CiA Draft Standard 420

CANopen

Profiles for extruder downstream devices

Part 3: Corrugator

Version: 3.0

31 January 2007

CAN in Automation (CiA) e. V.

�

Profiles for extruder downstream devices – Part 3: Corrugator

Changes

Publication of version 1.0 as draft standard proposal

Publication of version 2.0 as draft standard proposal

Publication of version 3.0 as draft standard

Editorial corrections and clarifications

HISTORY

Date

2002-10-22

2004-02-27

2007-01-31

General information on licensing and patents

CAN in AUTOMATION (CiA) calls attention to the possibility that some of the elements of this

CiA specification may be subject of patent rights. CiA shall not be responsible for identifying

any or all such patent rights.

Because this specification is licensed free of charge, there is no warranty for this

specification, to the extent permitted by applicable law. Except when otherwise stated in

writing the copyright holder and/or other parties provide this specification “as is” without

warranty of any kind, either expressed or implied, including, but not limited to, the implied

warranties of merchantability and fitness for a particular purpose. The entire risk as to the

correctness and completeness of the specification is with you. Should this specification prove

failures, you assume the cost of all necessary servicing, repair or correction.

© CiA 2008

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or

utilized in any form or by any means, electronic or mechanical, including photocopying and microfilm,

without permission in writing from CiA at the address below.

CAN in Automation e. V.

Kontumazgarten 3

DE - 90429 Nuremberg, Germany

Tel.: +49-911-928819-0

Fax: +49-911-928819-79

Url: www.can-cia.org

Email: headquarters@can-cia.org

2

CiA 2008 – All rights reserved

�

Profiles for extruder downstream devices – Part 3: Corrugator

CONTENTS

1 Scope ............................................................................................................................... 4

2 References ....................................................................................................................... 4

3 Abbreviations and definitions ............................................................................................ 4

3.1 Abbreviations........................................................................................................... 4

3.2 Definitions ............................................................................................................... 4

4 Operating principles .......................................................................................................... 4

4.1 General ................................................................................................................... 4

5 PDO specification ............................................................................................................. 4

5.1 Overview ................................................................................................................. 4

5.2 First TPDO .............................................................................................................. 5

5.3 Second TPDO.......................................................................................................... 8

5.4 First RPDO ............................................................................................................ 10

6 Application object specification ....................................................................................... 12

6.1 Object 6000h: Corrugator speed actual value ......................................................... 12

6.2 Object 6001h: Corrugator speed real maximum ...................................................... 13

6.3 Object 6002h: Corrugator speed set value.............................................................. 13

6.4 Object 6003h: Corrugator speed set maximum ....................................................... 14

6.5 Object 6004h: Corrugator speed set echo .............................................................. 14

6.6 Object 6005h: Corrugator speed step ..................................................................... 15

6.7 Object 6006h: Corrugator load actual value............................................................ 15

6.8 Object 6007h: Scaling factor .................................................................................. 16

6.9 Object 6008h: Product speed ................................................................................. 16

6.10 Object 6009h: Height adjustments ......................................................................... 17

6.11 Object 600Ah: Pressure set values ........................................................................ 18

6.12 Object 600Bh: Actual temperatures........................................................................ 19

6.13 Object 6010h: Configuration word .......................................................................... 20

6.14 Object 6020h: Control word.................................................................................... 21

6.15 Object 6030h: Status word ..................................................................................... 22

CiA 2008 – All rights reserved

3

�

Profiles for extruder downstream devices – Part 3: Corrugator

1 Scope

The CANopen application profile for extruder downstream devices include several parts:

Part 1 specifies general definitions

Part 2 specifies the device profile for the puller downstream device

Part 3 specifies the device profile for the corrugator downstream device

Part 4 specifies the device profile for the saw downstream device

Part 5 specifies the device profile for the co-extruder device

Part 6 specifies the device profile for the calibration-table downstream device

Note:

All parts of

Manufacturers for the Plastics and Rubber Industries (Euromap) and is documented there as Euromap 27.

this specification have been developed

jointly with

the European Committee of Machinery

This part specifies the CANopen interface for the corrugator downstream device.

2 References

/CiA420-1/: CiA 420, CANopen profile for extruder downstream devices — Part 1: General

definitions

The references given in /CiA420-1/ apply to this specification as well.

3 Abbreviations and definitions

3.1 Abbreviations

The abbreviations given in /CiA420-1/ apply to this specification as well.

3.2 Definitions

The definitions given in /CiA420-1/ apply to this specification as well.

4 Operating principles

4.1 General

The corrugator downstream device interface shall support all mandatory functions of /CiA301/

and /CiA420-1/ as well as all mandatory functions defined in this specification.

5 PDO specification

5.1 Overview

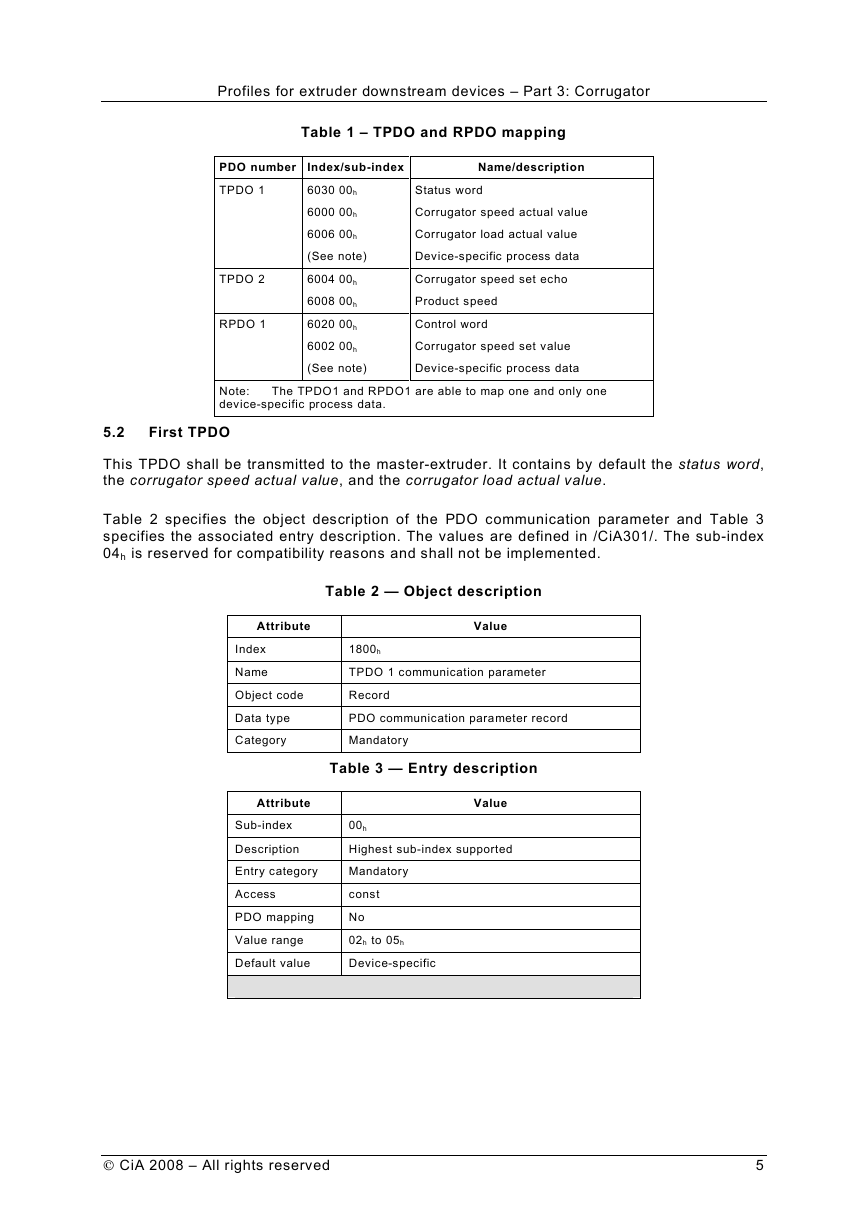

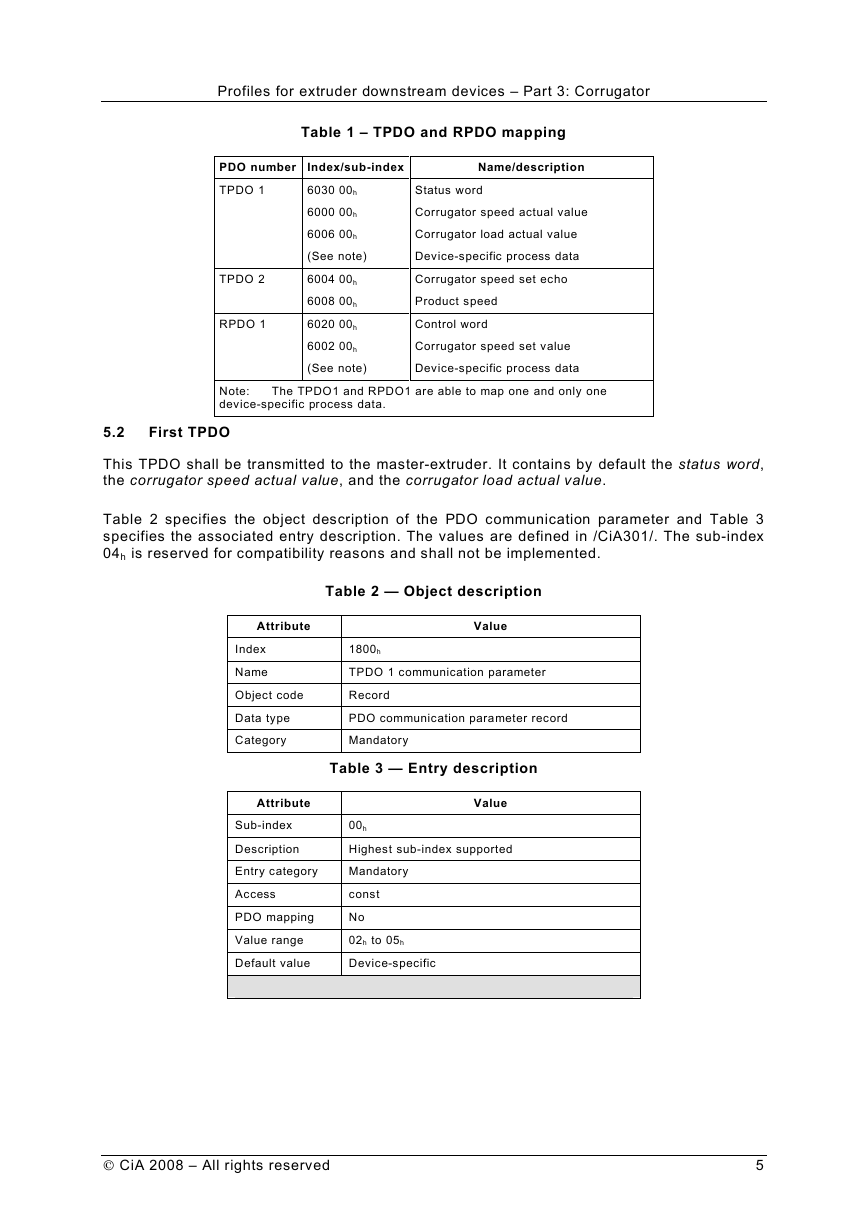

Table 1 shows the process data mapped into TPDOs and RPDOs.

4

CiA 2008 – All rights reserved

�

Profiles for extruder downstream devices – Part 3: Corrugator

PDO number

TPDO 1

TPDO 2

RPDO 1

Table 1 – TPDO and RPDO mapping

Index/sub-index

6030 00h

6000 00h

6006 00h

(See note)

6004 00h

6008 00h

6020 00h

6002 00h

(See note)

Name/description

Status word

Corrugator speed actual value

Corrugator load actual value

Device-specific process data

Corrugator speed set echo

Product speed

Control word

Corrugator speed set value

Device-specific process data

Note:

device-specific process data.

The TPDO1 and RPDO1 are able to map one and only one

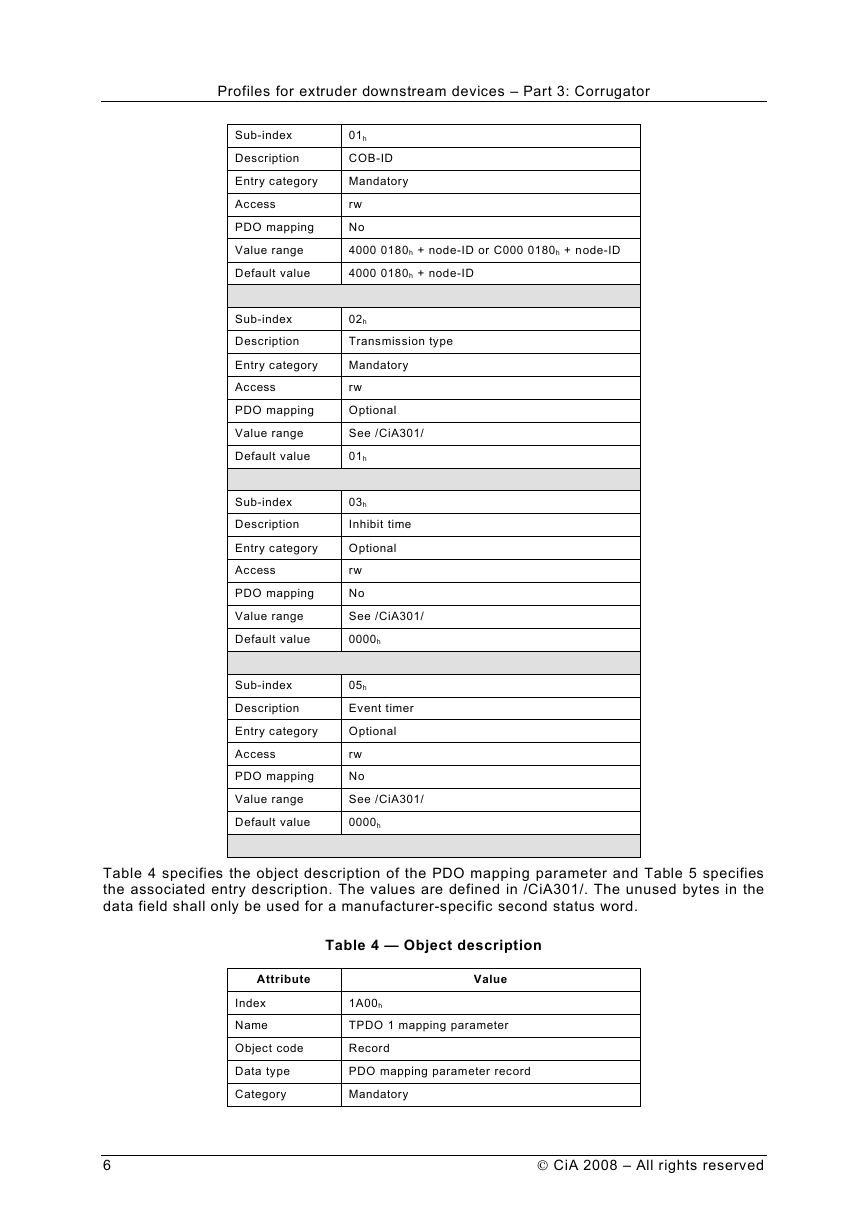

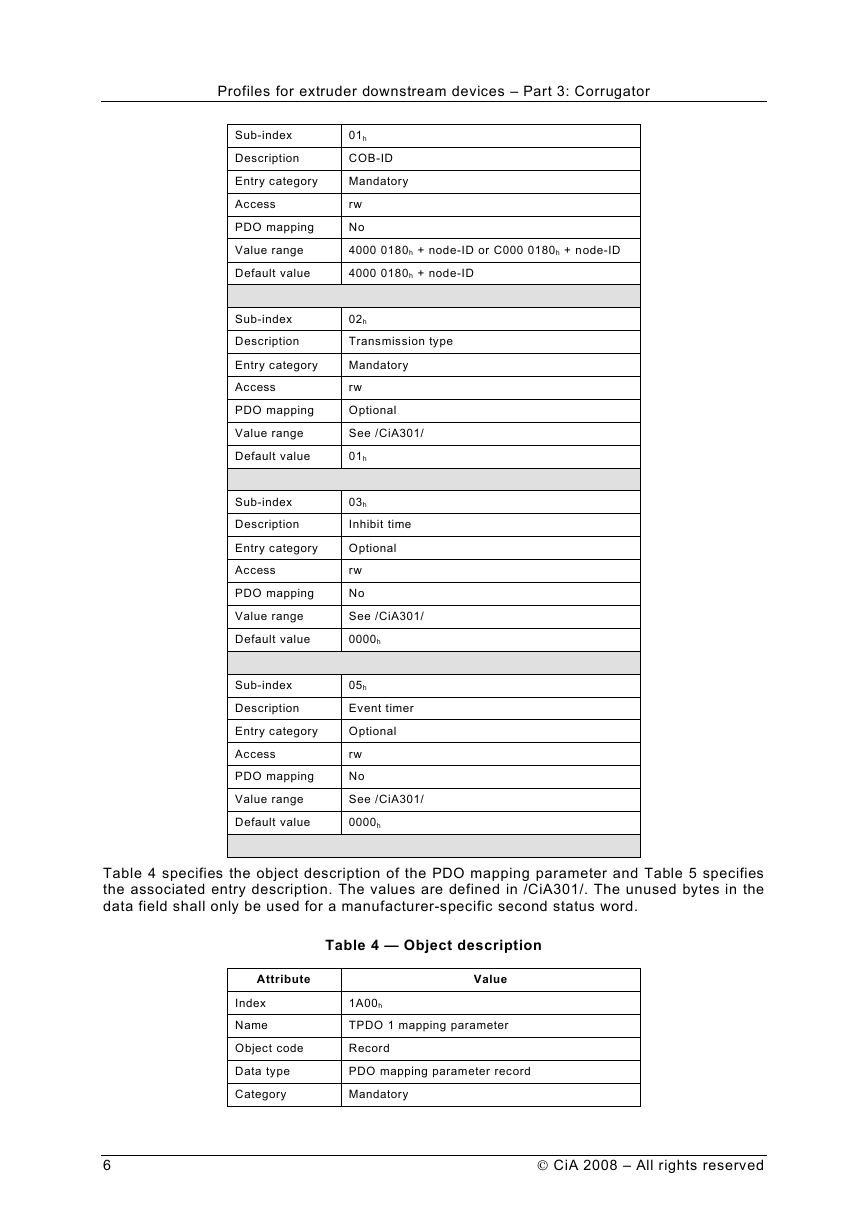

5.2

First TPDO

This TPDO shall be transmitted to the master-extruder. It contains by default the status word,

the corrugator speed actual value, and the corrugator load actual value.

Table 2 specifies the object description of the PDO communication parameter and Table 3

specifies the associated entry description. The values are defined in /CiA301/. The sub-index

04h is reserved for compatibility reasons and shall not be implemented.

Table 2 — Object description

Attribute

Index

Name

Object code

Data type

Category

Value

1800h

TPDO 1 communication parameter

Record

PDO communication parameter record

Mandatory

Table 3 — Entry description

Attribute

Sub-index

Description

Entry category

Access

PDO mapping

Value range

Default value

Value

00h

Highest sub-index supported

Mandatory

const

No

02h to 05h

Device-specific

CiA 2008 – All rights reserved

5

�

Profiles for extruder downstream devices – Part 3: Corrugator

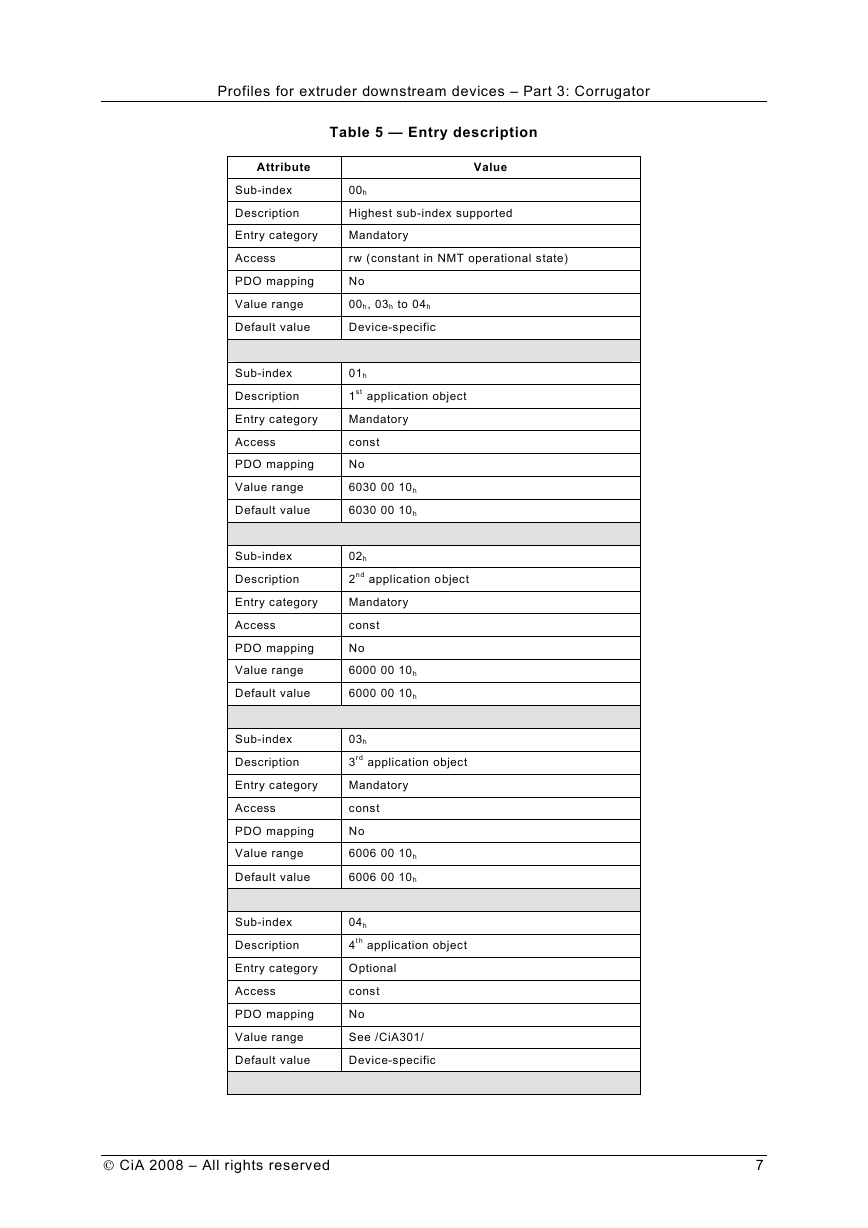

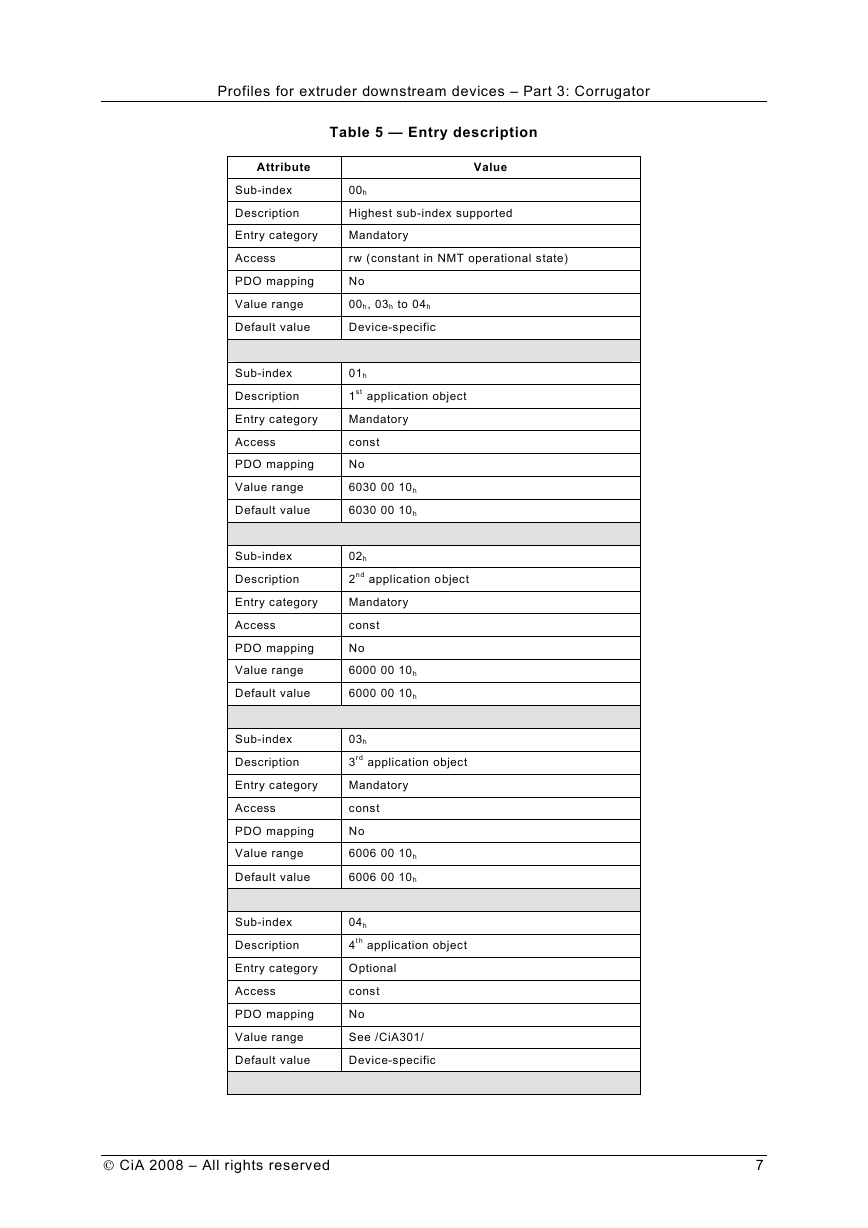

Sub-index

Description

Entry category

Access

PDO mapping

Value range

Default value

Sub-index

Description

Entry category

Access

PDO mapping

Value range

Default value

Sub-index

Description

Entry category

Access

PDO mapping

Value range

Default value

Sub-index

Description

Entry category

Access

PDO mapping

Value range

Default value

01h

COB-ID

Mandatory

rw

No

4000 0180h + node-ID or C000 0180h + node-ID

4000 0180h + node-ID

02h

Transmission type

Mandatory

rw

Optional

See /CiA301/

01h

03h

Inhibit time

Optional

rw

No

See /CiA301/

0000h

05h

Event timer

Optional

rw

No

See /CiA301/

0000h

Table 4 specifies the object description of the PDO mapping parameter and Table 5 specifies

the associated entry description. The values are defined in /CiA301/. The unused bytes in the

data field shall only be used for a manufacturer-specific second status word.

Table 4 — Object description

Attribute

Index

Name

Object code

Data type

Category

Value

1A00h

TPDO 1 mapping parameter

Record

PDO mapping parameter record

Mandatory

6

CiA 2008 – All rights reserved

�

Profiles for extruder downstream devices – Part 3: Corrugator

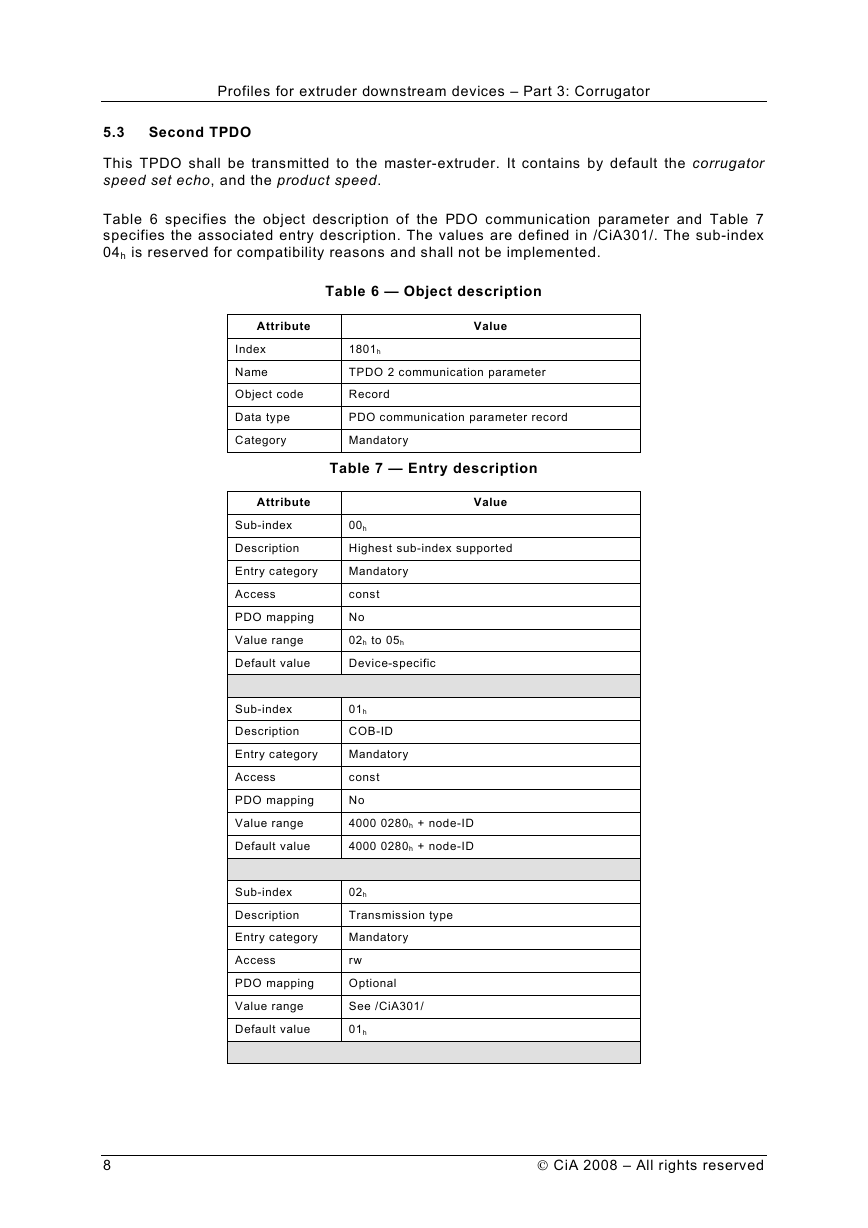

Attribute

Sub-index

Description

Entry category

Access

PDO mapping

Value range

Default value

Sub-index

Description

Entry category

Access

PDO mapping

Value range

Default value

Sub-index

Description

Entry category

Access

PDO mapping

Value range

Default value

Sub-index

Description

Entry category

Access

PDO mapping

Value range

Default value

Sub-index

Description

Entry category

Access

PDO mapping

Value range

Default value

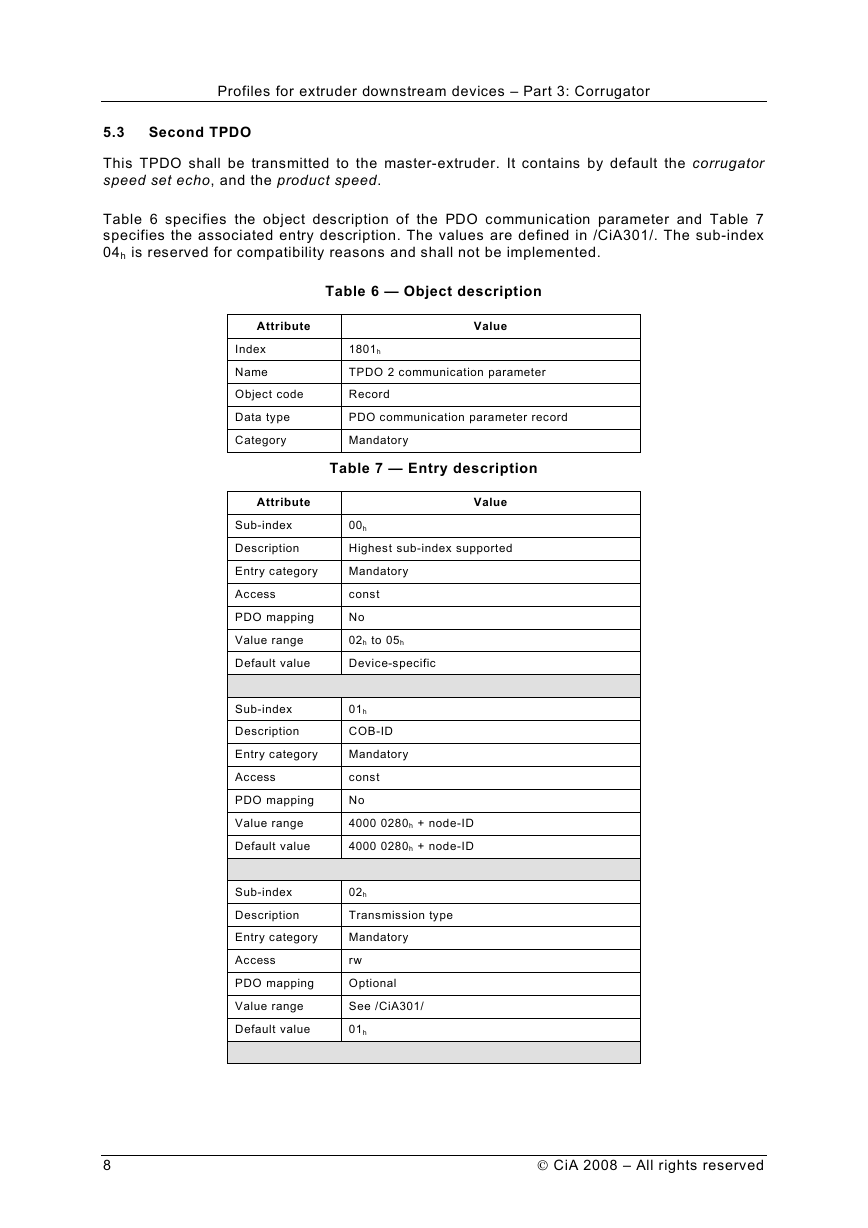

Table 5 — Entry description

Value

00h

Highest sub-index supported

Mandatory

rw (constant in NMT operational state)

No

00h, 03h to 04h

Device-specific

01h

1st application object

Mandatory

const

No

6030 00 10h

6030 00 10h

02h

2nd application object

Mandatory

const

No

6000 00 10h

6000 00 10h

03h

3rd application object

Mandatory

const

No

6006 00 10h

6006 00 10h

04h

4th application object

Optional

const

No

See /CiA301/

Device-specific

CiA 2008 – All rights reserved

7

�

Profiles for extruder downstream devices – Part 3: Corrugator

5.3

Second TPDO

This TPDO shall be transmitted to the master-extruder. It contains by default the corrugator

speed set echo, and the product speed.

Table 6 specifies the object description of the PDO communication parameter and Table 7

specifies the associated entry description. The values are defined in /CiA301/. The sub-index

04h is reserved for compatibility reasons and shall not be implemented.

Table 6 — Object description

Attribute

Index

Name

Object code

Data type

Category

Value

1801h

TPDO 2 communication parameter

Record

PDO communication parameter record

Mandatory

Table 7 — Entry description

Attribute

Sub-index

Description

Entry category

Access

PDO mapping

Value range

Default value

Sub-index

Description

Entry category

Access

PDO mapping

Value range

Default value

Sub-index

Description

Entry category

Access

PDO mapping

Value range

Default value

Value

00h

Highest sub-index supported

Mandatory

const

No

02h to 05h

Device-specific

01h

COB-ID

Mandatory

const

No

4000 0280h + node-ID

4000 0280h + node-ID

02h

Transmission type

Mandatory

rw

Optional

See /CiA301/

01h

8

CiA 2008 – All rights reserved

�