher precision, the SPL06-001 will read the sensor multiple times (oversampling), and

combine the readings into one result. This increases the current consumption and the measurement time, which

again reduces the maximum measurement rate.

The measurement precision, rate and time is set in the Pressure Configuration (PRS_CFG) and Temperature

Configuration (TMP_CFG) registers. The register descriptions contain information about the current consumption

and the possible combinations of measurement precision, time, and rate.

Please note that the pressure sensor is temperature dependent. Temperature measurements must be made together

with the pressure measurements in order to compensate for the temperature dependency. This reduces the

maximum pressure measurement rate, since: Ratetemperature*Timetemperature + Ratepressure*Timepressure<

1 second. Measurement Settings and Use Case Examples contains a table with examples of combinations of

pressure and temperature precision and rates for different use cases.

_________________________ ____________________________________________ __

Version 2.0

8 / 31

CONFIDENTIAL�