PROFINET

System Description

n

o

i

t

a

c

i

l

p

p

A

d

n

a

y

g

o

o

n

h

c

e

T

l

Open Solutions for the World of Automation

�

�

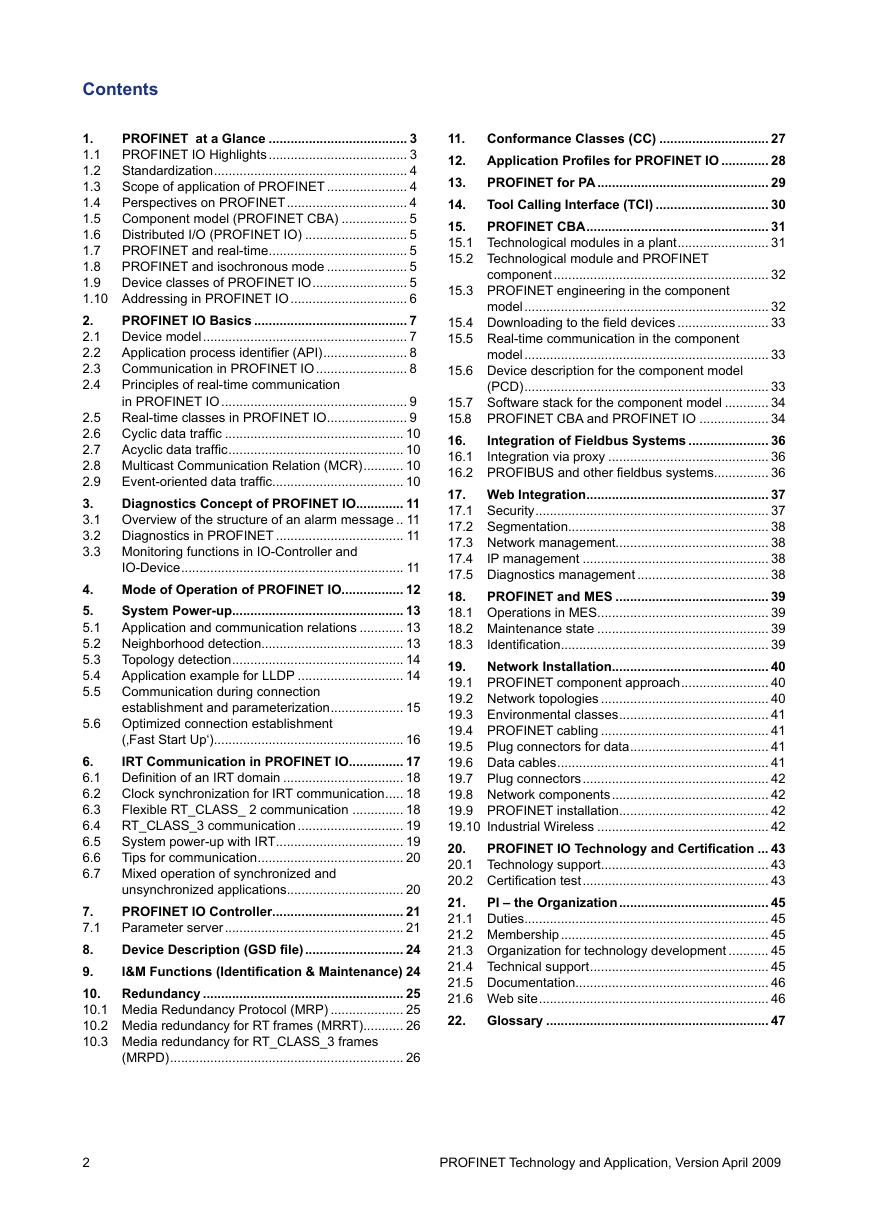

Introduction

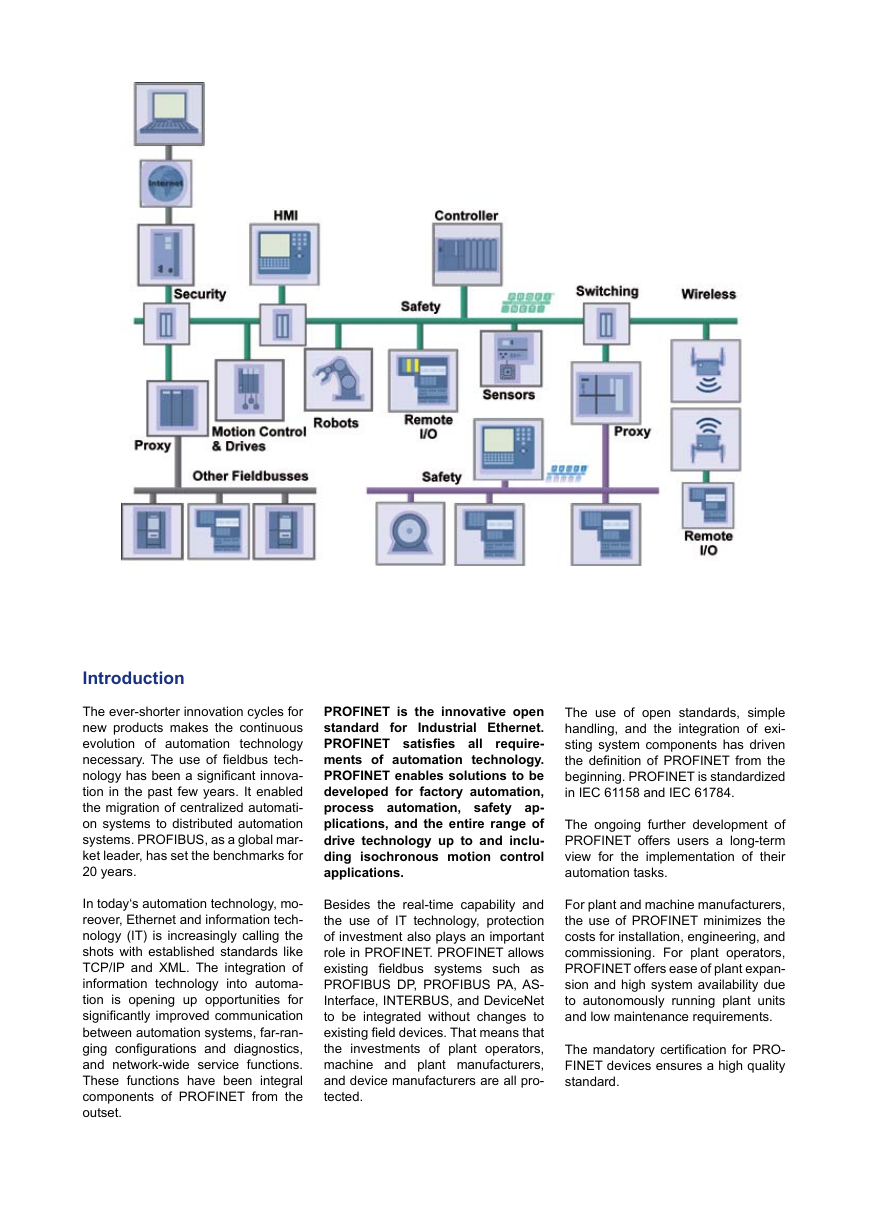

The ever-shorter innovation cycles for

new products makes the continuous

evolution of automation technology

necessary. The use of fieldbus tech-

nology has been a significant innova-

tion in the past few years. It enabled

the migration of centralized automati-

on systems to distributed automation

systems. PROFIBUS, as a global mar-

ket leader, has set the benchmarks for

20 years.

In today‘s automation technology, mo-

reover, Ethernet and information tech-

nology (IT) is increasingly calling the

shots with established standards like

TCP/IP and XML. The integration of

information technology into automa-

tion is opening up opportunities for

significantly improved communication

between automation systems, far-ran-

ging configurations and diagnostics,

and network-wide service functions.

These functions have been integral

components of PROFINET from the

outset.

PROFINET is the innovative open

standard for Industrial Ethernet.

PROFINET satisfies all require-

ments of automation technology.

PROFINET enables solutions to be

developed for factory automation,

process automation, safety ap-

plications, and the entire range of

drive technology up to and inclu-

ding isochronous motion control

applications.

Besides the real-time capability and

the use of IT technology, protection

of investment also plays an important

role in PROFINET. PROFINET allows

existing fieldbus systems such as

PROFIBUS DP, PROFIBUS PA, AS-

Interface, INTERBUS, and DeviceNet

to be integrated without changes to

existing field devices. That means that

the investments of plant operators,

machine and plant manufacturers,

and device manufacturers are all pro-

tected.

The use of open standards, simple

handling, and the integration of exi-

sting system components has driven

the definition of PROFINET from the

beginning. PROFINET is standardized

in IEC 61158 and IEC 61784.

The ongoing further development of

PROFINET offers users a long-term

view for the implementation of their

automation tasks.

For plant and machine manufacturers,

the use of PROFINET minimizes the

costs for installation, engineering, and

commissioning. For plant operators,

PROFINET offers ease of plant expan-

sion and high system availability due

to autonomously running plant units

and low maintenance requirements.

The mandatory certification for PRO-

FINET devices ensures a high quality

standard.

�

Contents

1. PROFINET at a Glance ...................................... 3

1.1 PROFINET IO Highlights ...................................... 3

1.2 Standardization ..................................................... 4

1.3 Scope of application of PROFINET ...................... 4

1.4 Perspectives on PROFINET ................................. 4

1.5 Component model (PROFINET CBA) .................. 5

1.6 Distributed I/O (PROFINET IO) ............................ 5

1.7 PROFINET and real-time ...................................... 5

1.8 PROFINET and isochronous mode ...................... 5

1.9 Device classes of PROFINET IO .......................... 5

1.10 Addressing in PROFINET IO ................................ 6

2. PROFINET IO Basics .......................................... 7

2.1 Device model ........................................................ 7

2.2 Application process identifier (API) ....................... 8

2.3 Communication in PROFINET IO ......................... 8

2.4 Principles of real-time communication

in PROFINET IO ................................................... 9

2.5 Real-time classes in PROFINET IO ...................... 9

2.6 Cyclic data traffic ................................................. 10

2.7 Acyclic data traffic ................................................ 10

2.8 Multicast Communication Relation (MCR) ........... 10

2.9 Event-oriented data traffic.................................... 10

3. Diagnostics Concept of PROFINET IO ............. 11

3.1 Overview of the structure of an alarm message .. 11

3.2 Diagnostics in PROFINET ................................... 11

3.3 Monitoring functions in IO-Controller and

IO-Device ............................................................. 11

4. Mode of Operation of PROFINET IO ................. 12

5. System Power-up............................................... 13

5.1 Application and communication relations ............ 13

5.2 Neighborhood detection....................................... 13

5.3 Topology detection ............................................... 14

5.4 Application example for LLDP ............................. 14

5.5 Communication during connection

5.6 Optimized connection establishment

(‚Fast Start Up‘) .................................................... 16

6.

IRT Communication in PROFINET IO ............... 17

6.1 Definition of an IRT domain ................................. 18

6.2 Clock synchronization for IRT communication ..... 18

6.3 Flexible RT_CLASS_ 2 communication .............. 18

6.4 RT_CLASS_3 communication ............................. 19

6.5 System power-up with IRT ................................... 19

6.6 Tips for communication ........................................ 20

6.7 Mixed operation of synchronized and

unsynchronized applications................................ 20

7. PROFINET IO Controller .................................... 21

7.1 Parameter server ................................................. 21

8. Device Description (GSD file) ........................... 24

9.

I&M Functions (Identification & Maintenance) 24

10. Redundancy ....................................................... 25

10.1 Media Redundancy Protocol (MRP) .................... 25

10.2 Media redundancy for RT frames (MRRT)........... 26

10.3 Media redundancy for RT_CLASS_3 frames

establishment and parameterization .................... 15

(MRPD) ................................................................ 26

model ................................................................... 33

component ........................................................... 32

11. Conformance Classes (CC) .............................. 27

12. Application Profiles for PROFINET IO ............. 28

13. PROFINET for PA ............................................... 29

14. Tool Calling Interface (TCI) ............................... 30

15. PROFINET CBA .................................................. 31

15.1 Technological modules in a plant ......................... 31

15.2 Technological module and PROFINET

15.3 PROFINET engineering in the component

model ................................................................... 32

15.4 Downloading to the field devices ......................... 33

15.5 Real-time communication in the component

15.6 Device description for the component model

(PCD) ................................................................... 33

15.7 Software stack for the component model ............ 34

15.8 PROFINET CBA and PROFINET IO ................... 34

Integration of Fieldbus Systems ...................... 36

16.

16.1

Integration via proxy ............................................ 36

16.2 PROFIBUS and other fieldbus systems............... 36

17. Web Integration .................................................. 37

17.1 Security ................................................................ 37

17.2 Segmentation....................................................... 38

17.3 Network management.......................................... 38

17.4

IP management ................................................... 38

17.5 Diagnostics management .................................... 38

18. PROFINET and MES .......................................... 39

18.1 Operations in MES............................................... 39

18.2 Maintenance state ............................................... 39

18.3

Identification......................................................... 39

19. Network Installation ........................................... 40

19.1 PROFINET component approach ........................ 40

19.2 Network topologies .............................................. 40

19.3 Environmental classes ......................................... 41

19.4 PROFINET cabling .............................................. 41

19.5 Plug connectors for data ...................................... 41

19.6 Data cables .......................................................... 41

19.7 Plug connectors ................................................... 42

19.8 Network components ........................................... 42

19.9 PROFINET installation ......................................... 42

19.10 Industrial Wireless ............................................... 42

20. PROFINET IO Technology and Certification ... 43

20.1 Technology support.............................................. 43

20.2 Certification test ................................................... 43

21. PI – the Organization ......................................... 45

21.1 Duties................................................................... 45

21.2 Membership ......................................................... 45

21.3 Organization for technology development ........... 45

21.4 Technical support ................................................. 45

21.5 Documentation..................................................... 46

21.6 Web site ............................................................... 46

22. Glossary ............................................................. 47

2

PROFINET Technology and Application, Version April 2009

�

Plant topology

Visualization of the plant topology

in conjunction with informative dia-

gnostics is integrated in PROFINET.

Plant diagnostics

PROFINET supports convenient plant

diagnostics through a combination of

basic services available as standard

features in the higher-level controller

.

Isochronous data transmission

With PROFINET, deterministic and iso-

chronous transmission of time-critical

process data is possible within a pe-

riod of a few hundred µs. PROFINET

requires this deterministic communi-

cation, for example, for high-accuracy

closed-loop control tasks.

Redundancy concept

PROFINET offers a scalable redun-

dancy concept, which guarantees

smooth changeover from one commu-

nication path to the other in the event

of a fault. The redundancy concept

defined in PROFINET increases the

plant availability significantly.

Device replacement without

ES tool

Failure of a PROFINET device is de-

tected and signaled automatically. No

special knowledge is required to re-

place the device. Any replacement de-

vice in the warehouse can be installed

in the automation system. Addressing

as well as loading of required para-

meters is carried out automatically.

Devices having an incorrect degree of

expansion are detected automatically

during power-up.

Engineering

Through support of the Tool Calling

Interface (TCI), any field device ma-

nufacturer can interact with any TCI-

capable engineering system (ES) and

communicate with „its“ field devices

(Device Tool) from the ES for purpo-

ses of assigning parameters and per-

forming diagnostics.

individual parameters

Saving of

(iPar server)

Parameters determined on a plant-

specific basis are saved and loaded

autonomously. The iPar server allows

vendor-neutral loading (e.g., via TCI)

of

individually-assigned parameters

optimized for the specific plant as well

as automatic archiving on a parameter

server. Downloading also occurs auto-

matically during device replacement.

1. PROFINET at a Glance

PROFINET is the automation stan-

dard of PROFIBUS&PROFINET In-

ternational (PI). PROFINET is 100%

Ethernet-compatible as defined

in

IEEE Standards. With PROFINET, the

following minimum data communica-

tion requirements are automatically

established:

• 100 Mbps data communication with

copper or fiber optic transmission

(100 Base TX and 100 Base FX)

• Full duplex transmission

• Switched Ethernet

• Autonegotiation

transmission parameters)

(negotiating of

• Autocrossover (sending and recei-

ving

the

switch)

lines are crossed

in

• Wireless communication (WLAN

and Bluetooth)

PROFINET uses UDP/IP as

the

higher level protocol for demand-

oriented data exchange. UDP (User

Datagram Protocol) contains the non-

secure, connectionless broadcast

communication in conjunction with IP.

In parallel to UDP/IP communication,

cyclic data exchange in PROFINET

is based on a scalable real-time con-

cept.

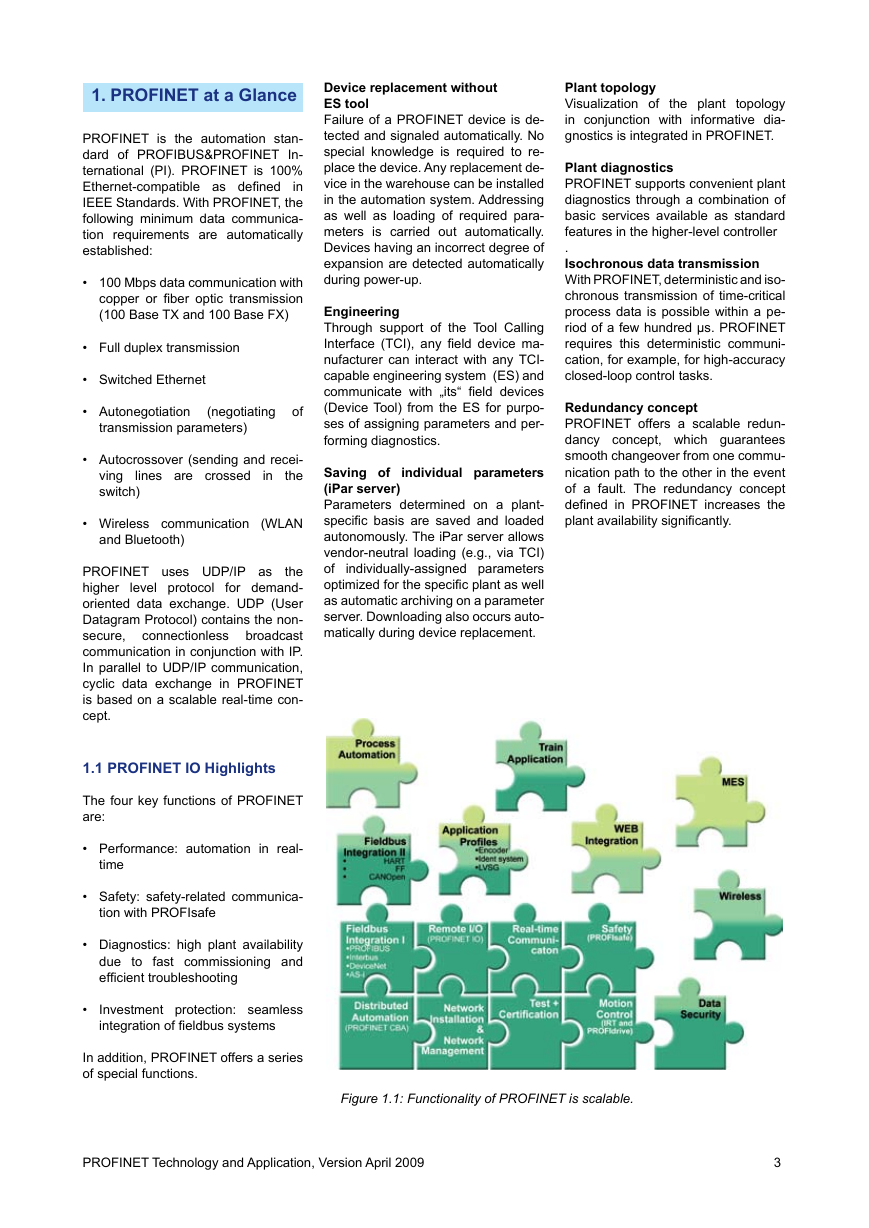

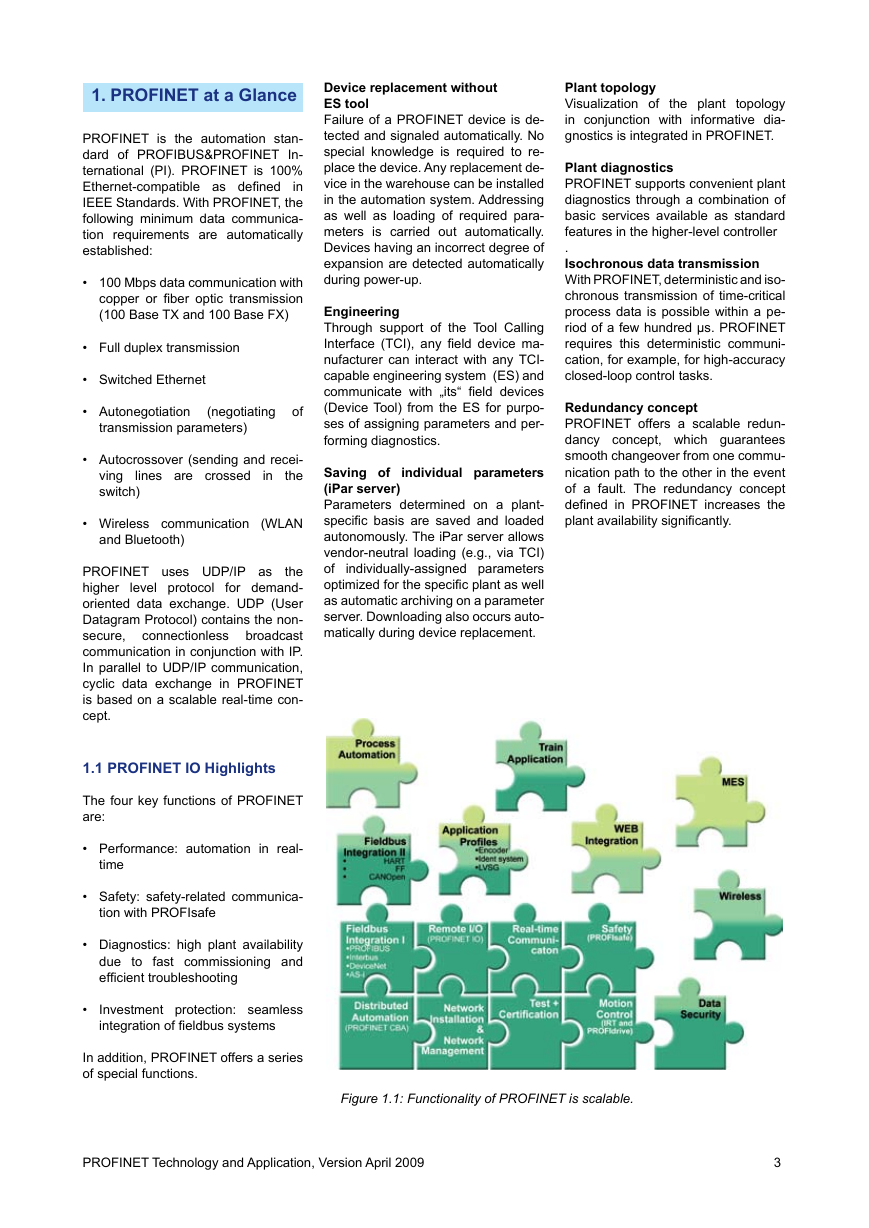

1.1 PROFINET IO Highlights

The four key functions of PROFINET

are:

• Performance: automation in real-

time

• Safety: safety-related communica-

tion with PROFIsafe

• Diagnostics: high plant availability

due to fast commissioning and

efficient troubleshooting

•

Investment protection: seamless

integration of fieldbus systems

In addition, PROFINET offers a series

of special functions.

Figure 1.1: Functionality of PROFINET is scalable.

PROFINET Technology and Application, Version April 2009

3

�

Very simple device replacement

The integrated neighborhood detec-

tion functionality enables PROFINET

field devices to identify their neigh-

bors. Thus, in the event of a problem,

field devices can be replaced without

additional tools or prior knowledge.

This information can be used to repre-

sent the plant topology in a very easy

to understand graphic display.

1.2 Standardization

PROFINET IO has been incorporated

in the current edition of IEC 61158.

IEC 61784 describes the subsets of

the services specified in IEC 61158

that are to be applied for PROFINET.

The PROFINET concept was defined

in close cooperation with end users.

Additions to the standard Ethernet

protocol as defined in IEEE 802 were

made by PI only in cases where the

existing standard could not meet the

requirements in a satisfactory man-

ner.

1.3 Scope of application of

PROFINET

PROFINET satisfies all requirements

of automation technology. The many

years of experience with PROFIBUS

and the widespread use of Industrial

Ethernet have been rolled into PRO-

FINET.

The use of IT standards, simple hand-

ling, and the integration of existing

system components have driven the

definition of PROFINET from the be-

ginning. The figure below summarizes

the functionality currently provided by

PROFINET.

The ongoing further development of

PROFINET offers users a long-term

view for the implementation of their

automation tasks.

For plant and machine manufactu-

rers, the use of PROFINET minimizes

the costs for installation, engineering,

and commissioning.

The plant operator benefits from the

ease of plant expansion and high avai-

lability due to autonomously running

plant units.

Establishment of the proven certifica-

tion process ensures a high standard

of quality for PROFINET products.

Use of the user profiles defined up to

now means that PROFINET can be

used in virtually every sector of auto-

mation engineering. PROFINET pro-

files for the process industry and for

train applications are currently under

development.

1.4 Perspectives on

PROFINET

The PROFINET concept is a modular

concept that allows the user to chose

the functionality he requires.

functionality differs mainly

The

in

terms of the type of data exchange.

This distinction is necessary to satis-

fy the very stringent requirements for

data transmission speed that exist for

some applications. Figure 1.2 shows

the relationship between the PROFI-

NET CBA and PROFINET IO perspec-

tives. Both communication paths can

be used in parallel.

PROFINET CBA is suitable for com-

ponent-based machine-to-machine

communication via TCP/IP and for

real-time communication to meet real-

time requirements in modular plant

manufacturing. It enables a simple mo-

dular design of plants and production

lines based on distributed intelligence

using graphics-based configuration

of communication between intelligent

modules.

PROFINET IO describes an I/O data

view on distributed I/O. PROFINET IO

features real-time (RT) communica-

tion and isochronous real-time (IRT)

communication with the distributed

I/O. The designations RT and IRT are

used solely to describe the real-time

properties of communication.

PROFINET CBA and PROFINET IO

can be operated separately and in

combination such that a PROFINET

IO unit appears in the plant view as a

PROFINET CBA plant.

Figure 1.2: PROFINET perspectives.

4

PROFINET Technology and Application, Version April 2009

�

1.5 Component model

(PROFINET CBA)

This variant is defined in PROFINET

CBA (Component Based Automation).

Its strength is revealed in communi-

cation between Programmable Logic

Controllers (PLC). The basic idea

behind CBA is that whole automation

systems can be often be grouped into

autonomously operating and, thus,

very clearly arranged units. The struc-

ture and functionality can be repeated

in identical, or slightly modified, form

in multiple plants. These so-called

PROFINET components are generally

controlled by an easily identified set of

input signals. Within the component,

a control program written by the user

executes the required functionality of

the component and sends the corre-

sponding output signals to another

controller. The engineering associated

with this is vendor-neutral. Communi-

cation in a component-based system

is configured rather than programmed.

The communication with PROFINET

CBA (without real-time) is suitable for

bus cycle times of approximately 50 to

100 ms. Data cycles on the order of

milliseconds are possible in the paral-

lel RT channel - same as in PROFI-

NET IO.

1.6 Distributed I/O

(PROFINET IO)

PROFINET IO is used to connect dis-

tributed I/O for fast data exchange.

The scalable real-time concept is the

basis for this.

PROFINET IO describes the overall

data exchange between controllers

(devices with master functionality ac-

cording to PROFIBUS) and devices

(devices with slave functionality) as

well as the parameterization and di-

agnostic options. A device developer

can implement PROFINET IO with

any commercially available Ethernet

controller. The bus cycle times for the

data exchange are in the milliseconds

range. Configuring an PROFINET IO

system has the same look and feel as

in PROFIBUS. The real-time concept

is included in PROFINET IO without

exception.

1.7 PROFINET and real-time

Within PROFINET IO, process data

and alarms are always transmitted in

real time. Real-Time for PROFINET

(RT) is based on the definitions of

IEEE and IEC for high-performance

data exchange of I/O data. RT com-

munication constitutes the basis for

data exchange in PROFINET IO.

Real-time data are handled with high-

er priority compared to TCP(UDP)/IP

data. This method of data exchange

allows bus cycle times in the range

of a few hundred milliseconds to be

achieved.

1.8 PROFINET and iso-

chronous mode

Isochronous data exchange with

PROFINET is defined in the Isochro-

nous-Real-Time (IRT) concept. Data

exchange cycles are normally in the

range of a few hundred microseconds

to 1 millisecond. Isochronous real-

time communication differs from real-

time communication mainly in its iso-

chronous behavior, meaning that the

bus cycles are started with maximum

precision. The start of a bus cycle can

deviate by a maximum of 1 µs. IRT is

required in motion control applications

(positioning operations), for example.

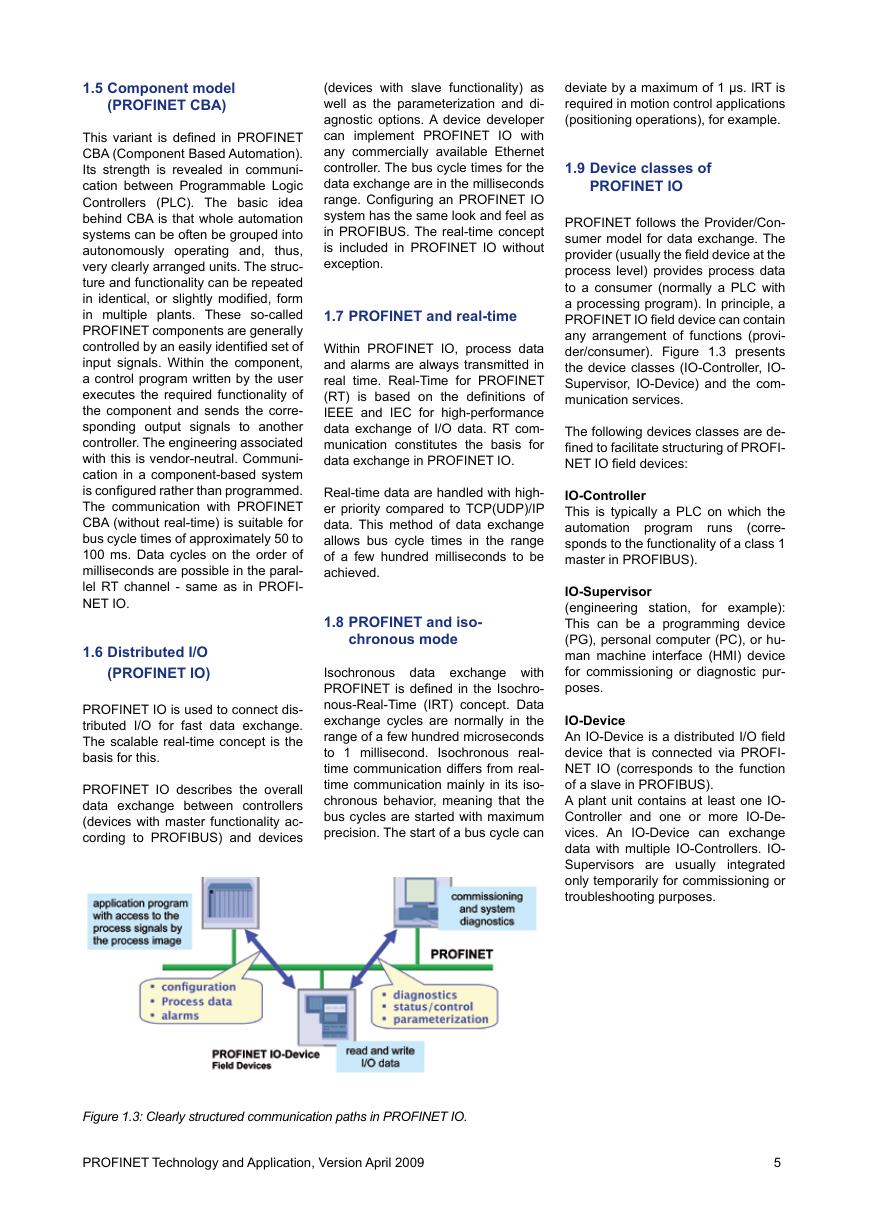

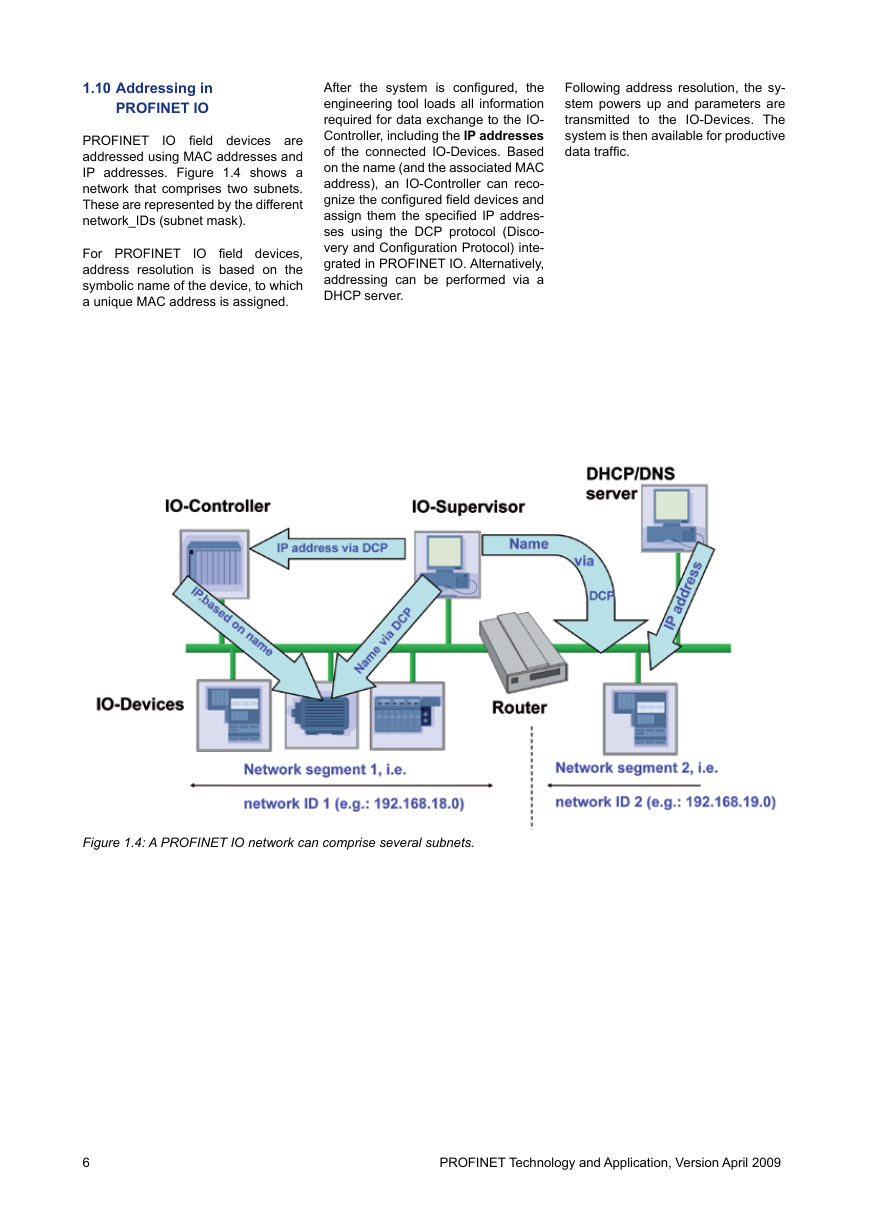

1.9 Device classes of

PROFINET IO

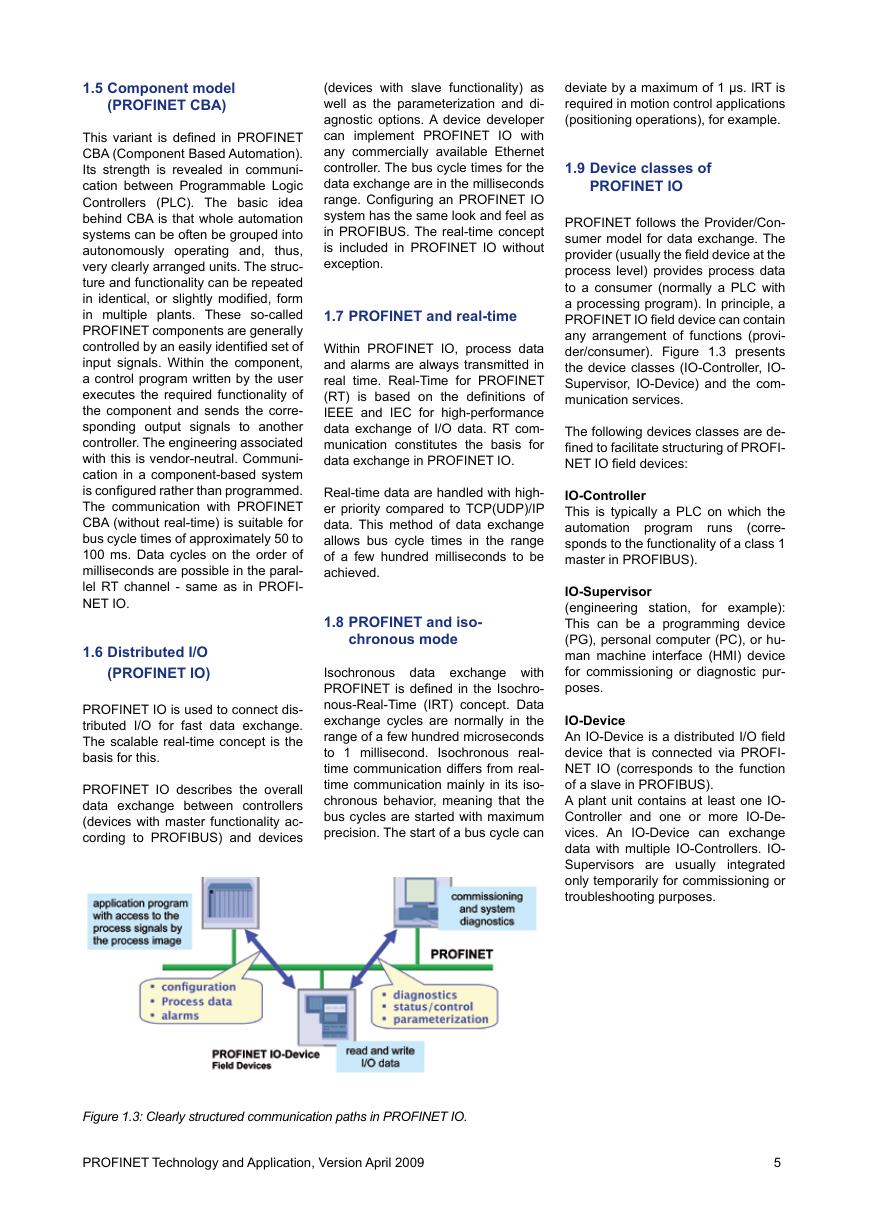

PROFINET follows the Provider/Con-

sumer model for data exchange. The

provider (usually the field device at the

process level) provides process data

to a consumer (normally a PLC with

a processing program). In principle, a

PROFINET IO field device can contain

any arrangement of functions (provi-

der/consumer). Figure 1.3 presents

the device classes (IO-Controller, IO-

Supervisor, IO-Device) and the com-

munication services.

The following devices classes are de-

fined to facilitate structuring of PROFI-

NET IO field devices:

runs

IO-Controller

This is typically a PLC on which the

automation program

(corre-

sponds to the functionality of a class 1

master in PROFIBUS).

IO-Supervisor

(engineering station, for example):

This can be a programming device

(PG), personal computer (PC), or hu-

man machine interface (HMI) device

for commissioning or diagnostic pur-

poses.

IO-Device

An IO-Device is a distributed I/O field

device that is connected via PROFI-

NET IO (corresponds to the function

of a slave in PROFIBUS).

A plant unit contains at least one IO-

Controller and one or more IO-De-

vices. An IO-Device can exchange

data with multiple IO-Controllers. IO-

Supervisors are usually

integrated

only temporarily for commissioning or

troubleshooting purposes.

Figure 1.3: Clearly structured communication paths in PROFINET IO.

PROFINET Technology and Application, Version April 2009

5

�

Following address resolution, the sy-

stem powers up and parameters are

transmitted to the IO-Devices. The

system is then available for productive

data traffic.

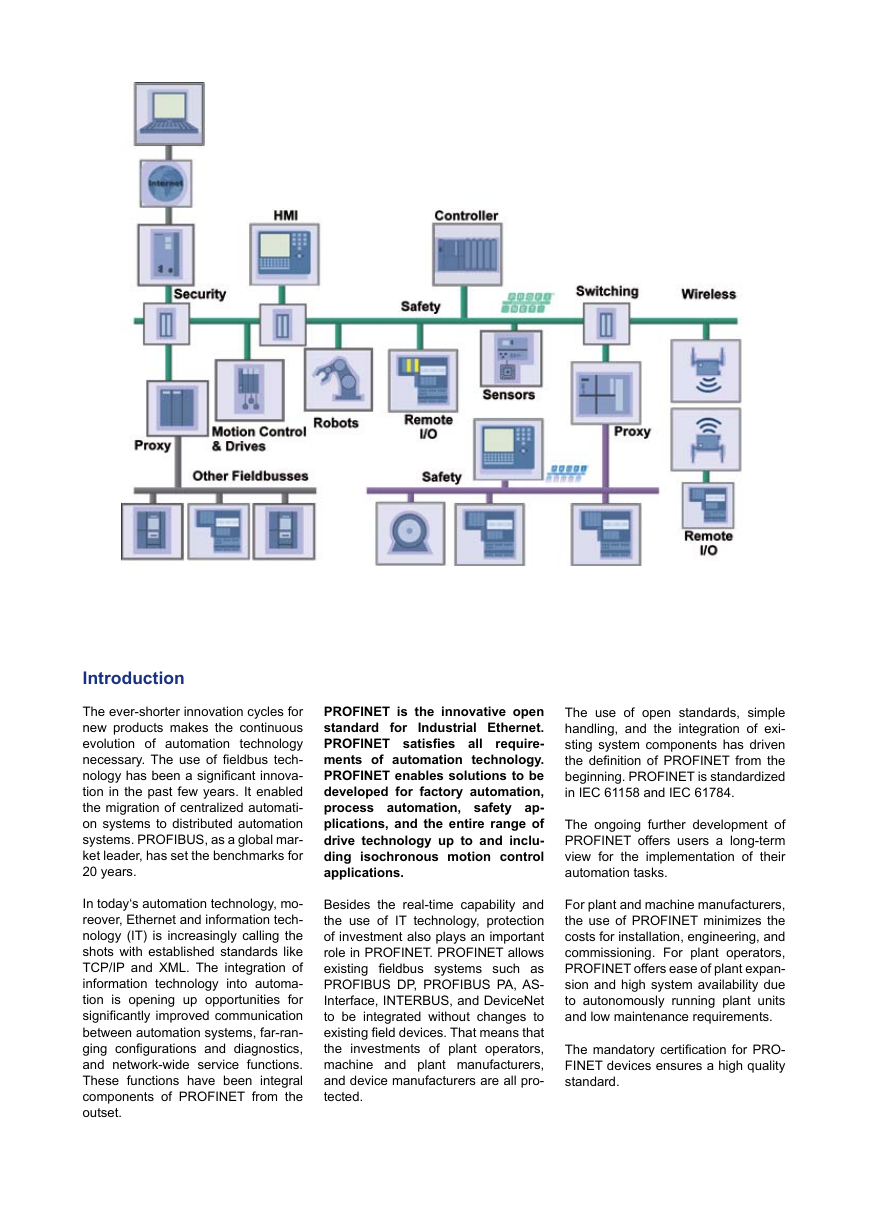

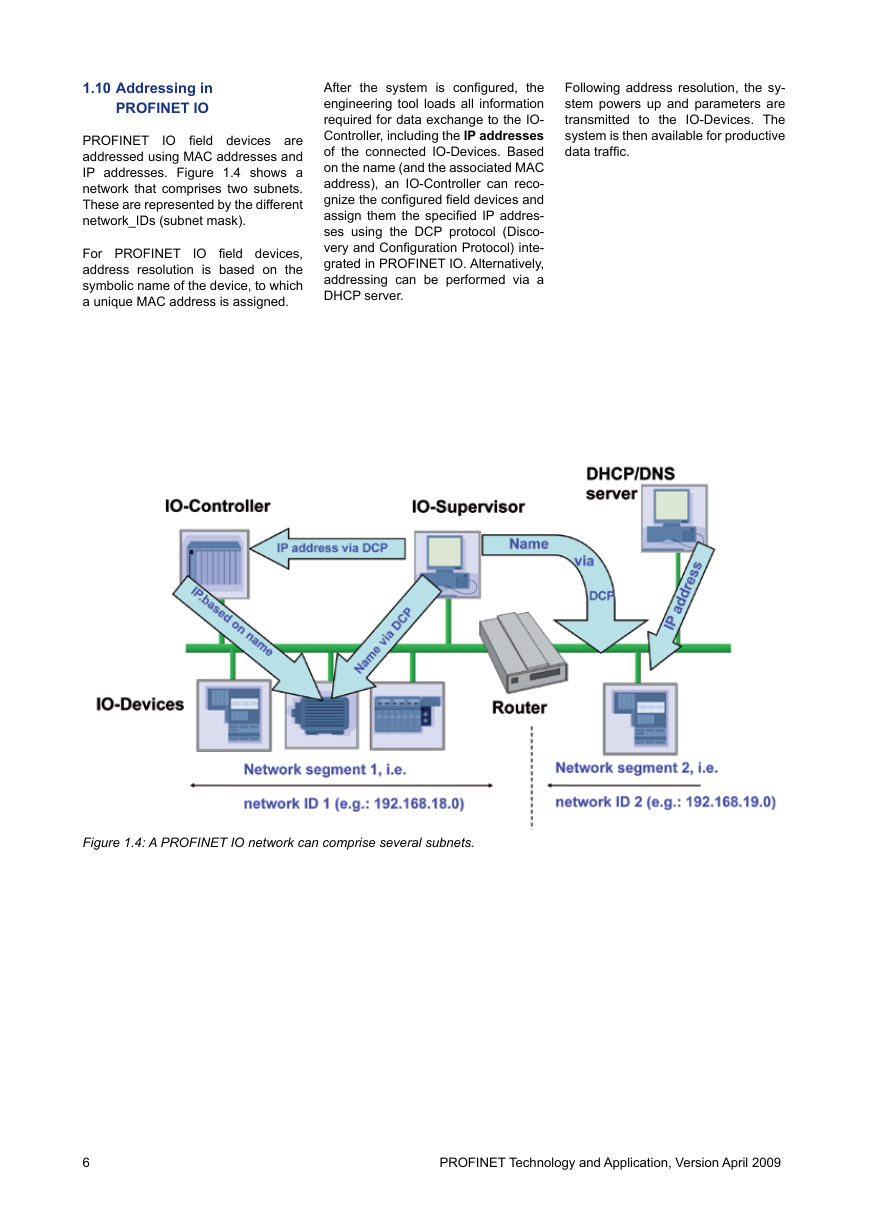

1.10 Addressing in

PROFINET IO

PROFINET

IO field devices are

addressed using MAC addresses and

IP addresses. Figure 1.4 shows a

network that comprises two subnets.

These are represented by the different

network_IDs (subnet mask).

For PROFINET

IO field devices,

address resolution is based on the

symbolic name of the device, to which

a unique MAC address is assigned.

After the system is configured, the

engineering tool loads all information

required for data exchange to the IO-

Controller, including the IP addresses

of the connected IO-Devices. Based

on the name (and the associated MAC

address), an IO-Controller can reco-

gnize the configured field devices and

assign them the specified IP addres-

ses using the DCP protocol (Disco-

very and Configuration Protocol) inte-

grated in PROFINET IO. Alternatively,

addressing can be performed via a

DHCP server.

Figure 1.4: A PROFINET IO network can comprise several subnets.

6

PROFINET Technology and Application, Version April 2009

�