CANopen

Device profiles for weaving machines

Part 2: Feeders

CiA Draft Standard 414

Version 1.1

18 June 2007

© CAN in Automation (CiA) e. V.

�

DS-414-2 V1.1

CANopen device profile for feeders

CiA

HISTORY

Date

2001-09-20

2007-06-18

Changes

• Publication of version 1.0 as draft standard proposal

• Publication of version 1.1 as draft standard

o Partly re-chaptered

o Minor editorial corrections

o Detailed description of PDO parameters added

General information on licensing and patents

CAN in AUTOMATION (CiA) calls attention to the possibility that some of the elements of this CiA

specification may be subject of patent rights. CiA shall not be responsible for identifying any or all such

patent rights.

Because this specification is licensed free of charge, there is no warranty for this

specification, to the extent permitted by applicable law. Except when otherwise stated in

writing the copyright holder and/or other parties provide this specification “as is” without

warranty of any kind, either expressed or implied, including, but not limited to, the implied

warranties of merchantability and fitness for a particular purpose. The entire risk as to the

correctness and completeness of the specification is with you. Should this specification prove

failures, you assume the cost of all necessary servicing, repair or correction.

© CiA 2008

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or

utilized in any form or by any means, electronic or mechanical, including photocopying and microfilm,

without permission in writing from CiA at the address below.

CAN in Automation e. V.

Kontumazgarten 3

DE - 90429 Nuremberg, Germany

Tel.: +49-911-928819-0

Fax: +49-911-928819-79

Url: www.can-cia.org

Email: headquarters@can-cia.org

2

© CiA 2008 - All rights reserved

�

DS-414-2 V1.1

CANopen device profile for feeders

CiA

CONTENTS

1 Scope........................................................................................................................................................5

2 Normative references ..............................................................................................................................6

3 Abbreviations............................................................................................................................................7

4 Communication objects ...........................................................................................................................8

4.1 Emergency message.......................................................................................................................8

4.2 RPDO 1 ............................................................................................................................................9

4.3 RPDO 2 ......................................................................................................................................... 12

4.4 RPDO 3 ......................................................................................................................................... 14

4.5 RPDO 4 ......................................................................................................................................... 17

4.6 TPDO 1 ......................................................................................................................................... 19

5 Object dictionary ................................................................................................................................... 21

5.1 Overview on object dictionary entries ......................................................................................... 21

5.2 Detailed specification of object entries........................................................................................ 21

5.2.1 Object 6000h: brush release ............................................................................................... 21

5.2.2 Object 6001h: feeder functions ........................................................................................... 23

5.2.3 Object 6002h: weft insertion type parameter ..................................................................... 25

5.2.4 Object 6003h: single weft filling parameter ........................................................................ 26

5.2.5 Object 6004h: global weft filling parameter........................................................................ 27

5.2.6 Object 6005h: trigger signal source.................................................................................... 28

5.2.7 Object 6006h: angle trigger timeout ................................................................................... 31

5.2.8 Object 6007h: feeder error condition.................................................................................. 32

5.2.9 Object 6008h: Feeder control box error condition ............................................................. 35

5.2.10 Object 6009h: feeder status .............................................................................................. 36

5.2.11 Object 600Ah: loom status ................................................................................................ 37

5.2.12 Object 600Bh: trigger signal.............................................................................................. 38

5.2.13 Object 600Ch: pick insertion ............................................................................................. 39

5.2.14 Object 600Dh: digital outputs............................................................................................ 41

5.2.15 Object 600Eh: feeder command ....................................................................................... 42

5.2.16 Object 600Fh: feeder test.................................................................................................. 44

5.2.17 Object 6010h: feeder unwinding time............................................................................... 46

5.2.18 Object 6011h: system feeder number assignment.......................................................... 47

© CiA 2008 - All rights reserved

3

�

DS-414-2 V1.1

CANopen device profile for feeders

CiA

5.2.19 Object 6012h: feeder color assignment ........................................................................... 48

4

© CiA 2008 - All rights reserved

�

DS-414-2 V1.1

CANopen device profile for feeders

CiA

1 Scope

Part 2 of the CANopen device profile for weaving machines specifies the CANopen interface for

feeders. This device profile for feeders covers ‘pre-measuring feeders’ as well as ‘weft feeders’.

© CiA 2008 - All rights reserved

5

�

DS-414-2 V1.1

CANopen device profile for feeders

CiA

2 Normative references

The normative references given in part 1 apply for this part, too.

6

© CiA 2008 - All rights reserved

�

DS-414-2 V1.1

CANopen device profile for feeders

CiA

3 Abbreviations

The abbreviations given in part 1 apply for this part, too.

© CiA 2008 - All rights reserved

7

�

DS-414-2 V1.1

CANopen device profile for feeders

CiA

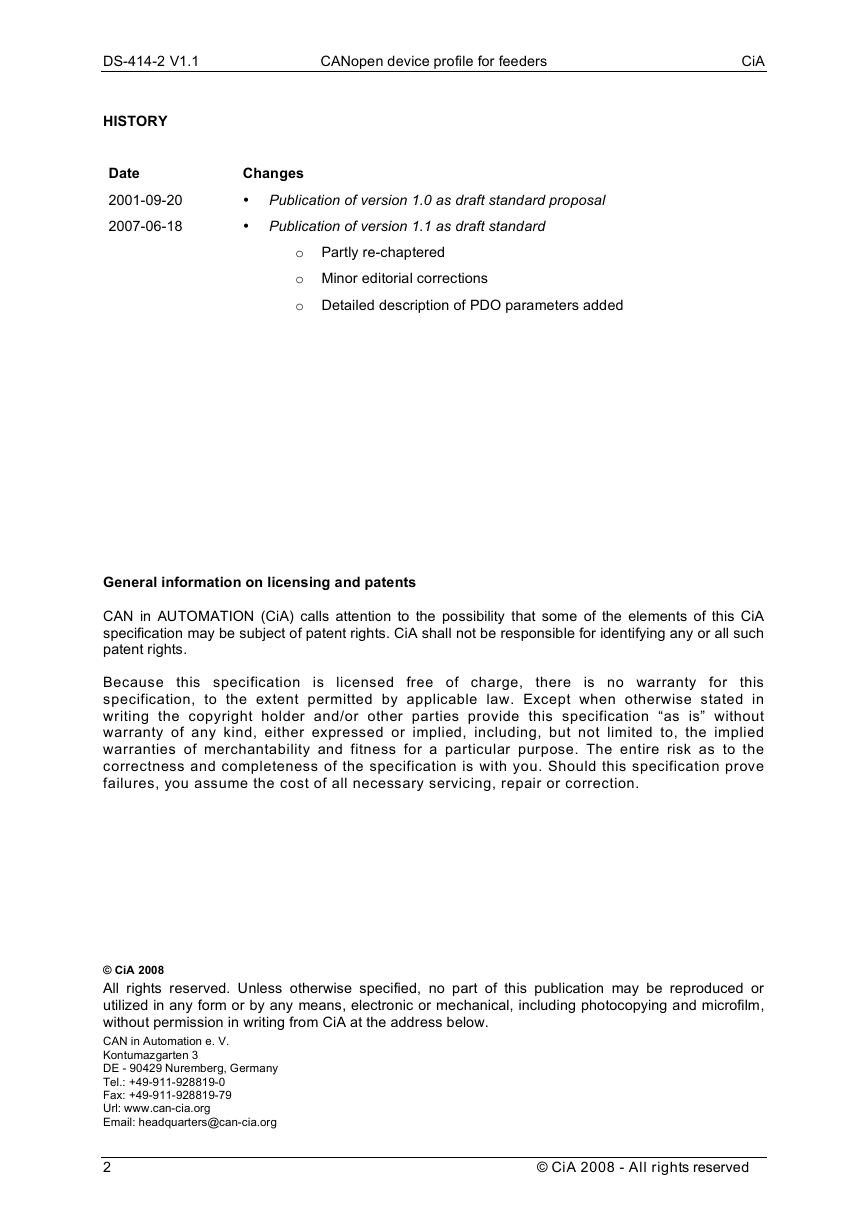

4 Communication objects

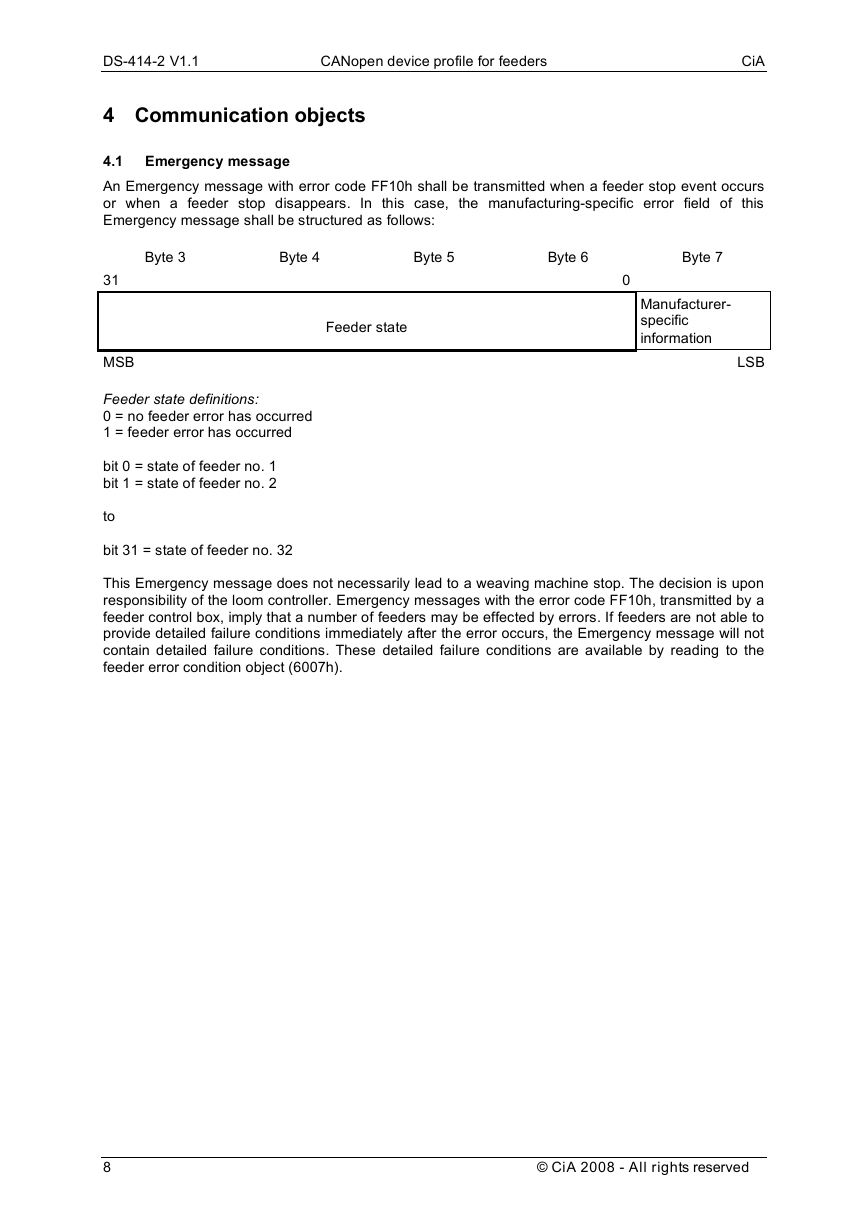

4.1 Emergency message

An Emergency message with error code FF10h shall be transmitted when a feeder stop event occurs

or when a feeder stop disappears. In this case, the manufacturing-specific error field of this

Emergency message shall be structured as follows:

Byte 3

31

Byte 4

Byte 5

Byte 6

Feeder state

Byte 7

0

Manufacturer-

specific

information

LSB

MSB

Feeder state definitions:

0 = no feeder error has occurred

1 = feeder error has occurred

bit 0 = state of feeder no. 1

bit 1 = state of feeder no. 2

to

bit 31 = state of feeder no. 32

This Emergency message does not necessarily lead to a weaving machine stop. The decision is upon

responsibility of the loom controller. Emergency messages with the error code FF10h, transmitted by a

feeder control box, imply that a number of feeders may be effected by errors. If feeders are not able to

provide detailed failure conditions immediately after the error occurs, the Emergency message will not

contain detailed failure conditions. These detailed failure conditions are available by reading to the

feeder error condition object (6007h).

8

© CiA 2008 - All rights reserved

�