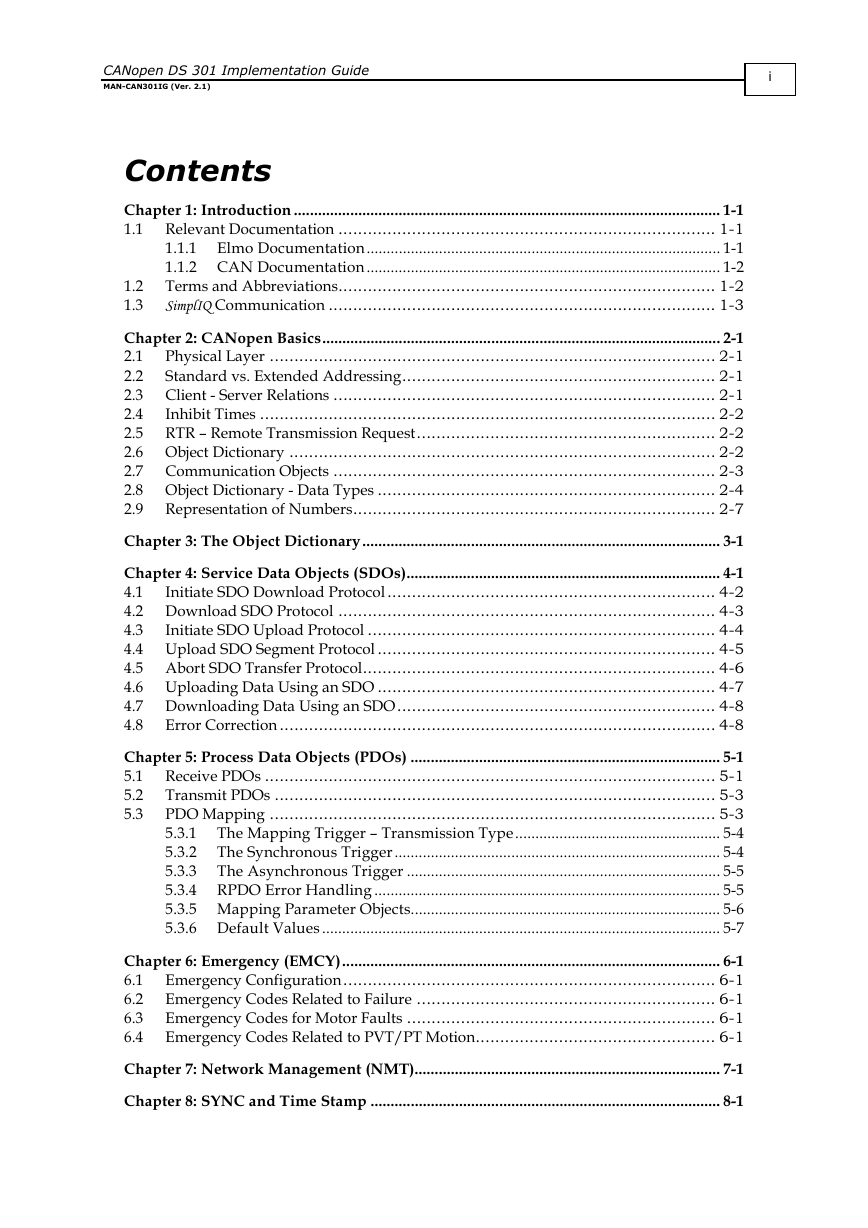

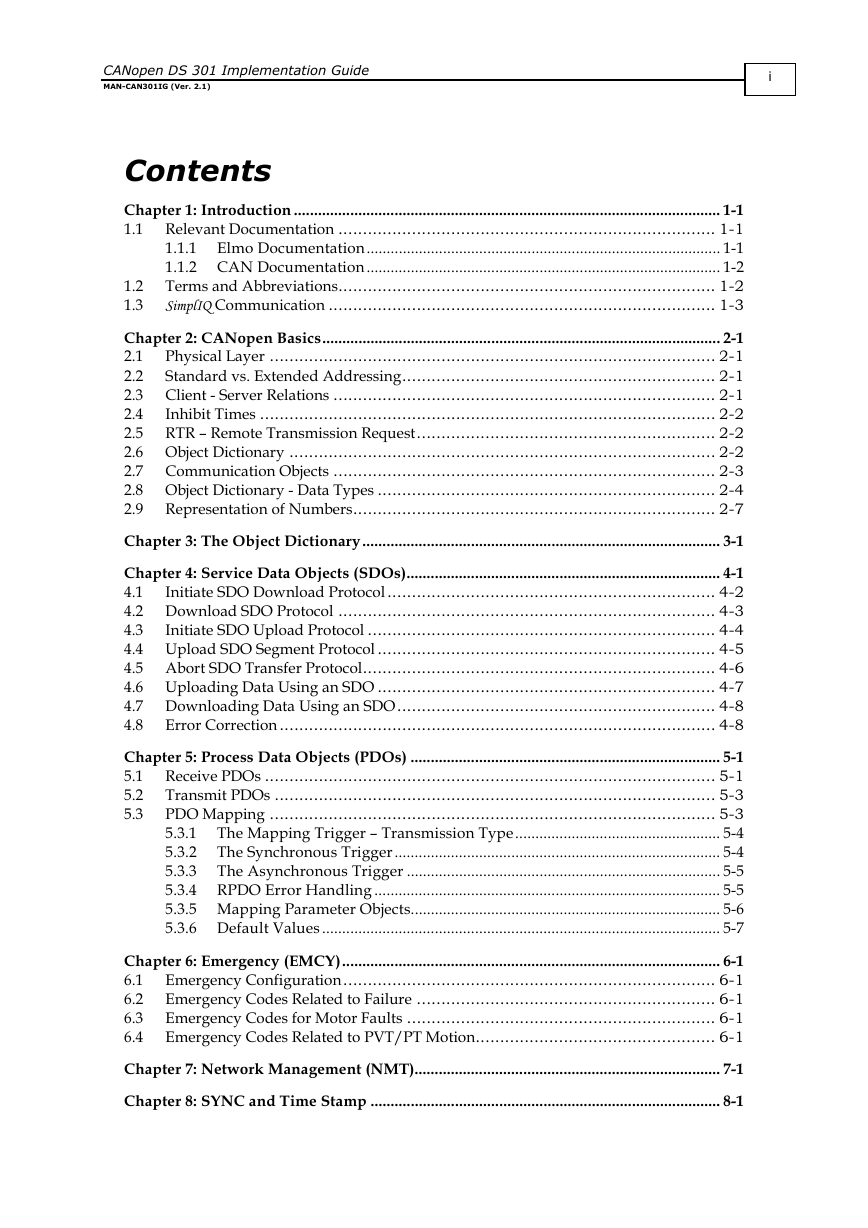

Chapter 1: Introduction

1.1 Relevant Documentation

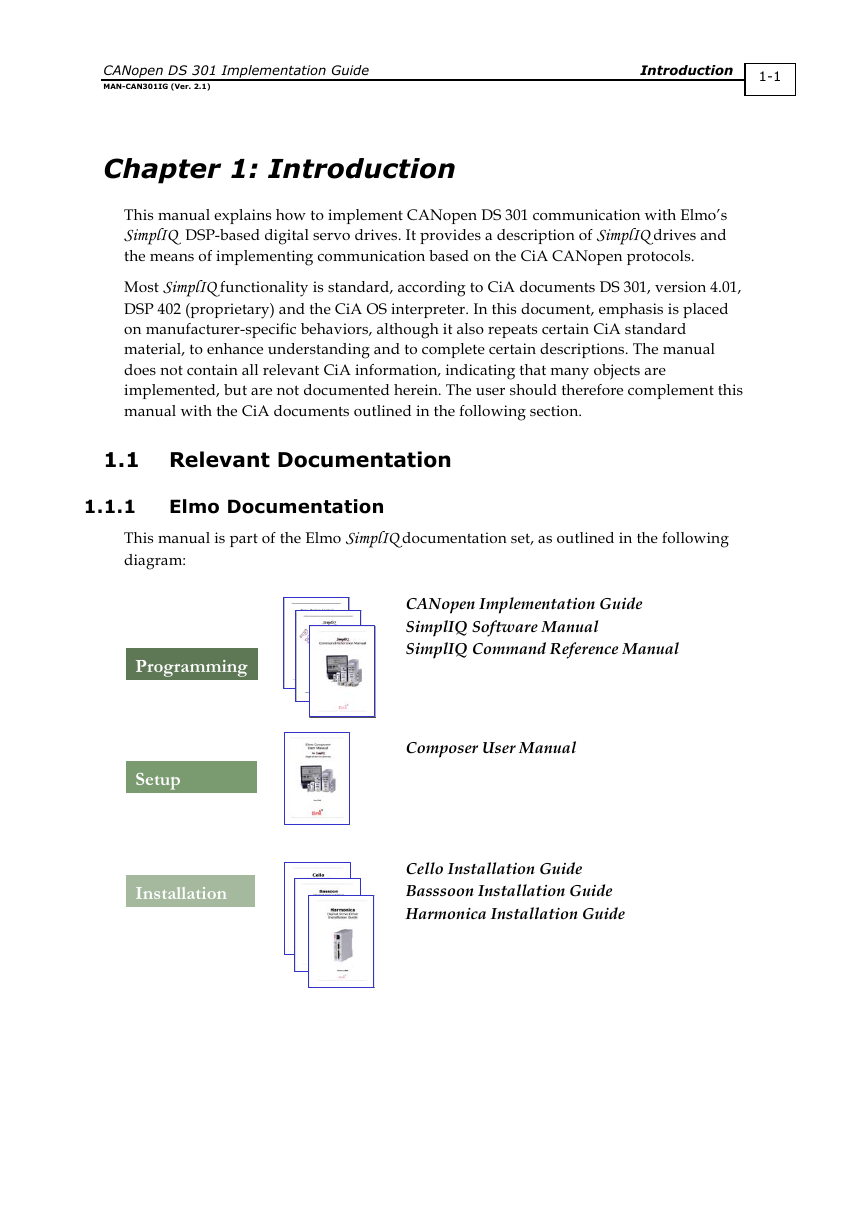

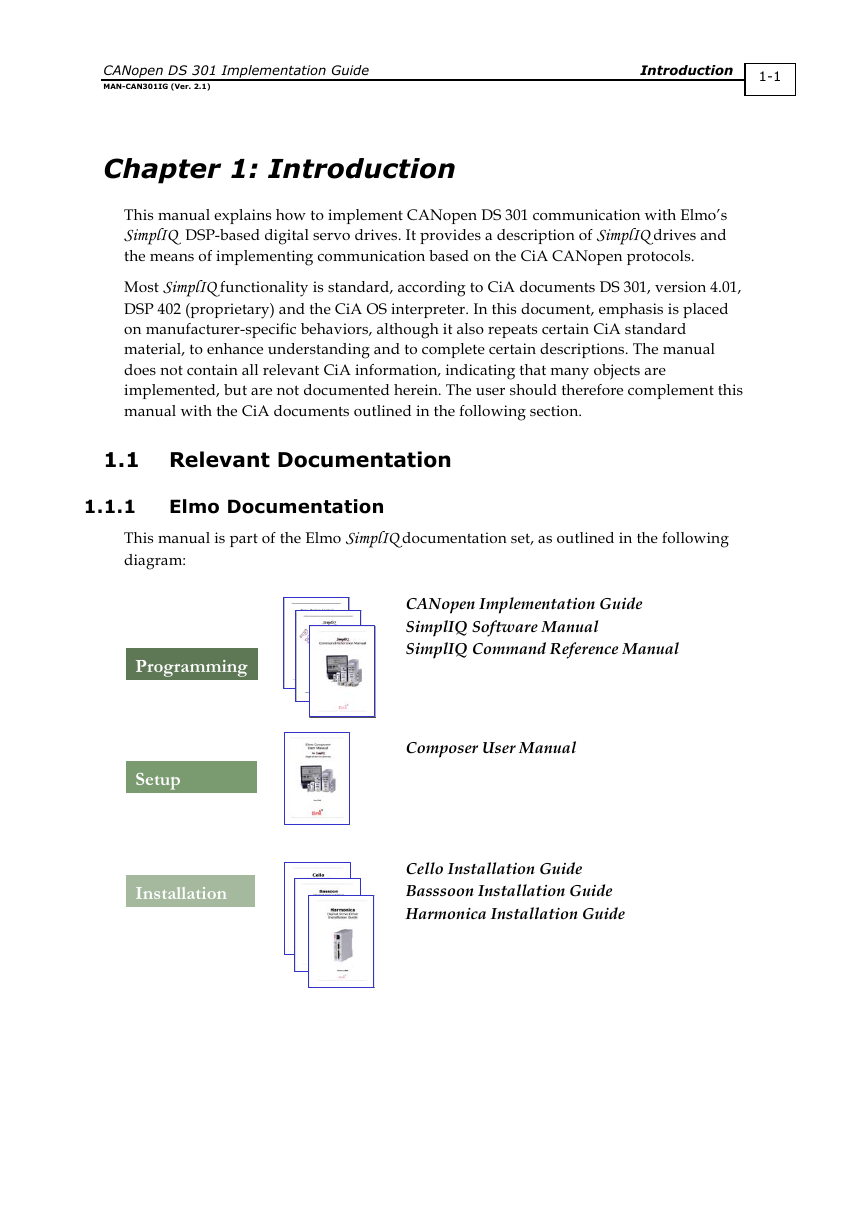

1.1.1 Elmo Documentation

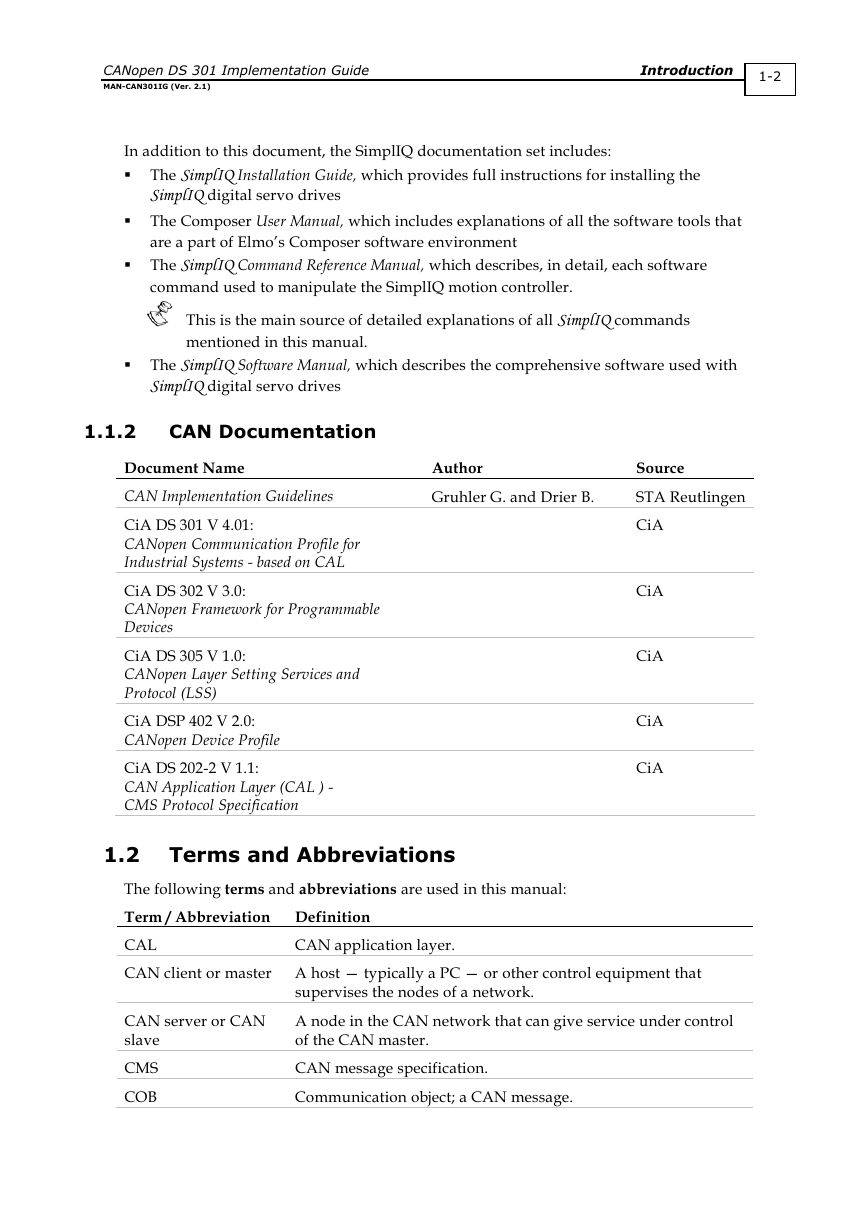

1.1.2 CAN Documentation

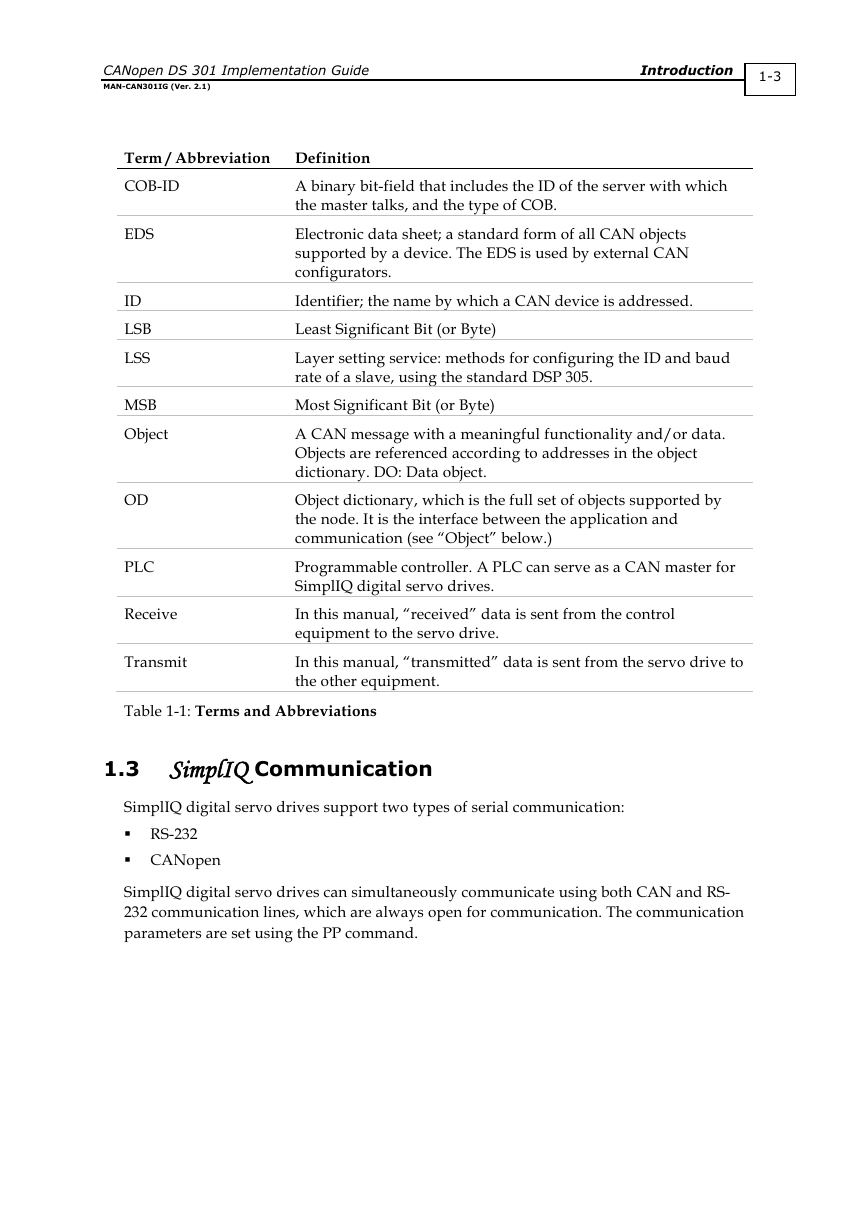

1.2 Terms and Abbreviations

1.3 SimplIQ Communication

Chapter 2: CANopen Basics

2.1 Physical Layer

2.2 Standard vs. Extended Addressing

2.3 Client - Server Relations

2.4 Inhibit Times

2.5 RTR – Remote Transmission Request

2.6 Object Dictionary

2.7 Communication Objects

2.8 Object Dictionary - Data Types

2.9 Representation of Numbers

Chapter 3: The Object Dictionary

Chapter 4: Service Data Objects (SDOs)

4.1 Initiate SDO Download Protocol

4.2 Download SDO Protocol

4.3 Initiate SDO Upload Protocol

4.4 Upload SDO Segment Protocol

4.5 Abort SDO Transfer Protocol

4.6 Uploading Data Using an SDO

4.7 Downloading Data Using an SDO

4.8 Error Correction

Chapter 5: Process Data Objects (PDOs)

5.1 Receive PDOs

5.2 Transmit PDOs

5.3 PDO Mapping

5.3.1 The Mapping Trigger – Transmission Type

5.3.2 The Synchronous Trigger

5.3.3 The Asynchronous Trigger

5.3.4 RPDO Error Handling

5.3.5 Mapping Parameter Objects

5.3.6 Default Values

Chapter 6: Emergency (EMCY)

6.1 Emergency Configuration

6.2 Emergency Codes Related to Failure

6.3 Emergency Codes for Motor Faults

6.4 Emergency Codes Related to PVT/PT Motion

Chapter 7: Network Management (NMT)

Chapter 8: SYNC and Time Stamp

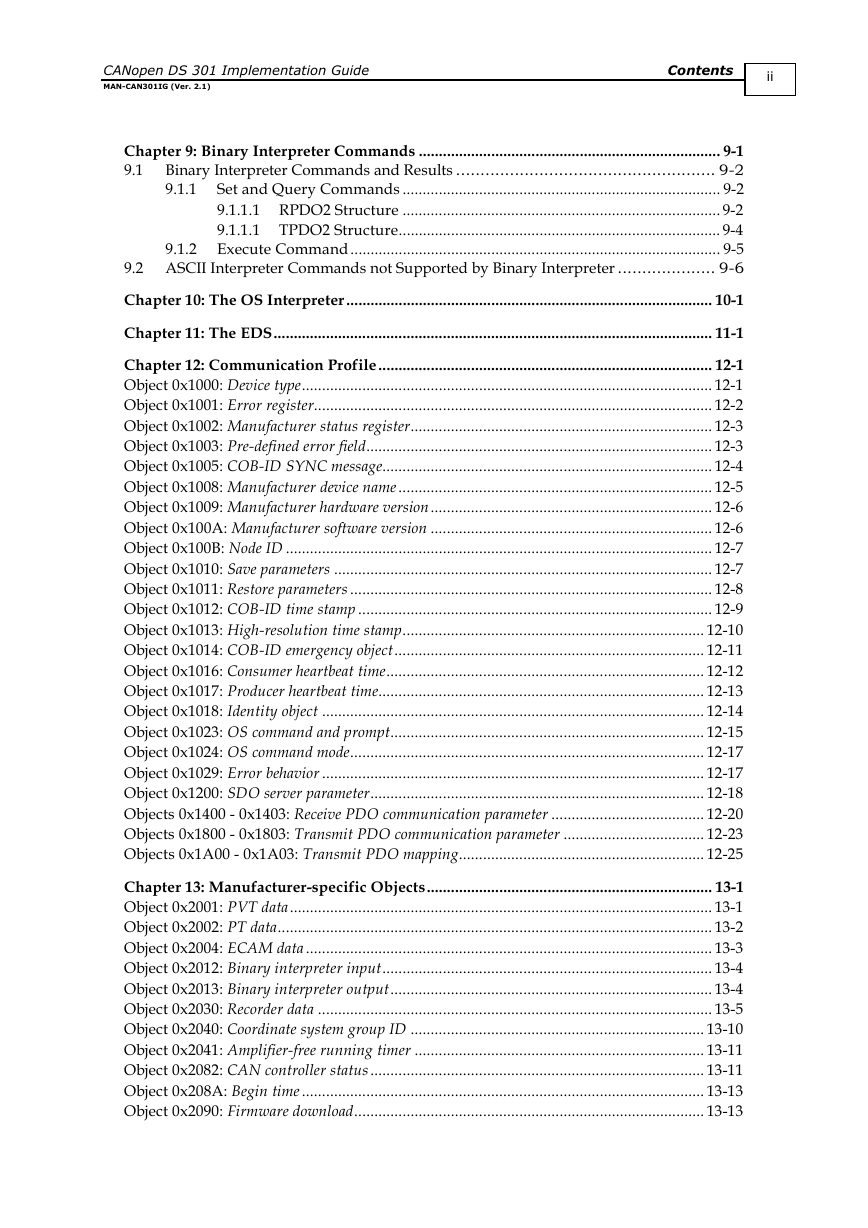

Chapter 9: Binary Interpreter Commands

9.1 Binary Interpreter Commands and Results

9.1.1 Set and Query Commands

9.1.1.1 RPDO2 Structure

9.1.1.1 TPDO2 Structure

9.1.2 Execute Command

9.2 ASCII Interpreter Commands not Supportedby Binary Interpreter

Chapter 10: The OS Interpreter

Chapter 11: The EDS

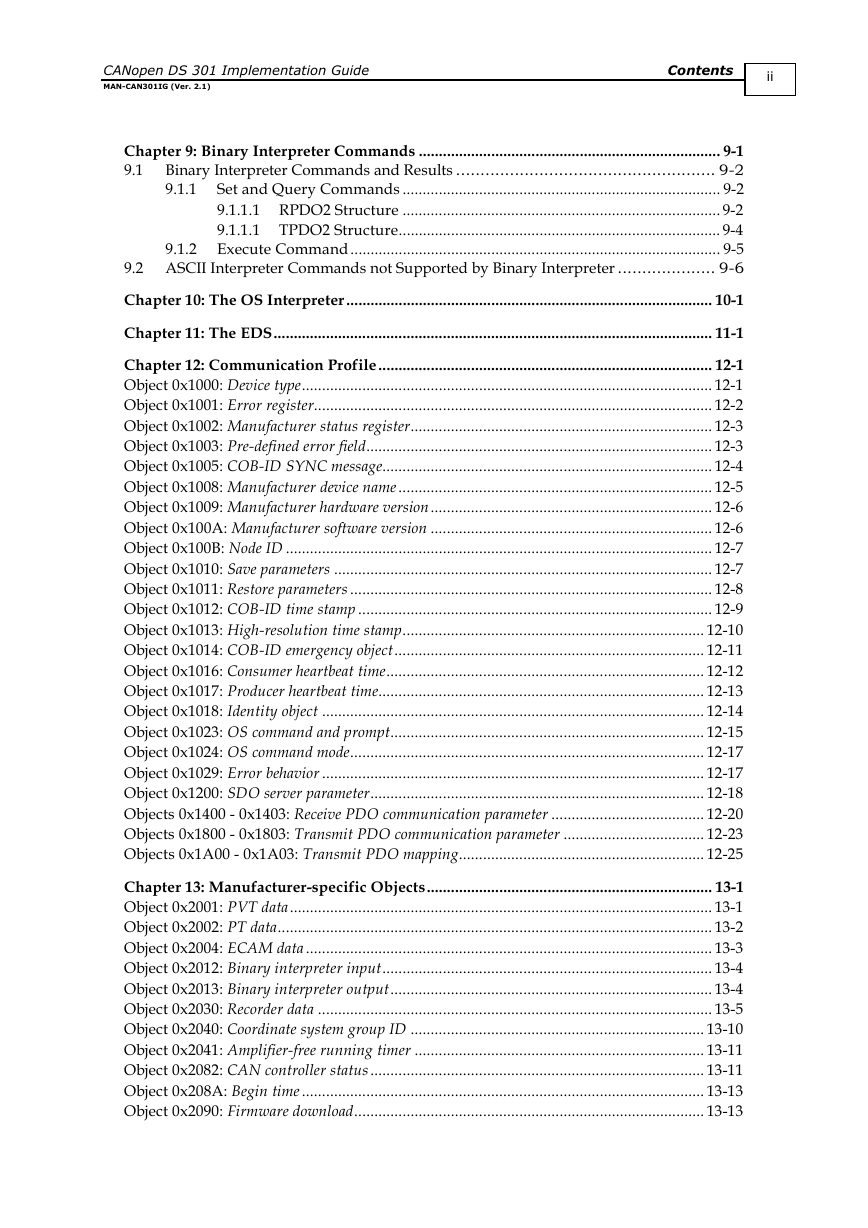

Chapter 12: Communication Profile

Object 0x1000: Device type

Object 0x1001: Error register

Object 0x1002: Manufacturer status register

Object 0x1003: Pre-defined error field

Object 0x1005: COB-ID SYNC message

Object 0x1008: Manufacturer device name

Object 0x1009: Manufacturer hardware version

Object 0x100A: Manufacturer software version

Object 0x100B: Node ID

Object 0x1010: Save parameters

Object 0x1011: Restore parameters

Object 0x1012: COB-ID time stamp

Object 0x1013: High-resolution time stamp

Object 0x1014: COB-ID emergency object

Object 0x1016: Consumer heartbeat time

Object 0x1017: Producer heartbeat time

Object 0x1018: Identity object

Object 0x1023: OS command and prompt

Object 0x1024: OS command mode

Object 0x1029: Error behavior

Object 0x1200: SDO server parameter

Objects 0x1400 - 0x1403: Receive PDO communication parameter

Objects 0x1800 - 0x1803: Transmit PDO communication parameter

Objects 0x1A00 - 0x1A03: Transmit PDO mapping

Chapter 13: Manufacturer-specific Objects

Object 0x2001: PVT data

Object 0x2002: PT data

Object 0x2004: ECAM data

Object 0x2012: Binary interpreter input

Object 0x2013: Binary interpreter output

Object 0x2030: Recorder data

Object 0x2040: Coordinate system group ID

Object 0x2041: Amplifier-free running timer

Object 0x2082: CAN controller status

Object 0x2090: Firmware download

Object 0x20A0: Auxiliary position actual value

Object 0x20A1: Main position error

Object 0x2200: Digital input

Object 0x2201: Digital input low byte

Object 0x2205: Analog Input Object

Object 0x2F00: User Integer

Object 0x2F01: User Float Array

Object 0x2F02: ET Array

Object 0x2F11: PVT head pointer

Object 0x2F12: PVT tail pointer

Object 0x2F15: Profile position remaining points

Object 0x2F20: PDO events

Object 0x2F21: Emergency events

Object 0x2F22: Bus off time out

Object 0x2F23: Digital input TPDO event parameters

Object 0x2F30: Last time stamp correction

Object 0x2F31: Last SYNC time

Object 0x2F40: Configuration object

Object 0x2F41: DS402 Configuration object

Object 0x2F60 – Zero torque threshold

Object 0x2F70 – CAN Encoder Range

Chapter 14: Error Control Protocol

Chapter 15: Downloading Firmware

Chapter 16: Initial CAN Communication Setup

16.1 Setup Using RS-232

16.2 Bootup Protocol

Appendix A: Little and Big Endians